In the competitive landscape of international trade, sourcing abrasive minerals presents a unique set of challenges for B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. The need for reliable suppliers, quality assurance, and cost-effectiveness is paramount for businesses looking to optimize their production processes. This comprehensive guide to abrasive minerals will help you navigate the complexities of sourcing these critical materials, providing insights into various types, applications, and market trends.

Throughout this guide, you will discover essential information on the different categories of abrasive minerals, including natural and synthetic options, and how each type serves specific industrial applications. We will also delve into best practices for vetting suppliers to ensure quality and compliance, as well as strategies for negotiating costs to maximize your purchasing power.

Empowering B2B buyers with actionable insights, this guide aims to facilitate informed decision-making, enhancing your ability to select the right abrasive minerals for your business needs. By understanding the global market dynamics, you can effectively mitigate risks and leverage opportunities, ensuring your operations remain competitive and efficient. Whether you're based in Germany, Australia, or beyond, this resource is designed to support your strategic sourcing efforts in the abrasive minerals market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Oxide | High hardness, excellent thermal stability | Metal fabrication, grinding | Pros: Durable, versatile. Cons: Can be costly for bulk purchases. |

| Silicon Carbide | Sharp, angular grains, high thermal conductivity | Ceramics, automotive, electronics | Pros: High cutting efficiency. Cons: Brittle, may require special handling. |

| Garnet | Naturally occurring, non-toxic, low dust | Waterjet cutting, sandblasting | Pros: Environmentally friendly, effective. Cons: Limited availability in some regions. |

| Diamond | Exceptional hardness, high cost | Precision cutting, polishing | Pros: Superior performance, longevity. Cons: High investment required. |

| Boron Carbide | Extremely hard, resistant to wear | Military applications, abrasives | Pros: Excellent for tough materials. Cons: Limited suppliers can drive up prices. |

Aluminum oxide is a widely used abrasive mineral known for its high hardness and thermal stability. It is commonly utilized in metal fabrication and grinding processes. Buyers should consider the durability and versatility of aluminum oxide, making it suitable for various applications. However, the cost can be a factor, especially for bulk purchases, which may affect budget-conscious companies.

Silicon carbide is characterized by its sharp, angular grains and high thermal conductivity, making it ideal for applications in ceramics, automotive, and electronics. Its cutting efficiency is a significant advantage for manufacturers looking for high-performance abrasives. However, its brittle nature necessitates careful handling, which can be a consideration for B2B buyers looking to streamline their production processes.

Garnet is a naturally occurring abrasive mineral that is non-toxic and generates low dust during use, making it an environmentally friendly option. It is primarily used in waterjet cutting and sandblasting applications. The effectiveness of garnet in various industries is a plus, but its availability can be limited in certain regions, which may impact supply chains for international buyers.

Diamond is renowned for its exceptional hardness and is often considered the gold standard in precision cutting and polishing applications. While it offers superior performance and longevity, the high cost associated with diamond abrasives can be a significant barrier for some businesses. B2B buyers must weigh the benefits of performance against their budget constraints when considering diamond abrasives.

Boron carbide is an extremely hard abrasive mineral known for its resistance to wear, making it suitable for military applications and other demanding environments. Its ability to work effectively with tough materials is a strong selling point. However, the limited number of suppliers can lead to higher prices, which is a crucial consideration for B2B buyers who may be looking for cost-effective solutions.

Related Video: Minerals | Types and Properties of Minerals | Video for Kids

| Industry/Sector | Specific Application of Abrasive Minerals | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Grinding and polishing of metals | Enhances surface finish, reduces machining time | Quality of abrasives, particle size distribution, availability of specialized grades |

| Construction | Concrete cutting and surface preparation | Improves efficiency and quality of construction | Compatibility with machinery, durability, and environmental regulations |

| Automotive | Abrasive blasting for surface treatment | Increases adhesion of coatings, enhances durability | Consistency in particle size, sourcing from reliable suppliers, compliance with safety standards |

| Electronics Manufacturing | Precision lapping of components | Achieves tight tolerances, improves product performance | Purity of abrasives, specific grit requirements, sourcing from trusted manufacturers |

| Mining and Mineral Processing | Ore dressing and mineral separation | Maximizes recovery rates, reduces operational costs | Availability of high-quality abrasives, adaptability to specific ore types, cost-effectiveness |

In the metal fabrication industry, abrasive minerals play a crucial role in grinding and polishing metals. These minerals, such as aluminum oxide and silicon carbide, are used to refine surfaces, remove excess material, and achieve a smooth finish. The primary benefit for businesses is the enhancement of surface quality, which directly impacts the product's performance and aesthetic appeal. For international buyers, especially from regions like Africa and South America, sourcing high-quality abrasives that meet specific particle size requirements is vital to ensure consistent results and minimize production downtime.

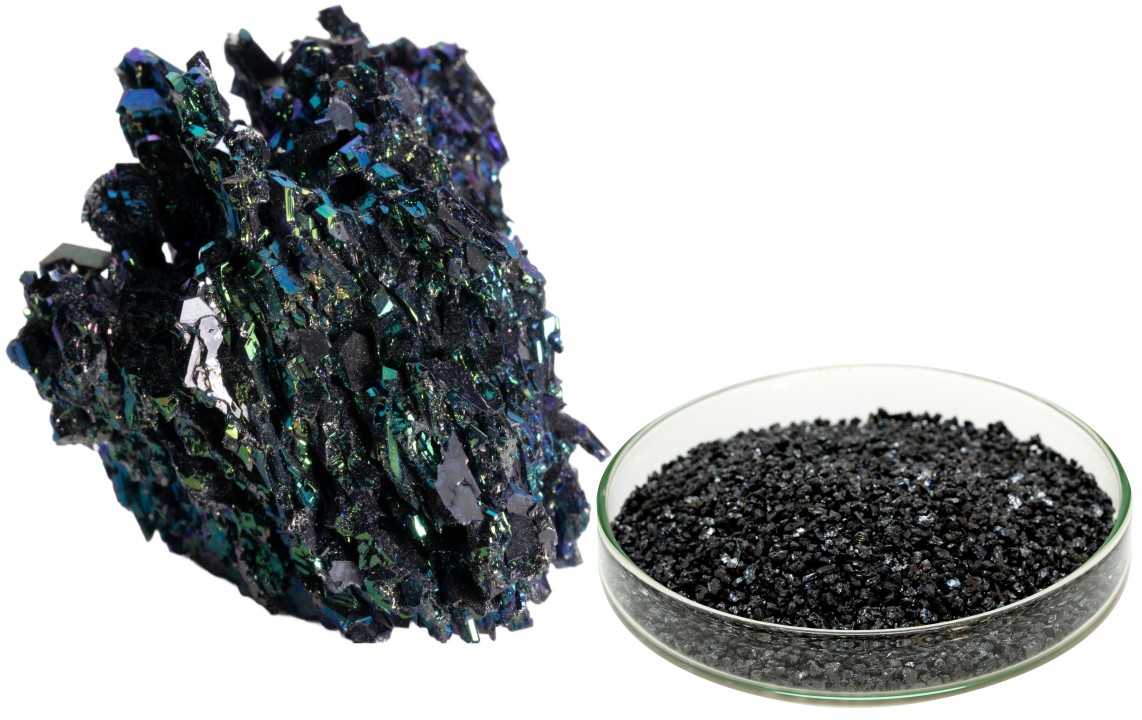

A stock image related to abrasive minerals.

Abrasive minerals are extensively utilized in the construction sector for concrete cutting and surface preparation. They help in achieving precise cuts and improving the overall quality of the construction work. The use of diamond blades, which incorporate abrasive minerals, allows for efficient cutting, reducing labor costs and time. Buyers from the Middle East and Europe should consider the compatibility of abrasives with their machinery and ensure compliance with local environmental regulations when sourcing these materials.

In the automotive industry, abrasive blasting with minerals like garnet is essential for surface treatment processes. This application enhances the adhesion of coatings and paints, leading to increased durability of the vehicle's exterior. Businesses benefit from improved aesthetic qualities and longer-lasting finishes. For international buyers, sourcing consistent particle sizes and ensuring compliance with safety standards are critical factors to consider when procuring abrasive materials.

Abrasive minerals are vital in the electronics manufacturing sector, particularly for precision lapping of components. This process requires high-purity abrasives to achieve tight tolerances, which is crucial for the performance of electronic devices. The value for businesses lies in improved product quality and operational efficiency. Buyers from Europe and South America should focus on sourcing abrasives that meet specific grit requirements while ensuring they come from trusted manufacturers to avoid quality issues.

A stock image related to abrasive minerals.

In mining and mineral processing, abrasive minerals are used for ore dressing and mineral separation. They help maximize recovery rates and reduce operational costs by efficiently separating valuable minerals from waste. Businesses benefit from improved yield and lower processing costs. For B2B buyers, particularly in Africa, it's essential to ensure the availability of high-quality abrasives that can adapt to specific ore types, as well as to consider cost-effectiveness when selecting suppliers.

Related Video: Grit Blasting process Vs Sand Blasting process, Types of Grit Blasting abrasive materials

The Problem: One of the most pressing challenges for B2B buyers of abrasive minerals is ensuring consistent quality in the materials sourced. Variability in mineral composition can lead to significant discrepancies in performance, which in turn affects production efficiency and product quality. For instance, a manufacturing company in South Africa might find that the garnet they purchase from different suppliers yields inconsistent results in cutting applications, leading to increased waste and rework. This unpredictability not only disrupts operations but can also tarnish the company's reputation among clients.

The Solution: To mitigate quality control issues, B2B buyers should prioritize establishing robust supplier relationships that emphasize quality assurance protocols. Start by conducting thorough due diligence on potential suppliers, including factory audits and reviews of quality certifications (like ISO 9001). Additionally, implement a testing regime for incoming materials—this may involve batch sampling and analysis of mineral properties such as hardness and grain size. Leveraging technology such as automated testing equipment can streamline this process, ensuring that only materials meeting specified criteria enter production. Regular communication with suppliers about quality expectations and performance feedback can also foster a culture of continuous improvement.

The Problem: Another common pain point for B2B buyers is the rising costs of abrasive minerals, compounded by a lack of pricing transparency. Buyers from Europe, for example, may encounter fluctuating prices based on global market conditions, tariffs, and supply chain disruptions. These unexpected costs can strain budgets and complicate financial forecasting, especially for companies that rely heavily on these materials for their operations.

The Solution: To address cost concerns, buyers should adopt a strategic sourcing approach that involves diversifying their supplier base. This not only reduces dependency on a single source but also creates competitive tension among suppliers, which can lead to better pricing. Additionally, buyers should negotiate long-term contracts that lock in prices and provide clauses for renegotiation based on market conditions. Utilizing market intelligence tools to monitor pricing trends can also empower buyers to make informed purchasing decisions. Engaging in collaborative partnerships with suppliers to share insights on cost structures and market dynamics can further enhance transparency and foster trust.

The Problem: Increasingly, B2B buyers face pressure to ensure that the abrasive minerals they purchase comply with environmental regulations and sustainability standards. Companies in regions like South America may struggle to verify that their suppliers are not only compliant with local laws but also adhere to international sustainability practices. Failing to address these concerns can result in legal repercussions, reputational damage, and loss of business opportunities, especially as more clients prioritize sustainable sourcing.

The Solution: To navigate environmental compliance, buyers should implement a due diligence process that includes environmental assessments of suppliers. This involves requesting documentation of environmental practices, certifications, and reports on the impact of mining operations. Establishing a clear set of sustainability criteria for suppliers can also guide sourcing decisions. Furthermore, buyers can consider engaging with third-party organizations that specialize in sustainability audits to ensure compliance and promote best practices in the supply chain. By integrating sustainability into the procurement process, buyers not only mitigate risks but also position themselves as responsible corporate citizens, enhancing their brand value and appeal to eco-conscious clients.

When selecting abrasive minerals for various industrial applications, understanding the properties, advantages, and limitations of different materials is crucial for international B2B buyers. This guide focuses on four common abrasive minerals: Aluminum Oxide, Silicon Carbide, Garnet, and Diamond. Each material has unique characteristics that can significantly impact performance, cost, and application suitability.

Aluminum Oxide (Al2O3) is a widely used abrasive mineral known for its hardness and durability. It has a high melting point (about 2050°C) and excellent thermal stability, making it suitable for high-temperature applications. Its corrosion resistance is moderate, which allows it to perform well in various environments, including wet and dry conditions.

Pros & Cons: Aluminum Oxide is relatively inexpensive and easy to manufacture, making it a popular choice for a wide range of applications, including grinding, polishing, and sandblasting. However, its performance can be limited in very high-pressure applications, and it may not be suitable for use with softer materials due to its aggressive nature.

Impact on Application: This mineral is compatible with a variety of media, including metals and plastics, which makes it versatile. However, buyers should be aware of potential wear on softer substrates.

Silicon Carbide (SiC) is another prominent abrasive material, recognized for its exceptional hardness and sharpness. It has a melting point of approximately 2700°C, which allows it to withstand high-temperature applications effectively. Additionally, it exhibits excellent chemical resistance, particularly against acids.

Pros & Cons: While Silicon Carbide is more expensive than Aluminum Oxide, its durability and cutting efficiency make it ideal for hard materials like ceramics and glass. The downside is that it can be brittle, which may lead to chipping in certain applications.

Impact on Application: Silicon Carbide is often used in grinding and cutting applications where precision is critical. International buyers should consider its compatibility with specific materials and the potential for increased wear on equipment.

Garnet is a naturally occurring mineral that is gaining traction as an abrasive due to its eco-friendly properties. It is non-toxic and produces minimal dust during use, which is advantageous for worker safety. Garnet has a hardness rating of 7.5 to 8 on the Mohs scale and is effective in water jet cutting and blasting applications.

Pros & Cons: One of the key advantages of Garnet is its cost-effectiveness and availability, especially in regions like Africa and South America where it is mined. However, it may not perform as well in high-temperature applications compared to synthetic abrasives.

Impact on Application: Garnet is particularly suitable for applications where environmental considerations are paramount. Buyers should verify compliance with local regulations regarding the use of abrasives.

Diamond is the hardest known material, with exceptional thermal conductivity and wear resistance. It can withstand extreme temperatures and pressures, making it ideal for cutting, grinding, and drilling applications.

Pros & Cons: The primary advantage of diamond abrasives is their unparalleled cutting efficiency and longevity. However, they are significantly more expensive than other abrasives, and their manufacturing process is complex, which can limit availability.

Impact on Application: Diamond is often used in precision machining and in industries requiring high-performance tools. B2B buyers should consider the specific applications and the return on investment when opting for diamond abrasives.

| Material | Typical Use Case for abrasive minerals | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Grinding, polishing, sandblasting | Cost-effective and durable | Limited performance in high-pressure applications | Low |

| Silicon Carbide | Precision cutting and grinding | Exceptional hardness and sharpness | Brittle, may chip in certain applications | Medium |

| Garnet | Water jet cutting, blasting | Eco-friendly, non-toxic | Not ideal for high-temperature applications | Low |

| Diamond | Precision machining, high-performance tools | Unmatched cutting efficiency | High cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into abrasive minerals, helping them make informed decisions that align with their operational needs and compliance standards.

The manufacturing of abrasive minerals involves several critical stages that ensure the quality and performance of the final products. Understanding these processes is essential for B2B buyers to evaluate potential suppliers effectively.

The first stage in the manufacturing process of abrasive minerals is material preparation. This involves sourcing high-quality raw materials such as corundum, silicon carbide, garnet, and alumina. The materials undergo several steps:

Once the materials are prepared, the next stage is forming. Various techniques are employed depending on the type of abrasive product being manufactured:

In cases where abrasive products consist of multiple components (e.g., grinding wheels with different layers), assembly is crucial. This stage typically involves:

The finishing stage is essential for achieving the desired surface quality and performance characteristics of abrasive products. Key processes include:

Quality assurance (QA) is paramount in the abrasive minerals industry, ensuring that products meet international standards and customer expectations.

International standards, such as ISO 9001, are critical for quality management systems in manufacturing. These standards help ensure that suppliers adhere to best practices and maintain consistent quality. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are essential for specific applications, particularly in Europe and North America.

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure product integrity:

Several testing methods are employed to assess the quality of abrasive minerals:

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Key areas to focus on include:

Buyers should request detailed quality reports from suppliers that include:

Engaging third-party inspection services can provide an unbiased assessment of a supplier's quality control measures. These inspections can include:

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

By comprehensively understanding the manufacturing processes and quality assurance practices in the abrasive minerals sector, international B2B buyers can make informed decisions when selecting suppliers, ultimately leading to improved product quality and customer satisfaction.

In today's competitive marketplace, sourcing abrasive minerals effectively is crucial for manufacturers and industrial buyers across various sectors. This practical sourcing guide provides a structured checklist to help B2B buyers navigate the procurement process, ensuring they make informed decisions that align with their business needs.

Understanding the specific requirements for abrasive minerals is the first step in the sourcing process. This includes determining the type of abrasive mineral (e.g., garnet, aluminum oxide, silicon carbide) and its intended application, whether for cutting, grinding, or polishing. Clearly defined specifications will aid in communicating your needs to potential suppliers and help filter out unsuitable options.

Conduct thorough research to identify reputable suppliers that specialize in abrasive minerals. Utilize platforms like industry trade shows, online B2B marketplaces, and local directories. Focus on suppliers that have a proven track record in your target regions—Africa, South America, the Middle East, and Europe—as they may have a better understanding of local regulations and market dynamics.

Before engaging with a supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 for quality management systems and environmental certifications like ISO 14001 are crucial indicators of a supplier's commitment to quality and sustainability. Ensure that the supplier adheres to relevant local and international regulations governing abrasive materials.

Always request samples of the abrasive materials you intend to procure. Conduct rigorous testing to evaluate performance against your specifications. Look for factors such as durability, particle size distribution, and consistency. This step is essential to ensure that the materials will meet your operational requirements and deliver the desired results.

Once you have shortlisted potential suppliers, gather detailed quotations that outline pricing, minimum order quantities, and payment terms. Compare these aspects across suppliers while considering the total cost of ownership, which includes shipping, handling, and potential tariffs. Negotiate favorable terms that align with your budget and cash flow requirements.

Understanding the logistics capabilities of your suppliers is vital for timely procurement. Evaluate their shipping methods, delivery timelines, and ability to handle customs requirements, especially when sourcing from international markets. Reliable logistics can significantly reduce downtime and ensure that your production schedules remain on track.

Effective communication is key to a successful sourcing relationship. Establish clear lines of communication with your chosen supplier to facilitate updates on order status, quality issues, or changes in specifications. Regular communication helps build trust and ensures that any potential challenges can be addressed promptly.

By following this step-by-step checklist, B2B buyers can streamline the sourcing process for abrasive minerals, minimize risks, and foster successful supplier partnerships.

Understanding the cost structure of abrasive minerals is vital for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. The primary cost components include:

Materials: The quality and type of abrasive mineral directly impact pricing. For example, high-purity alumina or silicon carbide typically costs more than lower-grade alternatives. Buyers should assess their specific requirements and choose materials that balance cost and performance.

Labor: Labor costs can vary significantly depending on the region of sourcing. Countries with higher labor costs, such as Germany or Australia, may see increased pricing. Conversely, sourcing from regions with lower labor costs can provide savings, but it’s essential to consider the trade-off in quality and compliance.

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and other operational expenses. Buyers should inquire about how these costs are factored into the pricing to better understand the total cost.

Tooling: The initial setup costs for specialized equipment or tooling can be substantial. Buyers should evaluate whether the tooling costs are being amortized over a larger volume, which could lower the price per unit for higher orders.

Quality Control (QC): The implementation of quality control measures adds to the overall cost. Suppliers that adhere to international quality standards may charge more but can provide assurance of product consistency and reliability.

Logistics: Shipping and transportation costs can vary widely based on the distance from the supplier to the buyer. Additionally, factors such as freight forwarding, customs duties, and insurance should be considered.

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the market dynamics can help buyers negotiate better prices.

Several factors influence the pricing of abrasive minerals, making it crucial for buyers to analyze them before procurement:

Volume/MOQ: Minimum Order Quantity (MOQ) can significantly affect pricing. Larger orders often lead to discounted rates, making it beneficial for buyers to consolidate purchases whenever possible.

Specifications and Customization: Custom orders that require specific grades or sizes may incur additional costs. Buyers should weigh the necessity of customization against potential price increases.

Materials and Quality Certifications: The presence of quality certifications (ISO, ANSI, etc.) can justify higher prices. Buyers should ensure that the benefits of certified products align with their operational needs.

Supplier Factors: The reputation and reliability of suppliers can influence prices. Established suppliers may charge a premium for their proven track record, whereas newer suppliers may offer lower prices to build market presence.

Incoterms: The choice of Incoterms can affect the total landed cost. Buyers should clearly understand the terms of shipping, insurance, and liability to avoid unexpected costs.

Negotiating effectively can lead to significant cost savings. Here are several actionable tips for international B2B buyers:

Research Market Prices: Before negotiations, conduct market research to understand the prevailing prices for abrasive minerals. This knowledge equips you with the leverage needed during discussions.

Leverage Volume Discounts: Highlight your purchasing volume to negotiate better terms. Suppliers are often willing to offer discounts for larger orders, which can lead to substantial savings.

Discuss Payment Terms: Flexible payment terms can also serve as a negotiation point. Proposing staggered payments or early payment discounts can help optimize cash flow.

Analyze Total Cost of Ownership (TCO): Consider the long-term costs associated with abrasive minerals, including maintenance, replacement, and operational costs. A slightly higher upfront price may result in lower TCO if it leads to better performance or durability.

The prices for abrasive minerals can vary widely based on the aforementioned factors and market conditions. Buyers should treat any indicative pricing as a starting point for negotiations and seek tailored quotes from suppliers to ensure the most accurate and favorable terms.

When evaluating solutions for abrasive applications, it's essential to consider not just the traditional abrasive minerals but also alternative technologies that may offer comparable or superior performance. This analysis will compare abrasive minerals against two viable alternatives: synthetic abrasives and waterjet cutting technologies. By examining these options, B2B buyers can make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Abrasive Minerals | Synthetic Abrasives | Waterjet Cutting |

|---|---|---|---|

| Performance | High durability and effectiveness for various materials | Customizable grit sizes and shapes enhance performance | Precision cutting with no heat-affected zone |

| Cost | Generally lower upfront costs, but may have higher long-term maintenance costs | Higher initial investment, but can reduce long-term costs due to efficiency | Higher operational costs, especially with water and energy usage |

| Ease of Implementation | Widely available, simple application in various industries | Requires training for optimal use and setup | Complex setup requiring skilled operators |

| Maintenance | Moderate; requires regular replacement and cleanup | Low; synthetic materials tend to last longer | High; maintenance of equipment and water filtration systems needed |

| Best Use Case | General industrial applications, metalworking, and construction | Precision machining and polishing in high-tech industries | Cutting complex shapes in various materials with minimal waste |

Synthetic abrasives, such as alumina and silicon carbide, are engineered materials designed to optimize cutting and grinding processes. Pros include their customizable grit sizes, which can be tailored to specific applications, providing enhanced performance and longevity. Furthermore, they often generate less waste, making them an environmentally friendly choice. Cons include a higher initial investment compared to traditional abrasive minerals, which may deter smaller operations or those with tight budgets.

Waterjet cutting uses a high-pressure stream of water mixed with abrasives to cut through materials. This technology provides exceptional precision and eliminates thermal distortion, making it ideal for sensitive materials. Pros include its ability to cut a wide variety of materials, including metals, glass, and composites, without altering their properties. However, the cons include significantly higher operational costs, as well as the need for skilled operators and regular maintenance of sophisticated equipment.

When selecting the right abrasive solution, B2B buyers must assess their specific application requirements, budget constraints, and operational capabilities. If cost-effectiveness and durability are the primary concerns, abrasive minerals might be the best choice. However, for applications requiring precision and minimal thermal impact, synthetic abrasives or waterjet cutting may be more appropriate despite their higher costs. Ultimately, understanding the unique needs of the operation and weighing the benefits and drawbacks of each option will guide buyers toward the most suitable solution for their business.

Understanding the essential technical properties of abrasive minerals is vital for B2B buyers to make informed purchasing decisions. Here are some critical specifications that play a significant role in the selection process:

Material grade refers to the quality and composition of the abrasive mineral. It indicates the mineral's effectiveness in cutting, grinding, or polishing applications. Higher-grade materials typically offer better performance and durability, making them suitable for high-precision tasks. Buyers should assess material grade to ensure they meet their operational requirements and industry standards.

Hardness is a measure of a mineral’s resistance to abrasion, commonly assessed using the Mohs scale. Harder minerals, like diamond and corundum, are preferred for applications requiring aggressive cutting. Understanding hardness helps buyers select the right abrasive for their specific applications, ensuring optimal performance and longevity.

Tolerance refers to the allowable deviation from a specified dimension or property of the abrasive material. In many industrial applications, tight tolerances are crucial for maintaining the quality of finished products. Buyers should ensure that suppliers can meet their tolerance requirements to prevent production delays and quality issues.

Grain size, or particle size, impacts the cutting efficiency and surface finish of the abrasive material. Finer grains provide smoother finishes, while coarser grains are more aggressive in cutting. Buyers need to specify the desired grain size based on their application to achieve the intended results.

The bonding type defines how the abrasive particles are held together, influencing the durability and performance of the abrasive product. Common bonding types include resin, vitrified, and metal bonds. Each type has its advantages and is suited for different applications. Understanding bonding types helps buyers select products that align with their operational needs.

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms that buyers should understand:

OEM refers to companies that manufacture products that are sold under another company's brand. In the abrasive minerals sector, buyers may source abrasives from OEMs who produce high-quality products tailored for specific applications. Understanding OEM relationships can help buyers identify reliable suppliers.

MOQ is the minimum amount of product that a supplier is willing to sell in a single order. This term is crucial for buyers, especially small to medium-sized enterprises, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing capabilities and demand forecasts.

An RFQ is a document used by buyers to solicit price quotations from suppliers for specific products or services. This process allows buyers to compare prices, terms, and conditions. Crafting a clear and detailed RFQ can lead to better pricing and terms for abrasive minerals.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Buyers should familiarize themselves with Incoterms to avoid misunderstandings and ensure smooth transactions.

Lead time refers to the amount of time between placing an order and receiving the product. In the abrasive minerals industry, lead times can vary based on factors such as order size and supplier capabilities. Understanding lead times is crucial for effective supply chain management and timely project execution.

For international B2B buyers in Africa, South America, the Middle East, and Europe, comprehending the essential technical properties and trade terminology associated with abrasive minerals is fundamental. By leveraging this knowledge, buyers can make better purchasing decisions, negotiate effectively, and ultimately enhance their operational efficiency.

The abrasive minerals sector is experiencing significant transformation driven by global demand, technological advancements, and evolving buyer preferences. Key trends include a shift towards automation and digitalization in manufacturing processes, allowing for improved efficiency and product quality. Additionally, the rise of e-commerce platforms has enabled international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to source abrasive minerals more conveniently and transparently.

Emerging technologies such as artificial intelligence and machine learning are being adopted to optimize supply chains and enhance predictive analytics, allowing buyers to make informed sourcing decisions. Furthermore, the increasing focus on customization is prompting suppliers to provide tailored solutions to meet specific industry needs, which is particularly valuable for buyers in sectors like automotive and construction.

Another critical driver is the rising demand for high-performance abrasives that can withstand harsher conditions and provide longer-lasting results. This trend is evident in the growing popularity of synthetic abrasives over traditional natural options, as they often offer superior performance and consistent quality. As international buyers navigate these market dynamics, understanding the implications of these trends will be essential for making strategic sourcing decisions.

Sustainability is becoming a cornerstone of sourcing practices in the abrasive minerals sector. International buyers are increasingly aware of the environmental impacts associated with mineral extraction and processing. As a result, there is a growing emphasis on ethical sourcing practices that prioritize environmental stewardship and social responsibility.

Buyers are encouraged to seek suppliers who adhere to sustainable practices, such as minimizing waste, reducing energy consumption, and utilizing eco-friendly materials in their manufacturing processes. Certifications like ISO 14001 and other 'green' credentials are becoming essential criteria in supplier evaluations, as they demonstrate a commitment to environmental management and sustainability.

Moreover, the trend towards circular economy models is gaining traction, with many companies exploring ways to recycle and repurpose abrasive materials. This not only reduces the environmental footprint but also offers economic advantages by lowering raw material costs. For B2B buyers, investing in suppliers with a strong sustainability ethos not only aligns with corporate social responsibility goals but also enhances brand reputation and customer loyalty.

The abrasive minerals sector has a rich history that reflects broader industrial advancements. Initially dominated by natural abrasives such as emery and garnet, the industry began to evolve significantly in the early 20th century with the introduction of synthetic alternatives like aluminum oxide and silicon carbide. These materials offered improved performance characteristics, leading to their widespread adoption in various applications.

The post-war industrial boom further accelerated innovation in abrasive technologies, resulting in the development of advanced bonding systems and coated abrasives. This evolution has positioned the abrasive minerals sector as a critical component in modern manufacturing processes, impacting industries ranging from automotive to aerospace.

As the sector continues to adapt to changing market demands, its historical evolution provides valuable insights for B2B buyers looking to navigate current trends and anticipate future developments. Understanding this context can facilitate more informed sourcing strategies and foster stronger partnerships with suppliers.

How do I choose the right abrasive mineral supplier for my business?

Selecting the right supplier involves several critical steps. First, assess their industry experience and reputation through online reviews and testimonials. Verify their certifications and compliance with international standards, especially in quality assurance and environmental regulations. Engage in direct communication to discuss your specific needs, such as product customization and delivery timelines. Finally, consider visiting their facility if possible, or request samples to evaluate the quality of their products.

What factors should I consider when sourcing abrasive minerals internationally?

When sourcing abrasive minerals internationally, consider factors such as the supplier's reliability, shipping logistics, and import regulations in your country. Evaluate the total landed cost, including shipping, tariffs, and customs duties. Additionally, ensure the supplier can meet your quality standards and has a robust supply chain that can handle fluctuations in demand. Understanding local market trends and geopolitical risks can also influence your sourcing strategy.

What are the typical minimum order quantities (MOQ) for abrasive minerals?

Minimum order quantities for abrasive minerals can vary widely depending on the supplier and the specific product. Generally, MOQs can range from a few tons to several hundred tons. Larger suppliers may offer more flexible MOQs, especially if they are looking to build long-term relationships. It is advisable to discuss your needs directly with suppliers to negotiate favorable terms that align with your business requirements.

What payment terms are common in international abrasive mineral transactions?

Common payment terms in international transactions typically include options such as Letter of Credit (LC), advance payments, or open account terms. Letters of Credit provide security for both parties, ensuring payment upon shipment verification. Advance payments may be required for first-time orders or smaller suppliers. Discuss and agree on payment terms that protect your interests while maintaining a good relationship with the supplier.

How can I ensure quality assurance when sourcing abrasive minerals?

To ensure quality assurance, request certificates of analysis (CoA) from the supplier that detail the product specifications and testing results. Conduct regular audits of the supplier's facilities and processes to verify compliance with quality standards. Establish a quality control plan that includes routine inspections and testing of received materials. Additionally, consider third-party testing services to independently verify product quality before use in your operations.

What logistics considerations should I keep in mind when importing abrasive minerals?

Logistics considerations for importing abrasive minerals include selecting reliable freight forwarders, understanding shipping routes, and ensuring compliance with customs regulations. Discuss the shipping terms (Incoterms) with your supplier to clarify responsibilities for shipping costs, insurance, and risk. Additionally, factor in lead times for production and delivery, and consider potential delays due to customs clearance. Planning for these logistics can help prevent disruptions in your supply chain.

Can abrasive minerals be customized to meet specific application needs?

Yes, many suppliers offer customization options for abrasive minerals to meet specific application requirements. This could include adjustments in grain size, shape, or chemical composition. When discussing your needs, provide detailed specifications and the intended use of the abrasive material. Collaborating closely with the supplier can lead to the development of tailored solutions that enhance performance in your specific applications.

What are the common uses of abrasive minerals in various industries?

Abrasive minerals are widely used across various industries, including manufacturing, construction, and automotive. In manufacturing, they are essential for grinding, cutting, and polishing metals and other materials. The construction industry utilizes abrasives for surface preparation and finishing work. Additionally, in the automotive sector, abrasives are used for sanding and surface treatment processes. Understanding these applications can help you select the right type of abrasive mineral for your business needs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, strategic sourcing is pivotal for international B2B buyers in the abrasive minerals sector. By focusing on long-term partnerships, optimizing supply chains, and leveraging data-driven insights, businesses can significantly enhance their operational efficiency and reduce costs. Buyers from Africa, South America, the Middle East, and Europe should prioritize understanding regional market dynamics, supplier capabilities, and compliance requirements to make informed purchasing decisions.

As the demand for abrasive minerals continues to evolve, staying ahead of industry trends is essential. Buyers should explore innovative materials and sustainable practices to align with global shifts towards eco-friendly solutions. Additionally, investing in technology can streamline procurement processes and improve supplier communication.

The outlook for abrasive minerals is promising, with opportunities for growth across various industries such as manufacturing, construction, and automotive. We encourage B2B buyers to engage actively with suppliers, attend industry events, and participate in market research to identify emerging trends and opportunities. By taking proactive steps today, businesses can secure a competitive advantage for tomorrow.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina