Navigating the complexities of sourcing alpha alumina fused aluminum oxide MSDS can be a daunting task for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. With the growing demand for high-performance materials in industries such as abrasives, ceramics, and electronics, understanding the properties, applications, and safety requirements of this material is crucial. This guide offers a comprehensive overview, covering everything from the types of alpha alumina available and their specific applications to essential supplier vetting processes and cost considerations.

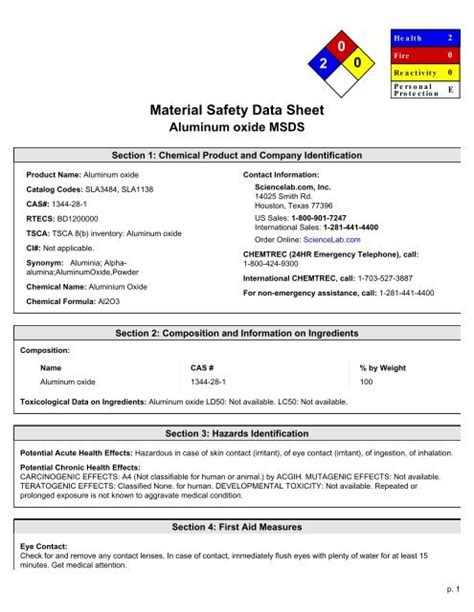

As a buyer, you are likely faced with challenges such as ensuring compliance with local regulations, evaluating product quality, and finding reliable suppliers. This guide empowers you to make informed purchasing decisions by providing actionable insights and detailed information on the Material Safety Data Sheets (MSDS) associated with alpha alumina fused aluminum oxide. By addressing critical factors like sourcing strategies, quality assurance, and market trends, we aim to enhance your procurement process and help you build successful partnerships with suppliers.

Whether you are based in Egypt, Argentina, or any other key market, this guide serves as an essential resource for navigating the global landscape of alpha alumina fused aluminum oxide, ensuring that you can confidently meet your business needs while adhering to safety and quality standards.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alpha Alumina Fused | High purity, low porosity, excellent hardness | Abrasives, ceramics, refractory materials | Pros: Cost-effective; Cons: Limited customization options |

| High Purity Alpha Alumina Fused | Extremely low impurity levels, high thermal stability | Electronics, advanced ceramics | Pros: Superior performance; Cons: Higher cost |

| Coated Alpha Alumina Fused | Surface coatings for enhanced properties | Polishing, surface treatments | Pros: Improved finish quality; Cons: Requires specific handling |

| Micronized Alpha Alumina Fused | Fine particle size, high surface area | Paints, coatings, plastics | Pros: Versatile applications; Cons: May require specialized processing |

| Reactive Alpha Alumina Fused | Enhanced reactivity for specific applications | Catalyst supports, chemical processes | Pros: Tailored for specific uses; Cons: Potentially more complex sourcing |

Standard alpha alumina fused aluminum oxide is characterized by its high purity and low porosity. This type is known for its exceptional hardness, making it suitable for a wide range of applications, particularly in the abrasive and refractory sectors. B2B buyers should consider its cost-effectiveness and durability, although they might find limited options for customization in terms of particle size and form.

High purity alpha alumina fused aluminum oxide features extremely low impurity levels and high thermal stability. This makes it particularly valuable in electronics and advanced ceramics, where performance and reliability are critical. Buyers should weigh the benefits of superior performance against the higher costs associated with this premium product.

Coated alpha alumina fused aluminum oxide has surface coatings that enhance its properties, such as wear resistance and chemical stability. It is commonly used in polishing and surface treatment applications. While it provides improved finish quality, buyers must be aware of the specific handling requirements to maintain the integrity of the coatings.

Micronized alpha alumina fused aluminum oxide offers a fine particle size and high surface area, making it versatile for applications in paints, coatings, and plastics. Its adaptability is a significant advantage for B2B buyers looking for materials that can enhance product performance. However, the need for specialized processing may add complexity to sourcing.

Reactive alpha alumina fused aluminum oxide is designed for enhanced reactivity, making it particularly useful in catalyst supports and various chemical processes. This type allows for tailored solutions in specific applications, providing significant advantages in performance. Buyers should consider the potential complexities in sourcing and application when opting for this specialized variant.

Related Video: Technology | Fused Aluminum Oxide Process | Imerys

| Industry/Sector | Specific Application of alpha alumina fused aluminum oxide msds | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives | Used as a primary abrasive in grinding and polishing applications. | Enhances product finish and durability, reducing processing time. | Quality of grain size, purity levels, and supplier reliability. |

| Ceramics | Employed in the manufacturing of high-performance ceramics. | Improves strength, thermal stability, and wear resistance of products. | Consistency in particle size distribution and compliance with safety standards. |

| Refractories | Utilized in refractory linings for furnaces and kilns. | Increases thermal shock resistance and lifespan of refractory materials. | Sourcing from certified suppliers to ensure material integrity. |

| Coatings | Incorporated into protective coatings for industrial equipment. | Provides enhanced abrasion resistance and prolongs equipment life. | Compatibility with existing systems and environmental compliance. |

| Electronics | Applied in the production of substrates and insulators. | Offers high dielectric strength and thermal conductivity. | Specifications for purity and dielectric properties must be met. |

In the abrasives industry, alpha alumina fused aluminum oxide is primarily utilized in grinding and polishing applications. Its hardness and durability make it an ideal choice for producing high-quality abrasive materials. This application solves issues related to surface finish and material wear, allowing manufacturers to achieve smoother finishes in less time. Buyers in this sector, particularly from regions like Africa and South America, should focus on sourcing high-purity materials to ensure optimal performance.

In ceramics manufacturing, alpha alumina fused aluminum oxide is crucial for creating high-performance ceramic products. It enhances the mechanical strength and thermal stability, making ceramics more resistant to wear and tear. This is particularly beneficial for industries that require materials to withstand extreme conditions, such as those in the Middle East. Buyers need to consider the consistency in particle size and purity, as these factors directly impact the quality of the final ceramic products.

A stock image related to alpha alumina fused aluminum oxide msds.

Alpha alumina fused aluminum oxide is extensively used in the production of refractory linings for kilns and furnaces. Its ability to withstand high temperatures and thermal shock significantly extends the lifespan of refractory materials. This application is critical for industries in Europe, where stringent regulations on energy efficiency and material durability are prevalent. Buyers should ensure that their suppliers are certified to provide materials that meet these demanding standards.

In the coatings sector, alpha alumina fused aluminum oxide is incorporated into protective coatings for industrial equipment. It provides exceptional abrasion resistance, which prolongs the life of machinery and reduces maintenance costs. This is particularly relevant for businesses in South America looking to enhance equipment longevity. Buyers must evaluate the compatibility of the coating materials with their existing systems, along with ensuring compliance with environmental regulations.

In the electronics industry, alpha alumina fused aluminum oxide is applied in the production of substrates and insulators. Its high dielectric strength and thermal conductivity make it an ideal material for ensuring reliable performance in electronic components. This application is vital for manufacturers in Europe, where precision and reliability are paramount. Buyers need to pay attention to the purity levels and dielectric properties specified by their applications to ensure optimal functionality.

The Problem: Many B2B buyers, particularly those in regions like Africa and South America, struggle with comprehending the complex language and technical jargon found in Material Safety Data Sheets (MSDS) for alpha alumina fused aluminum oxide. This can lead to confusion regarding the material's handling, storage, and safety measures, increasing the risk of accidents and compliance issues. Furthermore, regulatory requirements may vary significantly between countries, making it challenging for buyers to ensure they meet local standards.

The Solution: To overcome this challenge, buyers should invest in training for their staff focused on interpreting MSDS documents. This training can include workshops with safety experts or online courses that cover the basics of chemical safety and MSDS comprehension. Additionally, buyers can collaborate with suppliers who provide user-friendly summaries or translations of the MSDS in the local language, highlighting critical safety information. Engaging a local regulatory consultant can also provide tailored guidance on compliance with regional regulations, ensuring that all necessary precautions are in place.

The Problem: International buyers often face challenges in sourcing high-quality alpha alumina fused aluminum oxide. Variability in the quality of the product can occur due to differences in manufacturing processes across suppliers, leading to inconsistent performance in applications such as abrasives or ceramics. This inconsistency can disrupt production schedules and lead to subpar end products, affecting business reputation and client satisfaction.

The Solution: To mitigate this risk, buyers should establish a robust supplier qualification process that includes thorough quality assessments and audits of potential suppliers. This process should involve requesting samples for testing before making bulk purchases. Buyers can also benefit from forming strategic partnerships with a few reliable suppliers who have a proven track record of quality and consistency. Implementing a quality assurance program that includes regular quality checks and feedback loops will help maintain product standards and address any deviations promptly.

The Problem: B2B buyers, especially in Europe and the Middle East, face increasing scrutiny regarding environmental compliance when using materials like alpha alumina fused aluminum oxide. These regulations often require comprehensive reporting on the environmental impact of materials used in production. Failure to comply can lead to hefty fines and damage to corporate reputation.

The Solution: Buyers should proactively engage with environmental compliance experts to understand the specific regulations that apply to their operations. Developing an environmental management system (EMS) that tracks the use and disposal of alpha alumina fused aluminum oxide can help in maintaining compliance. Suppliers should be asked to provide documentation demonstrating adherence to environmental standards and certifications. Additionally, adopting sustainable practices such as recycling and waste minimization can not only ensure compliance but also enhance the company’s image as an environmentally responsible business. Regular training sessions for employees on environmental policies and practices will further solidify compliance efforts and foster a culture of sustainability within the organization.

Alpha alumina fused aluminum oxide is a versatile material known for its exceptional hardness and thermal stability. It typically exhibits a high melting point (around 2050°C) and can withstand extreme temperatures and pressures, making it suitable for various industrial applications. Additionally, its excellent corrosion resistance allows it to perform well in harsh environments, such as chemical processing and manufacturing.

Alpha alumina is widely used in applications such as abrasives, ceramics, and refractory materials. Its compatibility with various media, including acids and alkalis, makes it suitable for chemical processing equipment. However, its brittleness can limit its use in applications requiring high impact resistance, necessitating careful consideration during material selection.

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, compliance with local and international standards is crucial. Standards such as ASTM, DIN, and JIS govern the quality and safety of materials. Buyers should also consider the availability of suppliers who can provide certifications and documentation to ensure the material meets specific requirements. Additionally, understanding the local market dynamics, including pricing and logistics, can significantly influence procurement decisions.

| Material | Typical Use Case for alpha alumina fused aluminum oxide msds | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alpha Alumina Fused Aluminum Oxide | Abrasives, ceramics, and refractory applications | Exceptional hardness and thermal stability | Higher production cost and manufacturing complexity | High |

| Alpha Alumina Fused Aluminum Oxide | Chemical processing equipment | Excellent chemical resistance | Brittle nature can lead to cracking | High |

| Alpha Alumina Fused Aluminum Oxide | Thermal insulation materials | Inert to most chemicals, ensuring longevity | Requires specialized manufacturing processes | High |

| Alpha Alumina Fused Aluminum Oxide | High-performance coatings | Maintains properties under extreme conditions | Limited impact resistance due to brittleness | High |

A stock image related to alpha alumina fused aluminum oxide msds.

This detailed analysis provides a comprehensive overview of alpha alumina fused aluminum oxide, assisting international B2B buyers in making informed decisions regarding material selection for their specific applications.

The manufacturing process of alpha alumina fused aluminum oxide involves several critical stages that ensure the final product meets specific quality and performance standards. Understanding these stages is essential for international B2B buyers looking to source reliable materials.

Material Preparation

The initial stage involves sourcing high-purity aluminum oxide (Al2O3). This material is typically derived from bauxite ore, which undergoes refining to produce alumina. In this stage, impurities are removed to ensure that the final product has the desired properties, such as hardness and thermal stability.

Forming

After preparation, the alumina is subjected to high-temperature fusion, often in an electric arc furnace. This process transforms the alumina into a molten state, allowing for the formation of alpha alumina. The molten material is then cooled and solidified into large blocks or ingots. The formation stage is crucial as it dictates the microstructure and mechanical properties of the final product.

Crushing and Milling

Once solidified, the blocks of alpha alumina are crushed and milled to achieve the desired particle size. This step is essential for applications in abrasives, ceramics, and other industrial uses. The particle size can significantly influence the performance characteristics of the alumina in various applications.

Finishing

The final stage of manufacturing involves various finishing techniques, including sieving, classification, and surface treatment. These processes refine the particle size distribution and improve surface characteristics, which can enhance performance in specific applications.

Quality control (QC) is a fundamental aspect of the manufacturing process for alpha alumina fused aluminum oxide. It ensures that the product meets international standards and customer specifications.

International Standards Compliance

Adhering to international quality standards, such as ISO 9001, is crucial. These standards provide a framework for consistent quality management systems, which help manufacturers maintain high-quality production processes. In addition to ISO standards, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can further assure buyers of product quality and safety.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This initial check assesses raw materials upon arrival at the manufacturing facility. Ensuring that the incoming alumina meets specified purity levels is critical to the overall quality of the final product.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various checkpoints are established to monitor production. This includes temperature controls during fusion and particle size analysis during milling.

- Final Quality Control (FQC): Before the product is packaged and shipped, it undergoes final inspections to verify that it meets all specifications. This stage often includes testing for physical and chemical properties.

Common Testing Methods for Quality Assurance

- X-Ray Diffraction (XRD): Used to determine the crystalline structure of the alpha alumina.

- Scanning Electron Microscopy (SEM): Provides detailed images of the particle morphology.

- Chemical Analysis: Techniques such as X-ray fluorescence (XRF) ensure the material meets purity requirements.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier's quality control practices is essential for ensuring product reliability.

Supplier Audits

Conducting on-site audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control measures. During these audits, buyers should look for adherence to international standards and the presence of established quality management systems.

Requesting Quality Reports

Buyers should ask for quality assurance documentation, including test reports and certificates of compliance. These documents should detail the results of various tests conducted during the manufacturing process, confirming that the product meets specified standards.

Third-Party Inspections

Engaging third-party inspection services can further validate the quality claims of suppliers. Independent inspectors can perform audits and tests, providing an unbiased assessment of the supplier’s quality control processes.

Understanding the nuances of quality control is particularly important for B2B buyers operating in diverse markets. Here are some considerations:

Cultural and Regulatory Differences

Buyers must be aware of varying quality standards and regulations across different regions. For instance, compliance with European standards might differ from those in Africa or South America. It’s crucial to understand these differences when negotiating contracts and quality expectations.

Communication with Suppliers

Effective communication with suppliers about quality expectations is vital. Buyers should ensure that suppliers understand the specific standards required for their markets, including any relevant local regulations.

Building Long-Term Relationships

Establishing long-term relationships with suppliers can enhance quality assurance. Consistent collaboration allows buyers to better understand supplier capabilities and quality practices, leading to improved product quality over time.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for alpha alumina fused aluminum oxide is crucial. By focusing on the manufacturing stages, implementing robust quality control practices, and verifying supplier capabilities, buyers can ensure they source high-quality materials that meet their specific needs.

In today's competitive market, sourcing high-quality alpha alumina fused aluminum oxide requires a structured approach, especially for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive checklist to ensure you procure the right materials while adhering to safety and regulatory standards.

Before reaching out to suppliers, it's essential to clearly outline your technical requirements for alpha alumina fused aluminum oxide. This includes particle size, purity levels, and intended applications (e.g., abrasives, ceramics).

Conduct thorough research to identify potential suppliers. Utilize online directories, industry trade shows, and networking platforms to compile a list of companies that specialize in alpha alumina fused aluminum oxide.

Ensure that the suppliers you are considering have the necessary certifications such as ISO 9001 or relevant safety and environmental standards.

Ask each supplier for the MSDS related to their alpha alumina fused aluminum oxide products. This document provides critical information about the handling, storage, and potential hazards associated with the material.

Inquire about the quality control measures that suppliers have in place to ensure product consistency and reliability.

Once you have gathered information from various suppliers, compare their pricing structures and payment terms.

Before making a large order, request samples to evaluate the material's performance in your specific application.

By following this structured checklist, international B2B buyers can confidently navigate the procurement process for alpha alumina fused aluminum oxide, ensuring they select the best suppliers while adhering to safety and quality standards.

When sourcing alpha alumina fused aluminum oxide, understanding the cost structure is essential for B2B buyers. The main cost components include:

Materials: The primary cost driver, accounting for a significant portion of the total price. The quality and source of the alumina can greatly influence costs. Sourcing from established suppliers may offer quality assurance but can also lead to higher prices.

Labor: This encompasses the workforce involved in manufacturing, handling, and quality control. Labor costs can vary significantly based on the region. For instance, labor costs in European countries may be higher compared to South American nations.

Manufacturing Overhead: Includes expenses related to factory operations, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, making sourcing more competitive.

Tooling: The cost associated with specialized equipment and molds necessary for production. This can be a fixed cost that is amortized over production volumes, so larger orders may benefit from lower per-unit tooling costs.

Quality Control (QC): Ensuring that the product meets industry standards and specifications can add to the overall cost. Investing in robust QC processes can prevent costly returns and maintain supplier relationships.

Logistics: Transportation costs can vary greatly depending on the distance between the supplier and the buyer, as well as the chosen shipping methods. Incoterms play a crucial role in determining who bears these costs.

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding standard margins in the industry can help buyers negotiate better prices.

Several factors can influence the pricing of alpha alumina fused aluminum oxide:

Volume/MOQ: The minimum order quantity (MOQ) significantly impacts pricing. Larger orders often qualify for discounts, making it essential to assess potential needs to leverage better pricing.

Specifications and Customization: Custom specifications may lead to increased costs due to the need for specialized processes or materials. Buyers should clearly define their requirements to avoid unexpected costs.

Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can command higher prices. Buyers must balance the need for quality with their budget constraints.

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Engaging with multiple suppliers can provide insights into competitive pricing structures.

Incoterms: Understanding shipping terms can impact the overall cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who pays for transportation and insurance, influencing the total purchase price.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

Negotiate Terms: Always negotiate not just on price, but also on payment terms and delivery schedules. Establishing a good relationship with suppliers can lead to better terms over time.

Evaluate Total Cost of Ownership (TCO): Consider all costs involved, including shipping, customs, and potential tariffs. A lower purchase price might not always equate to a better deal if hidden costs are involved.

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing, especially in commodity markets. Timing your orders can lead to significant savings.

Conduct Market Research: Stay informed about market trends and price movements. This knowledge can empower you during negotiations and help you recognize fair pricing.

Utilize Local Suppliers When Possible: Local suppliers may offer lower logistics costs and faster delivery times, which can be beneficial for operational efficiency.

Prices for alpha alumina fused aluminum oxide can fluctuate based on market conditions, supplier pricing strategies, and geopolitical factors. It is advisable for buyers to obtain multiple quotes and perform due diligence when engaging with suppliers to ensure competitive pricing.

In the realm of industrial materials, especially for applications requiring high durability and performance, alpha alumina fused aluminum oxide is a key player. However, it is essential for B2B buyers to be aware of alternative solutions that might offer similar benefits tailored to specific needs. Understanding these alternatives can help in making informed purchasing decisions that align with operational goals and budget constraints.

| Comparison Aspect | Alpha Alumina Fused Aluminum Oxide MSDS | Silicon Carbide (SiC) | Zirconia (ZrO2) |

|---|---|---|---|

| Performance | High hardness and wear resistance | Superior thermal conductivity and hardness | Excellent toughness and thermal stability |

| Cost | Moderate to high | High | Moderate |

| Ease of Implementation | Requires specialized handling procedures | Complex processing involved | Easier handling than SiC |

| Maintenance | Low maintenance required | Moderate maintenance needed | Low maintenance required |

| Best Use Case | Abrasives, ceramics, and refractory applications | High-temperature applications, cutting tools | Dental applications, structural components |

Silicon Carbide is renowned for its exceptional thermal conductivity and hardness, making it ideal for high-temperature environments and cutting tools. Its durability enables the production of robust components that withstand extreme conditions. However, the primary drawback is its cost; SiC is generally more expensive than alpha alumina fused aluminum oxide, which can be a significant consideration for budget-conscious buyers. Additionally, the complexity of processing SiC may require specialized machinery and expertise, leading to longer lead times.

Zirconia is another viable alternative, particularly valued for its toughness and thermal stability. It is often used in applications such as dental materials and structural components where strength and durability are paramount. The cost of zirconia is moderate, making it a more accessible option than SiC but still potentially higher than alpha alumina fused aluminum oxide. One of the advantages of zirconia is its relatively easy handling and lower maintenance requirements compared to silicon carbide, making it an attractive option for manufacturers looking for efficiency in production.

When deciding between alpha alumina fused aluminum oxide and its alternatives, B2B buyers should consider several factors, including performance requirements, budget constraints, and the specific applications for which the materials will be used. For instance, if the application demands high thermal resistance and cost is less of an issue, silicon carbide might be the preferred choice. Conversely, for applications that require a balance of toughness and cost-effectiveness, zirconia could be the best fit. Ultimately, evaluating the unique needs of the operation and aligning them with the material properties will lead to the most strategic purchasing decision.

Alpha alumina fused aluminum oxide, often referred to as corundum, is a critical material in various industrial applications, particularly in abrasives, ceramics, and refractory products. Understanding its technical properties is essential for international B2B buyers to ensure they select the right grade for their specific needs.

Material Grade

Material grade indicates the purity and crystalline structure of the alumina. Common grades include 99.5% and 99.9% pure alumina. For buyers, selecting the appropriate grade is crucial, as higher purity levels generally enhance performance in demanding applications, such as high-temperature environments or precision grinding.

Particle Size Distribution

This specification refers to the range and average size of particles in the product. Typical distributions can range from coarse (over 100 microns) to fine (under 5 microns). Particle size affects the material’s abrasiveness and packing density, influencing the effectiveness in grinding and polishing applications. Buyers should assess their specific application requirements to select the optimal particle size.

Hardness (Mohs Scale)

Alpha alumina exhibits a hardness of approximately 9 on the Mohs scale, making it one of the hardest materials available. This property is vital for applications in grinding wheels and cutting tools, as a harder material can withstand greater wear and tear, resulting in longer service life and reduced costs over time.

Thermal Stability

This property defines the material’s ability to maintain its structural integrity at high temperatures. Alpha alumina can typically withstand temperatures exceeding 1,600°C (2,912°F). For buyers in industries such as aerospace or metalworking, thermal stability is a key consideration when selecting materials for furnace linings or other high-heat applications.

Chemical Resistance

Alpha alumina is chemically inert, providing resistance against acids and bases. This property is particularly important for applications in chemical processing or environments where exposure to corrosive substances is likely. Buyers need to ensure that their selected grade can withstand specific chemical environments to avoid premature degradation.

Navigating the landscape of international trade can be complex, especially when dealing with specialized materials like alpha alumina fused aluminum oxide. Familiarity with specific trade terms can enhance communication and negotiation with suppliers.

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of alpha alumina, understanding OEM relationships can help buyers ensure they source products that meet their equipment specifications.

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is essential for budgeting and inventory management. It also impacts negotiation strategies, as suppliers may be more flexible with higher volume orders.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Buyers should prepare a detailed RFQ for alpha alumina, including specifications and quantities, to receive accurate and competitive quotes.

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms used to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and liabilities during shipping, which is crucial for cost management and risk assessment.

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for international buyers to plan their production schedules effectively and avoid delays in their supply chain.

By grasping these technical properties and trade terms, B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions, optimize their procurement processes, and enhance their operational efficiency in using alpha alumina fused aluminum oxide.

The global market for alpha alumina fused aluminum oxide is witnessing substantial growth, driven by increased demand in various industries such as abrasives, ceramics, and refractories. Key factors propelling this market include the rising need for high-performance materials that can withstand extreme temperatures and aggressive environments. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several emerging trends.

Firstly, digital transformation is reshaping sourcing processes, with many companies adopting advanced technologies such as AI and machine learning to enhance supply chain efficiency. This shift enables buyers to access real-time data for better decision-making, allowing for more informed sourcing strategies. Additionally, the trend towards local sourcing is gaining traction, particularly in regions like Egypt and Argentina, where buyers are looking to reduce lead times and transportation costs while supporting local economies.

Furthermore, sustainability is becoming a critical consideration for international buyers. As environmental regulations tighten, there is a growing emphasis on sourcing materials that are not only high in performance but also sustainable. This shift is prompting suppliers to innovate their production processes to minimize environmental impact, thus enhancing their appeal to eco-conscious buyers.

The importance of sustainability in the alpha alumina fused aluminum oxide sector cannot be overstated. With increasing awareness of environmental issues, B2B buyers are prioritizing suppliers that adhere to sustainable practices. This encompasses not only the sourcing of raw materials but also the manufacturing processes employed.

Ethical supply chains are critical, as they ensure that materials are sourced responsibly and that the labor involved in their production meets ethical standards. Buyers should seek suppliers who possess certifications such as ISO 14001, which indicates effective environmental management systems, and other 'green' certifications that validate their commitment to sustainability.

Moreover, the demand for recycled materials is on the rise. As businesses strive to reduce their carbon footprints, incorporating recycled alpha alumina in their products is becoming a viable option. This not only meets regulatory requirements but also enhances brand reputation among environmentally conscious consumers.

The alpha alumina fused aluminum oxide market has evolved significantly over the decades. Initially utilized primarily in industrial applications, its versatility has led to broader adoption across various sectors. The material's exceptional hardness and thermal stability have made it a preferred choice in abrasives and cutting tools.

Over time, advancements in production technologies have enhanced its properties, making it suitable for more demanding applications such as electronic components and high-performance ceramics. The introduction of innovative manufacturing processes has also led to the development of specialized grades of alpha alumina, catering to specific industry requirements.

As the market continues to mature, international B2B buyers are encouraged to stay informed about technological advancements and sourcing trends that can impact their purchasing decisions. Understanding the history and evolution of alpha alumina fused aluminum oxide can provide valuable context for making strategic sourcing choices in today’s dynamic market landscape.

What are the key properties of alpha alumina fused aluminum oxide?

Alpha alumina fused aluminum oxide is known for its exceptional hardness, chemical stability, and resistance to wear and corrosion. This material exhibits a high melting point, making it suitable for high-temperature applications. Its fine particle size allows for superior surface finishes in abrasive applications, while its toughness ensures durability. These properties make it a preferred choice in industries such as ceramics, electronics, and metal finishing.

How can I obtain the Material Safety Data Sheet (MSDS) for alpha alumina fused aluminum oxide?

To obtain the MSDS for alpha alumina fused aluminum oxide, contact your supplier directly or visit their website. Most reputable suppliers provide downloadable MSDS documents for their products. It is essential to review the MSDS to understand the handling, storage, and safety measures necessary to work with this material, especially in compliance with local regulations.

What factors should I consider when selecting a supplier for alpha alumina fused aluminum oxide?

When choosing a supplier, consider their industry reputation, compliance with international quality standards, and the availability of product certifications. Assess their experience in the market and customer feedback. Additionally, inquire about their ability to provide customized solutions, minimum order quantities (MOQ), and reliable logistics capabilities to ensure timely delivery.

What is the typical minimum order quantity (MOQ) for alpha alumina fused aluminum oxide?

The MOQ for alpha alumina fused aluminum oxide can vary significantly depending on the supplier and the specific product form (e.g., powder, grains). Generally, MOQs can range from 100 kg to several tons. Discussing your specific needs with potential suppliers will help you negotiate favorable terms and ensure that you can meet your production requirements without excess inventory.

What payment terms are commonly offered by suppliers of alpha alumina fused aluminum oxide?

Payment terms can vary widely among suppliers, but common arrangements include payment in advance, letters of credit, or payment upon delivery. Some suppliers may offer flexible terms such as net 30 or net 60 days, depending on your relationship and order size. It is advisable to clarify payment terms upfront to avoid misunderstandings and ensure smooth transactions.

How can I ensure the quality of alpha alumina fused aluminum oxide during sourcing?

To ensure quality, request samples before placing a large order. Conduct thorough testing to confirm that the material meets your specifications. Additionally, ask suppliers for their quality assurance processes, certifications, and any third-party testing results. Establishing a quality control agreement can also help safeguard your interests and maintain product consistency.

What logistical considerations should I keep in mind when importing alpha alumina fused aluminum oxide?

When importing, consider shipping costs, customs duties, and delivery timelines. Work with suppliers who have experience with international shipping to streamline the process. Ensure that all necessary documentation, including import permits and compliance certificates, is in order. Additionally, consider the potential for delays at customs and plan your inventory levels accordingly.

Can alpha alumina fused aluminum oxide be customized for specific applications?

Yes, many suppliers offer customization options for alpha alumina fused aluminum oxide, including variations in particle size, purity levels, and packaging. Discuss your specific application requirements with potential suppliers to determine the best formulation for your needs. Customization can enhance performance in specialized applications, making it critical to communicate your expectations clearly.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of alpha alumina fused aluminum oxide is crucial for international B2B buyers seeking quality materials for various industrial applications. By understanding the properties outlined in the Material Safety Data Sheet (MSDS), buyers can ensure compliance with safety standards while maximizing operational efficiency. This material not only offers superior hardness and durability but also plays a significant role in enhancing product performance across sectors such as manufacturing and construction.

Investing in a strategic sourcing strategy allows companies in Africa, South America, the Middle East, and Europe to build resilient supply chains. By fostering relationships with reliable suppliers and leveraging market intelligence, businesses can mitigate risks associated with supply disruptions and price volatility. Additionally, aligning sourcing decisions with sustainability goals can enhance brand reputation and attract environmentally conscious customers.

Looking ahead, B2B buyers should remain agile and informed about market trends and innovations related to alpha alumina fused aluminum oxide. Embracing digital tools for procurement and collaborating with suppliers can lead to significant cost savings and improved product quality. Now is the time to act—evaluate your sourcing strategies, engage with trusted suppliers, and position your business for long-term success in an increasingly competitive landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina