In today’s interconnected economy, alpha sic stands as a pivotal component driving innovation and efficiency across multiple industries. For international B2B buyers—especially those operating in dynamic markets such as Africa, South America, the Middle East, and Europe—understanding the complexities of alpha sic is essential to securing competitive advantages and fostering sustainable partnerships. Whether your business is based in Brazil, Thailand, or beyond, mastering the nuances of alpha sic sourcing can significantly impact cost efficiency, product quality, and supply chain resilience.

This comprehensive guide delivers an authoritative roadmap through the global landscape of alpha sic, meticulously covering every critical aspect. From exploring the diverse types and materials that define alpha sic products, to unveiling best practices in manufacturing and quality control, the guide equips buyers with the insights needed to evaluate suppliers rigorously. Additionally, it demystifies pricing structures, highlights key market trends, and addresses frequently asked questions to sharpen your negotiation and procurement strategies.

By leveraging this guide, international buyers will be empowered to make informed, strategic decisions that align with their operational goals and regional market conditions. Whether navigating regulatory environments or identifying trustworthy suppliers, this resource is designed to enhance your sourcing confidence and maximize value in your alpha sic acquisitions. Embrace this knowledge to transform challenges into opportunities within the global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alpha SIC Standard | Baseline specification, widely adopted globally | General industrial manufacturing, logistics | + Broad compatibility – May lack specialized features |

| Alpha SIC Enhanced | Includes advanced analytics and automation support | High-tech manufacturing, supply chain management | + Improved efficiency – Higher initial investment |

| Alpha SIC Modular | Customizable modules for specific industry needs | Modular production lines, flexible operations | + Tailored solutions – Complexity in integration |

| Alpha SIC Eco | Focus on sustainability and energy efficiency | Green manufacturing, eco-conscious supply chains | + Reduces environmental impact – Possible performance trade-offs |

| Alpha SIC IoT-Ready | Integrated IoT connectivity and real-time monitoring | Smart factories, remote asset management | + Real-time data insights – Requires robust IT infrastructure |

Alpha SIC Standard

This foundational type offers a universally accepted specification ideal for businesses seeking reliable, proven solutions. Its broad compatibility makes it a solid choice for companies in traditional manufacturing and logistics sectors. For B2B buyers, it presents a low-risk investment with straightforward implementation. However, it may lack the advanced capabilities required by highly specialized or tech-driven industries.

Alpha SIC Enhanced

Designed for enterprises aiming to leverage automation and data analytics, this variation integrates advanced features to optimize operational workflows. It suits high-tech manufacturing and sophisticated supply chain environments where efficiency gains are critical. Buyers should consider the higher upfront costs and ensure their teams are prepared for the technology adoption curve. The long-term ROI often justifies these investments.

Alpha SIC Modular

Offering flexible, customizable modules, this type caters to businesses with unique or evolving operational demands. It is particularly beneficial for companies with modular production lines or those requiring adaptable systems. While this customization allows precise fit-for-purpose solutions, it introduces integration complexity. B2B buyers should assess their technical capacity and vendor support to manage this effectively.

Alpha SIC Eco

With increasing global emphasis on sustainability, this variation prioritizes energy efficiency and environmentally friendly processes. It appeals to companies committed to green manufacturing and responsible supply chains. Buyers benefit from aligning with environmental standards and potential cost savings on energy. However, they should evaluate potential compromises in performance or higher costs associated with eco-friendly components.

Alpha SIC IoT-Ready

This type integrates Internet of Things (IoT) capabilities, enabling real-time monitoring and data-driven decision-making. It is ideal for smart factories and enterprises requiring remote asset management. The IoT-ready nature enhances transparency and predictive maintenance but demands a robust IT infrastructure and cybersecurity measures. B2B buyers must plan for these requirements to fully capitalize on its benefits.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of alpha sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

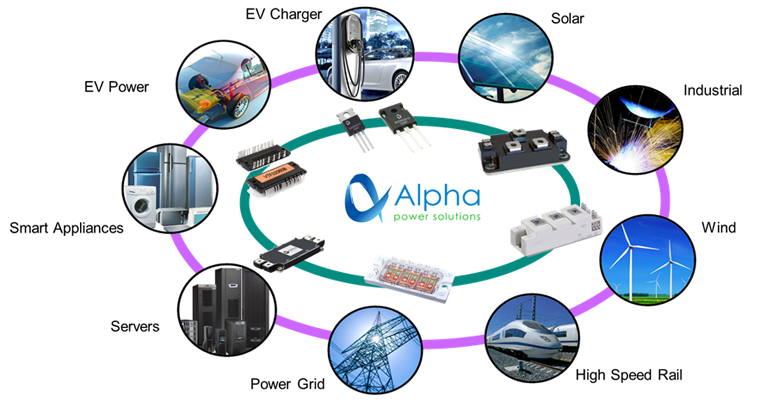

| Power Electronics | High-performance semiconductor devices for inverters and converters | Enhanced thermal conductivity and efficiency, leading to lower energy losses and improved device reliability | Ensure high purity alpha SiC with consistent crystal quality; consider supplier certifications and lead times for bulk orders |

| Automotive | Electric vehicle (EV) power modules and battery management systems | Improved durability under high temperature and voltage stress, resulting in longer component life and vehicle range | Source alpha SiC with precise doping and defect control; verify compatibility with automotive-grade manufacturing standards |

| Industrial Machinery | Wear-resistant components and cutting tools | Increased operational lifespan and reduced downtime due to superior hardness and chemical stability | Prioritize alpha SiC with uniform grain size and mechanical properties; confirm supplier can meet volume and customization needs |

| Renewable Energy | Semiconductor substrates for solar inverters and wind turbine controls | Increased efficiency and reliability in harsh environmental conditions, supporting sustainable energy goals | Choose alpha SiC with excellent thermal stability and low defect density; assess logistics for delivery to remote locations |

| Aerospace & Defense | High-frequency, high-power electronic devices | Superior performance in extreme temperature and radiation environments, enhancing mission-critical system reliability | Verify alpha SiC purity and structural integrity; ensure compliance with international quality standards and export regulations |

Alpha silicon carbide (alpha SiC) is widely utilized in power electronics, particularly in semiconductor devices such as inverters and converters. Its exceptional thermal conductivity and electrical properties allow manufacturers to produce components that operate efficiently under high power loads with reduced energy loss. For international B2B buyers, especially in emerging markets like Africa and South America, sourcing alpha SiC with consistent crystal quality and purity is crucial to meet stringent performance and reliability standards. Establishing relationships with certified suppliers who can handle bulk orders is essential for scaling production.

In the automotive industry, alpha SiC plays a pivotal role in electric vehicle (EV) power modules and battery management systems. Its ability to withstand high temperatures and voltage stresses enhances the durability and efficiency of EV components, directly contributing to longer vehicle range and reduced maintenance costs. Buyers from regions such as the Middle East and Europe should focus on alpha SiC materials with precise doping control and minimal defects to comply with automotive manufacturing standards, ensuring seamless integration into advanced EV systems.

Illustrative Image (Source: Google Search)

The industrial machinery sector benefits from alpha SiC’s wear resistance and hardness in producing cutting tools and machine components. These properties significantly extend operational lifespan and reduce downtime caused by frequent replacements. For B2B buyers in countries like Brazil and Thailand, it is important to procure alpha SiC with uniform grain size and mechanical properties tailored to specific machinery requirements. Suppliers capable of customization and reliable delivery schedules are valuable partners in this sector.

In renewable energy, alpha SiC substrates are critical for solar inverter and wind turbine control electronics. Its stability under extreme environmental conditions ensures consistent performance and longevity, supporting sustainable energy initiatives worldwide. Buyers in remote or developing regions should prioritize alpha SiC with low defect density and high thermal stability, while also considering logistical factors such as shipping to less accessible locations.

Finally, in aerospace and defense, alpha SiC is used in high-frequency, high-power electronic devices that must perform reliably under extreme temperature and radiation exposure. This application demands alpha SiC with exceptional purity and structural integrity. International buyers must verify compliance with international quality standards and export regulations to avoid supply chain disruptions and ensure mission-critical reliability.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Key Properties:

Standard alpha SiC is characterized by excellent thermal conductivity (up to 120 W/m·K), high hardness (Mohs scale ~9.5), and outstanding chemical inertness. It can withstand temperatures exceeding 1600°C and exhibits excellent resistance to oxidation and corrosion in harsh environments.

Pros & Cons:

Its durability and thermal stability make it ideal for high-temperature applications, including mechanical seals and high-performance bearings. However, manufacturing alpha SiC components involves complex sintering processes, which can elevate costs. The material’s brittleness requires careful handling during fabrication and installation.

Impact on Application:

Standard alpha SiC is highly compatible with aggressive media such as acids, alkalis, and organic solvents, making it suitable for chemical processing industries. Its wear resistance also supports applications in abrasive environments.

International B2B Considerations:

Buyers from Africa, South America, the Middle East, and Europe should verify compliance with ASTM C799 and ISO 8009 standards, which govern SiC quality and testing. In Brazil and Thailand, local certifications aligned with ASTM or DIN standards are often required. Importantly, ensure suppliers provide detailed material data sheets to meet regional regulatory and quality assurance demands.

Key Properties:

RBSC is produced by infiltrating porous carbon preforms with molten silicon, resulting in a composite of SiC and free silicon. This process yields materials with good thermal shock resistance and moderate mechanical strength, with operating temperatures typically up to 1400°C.

Pros & Cons:

RBSC offers cost advantages over fully sintered SiC due to simpler manufacturing. It also has superior machinability, allowing for complex shapes. However, the presence of free silicon reduces corrosion resistance, limiting its use in highly acidic or alkaline environments.

Impact on Application:

RBSC is preferred in applications requiring complex geometries and moderate chemical resistance, such as kiln furniture, heat exchangers, and some semiconductor components. It is less suitable for highly corrosive media but performs well in neutral or mildly oxidizing atmospheres.

International B2B Considerations:

For buyers in regions like the Middle East and Europe, RBSC must meet ASTM C795 or equivalent standards. South American buyers should confirm compatibility with local industrial norms and ensure suppliers provide traceability and certification. The slightly lower cost and machinability make RBSC attractive for cost-sensitive projects in emerging markets.

Key Properties:

This variant involves sintering alpha SiC with additives to enhance densification and mechanical properties. It typically exhibits higher flexural strength (up to 600 MPa) and improved fracture toughness compared to standard SiC, with excellent thermal and chemical stability.

Pros & Cons:

Additive-enhanced sintered SiC delivers superior performance in extreme environments, including high-pressure and high-wear applications. The trade-off is increased manufacturing complexity and cost. Additionally, some additives may influence corrosion behavior, necessitating careful selection based on the target environment.

Impact on Application:

Ideal for demanding applications such as mechanical seals in pumps handling abrasive slurries, high-pressure valves, and semiconductor wafer processing equipment. Its enhanced toughness reduces failure risk under mechanical stress.

International B2B Considerations:

Buyers from Europe and the Middle East should look for compliance with advanced ASTM or DIN standards that specify additive content and mechanical properties. African and South American markets may require additional local testing for additive-related chemical compatibility. Detailed supplier documentation on additive types and concentrations is critical for risk management.

Key Properties:

PC-SiC is a dense, polycrystalline form with uniform microstructure, offering excellent thermal conductivity (up to 200 W/m·K), high hardness, and exceptional wear resistance. It can operate reliably at temperatures above 1600°C and withstands aggressive chemical exposure.

Pros & Cons:

Its superior mechanical strength and thermal shock resistance make PC-SiC highly durable. However, it is the most expensive SiC variant due to advanced manufacturing techniques like hot pressing or chemical vapor deposition. The material’s hardness also complicates machining and increases tooling costs.

Impact on Application:

PC-SiC is suited for ultra-demanding environments such as aerospace components, high-performance heat exchangers, and semiconductor wafer carriers. It excels in corrosive and abrasive conditions, extending equipment life and reducing downtime.

International B2B Considerations:

European and Middle Eastern buyers often require PC-SiC to meet stringent ISO and ASTM standards for aerospace or semiconductor use. Buyers in Africa and South America should ensure supplier certifications and consider logistics for handling high-value, delicate materials. The high cost is justified in applications where longevity and performance outweigh initial investment.

| Material | Typical Use Case for alpha sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Alpha Silicon Carbide (SiC) | Mechanical seals, high-temp bearings, chemical processing | High thermal stability and corrosion resistance | Brittleness and higher manufacturing complexity | High |

| Reaction Bonded Silicon Carbide (RBSC) | Kiln furniture, heat exchangers, moderate chemical use | Cost-effective, good machinability | Lower corrosion resistance due to free silicon | Medium |

| Sintered Alpha SiC with Additives | Abrasive slurry pumps, high-pressure valves, semiconductor equipment | Enhanced toughness and strength | Increased cost and additive-related corrosion risk | High |

| Polycrystalline Silicon Carbide (PC-SiC) | Aerospace parts, high-performance heat exchangers | Superior strength, thermal conductivity, wear resistance | Highest cost and machining difficulty | High |

Alpha Silicon Carbide (α-SiC) is a high-performance ceramic material widely used in industrial applications due to its exceptional hardness, thermal conductivity, and chemical resistance. Understanding its manufacturing process is critical for B2B buyers to assess supplier capabilities and ensure product quality.

1. Material Preparation

The process begins with the selection and preparation of raw materials. High-purity silicon and carbon powders are carefully measured and blended to achieve the precise stoichiometric ratio. Additives or binders may be introduced to improve the forming process. This stage requires strict control to prevent contamination, which can affect the final material properties.

2. Forming and Shaping

The blended powder undergoes shaping through techniques such as:

These methods influence the microstructure and mechanical strength of the final product.

3. Sintering and Heat Treatment

The shaped green bodies are sintered at high temperatures (typically above 2000°C) in inert or vacuum atmospheres. This step densifies the material by bonding the particles without melting, resulting in enhanced mechanical and thermal properties. Some manufacturers may use hot pressing or hot isostatic pressing (HIP) to improve density and reduce porosity further.

4. Machining and Finishing

Due to the hardness of α-SiC, precision machining requires specialized diamond grinding tools. Finishing processes may include:

Each step demands advanced equipment and skilled operators to maintain tight tolerances.

Quality assurance in α-SiC manufacturing is critical due to the material’s application in demanding environments, such as aerospace, automotive, and electronics. International buyers must ensure their suppliers adhere to rigorous standards and maintain transparent QC processes.

Relevant International Standards

QC Checkpoints

Common Testing Methods

For international buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality beyond documentation is essential for risk mitigation and long-term partnership success.

1. Conduct Supplier Audits

On-site audits are the most effective way to assess manufacturing capabilities and QC processes. Buyers should evaluate:

Where travel is restricted, virtual audits via video conferencing and real-time factory walkthroughs can be alternatives.

2. Review Quality Documentation

Request detailed QC documentation including:

3. Employ Third-Party Inspection Services

Independent inspection agencies provide unbiased verification of product quality before shipment. They perform:

This is particularly valuable for buyers in regions with less developed local QC infrastructure.

International B2B buyers must navigate varying regulatory landscapes and quality expectations. Here are key considerations:

By understanding the manufacturing intricacies and quality assurance frameworks of α-SiC, international B2B buyers can make informed procurement decisions that balance cost, quality, and reliability.

Understanding the cost structure behind alpha sic sourcing is crucial for international B2B buyers aiming to optimize procurement strategies. The key cost components typically include:

Several factors influence the final pricing of alpha sic products, shaping how buyers should approach negotiations and sourcing decisions:

For buyers from Africa, South America, the Middle East, and Europe, understanding nuances in pricing and sourcing can unlock cost efficiencies and reduce risks:

Prices for alpha sic products can vary widely due to fluctuations in raw material costs, geopolitical factors, and evolving market demand. The figures and strategies discussed serve as indicative guidance. Buyers should conduct due diligence and obtain multiple quotations tailored to their specific requirements and regions before finalizing sourcing decisions.

By carefully analyzing these cost drivers and pricing influencers, B2B buyers can make informed procurement choices, optimize expenditure, and build resilient supply chains for alpha sic products across diverse international markets.

Understanding the critical technical properties of alpha silicon carbide (alpha SiC) is essential for B2B buyers to ensure the material fits their industrial applications, whether in abrasives, ceramics, or electronics. Here are the most important specifications to consider:

Material Grade

Alpha SiC is available in different purity levels and crystalline forms. Higher purity grades have fewer impurities, leading to improved mechanical strength and thermal conductivity. Selecting the right grade impacts product performance and longevity, especially in high-stress environments.

Particle Size and Distribution

The granularity of alpha SiC affects its suitability for various uses, such as fine powders for polishing or coarser grains for cutting tools. Uniform particle size distribution ensures consistent quality and predictable behavior during processing and application.

Density

Measured in grams per cubic centimeter (g/cm³), density influences the material’s strength and wear resistance. A higher density typically means better mechanical properties, which is crucial when alpha SiC is used in structural components or protective coatings.

Thermal Conductivity

Alpha SiC exhibits excellent thermal conductivity, important for applications requiring efficient heat dissipation, such as electronic substrates or heat exchangers. Knowing the exact thermal conductivity helps engineers design systems that avoid overheating.

Hardness (Mohs Scale)

Alpha SiC ranks around 9-9.5 on the Mohs hardness scale, making it extremely hard and durable. This property is vital for abrasive tools and wear-resistant parts, ensuring longevity and cutting efficiency.

Tolerance and Dimensional Stability

For precision parts, understanding dimensional tolerances—how much a part may deviate from specified dimensions—is key. Alpha SiC’s stability under temperature changes affects its performance in precision engineering and high-temperature applications.

Navigating international B2B trade requires familiarity with common industry terms. Here are key terms every buyer should know when procuring alpha SiC:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or products that are purchased by another company and retailed under that purchasing company's brand. If you’re sourcing alpha SiC for OEM applications, ensure material compliance with OEM specifications to maintain product integrity.

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell in one order. Understanding MOQ helps buyers from emerging markets or smaller enterprises plan purchases without overstocking or facing supply chain delays.

RFQ (Request for Quotation)

A formal document sent to suppliers asking for pricing, availability, and terms for alpha SiC products. A well-prepared RFQ that includes technical specs and delivery requirements speeds up supplier responses and ensures accurate quotations.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers for shipping, insurance, and tariffs. Common terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) clarify who bears costs and risks during transit, critical for cross-border transactions.

Lead Time

The time between placing an order and receiving the product. For alpha SiC, lead times can vary based on production complexity and logistics. Knowing lead times helps in planning inventory and production schedules.

Certificate of Analysis (CoA)

A document provided by suppliers detailing the chemical and physical properties of the batch of alpha SiC delivered. This certificate assures buyers of product quality and compliance with technical requirements, reducing risk in procurement.

By mastering these technical and trade aspects, international buyers can optimize procurement strategies for alpha SiC, achieving cost efficiency and product excellence in their markets.

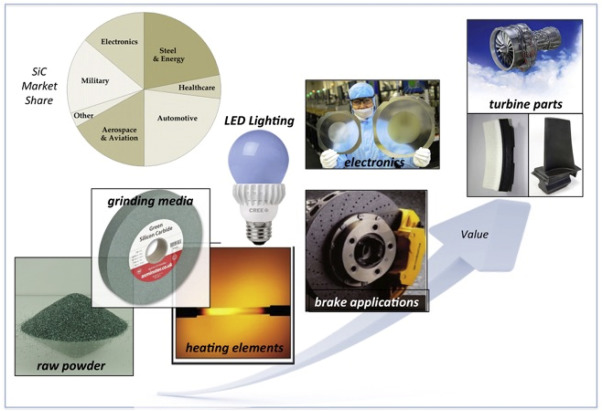

The alpha sic sector is experiencing dynamic growth driven by rapid technological advancements and evolving global supply chain demands. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding these shifts is critical to securing competitive advantages. Key market drivers include increasing demand for high-performance, durable materials in industries such as automotive, electronics, and renewable energy, where alpha sic’s superior thermal and mechanical properties are highly valued.

Current sourcing trends highlight a move toward digital procurement platforms and data-driven supplier management systems. These technologies enable buyers in diverse regions—from Brazil’s manufacturing hubs to Thailand’s industrial zones—to streamline supplier discovery, enhance transparency, and optimize cost efficiencies. Additionally, geopolitical factors and trade policy fluctuations are prompting buyers to diversify supplier bases, favoring regions with stable logistics and favorable trade agreements to mitigate risks.

Emerging trends also emphasize the integration of Industry 4.0 capabilities, such as smart manufacturing and real-time supply chain monitoring. This is particularly relevant for B2B buyers seeking agility in sourcing alpha sic components, as it allows for quicker response times and improved quality control. Furthermore, regional collaborations and trade partnerships, such as Mercosur in South America and the Gulf Cooperation Council (GCC) in the Middle East, are enhancing cross-border supply chain resilience and market access for alpha sic products.

Sustainability has become a cornerstone for B2B buyers in the alpha sic sector, driven by increasing regulatory pressures and corporate responsibility commitments. The environmental impact of alpha sic production, which involves energy-intensive processes, necessitates careful supplier evaluation to ensure eco-friendly practices. Buyers are prioritizing suppliers that minimize carbon footprints through renewable energy use, waste reduction, and efficient resource management.

Ethical sourcing is equally important, with a growing demand for transparency in labor practices and supply chain integrity. International buyers should seek suppliers who comply with global standards such as ISO 14001 for environmental management and SA8000 for social accountability. Certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are also critical for ensuring product safety and regulatory compliance.

Green materials and innovations in alpha sic manufacturing—such as recycled feedstock usage or low-impact sintering techniques—are gaining traction. Buyers from regions with strong environmental policies, including the European Union, are driving this trend and encouraging suppliers worldwide to adopt greener processes. Establishing long-term partnerships with sustainable suppliers not only mitigates risks but also enhances brand reputation and meets the expectations of increasingly eco-conscious end markets.

Illustrative Image (Source: Google Search)

Alpha sic, a form of silicon carbide, has evolved from a niche abrasive material in the early 20th century to a critical industrial component valued for its exceptional hardness, thermal conductivity, and chemical stability. Initially used primarily in grinding and cutting tools, advancements in material science have expanded its applications into semiconductors, automotive parts, and high-temperature electronics.

For B2B buyers, understanding this evolution is vital. The sector's maturity has led to a robust global supply network with specialized manufacturers in Asia, Europe, and the Americas. The progression toward high-purity alpha sic and engineered composites reflects ongoing innovation aimed at meeting the stringent requirements of modern industries. This history underscores the importance of sourcing from suppliers with proven expertise and technological capabilities to ensure product quality and performance in demanding applications.

How can I effectively vet suppliers of alpha sic to ensure reliability?

Thorough supplier vetting is crucial in international B2B sourcing. Start by verifying the supplier’s business licenses and certifications relevant to alpha sic production. Request references and past client testimonials, especially from buyers in your region. Utilize third-party audit services to inspect manufacturing facilities and quality management systems. Additionally, confirm the supplier’s compliance with international standards and inquire about their experience in exporting to your country to minimize risks associated with customs and logistics.

Is it possible to customize alpha sic products to meet specific business needs?

Yes, many alpha sic manufacturers offer product customization, including specifications such as size, purity, and packaging. When negotiating customization, clarify technical requirements upfront and request samples before bulk orders. Ensure the supplier’s R&D capabilities align with your customization needs, and discuss potential additional costs and lead times. Customization agreements should be clearly documented in contracts to avoid misunderstandings and ensure product consistency.

What are typical minimum order quantities (MOQs) and lead times for alpha sic, and how flexible are they?

MOQs for alpha sic vary widely depending on the supplier’s production scale, but international buyers should expect moderate to high MOQs due to manufacturing costs. Lead times generally range from 4 to 12 weeks, factoring in production and shipping. Some suppliers may offer flexibility on MOQs for long-term partnerships or trial orders, but this often affects pricing. Negotiate lead times with an understanding of your supply chain demands and always include buffer periods for customs clearance.

Which payment methods are safest and most commonly accepted in international alpha sic transactions?

Secure payment methods like Letters of Credit (LC) and Escrow services are preferred for international B2B deals as they protect both parties. Wire transfers (T/T) are common but carry higher risk if the supplier is unverified. For new suppliers, consider smaller initial payments or milestone-based payments tied to production and shipment stages. Always verify banking details independently to prevent fraud, and consult with trade finance experts to select the best payment terms aligned with your risk tolerance.

Illustrative Image (Source: Google Search)

What quality assurance measures and certifications should I expect from alpha sic suppliers?

Reliable alpha sic suppliers typically comply with ISO standards (e.g., ISO 9001 for quality management) and may hold industry-specific certifications depending on application (e.g., REACH for chemical safety in Europe). Request Certificates of Analysis (CoA) for each batch to verify product specifications and purity. Insist on third-party lab testing reports when possible. Establish clear quality benchmarks in contracts and consider on-site inspections or third-party quality audits before large orders.

How can I optimize logistics for shipping alpha sic internationally, especially to regions like Africa, South America, or the Middle East?

Efficient logistics require selecting suppliers experienced with your target region’s import regulations and infrastructure. Choose shipping methods balancing cost and delivery time—air freight for urgent orders, sea freight for cost efficiency. Ensure proper packaging to prevent damage and comply with hazardous material regulations if applicable. Work with freight forwarders familiar with customs clearance in your country to avoid delays. Plan shipments around local holidays and regulatory changes to maintain supply chain continuity.

What are best practices for handling disputes or quality issues with alpha sic suppliers?

Document all agreements, specifications, and communications in writing. Upon receiving goods, conduct prompt inspections and compare against agreed standards. If issues arise, notify the supplier immediately with evidence such as photos and lab reports. Refer to dispute resolution clauses in contracts, which may include mediation or arbitration. Maintain open communication to seek amicable solutions before escalating. Involve legal counsel familiar with international trade laws if disputes cannot be resolved amicably.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of alpha sic presents a compelling opportunity for international B2B buyers to enhance supply chain resilience, optimize cost-efficiency, and access superior product quality. By leveraging thorough supplier evaluation, embracing technological integration, and prioritizing sustainable procurement practices, businesses can unlock substantial competitive advantages. For buyers in Africa, South America, the Middle East, and Europe—including emerging markets such as Thailand and Brazil—tailored sourcing strategies that consider regional market dynamics and logistical complexities are essential.

Key takeaways include:

Looking ahead, the alpha sic market will continue evolving with innovations in production and supply chain transparency. International buyers are encouraged to proactively engage in strategic partnerships and continuous market intelligence gathering. This approach will not only secure supply but also foster long-term growth and innovation. Embrace strategic sourcing today to position your enterprise at the forefront of the alpha sic industry’s global transformation.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina