Navigating the complexities of sourcing aluminium oxide in the global market can be a daunting challenge for international B2B buyers. With diverse applications ranging from abrasive materials to chemical catalysts, understanding the various types and qualities of aluminium oxide is crucial for making informed purchasing decisions. This guide aims to demystify the aluminium oxide landscape, providing insights into its different forms, applications, and the critical factors that influence cost.

As buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers, it becomes imperative to understand the nuances of supplier vetting processes. This guide will equip you with the tools necessary to evaluate potential partners effectively, ensuring that your sourcing decisions align with both quality standards and budgetary constraints.

Whether you are looking to procure high-purity alumina for advanced ceramics or calcined aluminium oxide for industrial uses, the comprehensive scope of this guide offers valuable insights to empower your purchasing strategies. By addressing key challenges and providing actionable recommendations, this resource is designed to enhance your ability to navigate the global market confidently, ultimately leading to successful procurement outcomes.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alpha-Aluminium Oxide | High purity, crystalline structure | Aerospace, electronics, ceramics | Pros: Excellent thermal stability, high strength. Cons: Higher cost compared to other types. |

| Gamma-Aluminium Oxide | Amorphous, lower density, higher surface area | Catalyst supports, adsorbents | Pros: Good adsorption properties, versatile applications. Cons: Less stable under high temperatures. |

| Delta-Aluminium Oxide | Intermediate phase, unique morphology | Refractories, abrasives | Pros: Balance of properties, cost-effective. Cons: Limited availability in some regions. |

| Amorphous Aluminium Oxide | Non-crystalline, high surface area | Coatings, fillers, pharmaceuticals | Pros: High reactivity, versatile use. Cons: Less mechanical strength than crystalline types. |

| Aluminium Oxide Nanoparticles | Nanoscale size, increased surface reactivity | Nanocomposites, drug delivery systems | Pros: Enhanced properties, potential for innovative applications. Cons: Regulatory challenges and higher costs. |

Alpha-aluminium oxide, also known as corundum, is characterized by its high purity and crystalline structure, making it ideal for applications requiring exceptional thermal stability and mechanical strength. This type is primarily used in aerospace and electronics industries, where reliability is crucial. B2B buyers should consider the higher cost associated with alpha-aluminium oxide, which reflects its superior quality and performance in demanding applications.

Gamma-aluminium oxide is distinguished by its amorphous nature and lower density, which grants it a higher surface area. This type is commonly utilized in catalyst supports and adsorbents, making it a versatile choice for various industrial applications. Buyers should note that while gamma-aluminium oxide offers excellent adsorption properties, it is less stable under high temperatures, which may limit its use in specific environments.

Delta-aluminium oxide serves as an intermediate phase between alpha and gamma types, providing a unique morphology that balances properties. It finds applications in refractories and abrasives, making it a cost-effective solution for many industries. For buyers, the key consideration is its availability, which can vary by region, potentially impacting supply chains.

Amorphous aluminium oxide is known for its non-crystalline structure and high surface area, making it suitable for coatings, fillers, and pharmaceuticals. Its high reactivity allows for diverse applications, but it generally lacks the mechanical strength of crystalline forms. B2B buyers should weigh the versatility of amorphous aluminium oxide against its lower strength, depending on the specific application requirements.

Aluminium oxide nanoparticles are defined by their nanoscale size and increased surface reactivity, leading to enhanced properties in nanocomposites and drug delivery systems. While they offer exciting potential for innovative applications, buyers must be aware of regulatory challenges and higher costs associated with these materials. Understanding the implications of these factors is crucial for making informed purchasing decisions.

| Industry/Sector | Specific Application of Aluminium Oxide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine Components and Structural Parts | High strength-to-weight ratio, corrosion resistance | Certification standards, supplier reliability, material traceability |

| Electronics | Insulators and Substrates | Enhanced thermal conductivity, electrical insulation | Material purity, compliance with industry standards, sourcing from certified suppliers |

| Construction | Concrete Additives and Surface Treatments | Improved durability, resistance to wear and tear | Local sourcing options, compatibility with local materials, environmental regulations |

| Automotive | Brake Linings and Catalytic Converters | Improved performance, reduced emissions | Quality assurance, performance testing, supplier certifications |

| Metal Fabrication | Abrasives and Cutting Tools | Enhanced machining efficiency, longer tool life | Cost-effectiveness, availability of grades, supplier reputation |

In the aerospace industry, aluminium oxide is primarily used in engine components and structural parts due to its remarkable strength-to-weight ratio and corrosion resistance. This material is essential for manufacturing lightweight aircraft parts that can withstand extreme temperatures and pressures. For international buyers, particularly in regions like Europe and the Middle East, it is crucial to source aluminium oxide from suppliers who meet stringent certification standards and can provide detailed material traceability. This ensures compliance with safety regulations and enhances the reliability of aerospace applications.

Aluminium oxide serves as an insulator and substrate in various electronic applications, including circuit boards and semiconductor devices. Its high thermal conductivity and excellent electrical insulation properties make it indispensable for efficient heat management in electronic components. For B2B buyers in Africa and South America, sourcing aluminium oxide requires a focus on material purity and compliance with international standards, ensuring that the components will perform reliably in diverse operating conditions.

In the construction sector, aluminium oxide is utilized as an additive in concrete and surface treatments to enhance durability and resistance to wear. This application is particularly beneficial in regions with harsh environmental conditions, such as the Middle East, where materials must withstand high temperatures and abrasive elements. Buyers should consider local sourcing options to reduce costs and ensure compatibility with regional materials while adhering to environmental regulations.

In the automotive industry, aluminium oxide is found in brake linings and catalytic converters, where it improves performance and reduces emissions. The material's thermal stability and resistance to wear make it ideal for high-stress components. Buyers from Europe and Africa should prioritize quality assurance and performance testing when sourcing aluminium oxide, as these factors significantly impact the overall safety and efficiency of automotive applications.

Aluminium oxide is widely used in metal fabrication as an abrasive material and in cutting tools. Its hardness and durability enhance machining efficiency and extend tool life, making it a cost-effective choice for manufacturers. B2B buyers should evaluate the cost-effectiveness and availability of various grades of aluminium oxide, as well as the reputation of suppliers, to ensure they receive high-quality materials that meet their specific fabrication needs.

Related Video: Some Important Properties and Uses of Aluminium

The Problem: For international B2B buyers, particularly those in manufacturing sectors across Africa, South America, and the Middle East, sourcing high-quality aluminium oxide can be a significant challenge. Buyers often encounter issues related to inconsistent quality, as suppliers may not adhere to strict international standards. This inconsistency can lead to production delays, increased costs, and ultimately, loss of customer trust. For instance, a manufacturer in Egypt relying on substandard aluminium oxide may face higher rejection rates in their products, affecting their competitive edge in the market.

The Solution: To mitigate these issues, buyers should establish relationships with reputable suppliers who can provide certifications and proof of quality control processes. Conducting audits or on-site visits can further assure the consistency and quality of the aluminium oxide. Additionally, specifying the exact grade required for your specific application—whether it's for abrasives, ceramics, or chemical processing—can help suppliers provide the correct materials. Using quality assurance tools like batch testing and third-party laboratory analyses can also ensure that the aluminium oxide meets the necessary specifications before it is used in production.

The Problem: A common pain point for B2B buyers is the lack of understanding of the various grades and forms of aluminium oxide and how they impact performance in applications. For example, buyers in Europe may find themselves confused about whether to choose alpha-alumina or gamma-alumina for their specific needs, leading to suboptimal product performance and increased costs. This confusion can stem from insufficient product data and a lack of technical support from suppliers.

The Solution: Buyers should invest time in researching and understanding the different forms of aluminium oxide and their specific applications. Collaborating with suppliers who offer detailed technical data sheets and expert advice can significantly help in making informed decisions. Additionally, attending industry seminars and workshops can enhance knowledge about the properties of aluminium oxide, including its hardness, thermal stability, and chemical resistance. This knowledge will empower buyers to select the right type for their applications, thus optimizing performance and reducing wastage.

The Problem: B2B buyers often face significant logistics challenges when procuring aluminium oxide, especially when dealing with international suppliers. Delays in shipping, customs clearance issues, and unexpected tariffs can disrupt production schedules and lead to financial losses. For instance, a construction company in South America may experience project delays due to late delivery of aluminium oxide needed for manufacturing concrete additives, affecting timelines and budgets.

The Solution: To navigate these logistics challenges effectively, buyers should work closely with suppliers who have a proven track record of reliable shipping and logistics management. Establishing clear communication channels regarding delivery timelines and potential risks can help in managing expectations. Furthermore, buyers can benefit from diversifying their supplier base to include local suppliers or distributors who can provide quicker access to materials. Implementing a just-in-time inventory strategy can also help minimize storage costs while ensuring that materials are available when needed. By focusing on logistics planning and supplier reliability, buyers can significantly reduce the risk of disruptions in their procurement processes.

When selecting materials for applications involving aluminium oxide (Al₂O₃), international B2B buyers must consider various factors including performance properties, cost, and compliance with regional standards. Below is an analysis of four common materials used in conjunction with aluminium oxide, focusing on their properties, advantages, limitations, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Aluminium Oxide Ceramics

- Key Properties: High hardness, excellent wear resistance, and thermal stability up to 1,600°C. It exhibits good electrical insulation and is chemically inert.

- Pros & Cons: While durable and resistant to corrosion, the manufacturing process can be complex and costly. The brittleness of ceramics can limit their application in high-impact environments.

- Impact on Application: Ideal for applications requiring high wear resistance, such as cutting tools and wear plates. However, they may not be suitable for high-impact applications.

- Considerations for Buyers: Compliance with international standards such as ISO 12677 is crucial. Buyers should also consider the availability of local suppliers to reduce lead times.

Aluminium Oxide Composites

- Key Properties: Enhanced toughness and strength compared to pure aluminium oxide, often combined with polymers or metals. They maintain good thermal and electrical insulation properties.

- Pros & Cons: These composites offer a balance of durability and flexibility, making them suitable for a variety of applications. However, they can be more expensive than standard aluminium oxide materials.

- Impact on Application: Suitable for applications in aerospace and automotive industries where weight reduction is critical without sacrificing strength.

- Considerations for Buyers: Buyers should verify compliance with industry-specific standards (e.g., ASTM D638 for plastics) and assess the supplier's ability to meet custom specifications.

Aluminium Oxide Powders

- Key Properties: Fine particle size allows for versatile applications, including abrasives and fillers. They exhibit high melting points and are chemically stable.

- Pros & Cons: Cost-effective and easy to manufacture, but the performance can vary based on particle size and purity. They may not provide the same mechanical strength as bulk materials.

- Impact on Application: Commonly used in polishing and grinding applications, as well as in the production of ceramics and glass.

- Considerations for Buyers: Ensure that the powder meets specific purity standards and is sourced from reliable suppliers to avoid contamination issues, particularly important in regulated industries.

Aluminium Oxide Coatings

- Key Properties: Provides a protective layer that enhances corrosion resistance and wear resistance. Coatings can be applied to various substrates, improving their performance.

- Pros & Cons: They are effective at extending the life of components but require precise application techniques. The cost can be higher depending on the coating method used.

- Impact on Application: Ideal for components exposed to harsh environments, such as marine or chemical processing applications.

- Considerations for Buyers: Buyers should consider the compatibility of coatings with existing materials and ensure compliance with environmental regulations, especially in regions with strict standards.

| Material | Typical Use Case for aluminiumoxide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminium Oxide Ceramics | Cutting tools, wear plates | High hardness and wear resistance | Brittle, complex manufacturing | High |

| Aluminium Oxide Composites | Aerospace and automotive applications | Balance of strength and flexibility | Higher cost than standard materials | Med |

| Aluminium Oxide Powders | Abrasives, fillers | Cost-effective and versatile | Variable performance based on purity | Low |

| Aluminium Oxide Coatings | Protective layers for components | Enhanced corrosion and wear resistance | Requires precise application techniques | Med |

This comprehensive analysis provides international B2B buyers with actionable insights into the strategic selection of aluminium oxide materials, ensuring they make informed decisions that align with their specific application needs and regional compliance requirements.

The manufacturing process of aluminium oxide (Al2O3), commonly known as alumina, involves several key stages that ensure the production of high-quality material suitable for various industrial applications. Understanding these stages is crucial for B2B buyers in sectors like ceramics, abrasives, and electronics.

Material Preparation: The process begins with the selection and preparation of raw materials. Bauxite ore, which contains 30-60% aluminium oxide, is primarily used. The ore undergoes crushing, grinding, and refining to remove impurities. This preparation is vital as the purity of the raw materials directly impacts the quality of the final product.

Forming: Once the materials are prepared, they are subjected to processes such as calcination. In this stage, bauxite is heated in rotary kilns at temperatures around 1000°C to 1100°C. This process drives off water and transforms the ore into alumina. The resulting material can be further processed into various forms, including powders or granules, depending on the intended application.

Assembly: In some applications, alumina is combined with other materials to create composites or advanced ceramics. The assembly stage involves mixing alumina with additives, which may require precise control over composition and mixing techniques to ensure uniformity.

Finishing: The final stage of manufacturing involves processes such as milling, sieving, and packaging. These processes ensure that the alumina meets specific granule size distributions and purity levels. Finishing is critical for applications that require precise specifications, such as in the production of abrasives or in the electronics industry.

Several techniques are employed throughout the manufacturing process to enhance the quality and efficiency of aluminium oxide production:

Bayer Process: This is the most widely used method for refining bauxite to produce alumina. It involves the extraction of aluminium oxide using sodium hydroxide, which dissolves the alumina and separates it from impurities.

Hydrothermal Synthesis: For high-purity alumina, hydrothermal methods can be employed. This technique uses high pressure and temperature to dissolve and recrystallize alumina, resulting in exceptionally pure material.

Spray Drying: In the finishing stage, spray drying is often used to produce fine alumina powders. This technique allows for the production of uniform particle sizes and is essential for applications requiring specific physical properties.

Quality assurance (QA) is a critical aspect of aluminium oxide production, ensuring that the final product meets international standards and customer specifications.

B2B buyers should be aware of various international standards that govern the quality of aluminium oxide.

ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

CE Marking: For products sold in Europe, CE marking is essential. It indicates that the product complies with EU safety, health, and environmental protection standards.

API Standards: In industries like oil and gas, compliance with American Petroleum Institute (API) standards may be necessary, especially for applications involving high-stress environments.

Effective quality control in aluminium oxide manufacturing includes several checkpoints:

Incoming Quality Control (IQC): This initial checkpoint involves the inspection of raw materials and components before they enter the manufacturing process. Ensuring the quality of incoming materials helps prevent defects in the final product.

In-Process Quality Control (IPQC): During manufacturing, regular inspections and tests are conducted to monitor processes and detect any deviations from quality standards. Techniques like statistical process control (SPC) can be employed to analyze data and maintain quality.

Final Quality Control (FQC): After production, the final product undergoes rigorous testing to ensure it meets specified standards. Common testing methods include chemical analysis, particle size distribution analysis, and physical property testing (e.g., hardness, density).

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are some actionable steps:

Conduct Supplier Audits: Regular audits of suppliers can help assess their adherence to quality standards. Buyers should consider both initial audits and ongoing evaluations to ensure continuous compliance.

Request Quality Reports: Suppliers should provide documentation that outlines their quality control procedures, including results from IQC, IPQC, and FQC. These reports can provide insight into the reliability of the supplier's processes.

Engage Third-party Inspectors: Hiring independent third-party inspectors can add an extra layer of verification. These professionals can conduct thorough assessments of the supplier's facilities and quality management systems.

Understand QC Nuances for International Markets: Different regions may have varying regulations and standards. Buyers should familiarize themselves with local requirements and ensure that suppliers are compliant with both international and regional standards.

Various testing methods are used to evaluate the quality of aluminium oxide:

Chemical Composition Analysis: Techniques like X-ray fluorescence (XRF) and inductively coupled plasma (ICP) are used to determine the chemical makeup of alumina, ensuring it meets required specifications.

Physical Property Testing: This includes measuring properties such as hardness, density, and thermal stability, which are critical for applications in ceramics and abrasives.

Performance Testing: For specific applications, performance tests may be conducted to assess the material's suitability under operational conditions, such as abrasion resistance or thermal shock resistance.

Understanding the manufacturing processes and quality assurance measures for aluminium oxide is essential for international B2B buyers. By familiarizing themselves with the stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions when sourcing this critical material. This knowledge not only helps in selecting reliable suppliers but also ensures that the products meet the required standards for their specific industrial applications.

The procurement of aluminium oxide, a crucial material in various industries including ceramics, metallurgy, and electronics, requires careful consideration and structured planning. This guide provides a step-by-step checklist to help international B2B buyers streamline their sourcing process effectively.

Clearly outline the specifications for the aluminium oxide you need. Consider factors such as purity levels, particle size, and intended application. This step is vital because it ensures that you communicate your requirements accurately to potential suppliers, reducing the chances of receiving unsuitable products.

Conduct thorough research to compile a list of potential suppliers specializing in aluminium oxide. Utilize industry directories, trade shows, and online marketplaces. Understanding the supplier landscape is crucial to finding reliable partners who can meet your needs.

Before proceeding, verify the certifications and quality standards of your shortlisted suppliers. Certifications such as ISO 9001 or industry-specific credentials can indicate a supplier’s commitment to quality and reliability.

Always request samples of aluminium oxide from potential suppliers before making a bulk purchase. Testing samples allows you to evaluate the material’s quality and suitability for your specific applications.

Once you have identified a suitable supplier, negotiate the terms and conditions of the purchase. This includes pricing, payment terms, delivery schedules, and return policies. Clear agreements can prevent misunderstandings later in the procurement process.

Draft a formal contract that outlines all agreed-upon terms. This document should cover specifications, quantities, pricing, delivery, and any warranties. A well-drafted contract protects both parties and serves as a reference point for future transactions.

After the successful procurement of aluminium oxide, focus on building a long-term relationship with your supplier. Regular communication and feedback can foster trust and lead to better pricing and service in the future.

By following this structured approach, B2B buyers can ensure a smooth and efficient procurement process for aluminium oxide, ultimately leading to enhanced operational success.

When sourcing aluminium oxide (Al2O3), understanding the cost structure is vital for international B2B buyers. The primary cost components include:

Materials: The cost of raw aluminium oxide varies based on purity and source. High-purity grades often command a premium price, while lower grades are more economical but may not meet all application requirements.

Labor: Labor costs can fluctuate significantly based on the region of production. For example, manufacturing in countries with lower labor costs, such as certain regions in Africa or South America, may provide cost advantages.

Manufacturing Overhead: This encompasses expenses related to production facilities, utilities, and maintenance. Efficient manufacturing processes can help reduce these costs.

Tooling: Initial tooling costs for specialized production processes can be substantial. However, these are often amortized over larger production runs, making it essential to assess order volumes before committing.

Quality Control (QC): Ensuring the quality of aluminium oxide is critical, especially for applications in aerospace or electronics. Investing in robust QC processes can add to costs but is necessary to maintain standards.

Logistics: Transportation costs can vary widely based on the sourcing location and delivery terms. International shipping, customs duties, and local distribution all contribute to the overall logistics cost.

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding market dynamics can help buyers negotiate better pricing.

Several factors influence the pricing of aluminium oxide in the B2B market:

Volume and Minimum Order Quantity (MOQ): Higher order volumes often result in lower per-unit costs. Buyers should negotiate MOQs to optimize their pricing strategy.

Specifications and Customization: Customized grades of aluminium oxide may incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses.

Materials and Quality Certifications: The quality of raw materials and any necessary certifications (such as ISO standards) can significantly impact pricing. Buyers should prioritize suppliers who meet required quality benchmarks.

Supplier Factors: The supplier's reputation, reliability, and production capabilities can influence pricing. Engaging with established suppliers can lead to better pricing and service.

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction is crucial. These terms dictate who is responsible for shipping, insurance, and tariffs, which can affect the total landed cost.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, implementing effective strategies can lead to significant savings:

Conduct a Total Cost of Ownership (TCO) Analysis: This goes beyond the initial purchase price to consider logistics, quality, and potential waste costs. A thorough TCO analysis can uncover hidden expenses and inform better purchasing decisions.

Leverage Volume Discounts: If feasible, consolidate purchases to increase order sizes, which may qualify for volume discounts. Building long-term relationships with suppliers can also yield better pricing over time.

Negotiate Terms: Effective negotiation can significantly impact overall costs. Discuss payment terms, delivery schedules, and other terms that can provide financial flexibility.

Stay Informed About Market Trends: Keeping abreast of market conditions, including raw material prices and geopolitical factors, can empower buyers during negotiations. A well-informed buyer is more likely to secure favorable terms.

Understand Pricing Nuances for International Transactions: Different regions may have varying pricing norms. For example, buyers in Europe may face different logistics costs compared to those in Africa or South America. Familiarizing yourself with these nuances can aid in better budgeting and negotiation.

Prices for aluminium oxide can fluctuate based on market conditions, supplier negotiations, and other external factors. It is advisable for buyers to obtain multiple quotes and conduct thorough research to understand current market pricing before making purchasing decisions.

When evaluating the use of aluminium oxide (Al₂O₃), it is essential for B2B buyers to consider viable alternatives that may meet their operational requirements more effectively or economically. This analysis will compare aluminium oxide with two alternatives: silicon carbide (SiC) and zirconium oxide (ZrO₂), focusing on key performance indicators relevant to industrial applications.

| Comparison Aspect | Aluminium Oxide | Silicon Carbide | Zirconium Oxide |

|---|---|---|---|

| Performance | Excellent hardness and wear resistance | Superior thermal conductivity and strength | High toughness and thermal stability |

| Cost | Moderate | High | Moderate to High |

| Ease of Implementation | Widely available, easy to process | Requires specialized equipment | Requires specific processing techniques |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | Abrasives, ceramics, coatings | High-temperature applications, semiconductors | Dental applications, high-performance ceramics |

Silicon carbide is renowned for its superior thermal conductivity and strength, making it suitable for high-temperature applications and semiconductor manufacturing. However, its cost is significantly higher than aluminium oxide, which can be a critical factor for budget-conscious B2B buyers. The processing of silicon carbide often requires specialized equipment, which may increase the initial investment and complexity of implementation. Despite these challenges, its performance in extreme conditions makes it an attractive option for industries demanding durability and efficiency.

Zirconium oxide is recognized for its exceptional toughness and thermal stability, making it ideal for applications in dental materials and high-performance ceramics. While its cost can be comparable to or higher than that of aluminium oxide, its benefits in specific applications can justify the investment. The processing of zirconium oxide may also require specialized techniques, which can complicate implementation. However, its low maintenance needs and durability in demanding environments often outweigh these drawbacks, particularly for applications requiring longevity and reliability.

When selecting the appropriate material for industrial applications, B2B buyers must carefully assess their specific needs, including performance requirements, budget constraints, and the complexity of implementation. Aluminium oxide offers a balanced combination of performance and cost-effectiveness, making it suitable for many standard applications. However, in scenarios requiring exceptional thermal properties or toughness, alternatives like silicon carbide or zirconium oxide may prove more advantageous despite their higher costs. Ultimately, the decision should align with the operational goals, production capabilities, and long-term sustainability of the business.

Understanding the technical properties of aluminium oxide (Al₂O₃) is crucial for B2B buyers, especially those in industries such as ceramics, electronics, and metallurgy. Here are some key specifications that impact purchasing decisions:

Aluminium oxide is available in various grades, including alpha (α) and gamma (γ) forms. The alpha form is primarily used for high-temperature applications due to its superior hardness and thermal stability, making it ideal for refractory materials. Gamma alumina is often utilized in catalyst supports and adsorbents. Recognizing the appropriate material grade can help buyers ensure they select the right type for their specific application.

The purity of aluminium oxide is often expressed as a percentage, indicating the amount of Al₂O₃ present versus impurities. High-purity aluminium oxide (over 99.5%) is essential in applications like semiconductors and advanced ceramics, where impurities can significantly affect performance. Buyers should verify the purity level to ensure compatibility with their production requirements.

The particle size of aluminium oxide can influence its reactivity and performance in applications. Fine particles enhance surface area and reactivity, making them suitable for catalytic applications, while coarser particles are often used for abrasive materials. Understanding the required particle size distribution is vital for optimizing product performance and ensuring efficiency in manufacturing processes.

Tolerance refers to the allowable deviation from a specified dimension. For aluminium oxide components used in precision applications, such as aerospace or medical devices, strict tolerances are critical. Buyers should pay close attention to the dimensional specifications to avoid costly rework or failures in their final products.

Aluminium oxide exhibits excellent thermal conductivity, making it suitable for applications requiring efficient heat dissipation, such as in electronics and LED devices. Buyers should evaluate the thermal conductivity specifications to ensure that the material will meet the thermal management needs of their products.

Familiarity with industry jargon can significantly enhance the purchasing process for aluminium oxide. Here are some common terms that B2B buyers should know:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminium oxide, buyers often engage with OEMs to source specialized materials tailored for their products. Understanding OEM relationships can facilitate smoother transactions and ensure quality compliance.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For aluminium oxide, MOQs can vary based on the supplier and product specifications. Buyers should be aware of MOQs to manage inventory and cash flow effectively while meeting production needs.

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products. When purchasing aluminium oxide, submitting an RFQ can provide clarity on pricing, delivery timelines, and terms. This process is essential for informed decision-making.

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is critical for B2B buyers, as they clarify the cost allocation and risk during shipping.

Lead time refers to the time taken from placing an order until it is delivered. In industries where timely delivery is critical, understanding lead times for aluminium oxide can help buyers plan production schedules and avoid disruptions.

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety criteria. Buyers should inquire about certification for aluminium oxide to ensure compliance with industry regulations and standards, which can impact product acceptance in their respective markets.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing aluminium oxide, ultimately enhancing their operational efficiency and product quality.

The aluminium oxide market is experiencing significant growth, driven by increasing demand across various industries such as automotive, aerospace, and electronics. Notably, the rise of electric vehicles (EVs) has spurred demand for lightweight materials, positioning aluminium oxide as a crucial component due to its strength and lightweight properties. Moreover, advancements in manufacturing technologies, including automation and artificial intelligence, are reshaping sourcing trends, allowing for more efficient production processes and supply chain management.

International B2B buyers from Africa, South America, the Middle East, and Europe should pay attention to emerging trends such as the shift towards digital procurement platforms. These platforms facilitate real-time sourcing and negotiations, enabling buyers to access a broader range of suppliers and optimize their procurement strategies. Additionally, the integration of blockchain technology is enhancing transparency in the supply chain, ensuring traceability of materials and compliance with international standards.

Furthermore, geopolitical factors are influencing market dynamics, with trade policies and tariffs affecting sourcing strategies. Buyers should be aware of regional regulations and local sourcing options that can mitigate risks associated with international logistics. As global competition intensifies, the ability to quickly adapt to market changes will be vital for maintaining a competitive edge.

Sustainability has become a focal point for B2B buyers in the aluminium oxide sector, as companies increasingly recognize the environmental impact of their sourcing decisions. The aluminium industry is a significant contributor to greenhouse gas emissions, primarily due to energy-intensive extraction and production processes. As such, buyers are prioritizing suppliers that adhere to sustainable practices, such as using renewable energy sources and implementing waste reduction strategies.

Ethical sourcing is equally important, with buyers seeking suppliers that demonstrate a commitment to fair labor practices and responsible mining. Certifications such as ISO 14001 (Environmental Management) and the Aluminium Stewardship Initiative (ASI) certification are gaining traction. These certifications provide assurance that suppliers meet stringent environmental and social standards.

The growing demand for 'green' aluminium oxide materials presents an opportunity for international buyers to align their procurement strategies with sustainability goals. By sourcing from certified suppliers, companies not only enhance their brand reputation but also contribute to a circular economy, reducing the overall environmental footprint of their operations.

The aluminium oxide sector has evolved significantly over the past few decades, transitioning from traditional extraction and processing methods to more advanced and efficient technologies. Initially, the focus was primarily on quantity, with little regard for environmental impact. However, the last decade has seen a paradigm shift, with innovation taking center stage. Techniques such as hydrometallurgy and the development of synthetic aluminas are now commonplace, allowing for more sustainable production methods.

For B2B buyers, understanding this evolution is crucial. It not only informs sourcing decisions but also highlights the importance of engaging with suppliers who are at the forefront of technological advancements. As the sector continues to evolve, staying abreast of new developments and sustainability practices will empower buyers to make informed decisions that align with their operational goals and corporate social responsibility commitments.

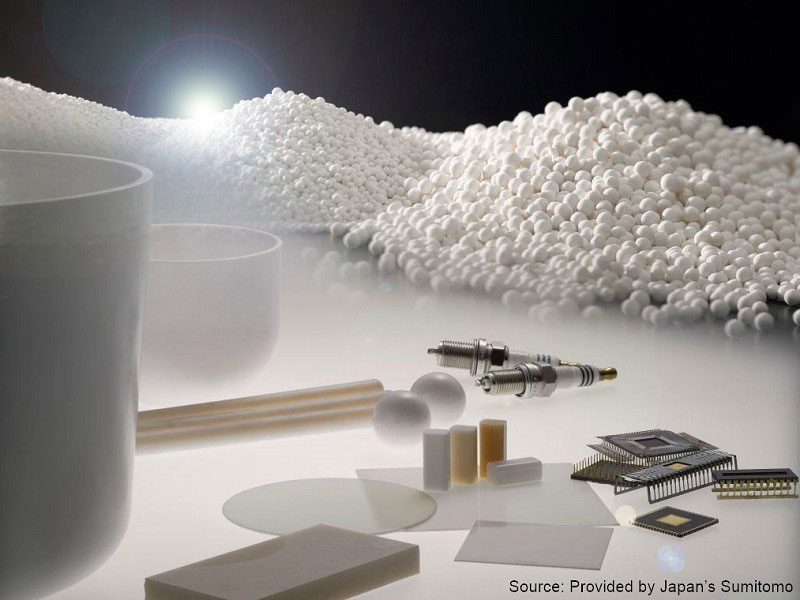

A stock image related to aluminiumoxide.

In summary, navigating the aluminium oxide market requires a comprehensive understanding of current dynamics, sustainability trends, and the sector's historical context. By leveraging this knowledge, international B2B buyers can optimize their sourcing strategies and enhance their competitive positioning in a rapidly changing global landscape.

How do I solve issues with sourcing aluminium oxide for my business?

To effectively solve sourcing issues for aluminium oxide, start by identifying reliable suppliers. Use platforms like Alibaba or Global Sources to find verified manufacturers. Assess supplier credibility through reviews and ratings, and request samples to evaluate product quality. Establish clear communication regarding specifications, delivery timelines, and pricing. Additionally, consider attending industry trade shows or webinars to connect with potential suppliers directly.

What is the best type of aluminium oxide for industrial applications?

The best type of aluminium oxide for industrial applications often depends on the specific use case. For abrasive applications, corundum (brown aluminium oxide) is preferred due to its hardness and durability. For applications requiring high purity, such as in electronics or ceramics, alpha-alumina is optimal. Always consult with suppliers about your specific requirements to ensure you select the right grade that meets your operational needs.

How can I ensure the quality of aluminium oxide from international suppliers?

To ensure quality when sourcing aluminium oxide internationally, request certifications such as ISO 9001 or product-specific quality assurance documentation. Conduct audits or inspections of the manufacturing facilities if feasible. Additionally, asking for a Certificate of Analysis (CoA) for each batch can provide insights into the chemical composition and purity levels. Establishing a clear return policy for defective products can further safeguard your purchase.

What are the typical minimum order quantities (MOQs) for aluminium oxide?

Minimum order quantities (MOQs) for aluminium oxide can vary significantly based on the supplier and the specific product type. Typically, MOQs range from 100 kg to several tons, especially for custom grades or formulations. It's advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing capabilities while ensuring you secure the best pricing.

What payment terms should I expect when buying aluminium oxide internationally?

Payment terms for international purchases of aluminium oxide can vary widely. Common practices include advance payment, letter of credit, or payment upon delivery. Some suppliers may offer 30-60 day terms for established customers. Always clarify payment methods upfront and consider using escrow services for large transactions to protect your investment.

What logistics considerations should I keep in mind when importing aluminium oxide?

When importing aluminium oxide, consider logistics factors such as shipping methods, customs duties, and import regulations specific to your country. Depending on the volume, you may choose between air freight for speed or sea freight for cost-effectiveness. Ensure that the supplier provides all necessary shipping documents, including the bill of lading and commercial invoice, to facilitate smooth customs clearance.

How do I vet potential suppliers of aluminium oxide for reliability?

To vet potential suppliers of aluminium oxide, start by researching their business history and reputation in the industry. Request references from previous customers and check online reviews. Additionally, consider conducting background checks using services like Dun & Bradstreet. Engaging in direct communication and asking detailed questions about their production processes can also reveal their reliability and commitment to quality.

Can aluminium oxide be customized for specific applications?

Yes, aluminium oxide can often be customized based on specific application needs. Suppliers may offer various grades, particle sizes, and purity levels tailored to your requirements. When discussing customization, provide detailed specifications regarding your application, including intended use, desired properties, and any regulatory compliance needed. Collaborating closely with suppliers will help ensure that the customized product meets your exact needs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of aluminium oxide presents a wealth of opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging a strategic sourcing approach, businesses can optimize their supply chains, reduce costs, and ensure a steady supply of high-quality materials essential for various applications, from manufacturing to advanced technologies.

Buyers should prioritize building strong relationships with suppliers, emphasizing transparency and reliability. Understanding market trends, such as pricing fluctuations and regional demand, can also enhance negotiation leverage. Furthermore, incorporating sustainability practices into sourcing strategies not only aligns with global standards but also appeals to increasingly eco-conscious consumers.

As the global demand for aluminium oxide continues to rise, now is the time for buyers to act. By investing in strategic sourcing initiatives, companies can secure a competitive edge in their respective markets. It is essential to remain adaptable and informed about new developments in the industry.

A stock image related to aluminiumoxide.

We encourage B2B buyers to take the initiative today—evaluate your sourcing strategies and explore innovative partnerships that will position your business for success in the evolving landscape of aluminium oxide.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina