In the competitive landscape of global trade, sourcing high-quality boron carbide (B4C) can present significant challenges for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With its unique properties, including exceptional hardness and chemical resistance, B4C is essential for various applications ranging from military armor to industrial abrasives. This guide aims to demystify the complexities surrounding the procurement of B4C by providing a comprehensive overview of its types, applications, and the critical factors to consider when vetting suppliers.

Buyers will gain insights into the diverse applications of boron carbide, enabling them to make informed decisions tailored to their industry needs. Additionally, the guide will cover essential aspects such as cost considerations, sourcing strategies, and the importance of supplier reliability, ensuring that buyers can secure the best deals without compromising on quality. Whether you are in the aerospace, defense, or manufacturing sector, this resource empowers you to navigate the global market with confidence. By understanding the nuances of B4C sourcing, buyers can optimize their purchasing strategies, ultimately leading to enhanced operational efficiency and competitive advantage in their respective markets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Boron Carbide Powder | Fine particulate form, high hardness | Abrasives, nuclear applications | Pros: Excellent wear resistance; Cons: Can be expensive. |

| Boron Carbide Ceramics | Dense, strong, and durable materials | Armor plating, industrial components | Pros: High strength-to-weight ratio; Cons: Brittle under impact. |

| Boron Carbide Composites | Mixture with other materials for enhanced properties | Aerospace, automotive industries | Pros: Tailored properties for specific needs; Cons: May require specialized processing. |

| Boron Carbide Coatings | Thin layers applied to surfaces | Protective coatings for tools and machinery | Pros: Extends life of components; Cons: Application can be complex. |

| Boron Carbide Nanoparticles | Nanoscale for unique properties | Advanced manufacturing, electronics | Pros: Enhanced performance in small volumes; Cons: Handling requires special precautions. |

Boron Carbide Powder is a finely milled form of boron carbide known for its exceptional hardness and wear resistance. This type is primarily used in abrasive applications, such as grinding wheels and cutting tools. When considering this product, B2B buyers should evaluate the grain size, purity, and specific surface area, as these factors can influence performance in demanding applications. While the price point can be higher, the longevity and efficiency it offers can justify the investment.

Boron Carbide Ceramics are engineered for high durability and strength, making them suitable for applications like armor plating and industrial components exposed to harsh environments. Their high strength-to-weight ratio is particularly appealing to industries such as defense and aerospace. Buyers should assess the specific mechanical properties required for their applications, as well as the manufacturing processes involved, which can impact lead times and costs. The brittleness under impact is a consideration; hence, applications requiring flexibility may need alternative solutions.

Boron Carbide Composites combine boron carbide with other materials to enhance specific characteristics, making them ideal for aerospace and automotive sectors. The ability to tailor properties such as thermal stability and impact resistance provides significant advantages in high-performance environments. Buyers should consider the compatibility of the composite materials and the intended application to ensure optimal performance. While these composites can be more expensive, their customized properties can lead to better overall performance and reduced maintenance costs.

Boron Carbide Coatings are applied as thin layers to enhance the surface properties of tools and machinery, significantly extending their lifespan. These coatings provide excellent resistance to wear and corrosion, making them ideal for harsh operational environments. B2B buyers should evaluate the coating application process, as it can be complex and may require specialized equipment. While the benefits of increased durability and reduced downtime are substantial, the initial application costs and the need for skilled labor can be drawbacks.

Boron Carbide Nanoparticles offer unique benefits due to their nanoscale size, which can enhance performance in advanced manufacturing and electronics applications. These particles are known for their high surface area and reactivity, leading to improved material properties. Buyers interested in this form should consider factors such as particle size distribution and purity, as they can significantly affect performance. However, handling these nanoparticles requires special precautions due to their small size and potential health risks, which may necessitate additional training and safety measures.

Related Video: Types of Chemical Reactions

| Industry/Sector | Specific Application of b4c chemical name | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight armor systems for aircraft | Enhanced protection without significant weight increase | Certifications for aerospace materials, compliance with safety regulations |

| Nuclear Energy | Control rods in nuclear reactors | Improved neutron absorption leading to efficient reactor operation | Supplier reliability, long-term supply agreements, and regulatory compliance |

| Automotive | Abrasives for manufacturing and finishing automotive components | Higher precision and durability in manufacturing processes | Quality certifications, delivery timelines, and cost-efficiency |

| Defense & Security | Ballistic armor for military vehicles and personal protection gear | Increased safety for personnel in high-risk environments | Compliance with military standards, availability of custom solutions |

| Electronics | Semiconductor manufacturing processes | Improved efficiency in electronic devices through enhanced materials | Technical support, compatibility with existing systems, and sourcing of high-purity materials |

In the aerospace sector, boron carbide (B4C) is primarily employed in the production of lightweight armor systems for aircraft. This application is critical as it provides enhanced protection against ballistic threats while maintaining a low weight, essential for flight efficiency. International buyers, particularly from regions with active defense contracts, must ensure that their suppliers adhere to strict aerospace material certifications and safety regulations to guarantee performance and reliability.

B4C is utilized in control rods within nuclear reactors due to its exceptional neutron absorption capabilities. This application is vital for maintaining safe and efficient reactor operations. For B2B buyers in the nuclear energy sector, particularly in Europe and the Middle East, sourcing B4C requires a focus on supplier reliability and long-term agreements to ensure a stable supply of materials that meet stringent regulatory compliance.

In the automotive industry, boron carbide is used as an abrasive in the manufacturing and finishing of various components. This application allows for higher precision and durability, improving overall product quality. Buyers from South America and Africa should prioritize sourcing B4C that meets quality certifications and can ensure timely delivery to maintain production schedules while also considering cost-efficiency.

Boron carbide is a critical component in ballistic armor used in military vehicles and personal protection gear. Its lightweight yet strong characteristics provide increased safety for personnel operating in high-risk environments. International buyers, especially from regions with active military engagements, need to ensure their sourcing aligns with military standards and the availability of custom solutions tailored to specific defense applications.

In the electronics sector, B4C is integrated into semiconductor manufacturing processes to enhance the efficiency of electronic devices. The use of high-purity B4C can significantly improve device performance. B2B buyers in Europe, particularly in high-tech industries, should focus on sourcing B4C that offers technical support and compatibility with existing systems to maximize the benefits of this advanced material.

Related Video: 20 most important apparatus used in chemistry lab | chemistry lab apparatus name with picture

The Problem:

B2B buyers, especially those in regions like Africa and South America, often struggle to find reliable suppliers of high-quality Boron Carbide (B4C). This challenge is compounded by limited access to international vendors, inconsistent product quality, and the risk of dealing with unverified suppliers. Buyers may find themselves unsure about the specifications they need, leading to potential operational disruptions and increased costs due to subpar materials.

The Solution:

To effectively source high-quality B4C, buyers should start by identifying established suppliers with a strong reputation in the industry. Conducting thorough research through online directories, industry-specific trade shows, and networking with industry peers can provide valuable insights into reliable vendors. When evaluating suppliers, request certifications and quality assurance documentation to ensure compliance with international standards.

Additionally, buyers should engage in direct communication with suppliers to discuss their specific needs and obtain samples for testing. This proactive approach not only helps in verifying the product quality but also fosters a relationship with the supplier that can lead to better terms and support in the future. Establishing clear specifications for B4C, including purity levels, grain size, and intended application, can further streamline the sourcing process and mitigate risks.

The Problem:

Many B2B buyers face confusion regarding the optimal application and usage of Boron Carbide in their manufacturing processes. Given its versatility—ranging from ballistic protection to abrasives—buyers often struggle to determine the right formulation and processing conditions for their specific needs. This uncertainty can result in inefficient production methods, wasted materials, and ultimately, financial losses.

The Solution:

To overcome this challenge, buyers should invest in training and resources that enhance their understanding of B4C applications. Collaborating with suppliers that offer technical support and consultancy can provide insights into best practices for using Boron Carbide effectively.

Moreover, participating in industry workshops and seminars focused on advanced materials can equip buyers with the knowledge needed to leverage B4C’s properties fully. Establishing a feedback loop with end-users can also help refine application methods, ensuring that the material meets performance expectations. By investing in education and establishing partnerships with knowledgeable suppliers, buyers can optimize their use of B4C, leading to improved production efficiency and product quality.

The Problem:

Buyers in the Middle East and Europe often encounter challenges related to the consistency of Boron Carbide quality and supply chain reliability. Fluctuations in the availability of raw materials can lead to delays in production, while variations in product quality can jeopardize the integrity of final products. This inconsistency can be particularly detrimental in industries like defense and aerospace, where precision is critical.

The Solution:

To address these supply chain issues, buyers should consider diversifying their supplier base. Establishing relationships with multiple vendors across different regions can mitigate risks associated with supply disruptions. Additionally, implementing a rigorous quality control process for incoming materials can help ensure that only B4C that meets the established standards is used in production.

Buyers should also explore the benefits of long-term contracts with key suppliers to stabilize pricing and guarantee supply. Utilizing technology such as blockchain for tracking material provenance can further enhance transparency and reliability in the supply chain. By proactively managing supplier relationships and implementing stringent quality controls, buyers can ensure a consistent supply of high-quality Boron Carbide, safeguarding their production processes and maintaining product integrity.

Boron carbide (B4C) is renowned for its exceptional hardness and chemical stability, making it a preferred choice in various industrial applications. Key properties include:

These properties make B4C suitable for applications in military armor, nuclear reactors, and wear-resistant coatings.

When considering boron carbide for B2B applications, it's essential to weigh its advantages and limitations:

Low Density: Compared to other hard materials, B4C is lightweight, beneficial in applications where weight is a concern, such as in aerospace.

Cons:

Boron carbide's properties significantly influence its application across various industries:

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, several considerations are crucial:

| Material | Typical Use Case for b4c chemical name | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Boron Carbide | Military armor and protective gear | Exceptional hardness and lightweight | High cost and manufacturing complexity | High |

| Boron Carbide | Nuclear reactor components | Excellent neutron absorption properties | Brittle nature can lead to fractures | High |

| Boron Carbide | Abrasives for grinding and cutting | Long-lasting durability | Expensive production costs | High |

| Boron Carbide | Wear-resistant coatings | Corrosion resistance | Requires specialized manufacturing methods | High |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding boron carbide materials, ensuring optimal application and compliance with industry standards.

The manufacturing process for Boron Carbide (B4C) involves several critical stages, each designed to ensure the production of high-quality materials suitable for various applications, including abrasives, armor, and nuclear technology. Understanding these stages can empower B2B buyers to evaluate potential suppliers effectively.

The first step in the manufacturing process is the preparation of raw materials. High-purity boron sources, often in the form of boron oxide (B2O3), and carbon sources, such as petroleum coke or graphite, are combined in precise ratios. This mixture undergoes a thorough milling process to achieve a uniform particle size, which is crucial for the subsequent reactions. Buyers should inquire about the sourcing of these materials to ensure that they meet industry standards for purity and quality.

Once the raw materials are prepared, the next stage involves forming the B4C. Common techniques include:

For B2B buyers, understanding the forming techniques used by suppliers can provide insight into the mechanical properties of the final product.

After forming, the B4C products may require additional processing. This can include grinding to achieve precise dimensions, coating for enhanced durability, or even assembling into composite materials for specialized applications. The finishing process is vital as it directly impacts the performance and suitability of B4C in various applications. Buyers should ask suppliers about their finishing capabilities and tolerances.

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for international B2B transactions. Suppliers must adhere to stringent quality standards to ensure that their products meet customer expectations and regulatory requirements.

For B4C manufacturing, several international standards are particularly relevant:

B2B buyers should verify that their suppliers are certified under these standards, as compliance indicates a commitment to quality and reliability.

Quality control (QC) checkpoints are integral to the B4C manufacturing process. Common checkpoints include:

B2B buyers should engage suppliers on their QC processes and request documentation of these checkpoints to ensure thorough quality oversight.

Testing methods for B4C products are essential for assessing performance characteristics, and they typically include:

B2B buyers should ask suppliers for detailed test reports and methodologies to understand the capabilities and limitations of the B4C products they are considering.

For buyers in Africa, South America, the Middle East, and Europe, verifying a supplier's quality control processes is vital to ensure product reliability. Here are some actionable strategies:

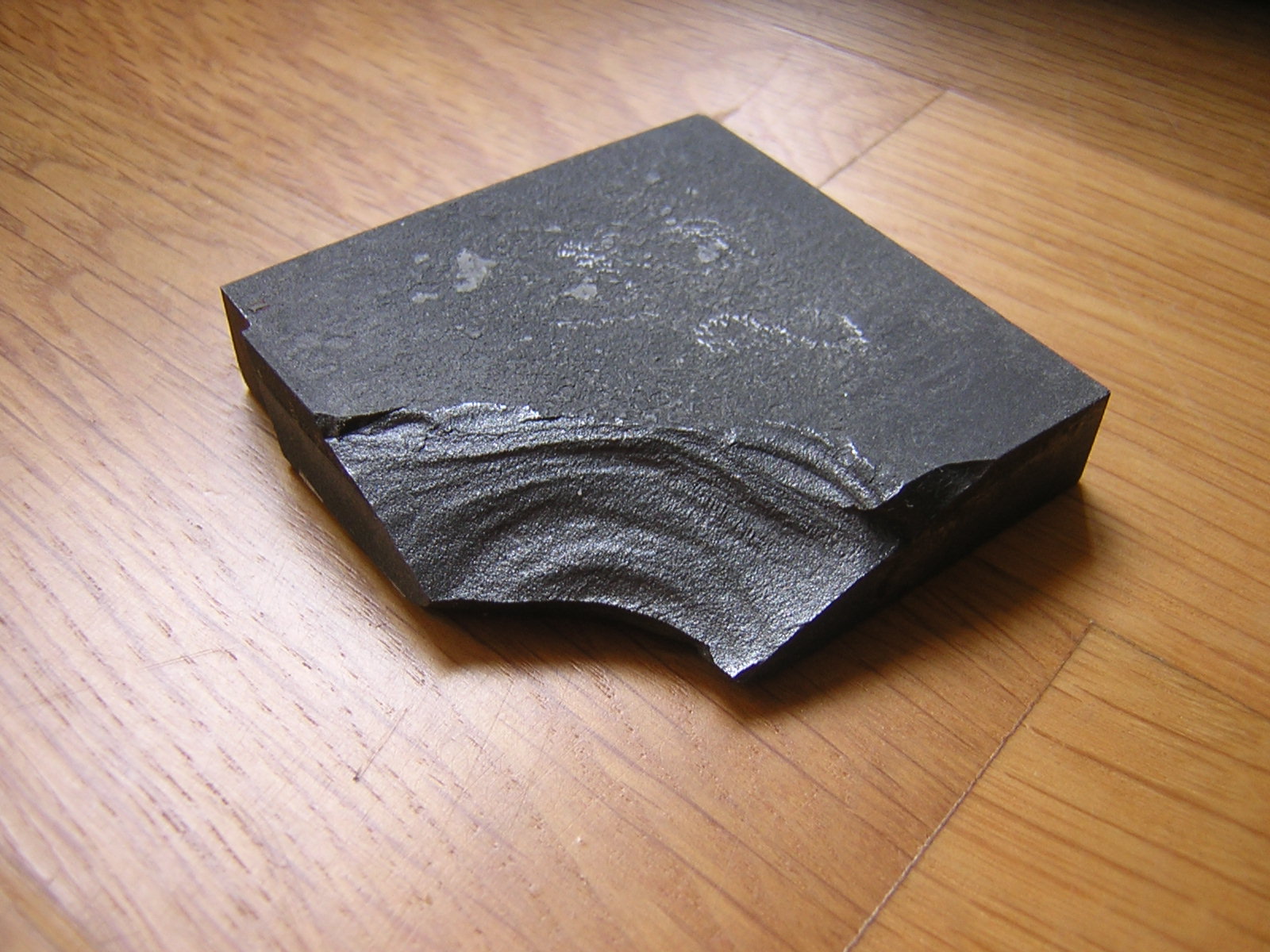

A stock image related to b4c chemical name.

Conduct Supplier Audits: Regular audits can help assess compliance with international standards and internal quality processes. Buyers should establish a checklist based on ISO standards and specific industry requirements.

Request Quality Reports: Suppliers should be able to provide comprehensive reports detailing their quality control processes, including IQC, IPQC, and FQC results.

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier's quality control systems and product integrity.

Evaluate Certifications: Buyers should verify that suppliers possess relevant certifications and ensure that they are up to date.

Seek References and Case Studies: Engaging with previous clients can provide insights into the supplier’s reliability and quality performance.

Understanding the manufacturing processes and quality assurance mechanisms for Boron Carbide is crucial for international B2B buyers. By focusing on supplier capabilities in material preparation, forming, assembly, and finishing, as well as their adherence to quality standards and testing methods, buyers can make informed decisions that meet their operational needs. With thorough due diligence, businesses can ensure they procure high-quality B4C products that drive success in their respective industries.

To effectively procure Boron Carbide (B4C), international B2B buyers should follow a structured approach. This guide provides a comprehensive checklist to streamline the sourcing process, ensuring quality and compliance with industry standards.

Clearly outlining your technical requirements is crucial when sourcing B4C. This includes identifying the desired purity levels, particle size, and intended applications (e.g., abrasives, ballistic protection).

- Why it Matters: Precise specifications help suppliers provide accurate quotations and ensure the final product meets your operational needs.

Conduct thorough research to compile a list of potential suppliers specializing in B4C. Focus on companies with a strong reputation in the chemical industry and verified client testimonials.

- What to Look For: Supplier experience, industry certifications, and geographical presence can significantly impact delivery times and logistics.

Before proceeding, verify that your shortlisted suppliers meet all necessary regulatory standards for B4C production and distribution. Look for certifications such as ISO 9001 or specific environmental compliance standards.

- Importance of Compliance: Ensuring that suppliers adhere to recognized standards reduces risks related to product quality and legal liabilities.

Request samples of B4C from potential suppliers to evaluate the material's quality. Testing the samples against your specifications will help confirm that the supplier can deliver what you need.

- Testing Criteria: Assess aspects such as hardness, purity, and performance in your specific application to ensure compatibility.

Obtain detailed quotations from your selected suppliers, making sure to analyze the pricing structures. Look for additional costs such as shipping, handling, and potential tariffs.

- Negotiation Points: Understanding pricing will enable you to negotiate better terms and potentially bulk discounts, which can significantly impact your overall procurement costs.

Reach out to existing clients of the suppliers to gauge their experiences. Ask about delivery timelines, product quality, and customer service.

- Why This Matters: First-hand accounts can reveal potential red flags and help you make an informed decision based on actual supplier performance.

Once you've selected a supplier, ensure that all contractual agreements are clear and comprehensive, covering aspects like delivery schedules, payment terms, and quality assurance processes.

- Ongoing Monitoring: Establish a system to track the supplier's performance throughout the contract duration, ensuring they meet agreed-upon standards.

Following this checklist will facilitate a more informed and efficient procurement process for Boron Carbide, ultimately enhancing your operational capabilities.

When sourcing Boron Carbide (B4C), understanding the cost structure is vital for international B2B buyers. The primary cost components include:

Materials: The price of raw materials significantly influences overall costs. High-purity boron and carbon are essential for producing B4C, and fluctuations in their market prices can impact sourcing costs. Monitoring these commodity prices can provide insights into potential price changes.

Labor: Labor costs can vary significantly based on geographic location and the skill level required for manufacturing B4C. In regions with higher labor costs, such as Western Europe, you might encounter higher pricing. Conversely, sourcing from regions with lower labor costs may offer savings but could affect quality.

Manufacturing Overhead: This encompasses expenses related to utilities, maintenance, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer competitive pricing.

Tooling: Initial investments in tooling can be substantial, especially for customized or high-specification products. For B4C, tooling costs are crucial for ensuring precision in manufacturing, impacting both quality and cost.

Quality Control (QC): Ensuring product quality is paramount, especially for industries requiring high-performance materials. The costs associated with QC processes, certifications, and testing can contribute to the final price of B4C.

Logistics: Shipping costs, tariffs, and handling fees can vary widely depending on the source and destination. International buyers should consider these expenses, as they can add significantly to the total cost.

Margin: Supplier margins will vary based on their business model and market conditions. Understanding the margin expectations of suppliers can aid in negotiation.

Several factors can influence the pricing of B4C, making it essential for buyers to navigate these complexities:

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly impact pricing. Suppliers often provide better rates for larger orders. Buyers should assess their needs against these quantities to optimize costs.

Specifications and Customization: Custom specifications can lead to increased costs due to additional processing and material requirements. Buyers should clearly define their needs to avoid unexpected price increases.

Materials Quality and Certifications: The quality of materials used in producing B4C can vary, affecting performance and price. Certifications, such as ISO standards, can also lead to higher costs due to the rigorous testing and compliance processes involved.

Supplier Factors: Supplier reputation and reliability can influence pricing. Established suppliers may charge a premium for their products due to their track record of quality and service.

Incoterms: Understanding Incoterms is critical for international transactions. These terms dictate the responsibilities of buyers and sellers in shipping, insurance, and tariffs, impacting the total landed cost of B4C.

To maximize cost-efficiency when sourcing B4C, buyers should consider the following strategies:

Negotiate Effectively: Establish clear communication with suppliers about pricing and terms. Leverage bulk purchasing and long-term contracts to negotiate better rates.

Assess Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider logistics, quality, and potential costs associated with product failures or defects to determine the TCO.

Stay Informed on Market Trends: Regularly review market conditions and commodity prices for boron and carbon. This knowledge will empower buyers during negotiations and purchasing decisions.

Evaluate Supplier Capabilities: Assess suppliers not just on price, but also on their ability to meet quality standards, delivery timelines, and service levels.

Utilize Local Resources: For buyers in Africa, South America, the Middle East, and Europe, consider local suppliers who may offer reduced shipping costs and faster delivery times.

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and other factors. It is advisable for buyers to conduct thorough market research and obtain quotes from multiple suppliers before making sourcing decisions.

When considering the procurement of materials like Boron Carbide (B4C), it’s essential for international B2B buyers to explore viable alternatives. Different materials may offer varying advantages in performance, cost, and application, making it crucial to evaluate options based on specific project requirements. This analysis compares B4C with two prominent alternatives: Silicon Carbide (SiC) and Alumina (Al2O3).

| Comparison Aspect | B4C Chemical Name | Silicon Carbide (SiC) | Alumina (Al2O3) |

|---|---|---|---|

| Performance | High hardness and excellent wear resistance; effective in ballistic applications. | Superior thermal conductivity and strength; excellent in high-temperature applications. | Good hardness, excellent electrical insulation, and chemical resistance. |

| Cost | Generally higher due to specialized manufacturing processes. | Competitive pricing, but can vary based on purity and form. | Typically lower, making it a cost-effective solution for various applications. |

| Ease of Implementation | Requires specialized handling and processing techniques. | Moderate; can be processed using standard ceramic methods. | Easy to implement with standard manufacturing processes. |

| Maintenance | Low maintenance; highly durable. | Low maintenance; however, brittleness can pose challenges. | Low maintenance; stable over time with minimal degradation. |

| Best Use Case | Ideal for ballistic protection, nuclear applications, and abrasive environments. | Best suited for high-temperature applications, automotive, and semiconductor industries. | Commonly used in electrical insulators, wear-resistant components, and as a filler material. |

Silicon Carbide is known for its exceptional thermal conductivity and mechanical strength, making it an ideal choice for high-temperature applications. Its ability to withstand extreme conditions makes it particularly useful in the automotive and semiconductor industries. However, while SiC can be competitively priced, its cost may escalate depending on the required purity levels and forms, such as wafers or powders. Additionally, its brittleness can lead to challenges in handling and processing.

Alumina is a widely used material due to its excellent electrical insulation and chemical resistance properties. It is generally more cost-effective than B4C, making it an attractive option for various applications, including wear-resistant components and electrical insulators. The ease of processing alumina with standard manufacturing techniques allows for greater flexibility in production. However, it lacks the extreme hardness and specialized applications that B4C offers, particularly in ballistic and nuclear contexts.

When selecting between B4C and its alternatives, B2B buyers should consider the specific requirements of their application. Factors such as performance needs, budget constraints, and the operational environment are critical in making an informed decision. While B4C excels in high-stress applications, alternatives like SiC and Al2O3 may provide better cost efficiency or ease of implementation for less demanding conditions. Ultimately, the choice should align with both immediate project goals and long-term operational strategies.

Boron carbide (B4C) is a ceramic material renowned for its unique properties, making it highly sought after in various industries, including defense, automotive, and nuclear applications. Understanding the technical specifications of B4C is crucial for international B2B buyers to make informed purchasing decisions.

The material grade of B4C indicates its purity and crystalline structure, which significantly affects its performance. Higher grades possess fewer impurities, leading to enhanced mechanical strength and durability. This is particularly important in applications requiring high wear resistance, such as armor plating and cutting tools. Buyers should specify the required grade based on the intended use to ensure optimal performance.

Boron carbide is one of the hardest materials available, rated at 9.5 on the Mohs scale. This exceptional hardness makes it ideal for applications in abrasives and ballistic protection. B2B buyers should consider hardness specifications when evaluating materials for industrial uses, as it directly correlates to the longevity and effectiveness of the product in harsh environments.

The density of B4C typically ranges from 2.52 to 2.55 g/cm³. Density is a critical factor in applications such as radiation shielding, where weight and volume constraints are vital. Buyers must assess the density of B4C to ensure that it meets their specifications for weight-sensitive applications.

Boron carbide exhibits excellent thermal stability, maintaining structural integrity at high temperatures up to 2500°C in inert atmospheres. This property is essential for applications in aerospace and nuclear industries, where materials are subjected to extreme conditions. Buyers should prioritize thermal stability to ensure reliability in high-temperature environments.

B4C is chemically inert, offering resistance to a wide range of corrosive environments. This property is particularly beneficial in chemical processing industries where materials are exposed to harsh chemicals. Understanding the chemical resistance of B4C can help buyers select the right materials for their specific applications, minimizing the risk of degradation.

Navigating the procurement process for B4C involves familiarity with specific trade terms. Understanding these terms can streamline negotiations and enhance communication with suppliers.

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of B4C, buyers might source products from OEMs who incorporate B4C into their own applications. Understanding the OEM structure can help buyers identify reliable suppliers that meet quality standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for B4C products is essential for buyers to manage inventory and costs effectively. It’s advisable to discuss MOQ with suppliers upfront to ensure that it aligns with your purchasing needs.

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. For B4C procurement, issuing an RFQ can help buyers gather competitive pricing and terms from multiple suppliers, enabling informed decision-making.

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is critical for international transactions involving B4C, as they dictate cost allocation and risk during transportation. Understanding these terms can help buyers negotiate better shipping agreements.

Lead time is the duration from placing an order until delivery. For B4C products, lead times can vary based on production schedules and shipping logistics. Buyers should inquire about lead times to plan their projects effectively and avoid delays.

By comprehensively understanding the technical properties and trade terminology associated with B4C, international B2B buyers can make informed decisions that enhance procurement efficiency and product performance.

The B4C (Boron Carbide) market is witnessing a significant transformation, driven by various global factors that affect international B2B buyers. The increasing demand for lightweight and durable materials in industries such as aerospace, defense, and automotive is propelling the growth of B4C. In regions like Africa and South America, the focus on mining and resource extraction is also fostering interest in B4C for its use in abrasive applications.

Emerging technologies such as advanced manufacturing processes and innovative recycling methods are shaping sourcing trends. For instance, the adoption of 3D printing technology is allowing companies to utilize B4C in customized applications, enhancing efficiency and reducing waste. Furthermore, digital platforms for procurement are becoming more prevalent, offering buyers from Europe and the Middle East streamlined access to suppliers, thereby improving transparency and reducing lead times.

A stock image related to b4c chemical name.

In addition to traditional markets, there is a notable rise in the interest from sectors focusing on high-performance ceramics and nuclear applications, particularly in Europe and the Middle East. As a result, international B2B buyers must stay informed about these evolving dynamics to capitalize on new opportunities and mitigate risks associated with sourcing.

The environmental impact of sourcing materials is becoming increasingly important for B2B buyers in the B4C sector. The production of Boron Carbide involves mining processes that can lead to significant ecological disruption if not managed responsibly. Therefore, companies that prioritize sustainability in their supply chains are likely to gain a competitive advantage.

Buyers should look for suppliers that hold certifications indicating adherence to environmental standards, such as ISO 14001. These certifications not only demonstrate a commitment to reducing carbon footprints but also assure buyers of responsible sourcing practices. Moreover, the increasing demand for 'green' materials is pushing suppliers to innovate in eco-friendly production methods, making it essential for B2B buyers to consider the sustainability credentials of their suppliers.

Additionally, ethical sourcing is becoming a key factor in supplier selection. Buyers from regions like Africa and South America must ensure that their suppliers comply with labor laws and ethical standards to avoid reputational risks and ensure a stable supply chain. By integrating sustainability and ethical considerations into their sourcing strategies, B2B buyers can enhance their brand reputation and appeal to a broader customer base.

The journey of Boron Carbide (B4C) dates back to its discovery in the early 20th century, where it was primarily recognized for its hardness and high melting point. Initially used in abrasive applications, B4C has evolved significantly over the decades. Its unique properties have led to its adoption in various advanced applications, including ballistic armor and neutron absorption in nuclear reactors.

As industries have sought materials that can withstand extreme conditions while remaining lightweight, the utilization of B4C has expanded. The growth of defense and aerospace sectors, particularly in Europe and the Middle East, has further accelerated its demand. Today, B4C is not just a niche product but a critical material across multiple sectors, reflecting its substantial evolution from a simple abrasive to a high-performance composite material essential for various advanced applications.

How do I ensure the quality of b4c chemical products before purchasing?

To ensure the quality of boron carbide (B4C) before making a purchase, request samples from potential suppliers. Conduct laboratory tests to verify the chemical composition, purity, and physical properties against your specifications. Additionally, check for certifications such as ISO 9001 or industry-specific standards. Engage with suppliers about their quality assurance processes, including production controls and testing methods. Consider visiting the supplier’s facility if feasible, as this can provide insights into their operational standards and commitment to quality.

What are the most common applications for b4c chemical products?

Boron carbide is primarily used in applications requiring high hardness and wear resistance. Key industries include aerospace for lightweight armor, nuclear reactors for neutron absorption, and manufacturing of cutting tools and abrasives. It is also utilized in the production of advanced ceramics and as a component in ballistic protection systems. Understanding your specific application needs will guide you in selecting the appropriate grade and formulation of B4C for your projects.

What is the ideal minimum order quantity (MOQ) for b4c chemical name?

The minimum order quantity for boron carbide varies by supplier and can range from a few kilograms to several tons, depending on the grade and intended use. For smaller enterprises or initial projects, some suppliers may accommodate lower MOQs. However, purchasing in larger quantities often results in better pricing and availability. Discuss your requirements with suppliers to negotiate favorable terms that align with your business needs and budget constraints.

How can I verify the credibility of a b4c chemical supplier?

To verify a supplier's credibility, conduct thorough research including checking their business credentials, customer reviews, and industry reputation. Look for certifications like ISO 9001, which indicate adherence to quality management standards. Request references from previous clients to gauge their reliability and service quality. Additionally, assess their responsiveness and willingness to provide detailed product information and support, as this reflects their commitment to customer satisfaction.

What payment terms should I expect when sourcing b4c chemical products internationally?

Payment terms can vary widely depending on the supplier and your negotiation. Common arrangements include advance payment, letters of credit, or open account terms for established buyers. It's essential to clarify terms upfront, including payment methods (bank transfer, credit card, etc.), due dates, and any penalties for late payments. Consider discussing partial payments for large orders, which can help mitigate risks for both parties involved in the transaction.

How do logistics and shipping impact the sourcing of b4c chemical products?

Logistics and shipping are critical factors in sourcing boron carbide, especially for international buyers. Ensure your supplier has a reliable logistics partner to handle transportation efficiently. Discuss shipping terms (Incoterms) to clarify responsibilities for costs and risks. Additionally, factor in lead times for production and shipping, as these can affect your project timelines. Being proactive about logistics planning will help minimize delays and ensure timely delivery of your orders.

What customization options are available for b4c chemical products?

Many suppliers offer customization options for boron carbide products, including variations in particle size, formulation, and packaging. Discuss your specific application requirements with potential suppliers to determine if they can tailor their products accordingly. Custom formulations can enhance performance for specialized applications, such as in aerospace or military sectors. Ensure that any customized solutions meet your quality and performance standards before finalizing orders.

What should I know about the regulatory compliance of b4c chemical products?

When sourcing boron carbide, it's crucial to understand the regulatory compliance requirements specific to your region or industry. Different countries have various regulations concerning chemical safety, handling, and environmental impact. Check if your supplier provides Material Safety Data Sheets (MSDS) and ensures compliance with local laws such as REACH in Europe or TSCA in the U.S. Being aware of these regulations will help you avoid legal issues and ensure safe handling of materials in your operations.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In today's competitive landscape, strategic sourcing of Boron Carbide (B4C) presents significant opportunities for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Understanding the properties and diverse applications of B4C—from its role in advanced ceramics to its use in ballistic protection—enables companies to leverage its unique characteristics for enhanced product offerings.

Investing in strategic sourcing not only ensures a reliable supply chain but also fosters long-term partnerships with suppliers who understand the specific needs of various industries. By engaging with manufacturers who specialize in B4C, buyers can optimize costs, improve product quality, and gain access to innovative applications that can differentiate their offerings in the market.

Looking ahead, as global demand for advanced materials continues to rise, the strategic sourcing of B4C will become increasingly vital. Buyers are encouraged to explore collaborative opportunities, attend industry events, and stay informed about technological advancements in B4C applications. This proactive approach will enable businesses to remain competitive and responsive to market trends.

In conclusion, international B2B buyers are urged to embrace strategic sourcing of B4C as a critical component of their supply chain strategy. By doing so, they position themselves to capitalize on emerging trends and drive sustainable growth in their respective markets.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina