In today’s interconnected economy, sourcing beta sic effectively has become a strategic imperative for international businesses aiming to maintain a competitive edge. As a critical material with diverse industrial applications, understanding its global market dynamics is essential for buyers across Africa, South America, the Middle East, and Europe. Whether you are a manufacturer in Brazil, a distributor in South Africa, or a project manager in the Middle East, mastering the nuances of beta sic procurement can unlock significant operational efficiencies and cost advantages.

This guide delivers a comprehensive roadmap for navigating the complexities of the beta sic market. It covers everything from the various types and grades of beta sic to the raw materials and manufacturing processes that define quality and performance. Detailed insights into quality control standards and certifications will help you assess supplier reliability and product consistency, minimizing risk in your supply chain.

Moreover, the guide provides an in-depth analysis of the global supplier landscape, highlighting key players and emerging markets tailored to your regional sourcing needs. You will also find practical advice on cost structures and pricing trends, enabling you to negotiate effectively and budget accurately. To address common concerns, a dedicated FAQ section demystifies technical terms and procurement challenges, empowering you with actionable knowledge.

By leveraging this resource, international B2B buyers can make informed, strategic sourcing decisions that align with their operational goals and market demands. Whether expanding your supplier base or optimizing current partnerships, this guide equips you to confidently engage in the beta sic market and drive sustained business growth.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Beta Sic Standard | Balanced performance with moderate cost | General industrial and manufacturing uses | + Cost-effective, versatile – May lack specialization |

| Beta Sic High Purity | Enhanced purity and chemical stability | Pharmaceuticals, electronics manufacturing | + High reliability – Higher price point |

| Beta Sic Composite | Combined with other materials for added strength | Aerospace, automotive components | + Superior durability – Complex sourcing |

| Beta Sic Nano-Enhanced | Incorporates nanomaterials for improved properties | Advanced tech industries, R&D | + Cutting-edge performance – Limited availability |

| Beta Sic Eco-Friendly | Produced with sustainable processes and materials | Green manufacturing, eco-conscious sectors | + Environmentally responsible – Potentially higher cost |

Beta Sic Standard

This variation offers a balanced profile suitable for a wide range of industrial applications, making it a go-to choice for manufacturers seeking reliability without premium costs. Its moderate cost and versatility make it attractive for buyers in Africa, South America, and Europe looking to optimize operational expenses while maintaining quality. When purchasing, consider volume pricing and supplier consistency to ensure steady supply chains.

Beta Sic High Purity

Designed for sectors requiring stringent chemical stability and purity, such as pharmaceuticals and electronics, this type provides enhanced performance but at a premium price. B2B buyers in the Middle East and Europe should weigh the benefits of product reliability against budget constraints. Verification of purity certifications and compliance with international standards is critical for procurement decisions.

Beta Sic Composite

By integrating Beta Sic with other materials, this variant achieves superior mechanical strength, making it ideal for aerospace and automotive industries. Buyers from advanced manufacturing hubs in South America and Europe benefit from its durability but must navigate more complex supplier networks. Assessing supplier expertise in composite fabrication and lead times is essential.

Beta Sic Nano-Enhanced

Utilizing nanotechnology, this type offers cutting-edge enhancements in conductivity, strength, or thermal resistance, appealing to R&D and high-tech sectors globally. However, limited availability and higher costs require buyers, especially in emerging markets like Africa and the Middle East, to plan procurement carefully and evaluate scalability for commercial use.

Beta Sic Eco-Friendly

Produced through sustainable methods, this variation aligns with growing global demand for environmentally responsible products. B2B buyers targeting green manufacturing in Europe and South America will find this type valuable for meeting regulatory requirements and corporate sustainability goals. The trade-off often involves higher upfront costs, so long-term ROI and brand impact should be factored into purchasing strategies.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of beta SiC | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | High-efficiency power semiconductor devices | Enhanced energy efficiency, reduced heat loss, longer device life | Supplier capability in wafer quality, consistency, and international certification compliance |

| Automotive | Electric vehicle (EV) powertrain components | Improved thermal management and durability under harsh conditions | Availability of customized SiC components compatible with global EV standards |

| Renewable Energy | Solar inverters and wind turbine power converters | Increased conversion efficiency, reliability in harsh environments | Lead times and supply chain resilience for bulk orders across regions |

| Industrial Manufacturing | High-temperature, high-voltage industrial motor drives | Increased operational reliability and reduced maintenance costs | Technical support for integration and compliance with local industrial standards |

| Aerospace & Defense | High-frequency, high-power RF and microwave devices | Superior performance in extreme environments and weight reduction | Strict quality assurance, traceability, and compliance with defense regulations |

Power Electronics:

Beta silicon carbide (SiC) is pivotal in producing high-efficiency power semiconductor devices such as MOSFETs and diodes. These devices benefit from beta SiC’s wide bandgap, which enables operation at higher voltages and temperatures with lower switching losses. For international B2B buyers in Africa, South America, the Middle East, and Europe, securing beta SiC wafers with consistent crystalline quality and certified manufacturing processes is critical to ensure device reliability and longevity. Buyers should focus on suppliers offering robust quality management systems and internationally recognized certifications to meet global market standards.

Automotive:

In the electric vehicle sector, beta SiC is used in powertrain components including inverters and onboard chargers. Its excellent thermal conductivity and high breakdown field strength allow components to perform reliably under elevated temperatures and mechanical stress, extending the lifespan of EV systems. For buyers in emerging EV markets like Brazil and the Middle East, sourcing beta SiC materials that meet stringent automotive quality standards (e.g., IATF 16949) and compatibility with global EV architectures is essential to support scalability and future-proof product lines.

Renewable Energy:

Beta SiC is increasingly integral in solar inverter and wind turbine power converter technology, where efficiency and reliability directly impact energy output and operational uptime. Its ability to withstand harsh environmental conditions such as high temperatures and electrical stress makes it ideal for renewable energy applications. Buyers from regions investing heavily in renewables, such as Europe and Africa, should prioritize suppliers with proven supply chain resilience and the capacity to fulfill large-volume orders while providing technical support for integration into existing energy systems.

Industrial Manufacturing:

Industrial motor drives and high-voltage switching devices benefit from beta SiC’s robustness at elevated temperatures and voltages. This results in improved operational reliability and reduced downtime due to lower failure rates. International buyers, especially in heavy industry hubs across South America and Europe, must consider suppliers that offer technical assistance for system integration and ensure compliance with local industrial safety and performance standards to optimize operational efficiency.

Aerospace & Defense:

Beta SiC’s superior performance in high-frequency, high-power RF and microwave devices makes it a material of choice in aerospace and defense applications, where weight reduction and durability under extreme conditions are paramount. For B2B buyers in defense sectors across the Middle East and Europe, sourcing beta SiC from suppliers with stringent quality assurance processes, full traceability, and adherence to defense-specific regulatory requirements is crucial to meet mission-critical specifications and maintain supply chain integrity.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Key Properties:

Pure beta silicon carbide is characterized by excellent hardness, high thermal conductivity, and outstanding chemical inertness. It can withstand temperatures up to 1600°C in inert atmospheres and exhibits excellent corrosion resistance against acids, alkalis, and molten metals. Its mechanical strength remains stable under high pressure and thermal cycling.

Pros & Cons:

- Pros: Exceptional wear resistance, high thermal shock resistance, and chemical stability make it ideal for harsh environments.

- Cons: Manufacturing complexity is relatively high due to the need for precise sintering processes, which can increase lead times and costs. Its brittleness requires careful handling during fabrication and assembly.

Impact on Application:

Pure β-SiC is best suited for applications involving abrasive slurries, high-temperature reactors, and chemical processing equipment. Its inertness makes it compatible with aggressive media such as strong acids and alkalis, common in mining and chemical industries across Africa and South America.

International B2B Considerations:

Buyers in Europe and the Middle East should verify compliance with ASTM C799 and ISO 19378 standards for silicon carbide ceramics. In Brazil and Australia, suppliers often align with JIS standards, so cross-certification is crucial. The high cost and manufacturing lead time necessitate strategic inventory planning for markets with longer shipping durations.

Key Properties:

Boron-doped β-SiC exhibits enhanced electrical conductivity while retaining most mechanical and thermal properties of pure β-SiC. It maintains high hardness and corrosion resistance but allows for applications requiring semi-conductive behavior.

Pros & Cons:

- Pros: Enables use in electrically conductive environments and electrochemical applications. Improved machinability compared to pure β-SiC.

- Cons: Slightly reduced chemical resistance compared to pure β-SiC and higher production costs due to doping processes.

Impact on Application:

Ideal for electrochemical sensors, semiconductor components, and applications involving electrical discharge machining (EDM). This material is favored in advanced manufacturing hubs in Europe and the Middle East, where precision and multifunctionality are prioritized.

International B2B Considerations:

Buyers should ensure that electrical properties meet IEC 60664-1 standards for insulation coordination. In South America and Africa, where industrial automation is growing, this material supports emerging high-tech sectors. However, availability may be limited, requiring partnerships with specialized suppliers.

Key Properties:

This composite material combines β-SiC’s hardness and thermal stability with carbon fiber’s tensile strength and toughness. It offers improved fracture toughness and reduced brittleness, with good thermal conductivity and corrosion resistance.

Pros & Cons:

- Pros: Enhanced mechanical durability and impact resistance, better suited for dynamic or load-bearing applications.

- Cons: Higher manufacturing complexity and cost, potential issues with uniformity in large-scale production.

Impact on Application:

Used in aerospace, automotive, and heavy machinery components where mechanical stress and thermal cycling are prevalent. Its toughness makes it suitable for environments with vibration and mechanical shocks, common in mining equipment in Africa and South America.

International B2B Considerations:

Compliance with ASTM D3039 (for composites) and ISO 14125 is important for buyers in Europe and Australia. The composite’s advanced nature may require longer lead times and higher minimum order quantities, impacting procurement strategies in regions with less developed supply chains.

Key Properties:

This material involves β-SiC grains bonded with a silicon binder, offering improved density and machinability. It retains good thermal and chemical resistance but has slightly lower hardness compared to pure β-SiC.

Pros & Cons:

- Pros: Easier to machine and shape, cost-effective for complex geometries, and good corrosion resistance.

- Cons: Reduced high-temperature performance and lower wear resistance compared to pure β-SiC.

Impact on Application:

Commonly used in mechanical seals, pump components, and valve parts where complex shapes are needed, but extreme temperatures are not a primary concern. Suitable for chemical processing plants in the Middle East and Europe where moderate thermal resistance suffices.

International B2B Considerations:

Buyers should verify adherence to ASTM C1464 and DIN EN 60672 standards. This material offers a cost-effective balance for markets in South America and Africa, where budget constraints are significant but performance requirements remain high.

| Material | Typical Use Case for beta sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Pure Beta Silicon Carbide (β-SiC) | High-temperature reactors, abrasive slurry pumps | Outstanding chemical and thermal resistance | Brittle, high manufacturing complexity | High |

| Beta SiC with Boron Doping | Electrochemical sensors, semiconductor components | Electrical conductivity with good durability | Slightly reduced chemical resistance | High |

| Beta SiC Composite with Carbon Fiber | Aerospace components, heavy machinery parts | Enhanced toughness and impact resistance | Complex manufacturing, higher cost | High |

| Beta SiC with Silicon Binder (Sintered SiC) | Mechanical seals, pump components, valve parts | Easier machining, cost-effective for complex shapes | Lower wear resistance and thermal limits | Medium |

This guide equips international B2B buyers with a strategic understanding of beta SiC material options, enabling informed decisions tailored to regional market demands and compliance requirements.

Beta silicon carbide (β-SiC) is a crucial material in high-performance applications due to its excellent thermal, mechanical, and chemical properties. Understanding its manufacturing process is essential for B2B buyers seeking reliable suppliers and high-quality products.

The initial stage involves sourcing and preparing raw materials, primarily high-purity silicon and carbon powders. These powders are carefully selected and blended to achieve the precise stoichiometric ratio needed for β-SiC synthesis. Purity and particle size distribution are critical factors, as impurities can significantly affect the final product's performance.

Beta SiC is typically formed using one or a combination of the following methods:

Post-forming, β-SiC components may undergo machining or assembly into larger systems. Due to its hardness, machining requires specialized diamond tools and controlled processes to avoid microcracking or thermal damage. For complex assemblies, brazing or diffusion bonding may be employed to join β-SiC parts with metals or other ceramics.

Finishing enhances surface quality and dimensional accuracy. Polishing, grinding, and sometimes chemical etching are applied to meet stringent tolerances and surface finish requirements. This step is crucial for applications in optics, electronics, or wear-resistant parts.

Quality assurance (QA) in β-SiC manufacturing is vital to ensure product consistency, performance, and compliance with international standards. B2B buyers should prioritize suppliers with robust QA systems that align with both global and industry-specific certifications.

Quality control is typically segmented into three main checkpoints:

Illustrative Image (Source: Google Search)

For B2B buyers in Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is crucial given the diverse regulatory environments and market expectations.

On-site audits remain the gold standard. Buyers should assess:

Remote audits can supplement physical visits, especially when travel is restricted.

Buyers should insist on detailed documentation, including:

Independent inspection bodies can validate supplier claims and provide unbiased reports. This is particularly valuable for first-time buyers or when dealing with new suppliers in emerging markets.

By thoroughly understanding β-SiC manufacturing and quality assurance, international B2B buyers can make informed decisions, reduce supply chain risks, and ensure the consistent delivery of high-performance materials.

When sourcing beta sic (beta silicon carbide) materials or components, international B2B buyers must carefully dissect the cost components that collectively determine the final price. These components typically include:

Several critical factors influence the pricing structure for beta sic products:

For buyers from Africa, South America, the Middle East, and Europe, navigating beta sic pricing requires strategic insight:

Prices for beta sic products vary widely based on technical specifications, order size, supplier, and market conditions. The figures discussed are indicative and should be validated through direct supplier quotes and market research. Buyers are encouraged to conduct thorough due diligence to obtain competitive and transparent pricing aligned with their quality and delivery requirements.

By understanding the multifaceted cost drivers and employing strategic sourcing practices, international B2B buyers can optimize their procurement of beta sic products—achieving a balance between cost-efficiency, quality assurance, and reliable supply chain management.

Understanding the key technical properties of beta silicon carbide (beta SiC) is essential for making informed procurement decisions in international B2B transactions. These properties directly impact the performance, compatibility, and cost-effectiveness of beta SiC in various industrial applications such as abrasives, semiconductors, and refractory materials.

Material Grade: Beta SiC is available in various purity levels and crystalline forms. Higher purity grades (typically 99%+ SiC) offer superior thermal conductivity and electrical properties, which are critical for high-performance electronics and advanced manufacturing. For buyers, specifying the correct grade ensures product consistency and suitability for your application.

Particle Size and Distribution: Beta SiC is supplied in powder or granule form with defined particle size ranges, typically measured in microns. Particle size affects sintering behavior, surface finish, and mechanical strength in final products. Buyers should request detailed particle size distribution data to match production requirements and optimize processing.

Tolerance and Dimensional Accuracy: When beta SiC is processed into components or substrates, dimensional tolerance is a vital specification. Tight tolerances (e.g., ±0.01 mm) are necessary for applications demanding precision, such as semiconductor wafers or high-performance mechanical parts. Specifying tolerance upfront reduces quality risks and downstream rework.

Thermal Conductivity: Beta SiC exhibits high thermal conductivity, often between 120–270 W/m·K, depending on purity and microstructure. This property is critical in heat dissipation applications like electronic packaging or thermal management systems. Buyers should verify thermal conductivity values to ensure operational efficiency.

Electrical Resistivity: Beta SiC’s electrical resistivity can vary widely based on doping and processing, influencing its use in semiconductors or resistors. Understanding resistivity parameters helps buyers select the right material for electronic or sensor applications.

Chemical Stability and Hardness: Beta SiC offers excellent chemical inertness and hardness (Mohs scale ~9.5). This makes it ideal for abrasive and refractory applications. Buyers must assess these properties to ensure durability and longevity under harsh operating conditions.

Navigating international procurement of beta SiC requires familiarity with common industry terms. These terms facilitate clear communication, contract negotiation, and risk management, especially when dealing across diverse regions such as Africa, South America, the Middle East, and Europe.

OEM (Original Equipment Manufacturer): Refers to companies that use beta SiC as a component in their end products. OEM buyers often demand strict quality standards, traceability, and customized specifications. Understanding OEM requirements helps suppliers tailor offers and supports buyers in securing compliant materials.

MOQ (Minimum Order Quantity): The smallest volume of beta SiC a supplier will accept in a single order. MOQs vary widely depending on production scale and material form. For smaller enterprises or pilot projects, negotiating MOQ flexibility can optimize inventory costs and reduce financial risk.

RFQ (Request for Quotation): A formal procurement step where buyers solicit detailed price and specification information from suppliers. An effective RFQ includes clear technical specs, delivery timelines, and payment terms, enabling precise supplier comparisons and informed decision-making.

Incoterms (International Commercial Terms): Standardized trade terms defining responsibilities, costs, and risks between buyers and sellers during shipping. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Choosing appropriate Incoterms impacts total landed cost and logistics control.

Lead Time: The duration between order placement and delivery. Lead times for beta SiC depend on supplier capacity, material form, and shipping logistics. Accurate lead time estimates are crucial for production planning and avoiding costly delays.

Certification and Compliance: Terms like ISO 9001, REACH, or RoHS refer to quality management and environmental compliance standards. Buyers should verify certifications to ensure beta SiC meets regulatory requirements relevant to their markets, reducing risk of import restrictions or product recalls.

By mastering these technical properties and trade terms, international B2B buyers can enhance negotiation leverage, optimize supply chain efficiency, and ensure that beta SiC materials meet their exact industrial needs. This knowledge is particularly valuable for companies operating across diverse regulatory and logistical landscapes in Africa, South America, the Middle East, and Europe.

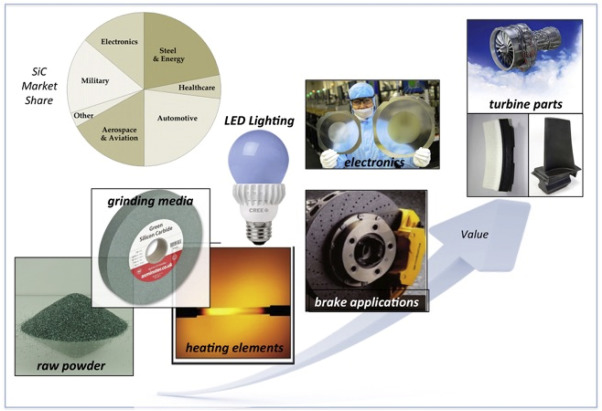

The beta sic sector is experiencing dynamic growth fueled by rapid technological advancements and shifting global supply chain patterns. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding these market dynamics is critical for strategic sourcing and risk management. Key drivers include increasing demand for high-performance materials in industries like automotive, aerospace, and electronics, where beta sic’s unique properties—such as high thermal conductivity and chemical stability—are highly valued.

Emerging sourcing trends highlight a growing preference for localized supply chains to mitigate geopolitical risks and logistics disruptions. Buyers in Africa and South America are increasingly looking to diversify suppliers beyond traditional hubs in Asia and Europe, seeking partnerships in emerging markets that offer competitive pricing and shorter lead times. Meanwhile, digital transformation in procurement—leveraging AI-driven supplier analytics and blockchain for supply chain transparency—is gaining traction, enabling buyers to make data-driven decisions and enhance supplier reliability.

Another significant trend is the integration of customization and value-added services by suppliers, catering to the specific technical and regulatory requirements of diverse markets. For example, European buyers often require strict compliance with REACH and RoHS standards, while Middle Eastern companies prioritize certifications related to halal and safety compliance. Understanding these regional nuances allows buyers to optimize sourcing strategies and align with local market expectations.

Sustainability is becoming a non-negotiable factor in the beta sic sector, with B2B buyers placing increasing emphasis on reducing environmental footprints across the supply chain. Beta sic production involves energy-intensive processes and raw materials that can impact ecosystems if not managed responsibly. Buyers from environmentally conscious markets, particularly Europe and Australia, are driving demand for suppliers who demonstrate carbon footprint reduction, waste minimization, and responsible resource extraction.

Illustrative Image (Source: Google Search)

Ethical sourcing extends beyond environmental concerns to include labor practices, transparency, and community impact. Establishing ethical supply chains ensures compliance with international labor standards and mitigates risks associated with forced labor or unsafe working conditions, which is especially critical for buyers engaging suppliers in developing regions.

Buyers should prioritize suppliers certified under recognized green standards and eco-labels, such as ISO 14001 for environmental management and the Responsible Minerals Initiative (RMI) for conflict-free sourcing. Additionally, innovations in beta sic materials—such as the use of recycled feedstock or bio-based alternatives—are emerging as differentiators for sustainability-conscious buyers. Partnering with suppliers who invest in circular economy principles can enhance brand reputation and meet growing regulatory demands.

Beta sic has evolved from a niche high-performance material to a cornerstone in advanced industrial applications over the past few decades. Initially developed in specialized research settings, its commercial production scaled significantly in the late 20th century, driven by the aerospace and semiconductor industries. The material’s unique combination of thermal and mechanical properties positioned it as a strategic component in sectors requiring durability under extreme conditions.

Historically, sourcing beta sic was concentrated in a handful of countries with advanced manufacturing capabilities. However, globalization and technology transfer have diversified production bases, opening opportunities for suppliers in emerging economies. For B2B buyers, this evolution means access to a broader range of suppliers but also necessitates more rigorous due diligence to ensure quality consistency and compliance with international standards. Understanding this trajectory helps buyers anticipate future innovations and market shifts in the beta sic sector.

How can I effectively vet suppliers of beta sic to ensure reliability and quality?

To vet beta sic suppliers, start by requesting detailed company profiles, including years of experience, client references, and certifications such as ISO 9001 or industry-specific quality standards. Verify their production capabilities through factory audits or virtual tours. Request samples and test reports to assess product quality. Additionally, check their export history, compliance with international regulations, and responsiveness in communication. Utilizing third-party inspection services before shipment can further mitigate risks. Prioritize suppliers with transparent processes and proven track records, especially when dealing with cross-continental transactions involving Africa, South America, the Middle East, and Europe.

Can beta sic products be customized to meet specific industrial requirements?

Yes, many beta sic manufacturers offer customization options such as varying purity levels, particle sizes, shapes, and packaging to align with your industrial application needs. When negotiating customization, clearly specify your technical requirements and intended use cases. Confirm the supplier’s ability to meet these specifications through technical datasheets and pilot batches. Customization may affect lead times and minimum order quantities (MOQs), so discuss these factors upfront to avoid delays. Engaging in a detailed technical dialogue ensures the product fits your operational parameters, critical for specialized markets in regions like Europe and the Middle East.

What are typical MOQ and lead times for international orders of beta sic?

MOQ and lead times vary significantly based on supplier capacity, customization level, and shipping logistics. Standard MOQs often range from 500 kg to several tons, but some suppliers may accommodate smaller trial orders, especially for new international buyers. Lead times typically span 4-8 weeks, factoring in production, quality checks, and freight. For buyers in Africa, South America, and other distant markets, consider potential customs clearance delays and shipping modes (sea freight is common but slower; air freight is faster but costlier). Early communication on order timelines helps align expectations and supply chain planning.

What payment terms are standard for international B2B transactions involving beta sic?

Payment terms commonly include advance payments (30-50%) with the balance settled upon shipment or delivery. Letters of credit (LC) are widely used to mitigate risk on both sides, providing security for buyers and suppliers. For established partnerships, suppliers may offer net payment terms (30-60 days). Ensure that payment methods comply with your country’s foreign exchange regulations, particularly in Africa and South America where currency controls may apply. Transparent negotiation of payment terms helps build trust and facilitates smoother international transactions.

How can I ensure the quality assurance of beta sic products from overseas suppliers?

Demand comprehensive quality assurance documentation such as Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and third-party lab test reports verifying purity and physical properties. Some suppliers offer batch-specific testing and traceability. Consider engaging independent quality control agencies to perform pre-shipment inspections and random sampling. Establishing clear quality benchmarks in your purchase agreement protects your interests. This is particularly important for buyers in regulated markets like Europe or industries with strict quality compliance requirements.

What certifications should I look for when selecting beta sic suppliers for international markets?

Look for internationally recognized certifications including ISO 9001 for quality management and, if applicable, ISO 14001 for environmental management. Suppliers adhering to REACH or RoHS compliance are preferable for European markets. Certifications related to occupational health and safety (e.g., OHSAS 18001 or ISO 45001) indicate responsible manufacturing practices. For food-grade or pharmaceutical applications, additional GMP certifications may be necessary. Verifying these credentials ensures the supplier meets global standards, reducing regulatory risks and facilitating smoother customs clearance.

What are the best logistics practices for shipping beta sic internationally?

Beta sic is typically shipped in sealed bags or containers to prevent contamination and moisture ingress. Sea freight is cost-effective for bulk orders but plan for longer transit times and potential port delays. Air freight suits urgent or smaller shipments but is costlier. Engage freight forwarders experienced in handling chemical raw materials and verify compliance with International Maritime Dangerous Goods (IMDG) or International Air Transport Association (IATA) regulations if applicable. Track shipments closely and prepare for customs documentation, especially in markets with stringent import controls like the Middle East and Europe.

How should disputes with beta sic suppliers be managed in cross-border transactions?

Prevent disputes by drafting clear contracts specifying product specifications, delivery terms, payment conditions, and dispute resolution mechanisms. Use Incoterms to define responsibilities in shipping and risk transfer. If disputes arise, attempt amicable resolution through direct negotiation or mediation. For unresolved issues, arbitration under internationally recognized bodies like the ICC (International Chamber of Commerce) is common. Understanding the legal frameworks in your supplier’s country and your own jurisdiction is essential. Maintaining open communication and documentation throughout the transaction helps mitigate conflicts and protect your business interests.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of beta sic presents a compelling opportunity for international B2B buyers seeking to optimize supply chain resilience, cost efficiency, and product quality. Key takeaways emphasize the importance of thorough supplier evaluation, leveraging regional advantages, and adopting a flexible procurement strategy tailored to diverse market conditions across Africa, South America, the Middle East, and Europe. Understanding local regulatory frameworks and fostering strong partnerships with reliable manufacturers can significantly reduce risks and enhance long-term value.

For B2B buyers, strategic sourcing is not merely a transactional activity but a critical business enabler that drives innovation and competitive differentiation. Prioritizing transparency, sustainability, and technological integration within your sourcing processes will unlock greater operational efficiencies and support global growth ambitions.

Looking ahead, the beta sic market is poised for continued evolution driven by advancements in material science and increasing demand for high-performance solutions. Buyers who proactively engage with emerging trends and build adaptable sourcing networks will be best positioned to capitalize on future opportunities. We encourage international buyers to deepen their market intelligence, strengthen cross-border collaborations, and invest in strategic sourcing capabilities to secure a robust supply of beta sic that aligns with their business goals and regional dynamics.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina