In today's competitive landscape, sourcing high-quality materials like fused alumina can be a daunting task for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reliable suppliers but also in understanding the various applications, specifications, and cost implications associated with this versatile substance. This comprehensive guide aims to empower decision-makers by providing detailed insights into the brand name for a substance composed of fused alumina, exploring its diverse applications, from abrasives to ceramics, and its critical role in various industries.

Throughout this guide, we will delve into essential topics such as the types of fused alumina available, the benefits of each type, effective supplier vetting processes, and cost considerations. By consolidating this information, we equip B2B buyers with the tools necessary to make informed purchasing decisions. Whether you are a procurement officer in Italy seeking the best options for manufacturing or a distributor in Brazil looking to expand your product range, this guide addresses your specific needs and concerns.

Navigating the global market for fused alumina does not have to be overwhelming. With the right knowledge and resources, you can streamline your sourcing process, ensuring you find the best quality products at competitive prices while fostering long-term supplier relationships that drive your business forward.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Alumina Grit | Coarse particles, high hardness, and durability | Abrasives in metalworking and construction | Pros: Excellent wear resistance; Cons: Can be more expensive than alternatives. |

| Fused Alumina Powder | Fine particle size, high purity, and consistency | Ceramics and refractories | Pros: Ideal for high-performance applications; Cons: Requires careful handling to avoid contamination. |

| Fused Alumina Blocks | Solid forms, high density, and thermal stability | Industrial furnaces and kilns | Pros: Excellent thermal insulation; Cons: Heavy and may incur high shipping costs. |

| Fused Alumina Sand | Granular form, variable sizes, and good flowability | Sandblasting and filtration | Pros: Versatile for various applications; Cons: Less durable than grit forms. |

| Fused Alumina Beads | Spherical shape, uniform size, and smooth surface | Polishing and finishing | Pros: Provides a smooth finish; Cons: Higher manufacturing costs due to precision requirements. |

Fused alumina grit is characterized by its coarse particle size and exceptional hardness, making it ideal for abrasive applications in metalworking and construction. This type of fused alumina is particularly suitable for grinding, cutting, and blasting operations. When purchasing, buyers should consider the grit size, as it directly impacts performance in specific applications. Although it offers excellent wear resistance, buyers should be aware that it may come with a higher price tag compared to other abrasives.

Fused alumina powder features fine particles with high purity, which makes it suitable for applications in ceramics and refractories. Its consistency in quality is crucial for manufacturing processes where precision is paramount. Buyers must focus on the powder’s particle size distribution and purity levels to ensure compatibility with their production needs. While it is ideal for high-performance applications, careful handling is necessary to prevent contamination, which can affect the final product's integrity.

Fused alumina blocks are solid forms known for their high density and thermal stability. They are commonly used in industrial furnaces and kilns, where insulation and durability are critical. The thermal properties of these blocks provide excellent insulation, reducing energy costs in heating applications. However, buyers should consider the weight of these blocks, as they can incur significant shipping costs. Their long lifespan makes them a worthwhile investment for industries requiring reliable thermal solutions.

Fused alumina sand is a granular form known for its variable sizes and good flowability, making it versatile for applications such as sandblasting and filtration. This type of fused alumina is often used in surface preparation, providing effective cleaning and finishing. While it is adaptable to various uses, buyers should note that it is generally less durable than grit forms. Therefore, understanding the specific application requirements is essential for making informed purchasing decisions.

Fused alumina beads are characterized by their spherical shape, uniform size, and smooth surface, making them ideal for polishing and finishing applications. Their design allows for a consistent finish on various materials, including metals and plastics. Buyers looking for high-quality finishes should prioritize the precision of these beads, as they can significantly impact the final product's appearance. However, the manufacturing costs for these beads may be higher due to the precision required, which should be factored into the overall budget.

| Industry/Sector | Specific Application of brand name for a substance composed of fused alumina | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives | Used as a key ingredient in grinding wheels and cutting tools. | Enhances durability and performance of tools. | Quality of fused alumina, grit size, and consistency. |

| Ceramics | Utilized in the production of high-performance ceramics. | Improves thermal stability and wear resistance. | Purity levels and thermal properties. |

| Refractories | Serves as a primary component in refractory bricks and linings. | Increases resistance to high temperatures and wear. | Sourcing from reliable suppliers with consistent quality. |

| Electronics | Employed in insulators and substrates for electronic devices. | Provides excellent thermal management and insulation. | Specifications for electrical resistance and thermal conductivity. |

| Construction | Incorporated in concrete and masonry for enhanced strength. | Improves structural integrity and longevity. | Particle size distribution and sourcing from certified suppliers. |

In the abrasives industry, 'brand name for a substance composed of fused alumina' is a critical component in the manufacturing of grinding wheels and cutting tools. Its hardness and durability allow for efficient material removal, making it ideal for metalworking and woodworking applications. International buyers, particularly from regions like Africa and South America, should prioritize the quality and grit size of the fused alumina to ensure optimal performance in their specific applications.

Fused alumina is integral to high-performance ceramics, enhancing their thermal stability and wear resistance. This is particularly important for industries requiring materials that can withstand extreme conditions, such as aerospace and automotive sectors. Buyers from Europe, especially Italy, should focus on the purity levels and thermal properties of the fused alumina to meet stringent industry standards.

In the refractories sector, 'brand name for a substance composed of fused alumina' is used in the production of refractory bricks and linings, vital for high-temperature applications. Its resistance to thermal shock and wear makes it indispensable for industries like steel and glass manufacturing. Buyers should ensure they source from reliable suppliers who can provide consistent quality and performance.

In electronics, fused alumina is utilized in insulators and substrates due to its excellent thermal management properties. This application is crucial for the reliability and efficiency of electronic devices. Buyers in the Middle East should consider specifications related to electrical resistance and thermal conductivity to ensure compatibility with their products.

In the construction industry, 'brand name for a substance composed of fused alumina' is added to concrete and masonry to enhance strength and durability. This application is particularly beneficial for infrastructure projects in emerging markets in Africa and South America. Buyers should evaluate the particle size distribution and ensure they are sourcing from certified suppliers to maintain the integrity of their construction materials.

Related Video: How to Produce Alumina Ceramic Parts

The Problem: B2B buyers often encounter challenges with the consistency of fused alumina products. Variability in quality can lead to manufacturing delays, increased costs, and compromised end products. For instance, a manufacturer in South America may receive a batch of fused alumina that does not meet the specified grit size or purity levels, causing production halts and the need for rework. This inconsistency not only impacts timelines but also strains supplier relationships and affects overall project viability.

The Solution: To mitigate quality inconsistencies, buyers should establish clear specifications and performance standards before procurement. Collaborating closely with suppliers to understand their quality control processes is crucial. Implementing regular audits and quality assurance checks can also help ensure that the products received meet the expected standards. Additionally, forming strategic partnerships with reputable suppliers who have a proven track record in quality management can provide peace of mind. Buyers should also consider investing in testing equipment to conduct preliminary checks on the material upon arrival, ensuring that any discrepancies are caught early.

The Problem: Finding reliable suppliers for fused alumina can be particularly challenging for international buyers, especially in regions like Africa and the Middle East, where local sourcing options may be limited. Buyers often struggle with a lack of transparency in supplier capabilities, leading to uncertainty about product reliability and delivery timelines. This challenge can hinder the procurement process and lead to missed business opportunities.

The Solution: To navigate the complexities of sourcing, buyers should utilize online platforms and industry directories to research potential suppliers thoroughly. Engaging in industry trade shows and networking events can also provide valuable insights and connections. Establishing a comprehensive evaluation process that includes supplier assessments based on criteria such as production capacity, delivery performance, and customer reviews will enable buyers to make informed decisions. Furthermore, considering suppliers who offer flexible terms, such as trial orders or smaller quantities, can help mitigate risk while assessing their reliability.

The Problem: B2B buyers often face challenges in understanding the specific application requirements for fused alumina in their processes. For example, a European company may require fused alumina for abrasive applications but may not fully grasp the differences between various grades and their suitability for different applications. This misunderstanding can lead to the purchase of inappropriate materials, resulting in inefficiencies and increased operational costs.

The Solution: To address this knowledge gap, buyers should invest time in educating themselves about the various grades of fused alumina and their specific applications. Engaging with technical experts from suppliers can provide valuable insights tailored to the buyer’s specific needs. Creating a detailed application profile that outlines the intended use, performance expectations, and operational conditions can help in selecting the appropriate material. Additionally, utilizing resources such as product datasheets and application guides provided by manufacturers can aid in making informed decisions. Buyers should also consider training sessions or workshops offered by suppliers, which can enhance their understanding of the product and its applications, leading to better purchasing outcomes.

Fused alumina is a versatile material commonly used in various applications due to its unique properties. It is characterized by high temperature resistance, excellent hardness, and good chemical stability. These properties make it suitable for use in abrasive applications, refractory materials, and as a filler in various composites. For international B2B buyers, understanding these properties is crucial for making informed decisions that align with their specific application requirements.

When considering fused alumina, several advantages and disadvantages come into play.

Pros:

- Durability: Fused alumina is known for its exceptional durability and resistance to wear, making it ideal for high-performance applications.

- Corrosion Resistance: It exhibits high resistance to corrosion, which is essential for applications in harsh environments.

- Versatility: This material can be used in various forms, including grains, powders, and blocks, allowing for flexibility in manufacturing processes.

Cons:

- Cost: While fused alumina is durable, it can be more expensive than other materials, which may impact budget considerations for some buyers.

- Manufacturing Complexity: The production of fused alumina can involve complex processes, which may lead to higher manufacturing costs and longer lead times.

Fused alumina's properties significantly impact its performance across different applications. For instance, its high temperature and pressure ratings make it suitable for refractory linings in furnaces and kilns. Additionally, its compatibility with various media, including molten metals and chemicals, allows it to be used in diverse industrial settings. Buyers should consider the specific media they will be working with to ensure compatibility and optimal performance.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several considerations are essential:

| Material | Typical Use Case for brand name for a substance composed of fused alumina | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Alumina | Abrasives, refractory linings, and fillers in composites | High durability and wear resistance | Higher cost compared to alternatives | High |

| Silicon Carbide | Cutting tools and abrasive applications | Excellent hardness and thermal stability | Brittle nature can lead to breakage | Medium |

| Alumina Oxide | Insulating materials and ceramic applications | Good electrical insulation properties | Limited thermal shock resistance | Medium |

| Zirconia | High-performance ceramics and dental applications | Superior toughness and wear resistance | Higher cost than alumina | High |

This guide provides a structured overview of material selection for fused alumina, helping international B2B buyers make informed decisions tailored to their specific needs and regional considerations.

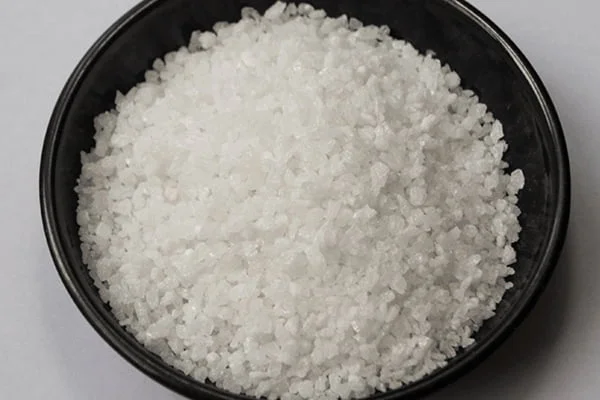

A stock image related to brand name for a substance composed of fused alumina.

The manufacturing of fused alumina involves several critical stages that ensure the production of high-quality materials. Understanding these stages is essential for B2B buyers looking to source reliable products.

Material Preparation

- The first stage involves sourcing high-purity raw materials, primarily bauxite and other alumina-rich materials. These materials undergo a thorough selection process to ensure they meet specific chemical and physical properties required for high-quality fused alumina.

- Once the materials are selected, they are crushed and mixed in precise proportions. This mixture is then calcined at high temperatures to remove moisture and impurities, preparing it for the next stage.

Forming

- In the forming stage, the calcined materials are melted in electric arc furnaces at temperatures exceeding 2000°C. This process transforms the raw materials into molten alumina, which is then cooled and solidified.

- The cooling process can be controlled to produce different grades of fused alumina, affecting its hardness, color, and other physical properties. This flexibility allows manufacturers to tailor their products to meet specific industry demands.

Finishing

- After solidification, the fused alumina is crushed and graded according to particle size and quality. The finished product is then subjected to various finishing processes, such as sieving, magnetic separation, and surface treatment, to enhance its performance characteristics.

- These processes ensure that the final product meets the stringent specifications required for different applications, from abrasives to refractory materials.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for fused alumina, ensuring that products meet international standards and customer specifications.

International Standards and Certifications

- Compliance with international standards such as ISO 9001 is crucial for manufacturers. ISO 9001 outlines the criteria for a quality management system (QMS) and emphasizes customer satisfaction, process efficiency, and continuous improvement.

- Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be required depending on the intended application of the fused alumina.

Quality Control Checkpoints

- Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

Common Testing Methods for Fused Alumina

- Various testing methods are employed to assess the quality of fused alumina. These include:

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential to ensure product reliability.

Conducting Supplier Audits

- One of the most effective ways to verify a supplier’s QC practices is through on-site audits. These audits assess the manufacturing processes, quality management systems, and compliance with international standards. Buyers should look for suppliers that encourage transparency and provide access to their facilities.

Requesting Quality Assurance Reports

- Suppliers should be able to provide detailed quality assurance reports, including testing results and compliance certifications. Buyers should ensure that these documents are up-to-date and relevant to the specific products being sourced.

Utilizing Third-Party Inspection Services

- Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These services can perform random inspections, testing, and certification, adding an extra layer of assurance for buyers.

When sourcing fused alumina, international buyers must navigate specific nuances that can impact quality assurance and compliance.

Understanding Regional Standards

- Different regions may have varying standards for fused alumina products. For example, European buyers may require CE certification, while buyers in the Middle East may prioritize compliance with local regulations. It is essential for buyers to clarify these requirements with their suppliers.

Evaluating Supply Chain Stability

- Supply chain stability is crucial for maintaining consistent quality. Buyers should assess suppliers' sourcing practices, inventory management, and production capabilities. A stable supply chain can mitigate risks related to quality fluctuations.

Cultural and Language Considerations

- Cultural differences and language barriers can affect communication regarding quality expectations. Buyers should consider working with local representatives or consultants who understand the regional market dynamics and can facilitate clear communication with suppliers.

Understanding the manufacturing processes and quality assurance protocols for fused alumina is vital for B2B buyers. By focusing on the key stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions that align with their business needs. Leveraging these insights will not only enhance the procurement process but also foster long-term partnerships with reliable suppliers in the global market.

To effectively source fused alumina, particularly for international markets in Africa, South America, the Middle East, and Europe, follow this practical checklist. This guide provides essential steps to ensure you make informed decisions when procuring this critical material.

Before initiating the sourcing process, it is imperative to clearly outline your technical requirements for fused alumina. This includes understanding the specific grades, particle sizes, and purity levels necessary for your application.

- Consider application needs: Different industries may require different specifications; for example, ceramics may need a higher purity level than abrasives.

- Document requirements: Create a detailed specification sheet to share with potential suppliers.

Conduct thorough research to identify reputable suppliers who specialize in fused alumina. This step is crucial to ensure you are dealing with reliable companies.

- Utilize industry directories: Online platforms and trade associations can provide lists of verified suppliers.

- Check for industry experience: Look for suppliers with a proven track record in your specific region or industry.

Before proceeding with any supplier, verify their certifications and compliance with international standards. This ensures that the products meet safety and quality regulations.

- Look for ISO certifications: ISO 9001 and other relevant certifications indicate a commitment to quality management.

- Ask for compliance documentation: Suppliers should be able to provide proof of compliance with environmental and safety standards.

Request samples of the fused alumina from shortlisted suppliers. Testing samples allows you to assess the material's quality and suitability for your intended application.

- Conduct thorough testing: Evaluate the samples for performance metrics relevant to your specifications.

- Involve your technical team: Ensure that your engineers or product developers are part of the testing process.

Once you have identified a suitable supplier, engage in negotiations to discuss pricing and terms of service. This is an important step to ensure you receive competitive rates while maintaining quality.

- Consider total cost of ownership: Factor in shipping, taxes, and potential duties to understand the complete financial impact.

- Establish payment terms: Clarify payment methods and timelines to avoid any future disputes.

Evaluate the logistics involved in transporting the fused alumina from the supplier to your location. Efficient logistics can significantly impact your project timelines.

- Discuss delivery schedules: Confirm lead times and whether the supplier can meet your deadlines.

- Explore shipping options: Consider both air and sea freight, depending on urgency and cost-effectiveness.

Finally, set up a clear communication plan with your chosen supplier. Effective communication is vital for addressing any issues that may arise during the sourcing process.

- Designate points of contact: Ensure both parties have clear contacts for operational queries.

- Schedule regular updates: Regular check-ins can help keep the sourcing process on track and ensure transparency.

By following this checklist, international B2B buyers can effectively source fused alumina, minimizing risks and ensuring that they secure high-quality materials for their needs.

When sourcing fused alumina, international B2B buyers must consider several cost components that contribute to the overall pricing structure. The primary cost elements include:

Materials: The cost of raw materials is a significant factor. Fused alumina is produced from high-purity alumina, and fluctuations in the price of aluminum can directly impact sourcing costs.

Labor: Labor costs vary significantly based on the region of production. Countries with lower labor costs may offer competitive pricing, but it is essential to consider the skill level and efficiency of the workforce in relation to production quality.

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, which can be beneficial for pricing.

Tooling: The cost of specialized tools and molds used in the production of fused alumina must be factored in. Custom tooling may increase initial costs but can improve efficiency in the long run.

Quality Control (QC): Rigorous quality control measures ensure that the product meets required specifications. Investing in QC can raise costs but is crucial for maintaining product integrity and customer satisfaction.

Logistics: Transportation and handling costs are vital, especially for international shipping. Factors such as distance, shipping method, and the need for specialized containers can influence logistics costs.

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market demand, competition, and perceived value.

Several factors influence the pricing of fused alumina that international buyers should be aware of:

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Understanding the MOQ can help buyers optimize their purchasing strategy to reduce costs.

Specifications and Customization: Custom specifications may lead to higher prices due to the need for unique tooling or processes. Buyers should evaluate whether standard products can meet their needs to avoid unnecessary costs.

Material Quality and Certifications: Higher-quality materials and certifications (like ISO standards) can justify higher prices. Buyers should assess the importance of these factors in relation to their specific applications.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their track record of quality and service.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears responsibility for shipping costs, insurance, and risk. This knowledge can prevent unexpected expenses during the procurement process.

B2B buyers from Africa, South America, the Middle East, and Europe should employ strategic negotiation tactics to secure favorable pricing:

Conduct Market Research: Understanding market trends and competitor pricing can provide leverage during negotiations. Knowledge of regional market dynamics is particularly beneficial.

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, logistics, and disposal costs. This holistic view can guide better purchasing decisions.

Build Relationships with Suppliers: Long-term relationships can lead to better pricing agreements and improved service. Suppliers may offer discounts or favorable terms to established customers.

Be Transparent About Requirements: Clearly communicate specifications and expectations to avoid misunderstandings that could lead to increased costs later in the procurement process.

Stay Flexible with Payment Terms: Offering flexible payment terms can sometimes yield better pricing. Suppliers may appreciate the assurance of timely payments and may be willing to negotiate on price.

Prices for fused alumina can vary widely based on the factors discussed above. Buyers should consider this information as a guideline and consult multiple suppliers to obtain accurate and current pricing relevant to their specific needs and circumstances.

In the competitive landscape of industrial materials, it's crucial for B2B buyers to evaluate various options available for substances composed of fused alumina. While a brand name for fused alumina may carry certain prestige and recognition, alternative solutions can offer distinct benefits that align with specific operational needs. This analysis presents a comparison of the brand name for fused alumina against two viable alternatives: silicon carbide and alumina-zirconia composites.

| Comparison Aspect | Brand Name For A Substance Composed Of Fused Alumina | Silicon Carbide | Alumina-Zirconia Composite |

|---|---|---|---|

| Performance | High thermal stability, excellent wear resistance | Exceptional hardness, thermal conductivity | High toughness, wear resistance |

| Cost | Premium pricing due to brand equity | Generally lower cost | Moderate cost |

| Ease of Implementation | Requires specialized handling | Easy to integrate in existing systems | Requires specific manufacturing processes |

| Maintenance | Low maintenance needs, durable | Moderate, depending on application | Regular checks needed |

| Best Use Case | Abrasives, ceramics, and refractory materials | Semiconductor, automotive, and aerospace | Dental applications, wear-resistant parts |

Silicon carbide (SiC) is an alternative that boasts exceptional hardness and thermal conductivity, making it suitable for high-performance applications. Its cost-effectiveness is a significant advantage, particularly for buyers in Africa and South America, where budget constraints are often a concern. However, while it is generally easy to integrate into existing systems, its performance can vary based on the specific application, which may require careful consideration during selection.

Alumina-zirconia composites are engineered materials that combine the properties of both alumina and zirconia, resulting in high toughness and wear resistance. This makes them ideal for applications in dental and structural components. While the cost is moderate, it may require specific manufacturing processes that could complicate implementation. Regular maintenance checks are also necessary to ensure optimal performance, which could add to the overall operational costs for some businesses.

When choosing between a brand name for a substance composed of fused alumina and its alternatives, B2B buyers should assess their specific operational needs, budget constraints, and application requirements. Understanding the unique performance characteristics and cost implications of each option will enable buyers to make informed decisions. Moreover, considering factors such as ease of implementation and maintenance will ultimately contribute to long-term satisfaction and operational efficiency. By conducting thorough research and comparing available solutions, businesses can effectively align their material choices with their strategic objectives.

When considering fused alumina for industrial applications, it’s essential to understand its critical technical properties. Here are some specifications that are particularly important for B2B buyers:

Material Grade

Material grade refers to the purity and composition of fused alumina. Different grades are suitable for various applications, such as abrasives, ceramics, or refractories. Higher grades often exhibit better performance, which is crucial for industries requiring precision and durability.

Hardness

The hardness of fused alumina, typically measured on the Mohs scale, indicates its resistance to wear and abrasion. This property is vital for buyers in sectors like manufacturing and construction, where durable materials are essential for equipment longevity.

Particle Size Distribution (PSD)

PSD defines the range of particle sizes within a batch of fused alumina. A uniform PSD can enhance the performance of the material in applications like grinding and polishing. Understanding PSD helps buyers select the appropriate material for specific applications, ensuring optimal results.

Thermal Stability

This property assesses how well fused alumina can withstand high temperatures without degrading. For industries such as metallurgy and ceramics, thermal stability is crucial, as it ensures that materials maintain their integrity under extreme conditions.

Chemical Resistance

The ability of fused alumina to resist chemical reactions with various substances is essential in many industrial processes. Buyers need to ensure that the material will perform well in their specific environment, particularly in applications involving corrosive chemicals.

Understanding trade terminology is essential for navigating the procurement process effectively. Here are some common terms you should know:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fused alumina, knowing your OEM can help in sourcing high-quality materials that meet specific manufacturing requirements.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management, particularly when dealing with bulk orders of fused alumina.

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. For international buyers, submitting an RFQ can streamline the procurement process and ensure that they receive competitive pricing.

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping costs, risks, and responsibilities, ensuring smooth cross-border trade.

Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order. For B2B buyers, understanding lead times is critical for planning production schedules and ensuring timely delivery of fused alumina.

Quality Assurance (QA)

QA refers to the systematic process of ensuring that products meet specific quality standards. For buyers, understanding a supplier's QA processes is essential for ensuring that the fused alumina they receive will perform as expected in their applications.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions when sourcing fused alumina, ultimately enhancing your operational efficiency and product quality.

The global fused alumina market is witnessing significant growth driven by various factors, including increased demand from the manufacturing, construction, and automotive industries. As countries in Africa, South America, the Middle East, and Europe continue to industrialize, the need for high-quality abrasives, refractories, and ceramics is on the rise. Technological advancements in production processes, such as the development of more efficient fusion techniques, are also enhancing product quality and reducing costs, making fused alumina more accessible to international buyers.

Emerging B2B tech trends, such as digital platforms for sourcing and supply chain management, are revolutionizing how companies engage with suppliers. Businesses are increasingly leveraging e-commerce solutions to streamline procurement processes and access a wider range of suppliers. Additionally, the use of data analytics in understanding market trends and consumer behavior is becoming more prevalent, enabling buyers to make informed sourcing decisions. For instance, buyers from Brazil and Italy can utilize analytics tools to assess supplier reliability and performance, thereby mitigating risks in their supply chains.

The market dynamics are also influenced by geopolitical factors, such as trade policies and tariffs, which can affect sourcing strategies. International B2B buyers must stay informed about regulatory changes that could impact their supply chains and pricing structures. Understanding local market conditions, consumer preferences, and regional economic trends will be crucial for effective sourcing in this competitive landscape.

Sustainability has become a critical consideration for international B2B buyers, particularly in the fused alumina sector. The environmental impact of sourcing materials is under increasing scrutiny, with stakeholders demanding greater transparency in supply chains. Ethical sourcing practices not only help mitigate environmental degradation but also enhance brand reputation and customer loyalty.

Buyers are encouraged to prioritize suppliers who adhere to sustainable practices, such as using renewable energy sources in production and ensuring minimal waste generation. Certifications such as ISO 14001 for environmental management systems and other green certifications can serve as indicators of a supplier's commitment to sustainability. By selecting suppliers with these certifications, companies can align their sourcing strategies with their corporate social responsibility (CSR) goals.

Moreover, the demand for 'green' materials is on the rise, prompting manufacturers to innovate and develop more sustainable alternatives to traditional fused alumina products. This trend not only addresses environmental concerns but also meets the growing consumer demand for eco-friendly products. As a result, B2B buyers must evaluate their sourcing strategies to incorporate sustainable options, which can lead to long-term cost savings and improved market positioning.

The history of fused alumina dates back to the early 20th century when it was first produced through the fusion of bauxite and other aluminum oxides at high temperatures. This innovative process allowed for the creation of a more durable and versatile abrasive material, which quickly gained popularity in various industrial applications.

Over the decades, advancements in technology and production techniques have significantly improved the quality of fused alumina products. The introduction of controlled fusion methods and the development of specialized grades tailored for specific applications have expanded its use in sectors such as metalworking, construction, and electronics. Today, fused alumina remains a key material for international B2B buyers, with ongoing research and development aimed at enhancing its properties and applications.

This evolution highlights the importance of continuous innovation in meeting the changing demands of global markets, and it serves as a reminder for buyers to seek suppliers who are committed to advancing their product offerings.

How do I choose the right supplier for fused alumina products?

Choosing the right supplier for fused alumina products involves several key steps. Start by verifying the supplier's reputation through reviews and testimonials from previous clients, especially those in your industry. Assess their production capacity to ensure they can meet your demand. Additionally, inquire about their compliance with international quality standards, certifications, and their ability to provide product customization. Lastly, consider their communication responsiveness and willingness to engage in long-term partnerships, as these factors will significantly impact your sourcing experience.

What are the key quality assurance measures for fused alumina?

Quality assurance for fused alumina involves stringent testing and certification processes. Request information about the supplier's quality control measures, including material sourcing, production processes, and final product testing. Look for certifications such as ISO 9001, which indicates adherence to international quality management standards. Additionally, ask for test reports or samples before placing large orders to assess the product's performance against your specifications. This proactive approach ensures that the materials meet your requirements for durability and effectiveness.

What is the typical minimum order quantity (MOQ) for fused alumina?

The minimum order quantity (MOQ) for fused alumina can vary significantly among suppliers, generally ranging from a few tons to several tons. It’s crucial to discuss MOQs upfront when contacting potential suppliers to ensure they align with your purchasing capabilities. Smaller orders may be possible with certain suppliers, especially if they offer custom solutions or are willing to negotiate. Understanding the MOQ will help you plan your budget and inventory management effectively.

What payment terms should I expect when sourcing fused alumina internationally?

Payment terms for international orders of fused alumina typically vary based on the supplier's policies and the buyer's creditworthiness. Common arrangements include advance payments, letters of credit, or payment upon delivery. It's essential to discuss and negotiate these terms upfront, ensuring they are mutually beneficial. Additionally, consider factors such as currency fluctuations, transaction fees, and the supplier’s flexibility regarding payment methods to avoid potential issues later in the procurement process.

How do I ensure timely logistics and delivery for my fused alumina order?

To ensure timely logistics and delivery of fused alumina, start by discussing shipping options with your supplier. Confirm their experience with international shipping and their ability to handle customs clearance efficiently. Establish clear timelines for production and shipping, and consider using a freight forwarder familiar with your region to streamline the process. Additionally, keep track of your order status and maintain open communication with the supplier to address any potential delays proactively.

What customization options are available for fused alumina products?

Many suppliers offer customization options for fused alumina products, including variations in grain size, purity levels, and packaging types. When discussing your requirements, clearly articulate your specific needs and applications to the supplier. They may also provide tailored formulations for specialized industries, such as manufacturing or construction. Understanding the available options allows you to select the most suitable product for your application, enhancing performance and efficiency.

How can I verify the authenticity and quality of my fused alumina supplier?

Verifying the authenticity and quality of your fused alumina supplier involves conducting due diligence. Start by checking the supplier's business registration, certifications, and industry affiliations. Request references from other international clients and seek third-party audits or assessments of their production facilities. Additionally, consider visiting the supplier’s operations if feasible, as this can provide invaluable insights into their processes and commitment to quality.

A stock image related to brand name for a substance composed of fused alumina.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing for fused alumina presents a unique opportunity for international B2B buyers to enhance their procurement processes, optimize costs, and ensure quality. By leveraging the distinctive properties of fused alumina, buyers can meet their specific industry needs, whether in manufacturing, construction, or advanced materials. Establishing strong relationships with reliable suppliers across regions such as Africa, South America, the Middle East, and Europe is essential for ensuring a steady supply chain and mitigating risks associated with sourcing.

What steps can international buyers take to improve their sourcing strategies? Emphasizing collaboration and transparency with suppliers can lead to improved product quality and innovation. Furthermore, conducting thorough market research and utilizing data analytics will empower buyers to make informed decisions, fostering competitive advantages in their respective markets.

Looking ahead, the demand for fused alumina is projected to grow as industries increasingly prioritize sustainable and efficient materials. International B2B buyers should act now to position themselves strategically within this evolving landscape. Engage with suppliers, explore innovative applications, and remain adaptable to market trends to ensure your business remains at the forefront of the industry.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina