In today's competitive industrial landscape, sourcing high-quality brown corundum abrasive for sale can pose significant challenges for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The demand for reliable abrasives is critical across various applications, from metalworking to surface preparation, necessitating a thorough understanding of product specifications, supplier capabilities, and cost factors. This guide aims to equip international buyers with actionable insights into the global market for brown corundum abrasives, covering essential aspects such as product types, their applications, and key considerations for effective supplier vetting.

Navigating the intricacies of sourcing brown corundum abrasives involves more than just identifying suppliers; it requires a strategic approach to ensure quality, compliance, and cost-effectiveness. The comprehensive scope of this guide will empower buyers by providing detailed information on the different grades of brown corundum, their specific uses, and the standards that manufacturers must meet. Additionally, it will address how to evaluate potential suppliers based on quality certifications, delivery capabilities, and pricing structures.

By leveraging the insights provided in this guide, B2B buyers can make informed purchasing decisions, ensuring that they not only meet their operational needs but also gain a competitive edge in their respective markets. Whether you are based in South Africa, Argentina, or elsewhere, understanding the dynamics of the brown corundum abrasive market is crucial for optimizing your procurement strategy.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Brown Corundum | High hardness, excellent wear resistance | Metal fabrication, grinding wheels | Pros: Cost-effective, versatile. Cons: Limited to specific applications. |

| White Fused Brown Corundum | Higher purity, finer grain sizes | Precision grinding, polishing | Pros: Produces finer finishes. Cons: Higher cost compared to regular brown corundum. |

| Brown Corundum Grit | Varied grit sizes for different applications | Blasting, surface preparation | Pros: Customizable grit sizes. Cons: May require additional processing for specific tasks. |

| Brown Corundum Powder | Fine powder form for detailed applications | Coatings, ceramics, and specialty abrasives | Pros: Ideal for detailed work. Cons: Can be more expensive per unit weight. |

| Calcined Brown Corundum | Enhanced thermal and mechanical properties | Refractories, abrasives | Pros: Improved durability and performance. Cons: Limited availability in some regions. |

Fused brown corundum is produced by melting aluminum oxide in an electric arc furnace. This type is characterized by its high hardness and excellent wear resistance, making it suitable for applications like metal fabrication and the production of grinding wheels. When considering this type for purchase, B2B buyers should assess the specific hardness requirements of their applications, as well as the cost-effectiveness compared to alternatives.

White fused brown corundum is known for its higher purity and finer grain sizes, resulting in a product that can achieve a more refined finish. This type is particularly advantageous for precision grinding and polishing applications. Buyers should consider the additional cost of this type against the potential benefits of improved surface finishes, especially in industries where precision is paramount.

Brown corundum grit is available in various sizes, allowing for customization based on specific project needs. It is commonly used in blasting and surface preparation tasks. B2B buyers should evaluate the required grit size for their applications and the potential need for additional processing to meet specific standards. The flexibility in grit sizing is a significant advantage for diverse industrial applications.

Brown corundum powder is utilized in applications requiring fine abrasives, such as coatings and ceramics. This form allows for detailed work and is essential in creating specialty abrasives. Buyers should weigh the cost against the benefits of precision and detail, as the powder form can be more expensive per unit weight, but may yield superior results in specialized applications.

Calcined brown corundum undergoes additional thermal processing, enhancing its thermal and mechanical properties. This type is suitable for use in refractories and abrasives due to its improved durability. When purchasing, B2B buyers should consider the availability of this product in their region, as it may not be as widely available as other forms of brown corundum, and evaluate whether the enhanced properties justify the potential price increase.

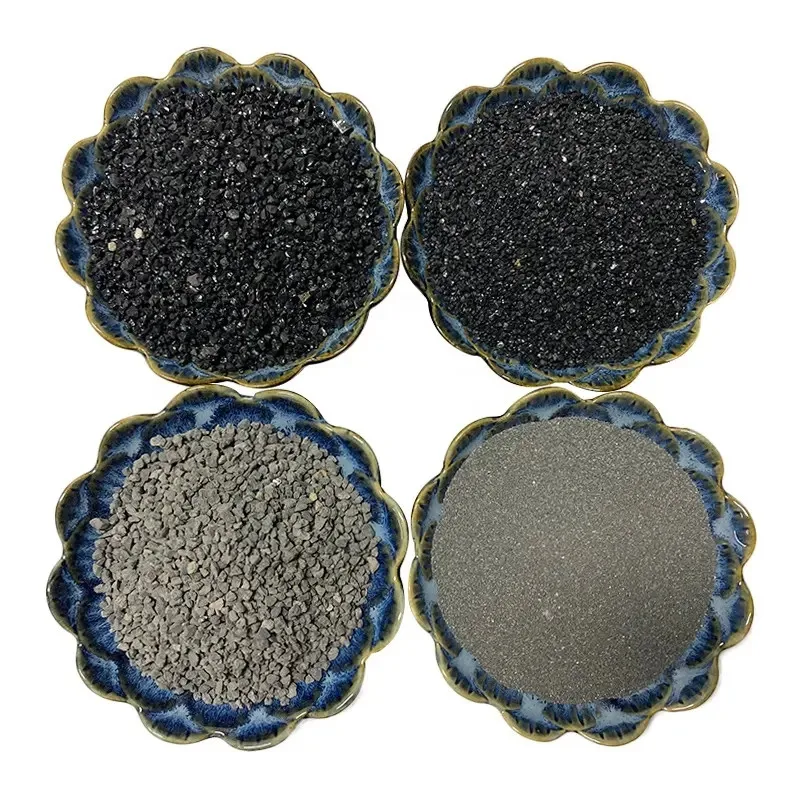

A stock image related to brown corundum abrasive for sale.

Related Video: How To Automate Deburring & Finishing: Nampower Abrasive Disc Brushes

| Industry/Sector | Specific Application of brown corundum abrasive for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Surface preparation and finishing of metal components | Enhances surface quality, improves adhesion for coatings | Ensure consistent grain size and hardness for optimal results |

| Automotive Manufacturing | Abrasive blasting for cleaning and finishing automotive parts | Reduces production time, enhances part durability | Verify supplier's quality certifications and delivery reliability |

| Construction and Building Materials | Abrasive tools for concrete and masonry surface finishing | Increases efficiency in surface preparation | Consider local availability and pricing stability |

| Glass and Ceramics | Grinding and polishing glass and ceramic products | Achieves precise finishes and reduces material waste | Assess the compatibility with specific materials used |

| Electronics Manufacturing | Precision grinding of semiconductor wafers | Ensures high-quality surface finish for electronic components | Source abrasives with tailored properties for specific applications |

In the metal fabrication industry, brown corundum abrasive is widely utilized for surface preparation and finishing of metal components. This abrasive material is effective in removing rust, scale, and other contaminants from metal surfaces, ensuring a clean base for further processing or coating. By improving surface quality, businesses can enhance adhesion for paints and protective coatings, leading to longer-lasting products. International buyers, particularly from regions like Africa and South America, should prioritize suppliers who offer consistent grain size and hardness to achieve optimal results.

Within automotive manufacturing, brown corundum abrasive is crucial for abrasive blasting processes that clean and finish various automotive parts. This application not only reduces production time but also significantly enhances the durability of components. For B2B buyers in the Middle East and Europe, it is essential to verify the supplier's quality certifications and reliability in delivery to ensure that production schedules are met without delays.

In the construction sector, brown corundum abrasive is employed in abrasive tools for concrete and masonry surface finishing. This application increases efficiency in preparing surfaces for further treatment, such as painting or sealing. Buyers from regions like Africa and South America should consider the local availability of this abrasive to ensure price stability and minimize transportation costs, thus optimizing their project budgets.

For the glass and ceramics industries, brown corundum abrasive is essential for grinding and polishing products to achieve precise finishes. This application not only enhances aesthetic appeal but also reduces material waste during the manufacturing process. B2B buyers should assess the compatibility of the abrasive with specific materials used in their production lines to ensure high-quality outcomes and reduce operational disruptions.

In electronics manufacturing, brown corundum abrasive is utilized for precision grinding of semiconductor wafers. This application is critical as it ensures a high-quality surface finish necessary for the performance of electronic components. International buyers should source abrasives with tailored properties to meet their specific application requirements, ensuring that they maintain competitive advantages in the fast-paced electronics market.

Related Video: Understanding Abrasive Belt Joints | KLINGSPOR Abrasives USA

The Problem:

B2B buyers often encounter significant variability in the quality of brown corundum abrasives from different suppliers. This inconsistency can lead to subpar performance in applications such as metal finishing or surface preparation, causing delays in production and increased costs. Buyers may find themselves unsure if the product they receive meets the required specifications, which can result in wasted materials and labor as well as damage to customer relationships.

The Solution:

To mitigate quality variability, buyers should establish a rigorous supplier evaluation process. This includes requesting material safety data sheets (MSDS) and certification of compliance to industry standards such as ISO 9001. It’s advisable to conduct a pre-purchase sample test to verify the abrasive's performance in your specific application. Additionally, forming long-term partnerships with suppliers who consistently deliver high-quality products can reduce uncertainty. Regular communication regarding quality expectations and feedback can also foster improvements and ensure that the abrasives meet performance standards.

The Problem:

Many B2B buyers are unsure about the best techniques for using brown corundum abrasives effectively, which can lead to inefficient processes and poor results. For instance, using the wrong grit size or incorrect pressure during application can result in surface damage or inadequate material removal, ultimately affecting the quality of the finished product.

The Solution:

To optimize the application of brown corundum abrasives, buyers should invest in training for their teams on best practices. This includes understanding the appropriate grit size for specific tasks and the optimal operating pressure and speed settings for different machines. Collaborating with suppliers for training sessions or informational resources can be invaluable. Additionally, implementing a trial-and-error phase on less critical projects can help teams gain practical experience without jeopardizing high-stakes operations. Documentation of successful techniques can also serve as a reference for future projects.

The Problem:

International B2B buyers, particularly from regions like Africa and South America, often face challenges related to supply chain logistics when sourcing brown corundum abrasives. Delays in shipping, customs issues, and fluctuating costs can disrupt production schedules and lead to financial losses. Buyers may struggle to find reliable suppliers who can guarantee timely delivery.

The Solution:

To address these supply chain challenges, buyers should adopt a proactive approach by diversifying their supplier base and considering local distributors when possible. This not only mitigates risks associated with international shipping but can also lead to faster turnaround times. Establishing clear communication channels with suppliers regarding lead times, shipping methods, and inventory levels is crucial. Additionally, leveraging technology such as supply chain management software can provide real-time tracking and alerts for potential delays, allowing buyers to adjust their plans accordingly. Engaging in strategic partnerships with logistics providers can also enhance efficiency in getting products delivered on time.

Brown corundum, also known as aluminum oxide, is a widely used abrasive material in various industrial applications. Its key properties include high hardness (Mohs hardness of 9), excellent thermal stability, and good chemical resistance. These characteristics make it suitable for grinding, cutting, and polishing applications across different materials, including metals, ceramics, and glass. The ability to withstand high temperatures (up to 2000°C) and pressures further enhances its performance in demanding environments.

The choice of brown corundum abrasives significantly impacts the application. For instance, its hardness makes it ideal for applications requiring aggressive material removal, such as metal fabrication. However, in applications involving softer materials, such as plastics, using brown corundum may lead to surface damage or excessive wear. Understanding the specific media compatibility is crucial for optimizing performance and achieving desired results.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several factors when sourcing brown corundum abrasives:

| Material | Typical Use Case for brown corundum abrasive for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brown Corundum | Metal grinding and polishing | High durability and hardness | Limited compatibility with softer materials | Medium |

| White Corundum | Fine polishing and finishing | Excellent surface finish | Higher cost compared to brown corundum | High |

| Silicon Carbide | Hard materials like ceramics and glass | Superior hardness and sharpness | More brittle, leading to potential breakage | Medium |

| Garnet | Blasting and waterjet cutting | Environmentally friendly and natural | Slower cutting speed compared to corundum | Low |

This comprehensive analysis provides essential insights for B2B buyers looking to select the right brown corundum abrasive for their specific applications, ensuring optimal performance and compliance with industry standards.

The manufacturing process of brown corundum abrasive involves several critical stages that ensure the final product meets industry standards and performance expectations.

Material Preparation: The primary raw material for brown corundum is bauxite, which undergoes a refining process to produce alumina. This alumina is then mixed with carbon to create a suitable feedstock for the manufacturing process. The quality of the raw materials is paramount, as impurities can significantly affect the abrasive properties of the final product.

Forming: Once the material is prepared, it is subjected to a high-temperature process in electric arc furnaces. This process melts the alumina and carbon mixture at temperatures exceeding 2000°C. After melting, the molten mass is cooled and solidified, forming large blocks of brown corundum. These blocks are then crushed and screened to achieve various particle sizes suitable for different applications.

Finishing: The crushed abrasive grains undergo further processing, which may include classification, magnetic separation, and additional grinding. This stage is crucial for achieving the desired particle size distribution and purity levels. The finishing process ensures that the abrasives have consistent characteristics, making them suitable for use in various applications such as grinding, blasting, and polishing.

Several key techniques are employed throughout the manufacturing process to ensure the quality and performance of brown corundum abrasives:

Electric Arc Furnace Technology: This technique allows for precise control over temperature and atmosphere, resulting in high-purity products. It is essential for producing abrasives with consistent hardness and toughness.

Crushing and Screening: Advanced crushing and screening technologies are utilized to achieve the desired particle size and distribution. This stage often employs mechanical separators and air classifiers to enhance efficiency.

Quality Control during Production: Continuous monitoring of the manufacturing process is critical. This includes real-time analysis of temperature, particle size, and composition to ensure adherence to specifications.

Quality assurance (QA) in the production of brown corundum abrasive is a multifaceted approach that incorporates various international and industry-specific standards.

International Standards: Compliance with ISO 9001 is fundamental in ensuring that manufacturers implement a quality management system that meets customer and regulatory requirements. This standard focuses on consistent quality in products and services.

Industry-Specific Standards: Certifications such as CE marking for safety and compliance with the American Petroleum Institute (API) standards are critical for buyers in specific industries. These certifications ensure that the abrasives meet stringent performance and safety criteria.

Quality control (QC) is integral to the manufacturing process, with multiple checkpoints established to maintain product integrity:

Incoming Quality Control (IQC): This involves testing raw materials before they enter production. The quality of bauxite and other materials is assessed for impurities and compliance with specifications.

In-Process Quality Control (IPQC): During the manufacturing process, samples are regularly taken for analysis. This includes monitoring the melting process and checking for consistency in particle size and distribution.

Final Quality Control (FQC): Once the abrasives are finished, they undergo rigorous testing to ensure they meet all defined specifications. This includes hardness tests, particle size analysis, and chemical composition checks.

B2B buyers should be familiar with the common testing methods used in the quality assurance of brown corundum abrasives:

Hardness Testing: This is typically performed using the Mohs scale or Vickers hardness tests to ensure the abrasives can withstand the required applications.

Chemical Analysis: Techniques such as X-ray fluorescence (XRF) are used to determine the chemical composition of the abrasives, ensuring they meet required standards.

Particle Size Distribution Analysis: Sieve analysis and laser diffraction methods are commonly employed to assess the particle size distribution, which is critical for performance in various applications.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some strategies:

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide firsthand insight into the quality control processes and standards implemented by the supplier.

Quality Reports: Requesting detailed quality reports from suppliers can help assess their compliance with international standards. These reports should include data from IQC, IPQC, and FQC stages.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality. These inspections can validate the supplier's claims and certifications.

International buyers need to be aware of certain nuances in quality control and certification when sourcing brown corundum abrasives:

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding local regulations in target markets (e.g., CE marking in Europe or ANSI standards in the U.S.) is crucial.

Cultural and Language Barriers: Communication can sometimes pose challenges. Ensure that suppliers can provide documentation and support in the buyer's preferred language.

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and standards. Regular engagement can help address any quality concerns proactively.

A stock image related to brown corundum abrasive for sale.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing brown corundum abrasives, ensuring they receive high-quality products that meet their operational needs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina