Carbide sandpaper stands at the forefront of industrial abrasion and finishing solutions, delivering unmatched durability and efficiency across diverse manufacturing sectors. For B2B buyers engaged in heavy-duty applications—from metal fabrication in Poland to construction projects in Nigeria—selecting the right carbide sandpaper is a strategic decision that directly impacts production quality, operational costs, and supply chain reliability.

This comprehensive guide offers a deep dive into the global carbide sandpaper market, tailored specifically for international buyers from Africa, South America, the Middle East, and Europe. You will gain insights into the various types of carbide abrasives, their core material compositions, and advanced manufacturing and quality control processes that ensure consistent performance and longevity. Understanding supplier landscapes, cost structures, and logistical considerations will empower you to negotiate better terms and avoid common pitfalls such as MOQ challenges or delayed deliveries.

Key areas covered include:

By leveraging this guide, international B2B buyers will be equipped to make informed, confident sourcing decisions that enhance production efficiency and competitive advantage in their respective industries. Whether you are expanding your supplier network or optimizing procurement workflows, this resource is designed to support your success in the dynamic global carbide sandpaper marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicon Carbide Sandpaper | Very sharp, hard abrasive with fine to coarse grit options | Metal finishing, automotive, woodworking | Pros: Long-lasting, versatile on hard materials; Cons: Can be brittle, higher cost |

| Aluminum Oxide Carbide Sandpaper | Durable, self-sharpening abrasive, commonly brown or white | General purpose sanding, metalwork, paint removal | Pros: Cost-effective, good for multiple materials; Cons: Less sharp than silicon carbide |

| Ceramic Carbide Sandpaper | Extremely tough, heat resistant, suitable for heavy-duty use | Industrial metal fabrication, aerospace, heavy machinery | Pros: High durability, maintains grit; Cons: Higher price, may require specialized handling |

| Zirconia Alumina Carbide Sandpaper | Combines toughness and sharpness, ideal for aggressive stock removal | Metal grinding, stainless steel, heavy fabrication | Pros: Long life, excellent for hard metals; Cons: More expensive, limited availability in some regions |

| Resin-Backed Carbide Sandpaper | Flexible backing with carbide grit, adaptable to curved surfaces | Precision finishing, electronics, fine woodworking | Pros: Flexible, reduces clogging; Cons: Less aggressive, shorter lifespan than rigid backings |

Silicon Carbide Sandpaper is prized for its sharpness and hardness, making it a preferred choice for precision finishing on metals, ceramics, and glass. Its versatility across grit sizes allows B2B buyers in automotive and woodworking sectors to achieve smooth finishes and efficient material removal. However, buyers should consider its brittleness and slightly higher cost, which may impact inventory turnover and cost management in bulk purchasing.

Aluminum Oxide Carbide Sandpaper is widely used due to its durability and self-sharpening properties, which make it suitable for a variety of materials including wood and metal. For B2B buyers, especially SMEs in South America and Africa, this type offers a cost-effective solution with reliable performance. The trade-off is a lower sharpness compared to silicon carbide, which may affect efficiency in high-precision applications.

Ceramic Carbide Sandpaper stands out for its exceptional toughness and heat resistance, ideal for heavy industrial use such as aerospace manufacturing or heavy machinery maintenance. Its longevity and grit retention justify the premium price for buyers in Europe and the Middle East seeking durable abrasives that reduce downtime. However, handling and storage require care due to its specialized nature.

Zirconia Alumina Carbide Sandpaper provides a balance of toughness and sharpness, excelling in aggressive stock removal on hard metals like stainless steel. It is favored by B2B buyers in heavy fabrication industries across Poland and Nigeria for its long life and efficiency. The higher cost and limited regional availability necessitate strategic sourcing and supplier relationship management.

Resin-Backed Carbide Sandpaper features a flexible backing that conforms to curved surfaces, making it suitable for precision finishing in electronics and fine woodworking. This type is valuable for buyers requiring adaptability and reduced clogging, common in specialized manufacturing sectors. The downside is a shorter lifespan compared to rigid-backed options, which buyers should factor into cost-per-use calculations.

Related Video: 4.51 | Carborundum is silicon carbide, SiC, a very hard material used as an abrasive on sandpaper

| Industry/Sector | Specific Application of carbide sandpaper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Surface finishing of hard metals and alloys in engine parts | Enables precision smoothing and deburring for durability and performance | Consistent grit quality, abrasion resistance, and supplier reliability for just-in-time delivery |

| Metal Fabrication | Grinding and polishing of stainless steel and carbide tools | Enhances surface quality, extends tool life, and reduces post-processing costs | Availability of different grit sizes, resistance to heat, and MOQ flexibility for SMEs |

| Aerospace Engineering | Finishing composite materials and hardened alloys | Critical for aerodynamic surface smoothness and structural integrity | Compliance with international quality standards and traceability of materials |

| Construction & Heavy Equipment | Abrasive finishing on concrete tools and carbide-tipped blades | Improves cutting efficiency and lifespan of heavy-duty tools | Bulk order discounts, durability under harsh conditions, and supplier certifications |

| Woodworking & Furniture | Sanding carbide-tipped saw blades and router bits | Maintains sharpness and precision, reducing downtime and replacement costs | Supplier expertise in carbide abrasives and customization options for different wood types |

In automotive manufacturing, carbide sandpaper is essential for finishing engine components made from hard metals and alloys. The abrasive quality of carbide enables manufacturers to smooth surfaces with high precision, eliminating burrs that can cause wear or mechanical failure. For B2B buyers in regions like Nigeria and Poland, sourcing carbide sandpaper with consistent grit size and high abrasion resistance is critical to maintain production quality and meet tight delivery schedules. Reliable suppliers who can provide just-in-time deliveries help prevent costly production delays.

Metal fabrication industries heavily rely on carbide sandpaper for grinding and polishing stainless steel and carbide tools. This application improves surface quality and extends the life of expensive tooling, ultimately lowering operational costs. Buyers from South America and the Middle East should prioritize suppliers that offer a broad range of grit sizes and heat-resistant abrasives to suit different metal types. Flexibility in minimum order quantities (MOQs) is also important for SMEs aiming to optimize inventory without overstocking.

The aerospace sector demands extremely precise finishing on composite materials and hardened alloys, where even minor surface imperfections can affect aerodynamic performance and safety. Carbide sandpaper is employed for its superior abrasive properties that ensure smooth, defect-free surfaces. International buyers, especially from Europe, must ensure that the carbide abrasives comply with stringent aerospace quality standards and offer full material traceability. Partnering with certified suppliers is crucial to meet regulatory requirements and maintain production integrity.

Carbide sandpaper is widely used to finish concrete tools and carbide-tipped blades in the construction and heavy equipment industries. Its durability under harsh conditions improves cutting efficiency and extends tool lifespan, reducing downtime and replacement costs. B2B buyers from Africa and the Middle East should focus on suppliers offering bulk purchase options and certifications that guarantee product robustness. Sourcing from vendors with proven quality control processes helps ensure that the abrasives withstand demanding field applications.

In woodworking, carbide sandpaper is used to sharpen and finish carbide-tipped saw blades and router bits, maintaining tool sharpness and precision. This reduces machine downtime and lowers replacement expenses, which is particularly valuable for manufacturers in South America and Europe. Buyers should seek suppliers with expertise in carbide abrasives tailored to various wood types and the ability to customize grit profiles. Reliable supply chains that can handle regional logistics challenges also enhance operational efficiency.

Related Video: How Is Carbide Made?

Key Properties: Silicon carbide is a very hard, sharp abrasive with excellent thermal resistance and chemical inertness. It withstands high temperatures up to 1600°C and exhibits good corrosion resistance, making it suitable for aggressive grinding applications.

Pros & Cons: Silicon carbide sandpaper delivers superior cutting efficiency and sharpness, especially on hard, brittle materials such as glass, ceramics, and stone. However, it tends to wear faster on softer metals and is more brittle, which can lead to premature grit breakdown. Manufacturing complexity is moderate, with well-established production methods.

Impact on Application: Ideal for applications requiring fast material removal and fine finishes on non-metallic surfaces. It is less suitable for high-pressure metal sanding due to its brittleness.

International B2B Considerations: Buyers in Africa and South America often prioritize cost-effectiveness and durability; SiC offers a balanced option here. Compliance with ASTM standards for abrasive grain size and grit consistency is common in Europe (including Poland) and the Middle East, ensuring quality assurance. Importers should verify supplier certifications and consider local storage conditions, as humidity can affect SiC’s shelf life.

Key Properties: Aluminum oxide is a tough, durable abrasive with high fracture toughness and good resistance to heat and chemicals. It performs well under high pressure and temperature, withstanding up to 1200°C.

Pros & Cons: This material is highly versatile, suitable for sanding metals, wood, and plastics, with a longer lifespan than silicon carbide on softer materials. It is moderately priced and widely available. The downside is a slightly lower cutting speed on very hard materials compared to SiC.

Impact on Application: Aluminum oxide is preferred for metal fabrication, automotive refinishing, and woodworking, where durability and cost-efficiency are critical.

International B2B Considerations: European buyers, especially in Poland, often require compliance with DIN and ISO abrasive standards, which aluminum oxide manufacturers typically meet. Middle Eastern and African markets value the material’s robustness for industrial uses. Buyers should assess supplier quality control processes and MOQ flexibility to optimize inventory and cash flow.

Key Properties: Ceramic alumina is an engineered abrasive with superior hardness and self-sharpening properties. It maintains sharpness under extreme heat and pressure, with excellent resistance to wear and fracture.

Pros & Cons: It offers the highest durability and cutting efficiency among common abrasives, making it ideal for heavy-duty industrial applications. The tradeoff is a higher cost and more complex manufacturing process.

Impact on Application: Best suited for precision metal finishing, aerospace components, and heavy machinery maintenance where extended tool life and consistent performance are paramount.

International B2B Considerations: Buyers in Europe and the Middle East often require adherence to stringent quality certifications such as ISO 9001 and ASTM F standards. For African and South American markets, the higher upfront cost may be justified by reduced downtime and replacement frequency. Strategic sourcing with reliable suppliers who provide traceability and compliance documentation is essential.

Key Properties: Zirconia alumina combines toughness and resilience with excellent heat resistance and self-sharpening characteristics. It performs well under heavy load and repetitive use.

Pros & Cons: It offers a good balance between durability and cost, outperforming aluminum oxide in lifespan and cutting speed but generally less expensive than ceramic alumina. However, it may not match ceramic alumina’s extreme hardness for ultra-precision tasks.

Impact on Application: Commonly used in metalworking, especially for grinding stainless steel and tough alloys, as well as in heavy fabrication industries.

International B2B Considerations: European and Middle Eastern buyers often expect compliance with ASTM and EN abrasive standards. African and South American manufacturers benefit from zirconia alumina’s cost-effectiveness and durability, especially where supply chain constraints make frequent reordering challenging. Evaluating supplier logistics capabilities and after-sales support is critical to ensure consistent supply.

| Material | Typical Use Case for carbide sandpaper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Grinding glass, ceramics, stone | High thermal resistance and sharpness | Brittle, faster wear on softer metals | Medium |

| Aluminum Oxide | Metal fabrication, woodworking, automotive | Versatile, durable, cost-effective | Lower cutting speed on very hard materials | Low |

| Ceramic Alumina | Aerospace, heavy machinery, precision metalwork | Superior hardness and self-sharpening | High cost and complex manufacturing | High |

| Zirconia Alumina | Metalworking, stainless steel grinding | Balanced durability and cutting speed | Less hard than ceramic alumina | Medium |

This guide empowers international B2B buyers to make informed decisions based on material properties, application needs, and regional compliance standards, optimizing procurement strategies for carbide sandpaper.

Carbide sandpaper is a high-performance abrasive product widely used in industrial applications for grinding, polishing, and finishing hard surfaces. For international B2B buyers, understanding its manufacturing process is critical to ensuring product quality, consistency, and suitability for specific industrial needs.

The production begins with the careful selection and preparation of raw materials. The primary abrasive component is silicon carbide grains, prized for their hardness and sharpness. These grains are typically synthesized through high-temperature chemical processes and must meet stringent purity and size distribution standards.

Backing materials vary depending on the sandpaper grade and application, commonly including paper, cloth, or film substrates. These substrates are treated to enhance adhesion and durability under operational stress.

After preparation, the silicon carbide grains are coated onto the backing substrate using bonding agents. Two main bonding methods dominate:

The coating process involves precise control of grain distribution and bonding thickness to optimize abrasive efficiency and product lifespan.

Once coated, the sheets or rolls undergo forming processes:

Assembly may also include adding features like anti-clog coatings or backing reinforcements to enhance performance in specific industrial environments.

The final stage involves finishing touches such as edge trimming and surface inspection. The sandpaper is then packaged under controlled conditions to prevent contamination or damage during transit. For international shipments, packaging standards often include moisture barriers and sturdy containers to withstand long-distance logistics.

Quality assurance (QA) is integral to carbide sandpaper manufacturing. B2B buyers must ensure their suppliers adhere to internationally recognized standards and implement robust quality control (QC) measures to guarantee product reliability and compliance with regulatory requirements.

Quality control in carbide sandpaper manufacturing is typically segmented into three key checkpoints:

For international buyers—especially from Africa, South America, the Middle East, and Europe—verifying supplier quality is paramount to mitigate risks related to inconsistent product quality, delivery delays, or compliance failures.

Conducting on-site or virtual supplier audits helps assess manufacturing capabilities, quality control systems, and compliance with international standards. Key audit focus areas include:

For buyers unable to visit in person, third-party audit firms can provide unbiased assessments.

Request detailed quality inspection reports and material certificates for each shipment. These documents should cover:

Transparent documentation builds trust and facilitates regulatory compliance in the buyer’s country.

Engaging independent quality inspection agencies to perform pre-shipment inspections (PSI) or during production inspections (DPI) offers an extra layer of assurance. These inspections can verify:

Third-party verification is especially valuable for buyers in regions like Nigeria or Poland, where import regulations may require strict adherence to international standards.

For international B2B buyers sourcing carbide sandpaper, a thorough understanding of manufacturing processes and quality assurance protocols is essential to secure reliable, high-performance products. By focusing on raw material quality, bonding techniques, and rigorous QC checkpoints aligned with international standards, buyers can minimize risks and optimize procurement outcomes. Employing supplier audits, demanding comprehensive documentation, and engaging third-party inspections further strengthens quality assurance, fostering successful global partnerships across Africa, South America, the Middle East, and Europe.

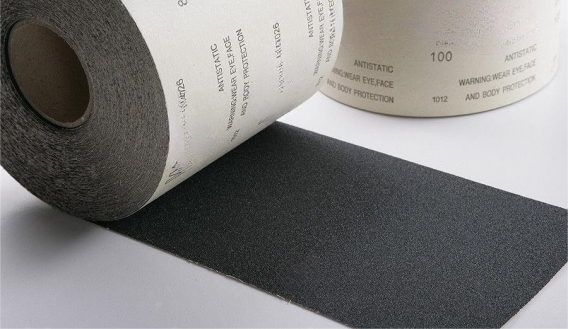

Illustrative Image (Source: Google Search)

Understanding the cost structure and pricing dynamics of carbide sandpaper is essential for international B2B buyers aiming to optimize procurement strategies and ensure competitive margins. This analysis breaks down key cost components, pricing influencers, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe, including countries like Nigeria and Poland.

Raw Materials

The core input is the carbide abrasive grit, usually tungsten or silicon carbide, combined with backing materials like paper, cloth, or film. Material quality and grade significantly influence cost. Suppliers sourcing high-purity carbide or eco-friendly backing may charge premiums. Fluctuations in raw material prices due to global supply-demand shifts or geopolitical factors can directly impact cost.

Labor Costs

Labor expenses vary widely depending on the manufacturing location. Production in low-wage countries can reduce costs but may affect quality control if not properly managed. For buyers in Europe or the Middle East, sourcing from regions with competitive labor costs (e.g., Southeast Asia) can provide cost advantages but requires diligent supplier oversight.

Manufacturing Overhead

This includes utilities, plant maintenance, and indirect labor. Automation levels affect overhead costs; advanced manufacturing facilities with robotic sanding and coating lines typically have higher fixed costs but produce consistent quality at scale.

Tooling and Equipment

Initial investment in precision coating equipment and grit embedding machines can be substantial. These costs are amortized over production volume but may increase unit costs for smaller orders or customized products.

Quality Control (QC)

Rigorous QC processes—such as grit size verification, adhesion testing, and durability assessments—add to cost but ensure product reliability. Certifications (ISO, REACH compliance) can also raise prices but are critical for buyers targeting regulated markets.

Logistics and Freight

International shipping, customs duties, import taxes, and local distribution expenses must be factored into total cost. For buyers in Africa or South America, higher freight costs and longer lead times can significantly affect landed price.

Supplier Margin

Suppliers include their profit margin based on market positioning, order volume, and competitive landscape. Margins may be negotiable for large or repeat orders.

Order Volume and Minimum Order Quantities (MOQs)

Larger volumes reduce per-unit cost due to economies of scale and lower relative overhead. However, some suppliers impose high MOQs that may lead to overstock and cash flow challenges, especially for SMEs in emerging markets.

Product Specifications and Customization

Custom grit sizes, backing materials, or specialty coatings increase complexity and cost. Buyers should balance specification needs with cost implications.

Material Quality and Certification Requirements

Products meeting international quality standards or environmental certifications often carry price premiums, essential for buyers targeting export markets or regulated industries.

Supplier Reliability and Location

Established suppliers with proven track records may charge more but reduce risk. Proximity to supplier can reduce logistics costs and lead times.

Incoterms and Payment Terms

Pricing varies with Incoterms (FOB, CIF, DDP) which determine responsibility for freight, insurance, and customs. Buyers should clarify terms to avoid unexpected costs.

Leverage Negotiation on MOQs and Pricing

Negotiate flexible MOQs or staggered deliveries to manage cash flow and inventory risks. Volume discounts or bundled orders can unlock better pricing.

Evaluate Total Cost of Ownership (TCO)

Consider not just unit price but freight, customs, warehousing, and quality-related costs. A slightly higher unit price with better quality and lower defect rates often yields better long-term value.

Prioritize Supplier Transparency and Communication

Clear visibility into cost breakdowns, lead times, and quality standards helps mitigate risks, especially for buyers in regions with longer supply chains.

Adapt Sourcing Strategies to Local Market Realities

For African and South American buyers, factoring in longer shipping times and potential customs delays is crucial. Working with freight forwarders familiar with regional logistics can optimize delivery schedules and reduce costs.

Use Digital Tools for Cost Monitoring and Forecasting

Employ procurement software or ERP modules to track pricing trends, supplier performance, and inventory levels, enabling proactive cost control.

Prices for carbide sandpaper vary significantly based on supplier, order size, and product specifications. Buyers should use indicative prices as a starting point and conduct thorough supplier evaluations and market research to obtain accurate quotes tailored to their unique requirements.

By systematically analyzing these cost and pricing factors, international B2B buyers can make informed sourcing decisions, negotiate effectively, and optimize procurement of carbide sandpaper to support their manufacturing and operational goals.

Understanding the critical technical specifications of carbide sandpaper enables B2B buyers to select products that precisely meet their manufacturing or finishing requirements, optimizing cost and performance.

Abrasive Material Grade

Carbide sandpaper typically uses silicon carbide or tungsten carbide as the abrasive. The grade indicates the hardness and cutting efficiency. Higher-grade carbide abrasives offer greater durability and faster material removal, essential for industrial applications requiring precision and longevity.

Grit Size

Grit size measures the coarseness of the abrasive particles, usually ranging from very coarse (e.g., 24 grit) to ultra-fine (e.g., 1200 grit). Choosing the correct grit size affects surface finish quality and processing speed. Coarse grits are for heavy stock removal, while fine grits are used for polishing and finishing.

Backing Material and Thickness

The backing supports the abrasive and influences flexibility and durability. Common backing materials include paper, cloth, or polyester. Thickness impacts how well the sandpaper conforms to surfaces and its resistance to tearing. For industrial buyers, matching backing type and thickness to the application ensures optimal performance and cost-efficiency.

Bonding Type

The adhesive bonding the abrasive to the backing can be resin, glue, or electroplated. Resin bonds provide strong adhesion for wet or dry sanding, while electroplated bonds are used for heavy-duty grinding. Understanding bonding types helps buyers ensure longevity and consistent abrasive performance in different environments.

Tolerance and Dimensions

Precision in size and shape (length, width, hole placement) is critical, especially for automated sanding equipment. Tight tolerances reduce waste and machine downtime. Buyers should confirm dimensional specifications align with their machinery requirements to avoid compatibility issues.

Coating and Treatment

Some carbide sandpapers feature special coatings, such as anti-clog or waterproof treatments. These enhance performance by preventing clogging with dust or debris and enabling use in wet sanding applications, extending the lifespan of the abrasive.

Familiarity with industry jargon facilitates clearer communication, better negotiation, and smoother transactions between international buyers and suppliers.

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce sandpaper to be branded and sold by another company. B2B buyers can source OEM products for private labeling or ensure compatibility with specific machinery.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ is crucial for inventory planning and cash flow management, especially for SMEs in emerging markets where capital and storage space might be limited.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms. RFQs help buyers compare offers and negotiate better deals, ensuring transparency and cost control.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Knowing Incoterms helps buyers from regions like Africa, South America, and the Middle East to manage logistics, customs, and costs effectively.

Lead Time

The period between placing an order and receiving the goods. Accurate knowledge of lead times helps buyers plan production schedules and avoid costly delays.

Batch/Lot Number

A unique identifier for a production batch. This is important for quality control, traceability, and managing warranty or defect claims.

By mastering these technical specifications and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and establish reliable partnerships in the carbide sandpaper market. This knowledge ultimately supports better product quality, cost-efficiency, and supply chain resilience.

The carbide sandpaper sector is witnessing robust growth driven by increasing demand across manufacturing, automotive, aerospace, and construction industries worldwide. Global industrialization and infrastructure development in emerging markets such as Nigeria and South America are fueling demand for high-performance abrasive materials like carbide sandpaper. Meanwhile, European countries like Poland continue to prioritize precision manufacturing and quality standards, sustaining steady demand.

Key market dynamics reveal a shift toward advanced sourcing strategies that emphasize supply chain resilience and cost-efficiency. International B2B buyers increasingly leverage digital procurement platforms and smart manufacturing tools, integrating material requirement planning (MRP) with automated purchasing workflows to mitigate risks like supply delays and MOQ challenges. This is particularly critical for buyers in Africa and the Middle East, where logistics complexities and fluctuating raw material availability require agile sourcing.

Illustrative Image (Source: Google Search)

Emerging trends include a move toward customized carbide grit sizes and backing materials, enabling suppliers to meet specific application needs from heavy-duty metal grinding to fine finishing. Additionally, supplier diversification is becoming a priority to reduce dependency on single geographies, with China, India, and select European manufacturers offering competitive options.

Technology adoption, such as real-time inventory tracking and supplier performance analytics, empowers buyers to optimize procurement cycles, reduce overstock, and improve cash flow management. For B2B buyers targeting carbide sandpaper, establishing robust relationships with trusted suppliers who provide transparent MOQ terms and quality certifications is essential to maintaining production continuity and product quality.

Sustainability is increasingly central to sourcing decisions in the carbide sandpaper sector, especially among international buyers committed to reducing environmental footprints and enhancing corporate social responsibility. Carbide sandpaper manufacturing involves the use of tungsten carbide grit and bonding resins, which can have significant environmental impacts if not managed properly.

Environmental considerations include reducing energy consumption during production, minimizing hazardous waste, and sourcing raw materials from suppliers with sustainable mining practices. Buyers from regions like Europe and the Middle East are particularly focused on compliance with stringent environmental regulations and expect suppliers to provide evidence of eco-friendly manufacturing processes.

Ethical sourcing extends beyond environmental factors to encompass responsible labor practices and transparent supply chains. International buyers are increasingly requiring suppliers to hold certifications such as ISO 14001 (Environmental Management) and REACH compliance for chemical safety, alongside social responsibility standards like SA8000 or equivalent.

Green certifications for abrasive materials, including carbide sandpaper, are emerging as differentiators in the market. These certifications validate that the products meet criteria for reduced emissions, recyclable content, and minimal toxic substances. Buyers benefit from partnering with suppliers who offer eco-labeled products, enabling them to meet their own sustainability goals and appeal to environmentally conscious end customers.

Incorporating sustainability into procurement strategies helps mitigate risks associated with regulatory changes and reputational damage. It also opens opportunities for long-term cost savings through energy-efficient production and waste reduction. For B2B buyers, embedding sustainability criteria into supplier selection and contract negotiation is a strategic imperative in today’s carbide sandpaper market.

Carbide sandpaper has evolved significantly since its inception, originally emerging as a superior abrasive alternative to traditional materials like aluminum oxide and silicon carbide. The introduction of tungsten carbide grit in the mid-20th century revolutionized the abrasives industry by offering enhanced hardness, durability, and heat resistance—qualities essential for heavy-duty industrial applications.

Over the decades, advances in bonding technologies and grit formulation have refined carbide sandpaper’s performance, allowing it to cater to increasingly specialized manufacturing processes. This evolution reflects broader trends in industrial automation and precision engineering, where consistent abrasive quality directly impacts product finish and operational efficiency.

For international B2B buyers, understanding this historical progression highlights the critical role of carbide sandpaper in modern manufacturing and underscores the importance of sourcing from suppliers who invest in continuous innovation and quality assurance. The sector’s trajectory also signals ongoing opportunities for collaboration between buyers and manufacturers to develop tailored solutions aligned with evolving industrial needs and sustainability objectives.

Illustrative Image (Source: Google Search)

Is customization available for carbide sandpaper, and how do I communicate specifications effectively?

Most reputable manufacturers offer customization such as grit size, backing material, and dimensions to suit specific industrial applications. Provide detailed technical drawings or samples of your current products to ensure clarity. Use standardized industry terms and specify tolerances, grit types, and bonding materials. Confirm the supplier’s capacity for customization and minimum order quantities (MOQs) before finalizing. For complex requirements, consider a prototype order to validate the product before full-scale procurement.

What are typical minimum order quantities (MOQs) and lead times for carbide sandpaper when sourcing internationally?

MOQs vary widely, typically ranging from 500 to 5,000 units depending on customization and supplier scale. Standard lead times are between 3 to 8 weeks, influenced by order size, customization, and current demand. For buyers in regions like the Middle East or Nigeria, factor in additional transit and customs clearance time. Early communication about MOQs and lead times helps align production schedules and cash flow. Negotiate flexible MOQs when possible, especially for trial orders or new product lines.

What payment terms are common when purchasing carbide sandpaper internationally, and how can I mitigate payment risks?

Common payment terms include 30% upfront deposit with balance on shipment or letter of credit (LC) for larger orders. Using secure payment methods like escrow services or trade finance instruments reduces risk. For new suppliers, consider smaller initial orders with advance payment and progressively increase trust. Always clarify currency, bank charges, and payment deadlines upfront. Working with suppliers who accept internationally recognized payment platforms or have a presence in your region can improve transaction security.

How do I ensure quality assurance (QA) and certifications for carbide sandpaper from overseas suppliers?

Request certifications such as ISO 9001 for quality management and product-specific compliance documents (e.g., RoHS, REACH). Insist on pre-shipment inspections or third-party quality audits to verify grit consistency, bonding strength, and backing durability. Establish clear quality parameters in your contract and include penalties for non-compliance. Regularly review QA reports and maintain an Approved Vendor List (AVL) to track supplier performance. Engaging local inspection agencies in your region can provide added confidence.

What logistics considerations should I keep in mind when importing carbide sandpaper to countries like Poland or Nigeria?

Understand import regulations, customs duties, and taxes specific to abrasive materials in your country. Choose reliable freight forwarders experienced in handling industrial materials with proper packaging to prevent damage during transit. Air freight is faster but costlier; sea freight is economical but slower. Plan for potential delays in customs clearance and ensure all documentation (commercial invoice, packing list, certificates) is accurate and complete. Consolidating shipments can reduce costs but may increase lead times.

How can I resolve disputes or quality issues with carbide sandpaper suppliers abroad effectively?

Maintain clear, documented communication from order placement through delivery. If quality issues arise, promptly report with photographic evidence and product samples. Refer to agreed contract terms regarding dispute resolution, including warranty and return policies. Engage third-party inspection or mediation services if needed. Building long-term partnerships with open dialogue reduces conflict likelihood. For legal recourse, ensure contracts specify jurisdiction and arbitration mechanisms suitable for international trade.

Are there specific challenges B2B buyers from Africa, South America, or the Middle East should anticipate when sourcing carbide sandpaper?

Buyers in these regions often face challenges such as longer shipping times, fluctuating currency exchange rates, and limited local supplier options. Infrastructure constraints may affect logistics and delivery reliability. To mitigate risks, plan procurement well in advance, negotiate flexible payment and delivery terms, and collaborate closely with suppliers for real-time updates. Leveraging regional trade agreements or sourcing hubs closer to your location can reduce costs and lead times. Additionally, invest in training your team on international trade compliance to avoid customs delays.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

For international B2B buyers in Africa, South America, the Middle East, and Europe, sourcing carbide sandpaper effectively hinges on aligning quality, cost-efficiency, and reliable supply chain management. Prioritizing suppliers with proven consistency and transparent MOQ terms reduces risks of production delays and excessive inventory costs. Leveraging digital procurement tools can enhance visibility into lead times, pricing fluctuations, and vendor performance—crucial for markets with evolving logistics infrastructures.

Strategic sourcing is not merely transactional; it’s a dynamic partnership that drives competitive advantage. Buyers must integrate material purchasing tightly with production planning, ensuring raw materials like carbide sandpaper meet exact specifications and arrive just-in-time to optimize cash flow. Developing an Approved Vendor List (AVL) tailored to regional supply realities fosters negotiation leverage and quality assurance.

Looking ahead, the carbide sandpaper market will increasingly favor suppliers who embrace smart manufacturing, sustainability, and agile logistics. Buyers in emerging and mature markets alike should invest in supplier collaboration and technology adoption to navigate global uncertainties and evolving demand patterns.

To capitalize on these opportunities, B2B buyers are encouraged to proactively engage with trusted global sourcing partners, continuously evaluate supplier capabilities, and adopt integrated procurement strategies that safeguard product quality and supply resilience. This strategic approach will unlock growth potential and operational excellence in carbide sandpaper sourcing for years to come.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina