Carborundum, known for its exceptional hardness and thermal stability, is a cornerstone material in diverse industrial applications—from abrasives and cutting tools to electronics and refractory products. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding the complexities of sourcing high-quality carborundum is crucial to maintaining competitive advantage and operational excellence.

This comprehensive guide serves as an indispensable resource, meticulously covering the full spectrum of carborundum-related knowledge. It explores various types and grades of carborundum, detailing their distinct properties and best-fit applications. The guide also delves into raw materials, manufacturing processes, and quality control protocols, enabling buyers to assess supplier credibility and product consistency effectively.

Recognizing the global nature of supply chains, the guide provides insights into top suppliers and manufacturers, highlighting regional strengths and potential sourcing challenges. It further examines cost factors and market trends, empowering buyers to negotiate better deals and anticipate price fluctuations.

To address practical concerns, an extensive FAQ section tackles common queries and pitfalls, ensuring buyers from emerging and established markets alike—whether in Kenya, Indonesia, Brazil, or the Gulf region—can make informed, strategic purchasing decisions with confidence.

Illustrative Image (Source: Google Search)

By leveraging this guide, international buyers will gain a clear, authoritative understanding of the carborundum market landscape, enabling optimized procurement strategies that align with their operational needs and growth ambitions.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Carborundum | High purity, hard crystalline structure, dark gray to black | Abrasives, cutting tools, grinding wheels | + Excellent hardness and durability – Higher cost compared to other types |

| Green Carborundum | Contains additives for toughness, greenish hue | Polishing, surface finishing, precision grinding | + Enhanced toughness – Slightly less hard than black variant |

| Brown Carborundum | Mixed composition with higher impurity levels | General purpose abrasives, non-critical grinding | + Cost-effective – Lower performance in high-precision tasks |

| Fused Carborundum | Manufactured by fusing raw materials, uniform particle size | Industrial grinding, sandblasting, refractory linings | + Consistent particle size – Limited chemical resistance |

| Silicon Carbide Powder | Fine powder form, used as raw material for coatings and composites | Coatings, composite materials, electronics | + Versatile in manufacturing – Requires precise handling and storage |

Black Carborundum

Black carborundum is the most common and pure form of silicon carbide, prized for its exceptional hardness and wear resistance. It is ideal for abrasive applications such as cutting, grinding, and machining hard materials. For B2B buyers, especially in manufacturing sectors across Africa, South America, and Europe, the higher initial cost is offset by its longevity and efficiency in demanding environments. Buyers should ensure supplier quality certifications to guarantee material consistency.

Green Carborundum

Green carborundum is modified with additives to improve toughness, making it suitable for precision grinding and polishing tasks where resistance to fracture is critical. This variant is favored in industries requiring fine surface finishes, such as automotive and aerospace component manufacturing. For international buyers, understanding the specific additive composition is important to match the product with application requirements and to negotiate pricing based on performance benefits.

Brown Carborundum

Brown carborundum features a higher impurity content and is generally used for less demanding abrasive applications. It is a cost-effective choice for bulk grinding and non-critical operations, making it attractive for buyers in emerging markets or industries with budget constraints. However, it is less suitable for precision or high-speed machining. Buyers should evaluate the trade-off between cost savings and performance to avoid operational inefficiencies.

Fused Carborundum

Fused carborundum is produced by high-temperature fusion of raw materials, resulting in a uniform particle size and enhanced mechanical properties. This type is widely used in industrial grinding, sandblasting, and refractory linings. B2B purchasers should consider its limited chemical resistance when selecting for applications involving corrosive environments. Bulk procurement can benefit from economies of scale but requires reliable logistics to maintain product integrity.

Silicon Carbide Powder

Silicon carbide powder is a fine particulate form used as a raw material in coatings, composite manufacturing, and electronic components. Its versatility makes it essential for advanced manufacturing sectors. Buyers must prioritize powder purity, particle size distribution, and supplier quality assurance to ensure compatibility with downstream processes. Proper storage and handling protocols are critical to prevent contamination and maintain performance standards.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of carborondum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives & Cutting Tools | Manufacturing of grinding wheels, cutting discs, and abrasive powders | Enhanced durability and cutting efficiency leading to reduced downtime and maintenance costs | Consistent particle size and purity to ensure uniform performance; reliable supply chain for bulk orders |

| Automotive & Aerospace | High-performance brake pads and heat-resistant components | Improved thermal stability and wear resistance, increasing safety and lifespan of parts | Compliance with international quality standards; material certification and traceability |

| Electronics & Semiconductors | Use in heat sinks and semiconductor substrates | Superior thermal conductivity aiding in effective heat dissipation, enhancing device reliability | Precision in material composition; supplier capability to meet tight tolerances |

| Metallurgy & Foundry | Refractory linings and crucibles for high-temperature furnaces | High melting point and chemical inertness reduce contamination and extend equipment life | Availability of high-grade carborondum with minimal impurities; technical support for customization |

| Construction & Mining | Abrasive blasting and surface preparation tools | Efficient surface finishing and cleaning, improving adhesion and structural integrity | Bulk availability with consistent quality; logistics support for remote regions |

Carborondum is extensively utilized in the abrasives and cutting tools industry where it serves as the core material for manufacturing grinding wheels, cutting discs, and abrasive powders. Its exceptional hardness and thermal resistance enable businesses to achieve higher cutting precision and longer tool life. For international buyers, especially in regions like Africa and South America, sourcing carborondum with consistent particle size and purity is critical to maintain performance standards and optimize operational costs.

In the automotive and aerospace sectors, carborondum is a vital component in the production of high-performance brake pads and heat-resistant parts. Its ability to withstand extreme temperatures while maintaining structural integrity ensures enhanced safety and durability of vehicles and aircraft. Buyers from the Middle East and Europe should prioritize suppliers that provide certified materials compliant with global quality and safety regulations to meet stringent industry requirements.

The electronics and semiconductor industry leverages carborondum for heat sinks and substrates due to its superior thermal conductivity. Efficient heat dissipation is crucial for maintaining device reliability and performance. For B2B buyers in Indonesia and Kenya, it is essential to procure materials with precise composition and uniformity, along with suppliers capable of meeting tight manufacturing tolerances to support advanced electronic applications.

In metallurgy and foundry applications, carborondum is employed in refractory linings and crucibles used in high-temperature furnaces. Its high melting point and chemical inertness protect furnace structures from wear and contamination, thereby extending operational life and reducing downtime. Buyers should focus on sourcing high-grade carborondum with minimal impurities and seek suppliers offering technical support for customized material specifications to suit specific metallurgical processes.

Finally, in the construction and mining industries, carborondum is widely used for abrasive blasting and surface preparation tools. Its abrasive properties enable efficient cleaning and finishing of surfaces, improving adhesion for coatings and enhancing structural integrity. For businesses operating in remote or developing regions, ensuring bulk availability, consistent quality, and reliable logistics support are key factors when selecting suppliers to maintain uninterrupted operations.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Key Properties: Silicon carbide, commonly known as carborundum, boasts exceptional hardness, high thermal conductivity, and outstanding chemical inertness. It withstands temperatures up to 1600°C and exhibits excellent resistance to oxidation and corrosion, making it ideal for harsh environments.

Pros & Cons: SiC is extremely durable and wear-resistant, ideal for abrasive applications. However, its manufacturing complexity can lead to higher costs compared to other abrasives. The material’s brittleness requires careful handling during processing and installation.

Impact on Application: Silicon carbide performs exceptionally well in high-temperature and high-pressure environments, such as in mechanical seals, grinding wheels, and high-performance brake systems. It is compatible with a wide range of chemicals, including acids and alkalis, making it suitable for chemical processing industries.

Considerations for International B2B Buyers: Buyers from Africa, South America, the Middle East, and Europe should verify compliance with international standards such as ASTM C12 and DIN EN 13236 to ensure quality and safety. Due to its widespread use, SiC is generally available globally, but logistics and import duties can affect pricing and delivery times, especially in regions like Kenya and Indonesia. Local preferences may lean towards suppliers who provide certifications and technical support.

Key Properties: Boron carbide is one of the hardest materials known, with exceptional neutron absorption capabilities and high melting points (~2763°C). It offers excellent wear resistance and chemical stability, especially in acidic and alkaline environments.

Pros & Cons: B4C’s extreme hardness makes it suitable for ballistic armor and abrasive applications. However, it is more expensive and difficult to machine than silicon carbide. Its brittleness can limit its use in impact applications without proper design considerations.

Impact on Application: Boron carbide is favored in nuclear industry components, armor plating, and abrasive powders. Its chemical inertness also suits it for corrosive environments. However, its cost and machining challenges mean it is less common for general abrasive uses.

Considerations for International B2B Buyers: For buyers in emerging markets like South America and Africa, the higher cost of B4C may be a limiting factor. Compliance with ASTM C799 and ISO 9001 standards is crucial for industrial applications. Buyers should also assess supplier capabilities for custom shapes and sizes, given the material’s machining difficulty. Regional import regulations and tariffs can impact procurement strategies.

Key Properties: Aluminum oxide, or alumina, is a widely used abrasive with good hardness (Mohs ~9), high melting point (~2072°C), and excellent chemical stability. It offers moderate thermal conductivity and is resistant to corrosion.

Pros & Cons: Alumina is cost-effective and easier to manufacture than carbides, making it suitable for mass production. However, it has lower thermal conductivity and wear resistance compared to silicon carbide and boron carbide, limiting its use in extreme environments.

Impact on Application: Alumina is ideal for general-purpose grinding, polishing, and cutting tools. It performs well with ferrous metals and is often used in metal fabrication and automotive industries. Its chemical resistance makes it suitable for many industrial processes but less so for very high-temperature or highly corrosive applications.

Considerations for International B2B Buyers: Aluminum oxide is widely available and typically meets ASTM B74 and ISO 11126 standards. Buyers from the Middle East and Europe benefit from established supply chains, while those in Africa and South America should consider local availability and potential import delays. Cost-effectiveness and versatility make alumina a preferred choice for budget-conscious buyers.

Key Properties: Silicon nitride is a high-strength ceramic with excellent thermal shock resistance, high fracture toughness, and good chemical stability. It operates effectively at temperatures up to 1400°C and resists oxidation and wear.

Pros & Cons: Si3N4 offers superior mechanical strength and durability, making it suitable for high-stress applications. However, it is more expensive and complex to manufacture than silicon carbide and alumina. Its availability is more limited, which can affect lead times.

Impact on Application: Silicon nitride is used in precision components such as bearings, engine parts, and cutting tools where toughness and thermal stability are critical. It is less common as a bulk abrasive but excels in specialty applications requiring high reliability.

Considerations for International B2B Buyers: Buyers in Europe and the Middle East often require compliance with ISO 13356 and ASTM C1275 standards for advanced ceramics. For markets in Africa and South America, evaluating supplier reliability and after-sales support is essential due to the material’s specialized nature. Cost and supply chain considerations may limit its use to high-value applications.

| Material | Typical Use Case for carborondum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Abrasives, mechanical seals, brake systems | High hardness, thermal and chemical resistance | Brittle, higher manufacturing complexity | Medium |

| Boron Carbide | Ballistic armor, nuclear components, abrasives | Extreme hardness, neutron absorption | High cost, difficult to machine | High |

| Aluminum Oxide | General grinding, polishing, metal fabrication | Cost-effective, versatile | Lower wear resistance and thermal conductivity | Low |

| Silicon Nitride | Precision components, high-stress applications | Excellent toughness and thermal shock resistance | Expensive, limited availability | High |

Carborundum, also known as silicon carbide (SiC), is a highly durable and versatile abrasive material widely used in industrial applications. Its manufacturing involves a complex process designed to produce high-purity, high-strength particles or components suitable for cutting, grinding, and wear-resistant applications.

The production begins with sourcing high-quality raw materials, primarily silica sand and petroleum coke. These materials must be carefully selected for purity to ensure the final product’s performance. The raw materials undergo thorough drying and grinding to achieve uniform particle sizes, facilitating consistent chemical reactions in subsequent steps.

The core manufacturing step is the carbothermal reduction process. Here, the prepared silica and coke mixture is heated in an electric resistance furnace at temperatures ranging from 2,000°C to 2,500°C. This high-temperature reaction synthesizes silicon carbide crystals, which form the base abrasive grains. Controlling the furnace atmosphere and temperature is critical to obtaining the desired crystalline structure and minimizing impurities.

Post-synthesis, the silicon carbide mass is cooled and crushed mechanically into smaller grains. These grains are then classified by size using screening and air classification techniques to meet various industry specifications for grit size. This stage is essential to tailor the abrasive for different applications, from fine polishing to heavy-duty grinding.

For applications requiring shaped carborundum products (e.g., grinding wheels, cutting tools), the raw abrasive grains are mixed with binders and additives. The mixture is then molded using pressing or extrusion methods. Advanced forming techniques, such as isostatic pressing, ensure uniform density and strength in the shaped products.

Formed products undergo sintering, where they are heated to just below melting temperatures to enhance mechanical strength without melting the material. Finishing processes such as surface grinding, dressing, and coating may follow, depending on the final application requirements.

Quality assurance (QA) is paramount in carborundum manufacturing to guarantee product reliability, performance, and compliance with international standards. B2B buyers should understand the QA frameworks and verification methods to ensure supplier credibility.

For international buyers, particularly from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product consistency.

Conducting on-site or remote factory audits allows buyers to assess manufacturing capabilities, QC protocols, and compliance with international standards. Audits should focus on:

- Traceability of raw materials and finished products.

- Calibration and maintenance of testing equipment.

- Documentation and record-keeping practices.

- Employee training and safety standards.

Request detailed quality reports, including:

- Certificates of Analysis (CoA) for batches.

- ISO 9001 certification and any relevant industry-specific accreditations.

- Test result summaries for physical and chemical properties.

- Non-conformance and corrective action reports.

Engaging independent inspection agencies provides an unbiased assessment of product quality and manufacturing integrity. These inspections may include:

- Pre-shipment inspections.

- Sampling and laboratory testing.

- Verification of compliance with buyer-specific standards.

International B2B buyers must consider several factors unique to their regions to ensure smooth procurement and compliance.

For international B2B buyers, understanding the detailed manufacturing processes and stringent quality assurance practices behind carborundum products is critical. From material preparation through sintering, each stage demands precise control to deliver high-performance abrasives. Rigorous QC aligned with international standards and verified through audits and third-party inspections helps ensure product reliability. Buyers from Africa, South America, the Middle East, and Europe should also factor in regional regulatory compliance, environmental conditions, and supply chain logistics when selecting suppliers. This comprehensive approach safeguards investment and optimizes operational efficiency with carborundum products.

When sourcing carborondum, understanding the detailed cost structure is crucial for international B2B buyers aiming to optimize expenditures without compromising quality. The primary cost components include:

Several factors affect the final pricing of carborondum products in B2B transactions:

Pricing for carborondum products is highly variable and influenced by global raw material markets, production technology, and geopolitical factors. The insights provided here serve as a general guideline. Buyers should conduct direct negotiations and due diligence with suppliers to obtain precise quotes tailored to their specific requirements and supply chain conditions.

By comprehensively analyzing these cost factors and price influencers, international B2B buyers can make informed sourcing decisions, optimize procurement strategies, and enhance their competitive edge in demanding markets.

Understanding the critical technical properties of carborundum (silicon carbide) is essential for international buyers to ensure product quality, compatibility, and performance in industrial applications. Here are the most important specifications to consider:

Material Grade

Carborundum is available in various grades depending on purity, crystalline structure, and particle size. High-grade silicon carbide offers superior hardness and thermal conductivity, suitable for demanding applications like precision grinding or abrasive machining. Buyers should specify the grade to match their operational requirements and avoid costly mismatches.

Particle Size & Grit

The particle size, often classified by grit numbers, directly affects the abrasiveness and finish quality. Fine grits are used for polishing and finishing, while coarse grits serve rough cutting and grinding. Knowing the exact grit size needed helps buyers optimize efficiency and product output.

Tolerance and Purity

Tolerance refers to the allowable variation in particle size or shape, which impacts consistency in manufacturing processes. Purity levels influence the chemical reactivity and durability of carborundum, especially in high-temperature or corrosive environments. Buyers should request detailed tolerance and purity specifications from suppliers.

Hardness (Mohs Scale)

Carborundum typically ranks 9-9.5 on the Mohs hardness scale, making it one of the hardest materials available for abrasives. This property is crucial for cutting, grinding, and polishing hard metals and ceramics. Ensuring consistent hardness levels guarantees predictable performance and tool longevity.

Thermal Stability

The ability to withstand high temperatures without degradation is vital for applications like refractory linings or heat exchangers. Buyers should confirm the maximum operating temperature and thermal shock resistance of the carborundum supplied to avoid failures in extreme conditions.

Bulk Density

Bulk density affects packing, shipping costs, and the behavior of carborundum in processing systems. It also influences the abrasive’s performance during use. Requesting precise bulk density data assists in logistical planning and process calibration.

Navigating the global carborundum market requires familiarity with industry-standard trade terminology. Here are key terms that facilitate clear communication and smooth transactions:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or products used in another company’s end product. When buying carborundum, OEM specifications ensure compatibility with equipment or machinery, reducing the risk of operational issues.

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory, manage cash flow, and negotiate better terms, especially important for SMEs and buyers in emerging markets.

RFQ (Request for Quotation)

A formal inquiry sent by a buyer to suppliers asking for price, availability, and terms. A well-prepared RFQ that includes technical specifications and quantity requirements speeds up procurement and ensures accurate offers.

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs. Common Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) impact total landed cost and risk allocation. Buyers should clarify preferred Incoterms early in negotiations.

Lead Time

The time interval between placing an order and receiving the goods. For carborundum, lead time influences production scheduling and supply chain reliability. Buyers should seek realistic lead times to avoid downtime or stockouts.

Certification & Compliance

Documentation verifying that carborundum meets industry standards (e.g., ISO, REACH, RoHS) or specific client requirements. Certifications assure quality and regulatory compliance, which are crucial when exporting to regions with strict import controls.

By focusing on these essential technical properties and mastering the trade terminology, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions, optimize supply chains, and foster stronger supplier relationships in the competitive carborundum market.

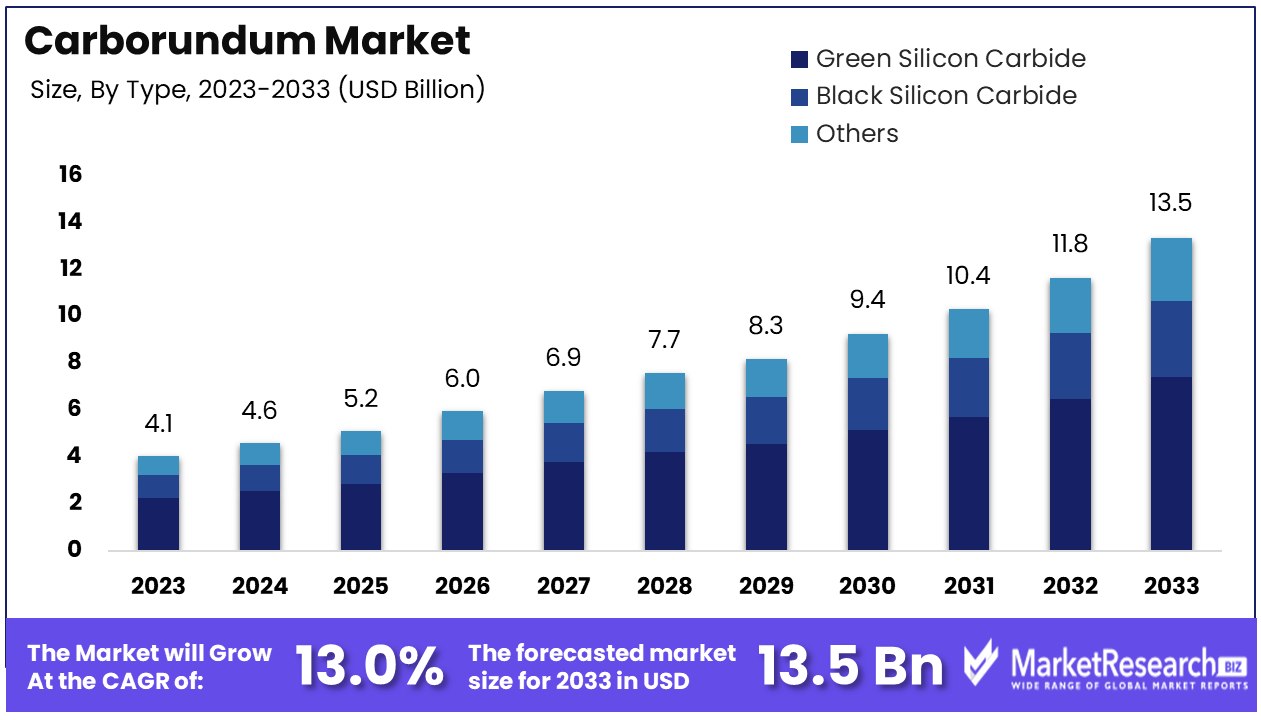

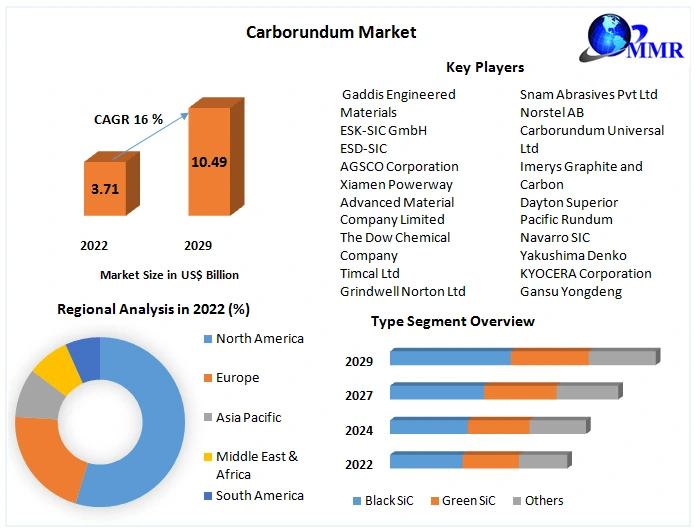

The global carborundum market is experiencing robust growth driven by increasing demand across industrial sectors such as automotive, aerospace, electronics, and construction. Carborundum’s exceptional hardness, thermal conductivity, and chemical stability make it a critical material for abrasive products, cutting tools, and high-performance ceramics. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding regional market dynamics is essential.

Key drivers include:

For B2B buyers, partnering with suppliers offering customized grades and technical support is becoming a key differentiator. Additionally, demand for smaller batch sizes and just-in-time delivery models is rising, reflecting the need for agility in global supply chains.

Sustainability is rapidly becoming a decisive factor in carborundum procurement. The environmental footprint of carborundum production—primarily energy-intensive manufacturing and mining of raw materials like silicon carbide—poses challenges that buyers must address.

Key sustainability considerations include:

By integrating sustainability into procurement policies, B2B buyers not only reduce risks but also enhance brand reputation and meet the growing expectations of environmentally conscious markets.

Carborundum, or silicon carbide, was first synthesized in the late 19th century by Edward Goodrich Acheson as a synthetic abrasive alternative to natural materials. Its discovery revolutionized industrial abrasives, offering superior hardness and thermal resistance. Over the decades, carborundum has evolved from a simple abrasive grit to a sophisticated engineered material used in semiconductors, high-temperature ceramics, and advanced composites.

The historical significance for B2B buyers lies in its established reliability and continuous innovation. Understanding this legacy helps buyers appreciate the mature supply chains and ongoing technological improvements that support diverse industrial applications globally. This historical foundation also underscores the importance of sourcing from experienced, quality-certified producers to leverage the full benefits of carborundum technology.

How can I effectively vet carborondum suppliers for international B2B purchases?

To vet suppliers, start by verifying their business licenses, certifications, and export capabilities. Request product samples and test reports to assess quality. Check references and customer reviews, especially from buyers in your region (Africa, South America, Middle East, Europe). Utilize third-party inspection services for factory audits. Confirm compliance with international standards such as ISO or ASTM. Establish direct communication to gauge responsiveness and transparency. This due diligence reduces risks and ensures you partner with reliable manufacturers or distributors.

Is it possible to customize carborondum products to meet specific industrial requirements?

Yes, many suppliers offer customization options including particle size, purity, shape, and packaging tailored to industry needs. Discuss your technical specifications upfront and request a prototype or sample batch. Customization might affect lead times and minimum order quantities (MOQ), so clarify these aspects early. Working with suppliers experienced in your sector (e.g., abrasives, metallurgy) helps ensure the final product aligns perfectly with your application, enhancing performance and cost-efficiency.

What are typical minimum order quantities (MOQ), lead times, and payment terms for carborondum in international trade?

MOQs vary widely depending on supplier scale and product form but generally range from 500 kg to several tons. Lead times average 2 to 6 weeks, influenced by customization, production schedules, and shipping logistics. Common payment terms include 30-50% advance via T/T or L/C, with balance paid upon shipment or delivery. Negotiate terms that suit your cash flow and risk tolerance, and consider suppliers offering flexible arrangements or smaller trial orders to build trust.

Which quality assurance certifications should I look for when sourcing carborondum internationally?

Key certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and product-specific standards such as ASTM or JIS that verify material properties. Certifications from recognized bodies like SGS or TÜV add credibility. Request certificates of analysis (COA) and batch test reports to confirm consistency. Ensuring these certifications helps meet regulatory requirements in your country and guarantees a product that meets industrial-grade quality standards.

What logistics considerations are critical when importing carborondum from global suppliers?

Consider shipping mode (sea freight is common for bulk but slower; air freight is faster but costly). Confirm supplier packaging meets international shipping standards to prevent contamination or damage. Understand import duties, taxes, and customs clearance procedures specific to your country. Work with freight forwarders experienced in handling industrial minerals. Plan for warehousing and distribution upon arrival. Clear communication on Incoterms (e.g., FOB, CIF) helps allocate responsibilities and costs transparently.

How can disputes related to quality or delivery be effectively managed in international carborondum transactions?

Include detailed contract clauses specifying quality standards, inspection rights, and delivery schedules. Use third-party inspection agencies to verify shipments before dispatch. Establish clear communication channels and document all agreements. In case of disputes, seek amicable resolution through negotiation or mediation before legal action. Familiarize yourself with international trade laws and consider arbitration clauses under ICC or similar bodies to resolve conflicts efficiently while preserving business relationships.

Illustrative Image (Source: Google Search)

Are there regional considerations for sourcing carborondum from suppliers in Asia, Europe, or the Middle East?

Yes, regional factors such as production capacity, price competitiveness, and quality standards differ. Asian suppliers, particularly in China and India, often offer cost-effective bulk supplies but require careful quality vetting. European suppliers may provide higher quality with advanced certifications but at a premium price. Middle Eastern suppliers might offer strategic logistics advantages for Africa and Europe. Understanding these regional strengths and challenges helps optimize your sourcing strategy.

What are the best practices for ensuring sustainability and ethical sourcing in carborondum procurement?

Request supplier transparency on raw material sourcing and environmental impact. Prioritize suppliers with certifications like ISO 14001 or those committed to responsible mining practices. Verify labor conditions and compliance with international labor laws to avoid ethical risks. Incorporate sustainability criteria into supplier selection and audits. Demonstrating commitment to sustainable sourcing can enhance your brand reputation and meet increasing regulatory and customer demands for responsible supply chains.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of carborundum presents a unique opportunity for international B2B buyers to leverage a high-performance material essential in diverse industrial applications, from abrasives to semiconductors. Key takeaways include the importance of understanding supplier capabilities, regional supply chain dynamics, and the critical role of quality assurance. Buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with reliable manufacturers who can deliver consistent specifications and timely logistics, mitigating risks associated with market volatility and geopolitical factors.

Emphasizing strategic sourcing enables businesses to:

Looking ahead, the carborundum market is poised for growth driven by expanding industrial demand and technological advancements. International buyers are encouraged to deepen supplier engagement, invest in supply chain transparency, and explore emerging markets where new production capacities are developing. By adopting a proactive, informed sourcing strategy, businesses can secure competitive advantages and foster sustainable growth in an increasingly complex global marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina