Navigating the global market for carborundum prints presents significant challenges for international B2B buyers, particularly those sourcing materials from diverse regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for high-quality silicon carbide products, understanding the nuances of sourcing carborundum prints becomes crucial. This guide aims to provide a comprehensive overview of the types of carborundum materials available, their various applications across industries, and essential considerations for supplier vetting and cost analysis.

As businesses look to enhance their product offerings, they require reliable insights into the properties and uses of carborundum. From abrasives to refractory materials, the versatility of silicon carbide can meet a wide range of industrial needs. This guide empowers B2B buyers by equipping them with actionable information to make informed purchasing decisions, ensuring they can navigate the complexities of the market with confidence.

In the following sections, we will delve deeper into the characteristics of different carborundum types, explore their applications in various sectors, and provide key strategies for evaluating suppliers. By the end of this guide, you will be better prepared to source carborundum prints that align with your operational requirements and business goals, ultimately driving efficiency and innovation in your industry.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carborundum Etching | Utilizes a textured surface to create depth and detail. | Fine art prints, limited editions | Pros: Unique texture, high-quality finish. Cons: Labor-intensive, requires skilled artists. |

| Carborundum Relief | Features raised areas for a three-dimensional effect. | Art installations, decorative pieces | Pros: Eye-catching, adds dimension. Cons: More expensive due to complexity. |

| Carborundum Monotype | One-of-a-kind prints created using a single plate. | Custom art, promotional materials | Pros: Unique, versatile design options. Cons: Limited quantity, may not suit bulk orders. |

| Carborundum Collage | Combines different materials for mixed media effects. | Art exhibitions, corporate gifts | Pros: Innovative, customizable. Cons: Requires careful planning and execution. |

| Carborundum Lithography | Combines lithography techniques with carborundum for unique textures. | High-end prints, art books | Pros: High fidelity, detailed textures. Cons: Requires specialized equipment and expertise. |

Carborundum etching is distinguished by its textured surface, which allows for intricate designs and depth in prints. This technique is often employed in fine art prints and limited editions, making it appealing for galleries and collectors. When considering purchasing, B2B buyers should evaluate the artist's skill level, as the process is labor-intensive and requires expertise to achieve high-quality results.

Carborundum relief prints are characterized by their raised surfaces, creating a three-dimensional appearance. This form is particularly effective for art installations and decorative pieces, offering an eye-catching alternative to traditional prints. Buyers should assess the production costs and the potential for customization, as the intricate nature of relief printing can lead to higher prices.

The carborundum monotype technique produces one-of-a-kind prints using a single plate, allowing for exceptional creativity and versatility. This method is ideal for custom art and promotional materials, making it attractive for businesses looking for unique branding options. However, B2B buyers should be aware that the limited quantity of prints may not meet bulk order needs.

Carborundum collage incorporates various materials to create mixed media effects, resulting in innovative and customizable art pieces. This approach is suitable for art exhibitions and corporate gifts, appealing to businesses seeking distinctive promotional items. Buyers must consider the complexity of the project and the artist's ability to execute a cohesive design.

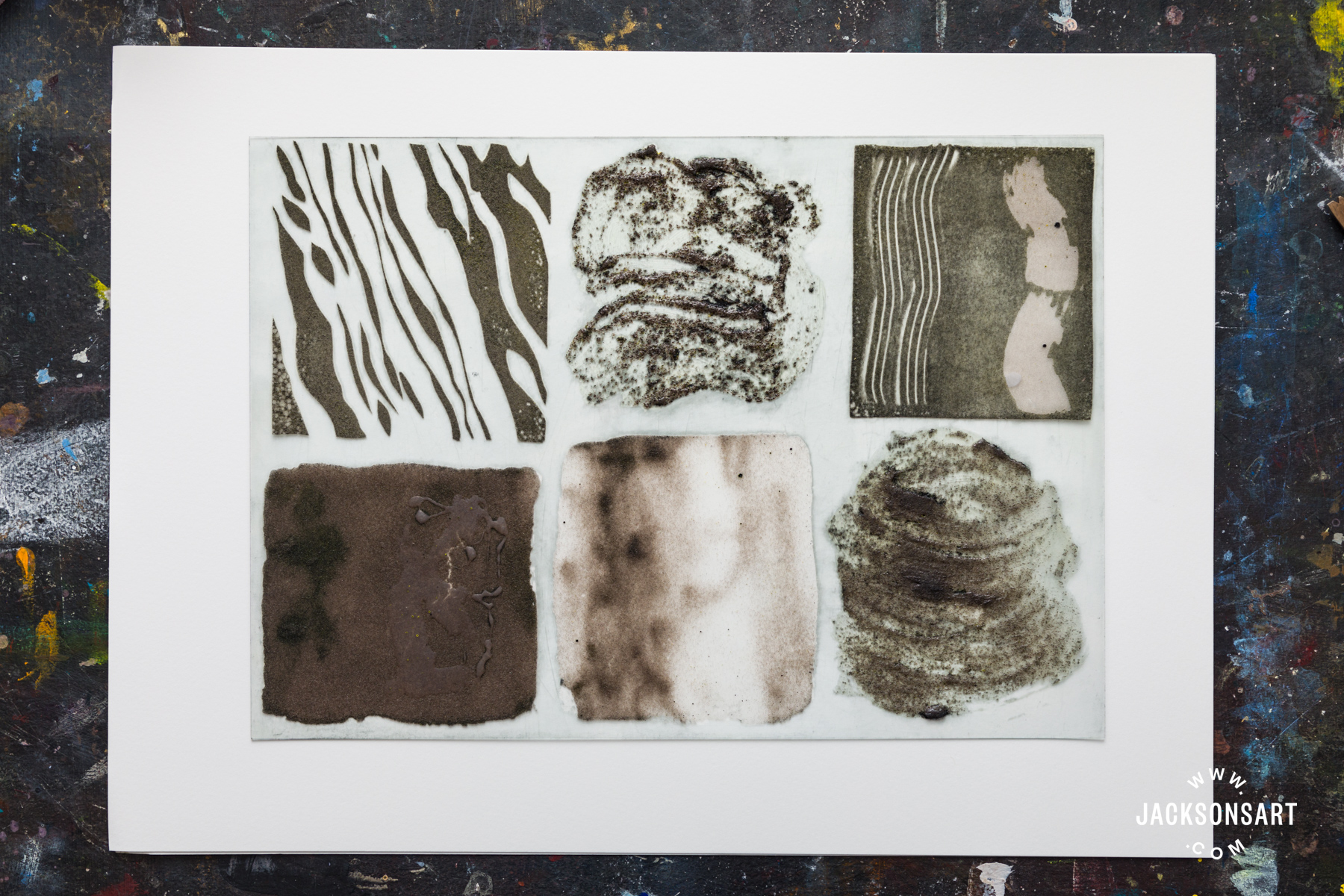

A stock image related to carborundum prints.

Carborundum lithography merges traditional lithographic techniques with carborundum, yielding unique textures and high-fidelity prints. This method is often used for high-end prints and art books, making it a valuable option for publishers and galleries. Buyers should factor in the need for specialized equipment and expertise when selecting this printing method, as it may impact production timelines and costs.

Related Video: Jeff Hirst-Carborundum Printing

| Industry/Sector | Specific Application of carborundum prints | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives | Manufacturing grinding wheels and sandpapers | Enhanced cutting efficiency and longer tool life | Ensure high purity and specific grain sizes for optimal performance. |

| Electronics | Production of semiconductors and power devices | Improved energy efficiency and thermal management | Look for suppliers with advanced manufacturing capabilities. |

| Automotive | Development of high-performance ceramic brake discs | Increased safety and performance in braking systems | Verify compliance with international automotive standards. |

| Refractory Materials | Lining of kilns and furnaces | Extended equipment lifespan and reduced downtime | Assess thermal resistance specifications and sourcing reliability. |

| Metallurgy | Use as a deoxidizing agent in metal processing | Enhanced metal quality and reduced impurities in products | Source from reputable suppliers with a proven track record in metallurgy. |

In the abrasives sector, carborundum prints are critical for manufacturing grinding wheels and sandpapers. Their exceptional hardness allows them to cut, shape, and finish a variety of materials, including metals and ceramics. For international buyers, particularly from regions like Africa and South America, sourcing high-purity carborundum is essential to ensure optimal performance. Buyers should prioritize suppliers that offer specific grain sizes tailored to their applications, as this can significantly impact the efficiency and longevity of the abrasive tools.

Carborundum prints are increasingly used in the electronics industry, particularly in the production of semiconductors and power devices. The material's excellent thermal conductivity and electrical properties enhance energy efficiency and thermal management in electronic components. International B2B buyers, especially from Europe and the Middle East, should seek suppliers who utilize advanced manufacturing techniques to ensure high-quality products. Compliance with international standards is crucial to guarantee that components meet performance and safety requirements.

In the automotive industry, carborundum prints are utilized to develop high-performance ceramic brake discs. These components provide superior braking performance, durability, and resistance to wear, significantly enhancing vehicle safety. For buyers in regions like the UAE and Thailand, it is vital to verify that suppliers comply with international automotive standards to ensure the reliability and safety of their products. Additionally, sourcing from manufacturers with a strong reputation can help mitigate risks associated with product quality.

A stock image related to carborundum prints.

Carborundum prints are essential in the production of refractory materials used for lining kilns and furnaces. Their ability to withstand high temperatures and resist wear leads to extended equipment lifespan and reduced downtime in industrial processes. Buyers from Africa and South America should assess the thermal resistance specifications of carborundum products and consider the reliability of sourcing options to ensure consistent performance in high-temperature applications.

In metallurgy, carborundum prints serve as an effective deoxidizing agent, helping to remove oxygen impurities from molten metals. This results in improved metal quality, strength, and ductility. International B2B buyers, particularly those in Europe and the Middle East, should prioritize sourcing from reputable suppliers with a proven track record in metallurgy. Ensuring that the carborundum used meets specific quality standards can lead to significant improvements in the overall quality of the final metal products.

Related Video: Akua Carborundum Gel with Wax Mediums

The Problem: B2B buyers in manufacturing industries often face challenges with the wear rate of cutting tools and abrasives that utilize carborundum prints. For instance, in metalworking, tools may degrade rapidly, leading to increased downtime and production costs. This issue is especially pronounced in high-volume operations where consistent tool performance is crucial for maintaining productivity and quality.

The Solution: To combat high wear rates, buyers should focus on sourcing high-quality silicon carbide (SiC) carborundum prints tailored for their specific applications. It’s essential to consult with suppliers about the material grades and specifications that best match the operational environment. Additionally, implementing a regular maintenance schedule can help identify wear patterns early, allowing for timely replacements. Using advanced monitoring systems to track tool performance can further enhance longevity, ensuring that the tools remain efficient for longer periods.

The Problem: Buyers often struggle to find reliable suppliers who provide consistent quality and timely delivery of carborundum prints. In regions such as Africa and South America, the supply chain can be unpredictable, leading to delays that can halt production lines and negatively impact project timelines. This inconsistency in supply can also result in mismatched product specifications, which can compromise the quality of end products.

The Solution: To ensure a steady supply of quality carborundum prints, B2B buyers should establish relationships with multiple suppliers across different regions. Conducting thorough due diligence on potential suppliers, including reviewing their production capabilities and quality control processes, is crucial. Additionally, consider leveraging local trade shows and industry networks to connect with suppliers who have a proven track record. Negotiating long-term contracts with preferred suppliers can also provide stability and ensure priority during high-demand periods.

The Problem: Many B2B buyers are unaware of the full range of applications and benefits of carborundum prints, leading to underutilization of this versatile material. This lack of knowledge can result in missed opportunities for improving operational efficiency and product quality, particularly in industries like automotive and electronics where precision is critical.

The Solution: Buyers should invest time in training and education regarding carborundum prints and their diverse applications. Engaging with industry experts, attending workshops, and accessing online resources can provide valuable insights into optimizing the use of carborundum in various processes. Moreover, collaborating with suppliers who offer technical support and application advice can help buyers implement best practices. By understanding how to leverage carborundum prints effectively, companies can enhance product performance and gain a competitive edge in their respective markets.

By addressing these pain points with actionable strategies, B2B buyers can significantly improve their sourcing, application, and utilization of carborundum prints, leading to enhanced productivity and reduced operational costs.

When selecting materials for carborundum prints, international B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below, we analyze several common materials used in carborundum prints, focusing on their properties, advantages, disadvantages, and implications for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

Silicon carbide (SiC) is the most widely used material in carborundum prints due to its exceptional hardness and thermal conductivity. It can withstand high temperatures (up to 1,600°C) and has excellent corrosion resistance, making it suitable for harsh environments. SiC is also chemically inert, which enhances its durability in various applications.

Pros and Cons

The primary advantage of SiC is its durability, which leads to longer service life and reduced maintenance costs. However, it can be relatively expensive compared to other materials, and its manufacturing process can be complex, requiring advanced technology.

Impact on Application

SiC is compatible with various media, including metals and ceramics, making it versatile for different printing applications. Its high thermal stability ensures that it maintains performance under extreme conditions.

Considerations for International Buyers

Buyers should ensure compliance with international standards such as ASTM and DIN, especially when sourcing from different regions. Understanding local regulations regarding material safety and environmental impact is crucial for successful procurement.

Boron carbide (B4C) is another high-performance material known for its outstanding hardness and wear resistance. It can operate effectively at temperatures up to 2,500°C and is often used in applications requiring high strength and durability.

Pros and Cons

The key advantage of B4C is its superior hardness, making it ideal for abrasive applications. However, its high cost and the complexity of its manufacturing process can be limiting factors for some buyers.

Impact on Application

B4C is particularly effective in high-stress environments, such as military applications and advanced ceramics. Its compatibility with various substrates enhances its utility in specialized printing scenarios.

Considerations for International Buyers

For B4C, compliance with military and industrial standards is essential, particularly in regions like the Middle East where defense applications are prevalent. Buyers should also consider the availability of B4C in their local markets, as it may be less commonly produced than SiC.

Tungsten carbide (WC), while not a traditional form of carborundum, shares many properties with silicon carbide and boron carbide. It is renowned for its hardness and wear resistance, making it suitable for cutting and drilling applications.

Pros and Cons

The main advantage of WC is its exceptional toughness and durability, which can significantly enhance the lifespan of printed products. However, its high cost and the challenges associated with its machining can be drawbacks.

Impact on Application

WC is particularly effective in applications requiring high precision and durability, such as in the automotive and aerospace industries. Its ability to withstand high pressures makes it suitable for demanding environments.

Considerations for International Buyers

Buyers in Europe and South America should be aware of the specific standards applicable to WC products, including those related to safety and environmental impact. Understanding the supply chain dynamics for WC is also critical, as sourcing may vary significantly by region.

| Material | Typical Use Case for carborundum prints | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Abrasives, cutting tools, and electronics | Exceptional hardness and thermal conductivity | High cost and complex manufacturing | High |

| Boron Carbide (B4C) | Military applications, advanced ceramics | Superior hardness and wear resistance | Very high cost and manufacturing complexity | High |

| Tungsten Carbide (WC) | Cutting tools, drilling equipment | Exceptional toughness and durability | High cost and machining challenges | High |

In conclusion, selecting the right material for carborundum prints involves careful consideration of properties, advantages, disadvantages, and regional compliance. By understanding these factors, international B2B buyers can make informed decisions that align with their operational needs and market conditions.

The manufacturing of carborundum prints involves several critical stages that ensure the final product meets the high standards required for various applications. Understanding these processes can help B2B buyers make informed decisions when sourcing from suppliers.

The first step in the manufacturing process is material preparation. This involves selecting high-purity silicon carbide (SiC) as the primary raw material. The SiC is typically processed into specific grain sizes and forms, depending on the intended application of the carborundum print.

The preparation stage often includes:

Once the materials are prepared, the next stage is forming. This can be accomplished through various methods, depending on the desired characteristics of the final product.

After forming, the assembly and finishing stages are critical for achieving the final product's specifications.

Quality assurance (QA) is paramount in the manufacturing of carborundum prints, particularly for B2B buyers who depend on consistent quality.

Manufacturers typically adhere to international standards to ensure product quality and consistency. The most relevant standards include:

Quality control in carborundum print manufacturing involves several key checkpoints throughout the production process, including:

To verify the quality of carborundum prints, manufacturers employ various testing methods, including:

For international B2B buyers, verifying the quality control processes of suppliers is crucial to ensure product reliability. Here are several strategies:

B2B buyers from Africa, South America, the Middle East, and Europe must be aware of the nuances in quality control and certification when sourcing carborundum prints. Key considerations include:

An in-depth understanding of the manufacturing processes and quality assurance measures for carborundum prints is essential for international B2B buyers. By focusing on material preparation, forming techniques, assembly, and stringent quality control measures, buyers can ensure they select reliable suppliers that meet their specific needs. Additionally, being aware of international standards and verification methods can enhance the procurement process, ensuring high-quality products that meet industry demands.

This guide is designed to assist international B2B buyers in effectively sourcing carborundum prints, ensuring that your procurement process is streamlined and efficient. Carborundum prints, known for their unique texture and durability, are increasingly popular in various industries. Follow these steps to make informed decisions and secure high-quality products.

Start by clearly outlining the technical requirements for your carborundum prints. Consider factors such as size, texture, and desired finish. This step is crucial as it helps you communicate your needs effectively to suppliers, ensuring they can meet your specific requirements.

Conduct thorough research to identify potential suppliers who specialize in carborundum prints. Look for companies with a proven track record and positive customer feedback. This step is vital to ensure you partner with reputable suppliers who can deliver quality products consistently.

Before making a commitment, verify the certifications and standards that suppliers adhere to. Certifications such as ISO 9001 can indicate a commitment to quality management practices. This ensures that you are sourcing from suppliers who prioritize quality and compliance.

Always request samples of the carborundum prints before placing a large order. This allows you to assess the quality, texture, and overall appearance of the prints. Evaluating samples helps you avoid costly mistakes and ensures the product meets your expectations.

Once you've selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Establishing clear terms upfront can prevent misunderstandings and ensure a smooth transaction process.

Finalize the logistics involved in shipping the carborundum prints to your location. Understanding the delivery timeline and shipping costs is essential for planning your inventory and project timelines.

After successfully sourcing your carborundum prints, consider establishing a long-term relationship with your supplier. Regular collaboration can lead to better pricing, priority service, and customized solutions that cater to your evolving needs.

By following this checklist, you can effectively navigate the complexities of sourcing carborundum prints, ensuring that you make informed decisions that benefit your business.

When sourcing carborundum prints, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Materials: The cost of raw materials, primarily silicon carbide, boron carbide, or tungsten carbide, is significant. Prices fluctuate based on global supply and demand dynamics. Buyers should consider sourcing materials from regions with stable prices to mitigate risks.

Labor: Labor costs can vary widely depending on the region of production. For instance, labor costs in Europe may be higher compared to South America or Africa. It's important to evaluate the skill level required for production, as specialized labor may increase costs.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. High overheads can result from inefficient processes or outdated machinery. Buyers should assess suppliers' manufacturing capabilities to ensure cost-effectiveness.

Tooling: Investment in tooling and molds is crucial for custom carborundum prints. This upfront cost can be substantial but is necessary for achieving the desired quality and specifications. Buyers should inquire about tooling costs upfront, especially for large orders.

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to costs but is vital for maintaining standards. Suppliers that prioritize QC may charge higher prices, but the long-term benefits often outweigh these initial expenses.

Logistics: Shipping and handling costs are critical, particularly for international transactions. Factors such as distance, shipping method, and customs duties can significantly affect total costs. Buyers should consider local suppliers to reduce logistics expenses.

Margin: The supplier's profit margin is an essential component of pricing. A higher margin may reflect superior quality or service, but buyers should ensure they are receiving value for the additional cost.

Various factors influence the pricing of carborundum prints, including:

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Understanding the MOQ can help buyers negotiate better terms and reduce per-unit costs.

Specifications and Customization: Customized prints that require specific dimensions or properties can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials and Quality Certifications: The choice of materials and adherence to quality certifications (such as ISO standards) can impact pricing. Buyers should assess whether they need standard or premium materials based on their application.

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers with a track record may charge more due to their experience and quality assurance.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears shipping costs and risks. Buyers should clarify terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to avoid unforeseen costs.

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

Leverage Volume Discounts: When feasible, consolidate orders to meet MOQs and negotiate bulk pricing. Suppliers are often willing to provide better rates for larger purchases.

Assess Total Cost of Ownership (TCO): Look beyond initial pricing. Consider long-term costs, including maintenance, efficiency, and potential downtime. A higher upfront cost may result in lower TCO over time.

Research Supplier Backgrounds: Conduct thorough research on potential suppliers, including their financial stability, production capabilities, and customer reviews. A reliable supplier can save costs related to defects and delays.

Negotiate Payment Terms: Flexible payment terms can improve cash flow and reduce financial strain. Discuss options such as extended payment periods or installment plans.

Understand Pricing Nuances for International Transactions: Be aware of potential tariffs, currency fluctuations, and import duties that may affect the final cost. Work with suppliers who are transparent about these factors.

Pricing for carborundum prints can vary widely based on the aforementioned factors and market conditions. Buyers are encouraged to request detailed quotes from multiple suppliers to ensure competitive pricing and to factor in all potential costs associated with sourcing.

When considering the use of carborundum prints for various industrial applications, it's essential to evaluate viable alternatives. This comparative analysis helps B2B buyers make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Carborundum Prints | Diamond Coated Tools | Ceramic-Based Solutions |

|---|---|---|---|

| Performance | High hardness, excellent wear resistance | Superior edge retention, high precision | Good thermal stability, moderate wear resistance |

| Cost | Moderate, depending on application | High initial investment | Generally lower cost |

| Ease of Implementation | Requires specialized equipment | Easy to integrate with existing systems | Simple application processes |

| Maintenance | Low maintenance, durable | Moderate, may require re-coating | Low maintenance, long lifespan |

| Best Use Case | Abrasives, cutting tools in heavy industries | Precision machining, high-end applications | General purpose, lower-stress applications |

Diamond coated tools are renowned for their superior performance, particularly in precision machining and high-end applications. The primary advantage is their exceptional edge retention, which allows for longer intervals between tool changes, significantly reducing downtime. However, the high initial investment can be a barrier for many businesses, particularly in regions where budgets are constrained. Additionally, while these tools are easy to integrate into existing systems, they may require periodic re-coating, which can add to the overall maintenance costs.

Ceramic-based solutions are often favored for their good thermal stability and lower cost compared to carborundum prints. They are suitable for general-purpose applications where extreme wear resistance is not critical. The ease of application makes them an attractive option for companies looking for quick implementation. However, they do not offer the same level of wear resistance as carborundum, which could lead to more frequent replacements in high-stress environments.

When selecting between carborundum prints and alternative solutions like diamond-coated tools or ceramic-based materials, B2B buyers should assess their specific operational needs. Considerations should include the performance requirements, budget constraints, and the nature of the applications involved. For high-performance needs in precision machining, diamond-coated tools may be ideal despite their cost. In contrast, carborundum prints offer a balanced approach for heavy-duty applications. Meanwhile, ceramic-based solutions could serve well for businesses focused on cost-effectiveness and general applications. By aligning these factors with organizational goals, buyers can make a choice that enhances productivity and minimizes costs in the long run.

When sourcing carborundum prints, understanding the essential technical properties and trade terminology is crucial for making informed decisions. This section outlines key specifications and industry jargon that can significantly impact the procurement process for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Material grade refers to the specific classification of carborundum based on its purity and crystalline structure. Higher grades indicate better performance characteristics such as hardness and thermal conductivity. For B2B buyers, selecting the appropriate material grade is vital as it directly influences the product's application and longevity in demanding environments.

Tolerance defines the permissible limits of variation in the dimensions and physical properties of carborundum prints. Tight tolerances are essential for applications requiring precision, such as in aerospace or automotive components. Understanding the tolerance levels helps buyers ensure that the products meet their specific engineering requirements, reducing the risk of costly rework or failures.

Abrasive hardness is a measure of a material's ability to resist wear and abrasion. In carborundum prints, this property is particularly important for applications in manufacturing and machining. Buyers should assess abrasive hardness to ensure that the prints will withstand the operational demands of their applications, thereby extending service life and reducing replacement costs.

Thermal conductivity indicates how well a material can conduct heat. Carborundum prints with high thermal conductivity are essential in applications that involve high temperatures, such as in electronics and refractory materials. B2B buyers must consider thermal conductivity to ensure efficient thermal management in their processes.

Chemical resistance reflects the ability of carborundum prints to withstand corrosive substances. This property is crucial in industries such as chemical processing and pharmaceuticals, where exposure to aggressive chemicals is common. Selecting carborundum prints with high chemical resistance can prevent material degradation and enhance product reliability.

OEM refers to companies that produce parts or equipment that are sold under another company's brand name. Understanding the OEM status of carborundum print suppliers can help buyers assess the quality and reliability of the products, ensuring they meet industry standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, being aware of MOQ is essential for budgeting and inventory management. Suppliers may impose MOQs to ensure cost-effectiveness, so negotiating favorable terms can lead to better pricing structures.

An RFQ is a document sent by buyers to suppliers to solicit price quotes for specific products. Providing detailed specifications in an RFQ can lead to more accurate quotes and better alignment with the buyer's needs. This process is critical for establishing clear expectations and fostering competitive pricing.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, insurance, and risk, thereby facilitating smoother international trade operations.

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for B2B buyers to plan their production schedules and manage inventory effectively. Knowing the lead time can also assist in mitigating potential delays in supply chains.

In conclusion, a solid grasp of both the technical properties and trade terminology associated with carborundum prints enables international B2B buyers to make informed purchasing decisions, optimize their supply chains, and enhance product performance in their respective industries.

The carborundum prints market is experiencing significant growth driven by several global factors. The increasing demand for high-performance materials in industries such as aerospace, automotive, and electronics is a primary driver. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek durable and efficient solutions, carborundum prints, known for their hardness and thermal stability, are gaining traction.

Emerging technologies such as 3D printing and advanced manufacturing techniques are reshaping sourcing trends. Buyers are increasingly interested in suppliers who can provide customized carborundum products tailored to specific applications. Additionally, digital platforms and online marketplaces are becoming vital for sourcing these materials, allowing buyers to easily compare prices and product specifications across suppliers globally.

Market dynamics are also influenced by geopolitical factors. Tariffs, trade agreements, and regional supply chain disruptions can significantly affect sourcing strategies. B2B buyers must stay informed about these changes to mitigate risks associated with their procurement processes. For example, the recent emphasis on local sourcing in Europe has led many businesses to seek regional suppliers, reducing dependence on long-distance shipping and potential delays.

Sustainability is becoming a crucial consideration for B2B buyers in the carborundum prints sector. The environmental impact of production processes and the sourcing of raw materials are increasingly under scrutiny. Buyers are now prioritizing suppliers that adopt sustainable practices, including the reduction of carbon footprints and waste management strategies.

Ethical sourcing is also essential. Ensuring that the materials used in carborundum prints are sourced from responsible suppliers not only enhances a company’s reputation but also aligns with global sustainability goals. Certifications such as ISO 14001 for environmental management systems and the use of 'green' materials can serve as indicators of a supplier's commitment to sustainability.

B2B buyers should actively seek suppliers who demonstrate transparency in their supply chains, as this fosters trust and long-term partnerships. Engaging with suppliers who invest in sustainable technologies can also provide a competitive edge, as the market increasingly favors products that are environmentally friendly.

Carborundum, or silicon carbide, was first synthesized in 1891 by Edward Goodrich Acheson, who aimed to create artificial diamonds. This accidental discovery marked the beginning of a material that would revolutionize various industries due to its unique properties, including exceptional hardness and thermal stability.

Initially used primarily in abrasives, the applications of carborundum have expanded significantly over the decades. Today, it plays a critical role in sectors such as electronics, automotive, and metallurgy, where its ability to withstand high temperatures and resist wear makes it an invaluable resource. As the technology and demand for high-performance materials continue to evolve, understanding the historical context of carborundum can provide B2B buyers with insights into its potential future applications and innovations.

Navigating the carborundum prints market requires an understanding of the key trends, sustainability considerations, and the material's historical context. By staying informed and strategically aligning sourcing practices with these insights, international B2B buyers can effectively enhance their procurement strategies and build resilient supply chains.

How do I ensure the quality of carborundum prints when sourcing internationally?

To ensure quality, it’s crucial to conduct thorough supplier vetting. Start by reviewing certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to assess the material’s hardness, finish, and durability. Additionally, consider third-party inspections at the manufacturing site, especially for large orders, to verify compliance with your specifications. Establishing clear quality assurance protocols in your contract can further safeguard against inconsistencies.

What is the best type of carborundum print for abrasive applications?

For abrasive applications, silicon carbide (SiC) carborundum prints are typically the most effective choice due to their exceptional hardness and wear resistance. SiC excels in various abrasive uses, such as grinding wheels and sandpapers. It's essential to consider the specific application requirements, such as the substrate material and operating conditions, to ensure optimal performance. Consulting with suppliers about the specific type of SiC that suits your needs can also enhance results.

What are the common minimum order quantities (MOQ) for carborundum prints?

Minimum order quantities for carborundum prints can vary significantly based on the supplier and the complexity of the product. Typically, MOQs range from 100 to 1,000 units. For customized prints, suppliers may set higher MOQs due to setup costs. Before placing an order, inquire about volume discounts and flexibility in MOQs, especially if you are testing a new product line or entering a new market.

What payment terms should I expect when buying carborundum prints from international suppliers?

Payment terms can vary widely among suppliers. Common practices include a 30% deposit upfront with the balance due upon delivery or a letter of credit for larger orders. It’s advisable to negotiate terms that reflect your cash flow needs while ensuring security for both parties. Always request detailed invoices and confirm the total cost, including shipping and potential tariffs, to avoid unexpected expenses.

How can I customize carborundum prints to meet my specific requirements?

Customization options for carborundum prints often include variations in grain size, color, and formulation to suit specific applications. When discussing customization with suppliers, provide clear specifications and examples of your desired outcomes. It's also beneficial to establish a collaborative relationship with your supplier, allowing for adjustments based on trial feedback. Ensure that you understand any additional costs or changes to the MOQ that may arise from customization requests.

What logistics considerations should I keep in mind when importing carborundum prints?

Logistics play a crucial role in the importation of carborundum prints. Consider the shipping method (air or sea), as this will affect delivery time and cost. Ensure that your supplier can provide the necessary documentation for customs clearance, including bills of lading and certificates of origin. Working with a freight forwarder experienced in handling industrial materials can streamline the process and mitigate delays. Lastly, factor in storage solutions upon arrival, especially if you anticipate delays in distribution.

What are the most common applications for carborundum prints in various industries?

Carborundum prints find applications across multiple sectors, including automotive, electronics, and construction. In the automotive industry, they are used for high-performance braking systems due to their durability. In electronics, carborundum is crucial for semiconductors and power devices. Understanding the specific applications relevant to your industry can guide your purchasing decisions and help you identify potential markets for resale or further distribution.

How do I assess the reliability of a supplier for carborundum prints?

To assess a supplier's reliability, start by checking their industry reputation through online reviews and testimonials. Request references from previous clients, particularly those in your region or industry, to gauge satisfaction levels. Additionally, investigate their manufacturing capabilities and lead times. A supplier's responsiveness to inquiries and transparency regarding production processes also indicate reliability. Establishing a trial order can further help evaluate their performance before committing to larger purchases.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of carborundum prints presents a unique opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. The exceptional properties of carborundum, including its hardness, thermal conductivity, and chemical resistance, make it an invaluable asset in various applications, from abrasives to electronics. By leveraging strategic sourcing, businesses can not only reduce costs but also enhance product quality and performance.

Understanding the nuances of carborundum types—such as silicon carbide, boron carbide, and tungsten carbide—allows buyers to make informed decisions that align with their specific operational needs. As industries evolve and demand for high-performance materials grows, the importance of building strong supplier relationships cannot be overstated.

Looking ahead, international buyers are encouraged to actively engage with suppliers and stay abreast of technological advancements in carborundum applications. This proactive approach will ensure that businesses remain competitive in a rapidly changing market landscape. Seize the opportunity to elevate your procurement strategies and unlock the full potential of carborundum prints for your operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina