Carborundum stone for grinders is a cornerstone material in industrial grinding applications, prized for its exceptional hardness, durability, and precision. For B2B buyers operating across Africa, South America, the Middle East, and Europe, sourcing high-quality carborundum stones is critical to ensuring operational efficiency, product consistency, and competitive advantage in manufacturing processes. Whether your business is in Colombia’s burgeoning manufacturing sector or Indonesia’s expanding industrial base, understanding the nuances of this abrasive material can significantly impact your supply chain and production outcomes.

This guide offers a thorough exploration of the global carborundum stone market, designed to empower international buyers with actionable insights. You will find detailed analyses of various stone types and their material compositions, enabling you to match the right product to your specific grinding requirements. Additionally, the guide covers manufacturing processes and stringent quality control standards that distinguish reliable suppliers, helping you mitigate risks associated with subpar materials.

Key sections include:

- Material characteristics and types: Understanding grades and performance parameters

- Manufacturing & quality assurance: How production methods affect stone durability

- Supplier landscape: Evaluations of global and regional producers and exporters

- Pricing structures: Factors influencing cost and how to negotiate effectively

- Market trends: Demand drivers and emerging opportunities in targeted regions

- Frequently Asked Questions: Clarifying common concerns and technical queries

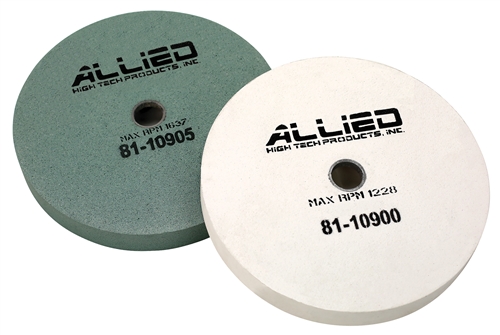

Illustrative Image (Source: Google Search)

By leveraging the insights presented, international buyers can make well-informed sourcing decisions, optimize procurement strategies, and build resilient supplier relationships tailored to the unique demands of their local markets. This comprehensive resource is your strategic partner in navigating the complexities of the global carborundum stone supply chain.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Grit Carborundum | Medium grit size, balanced hardness and durability | General grinding and sharpening in metalworking | + Versatile, cost-effective – Not ideal for precision work |

| Fine Grit Carborundum | Smaller grit size, smoother finish | Precision grinding, finishing of delicate parts | + High precision, smooth finish – Slower material removal |

| Coarse Grit Carborundum | Larger grit size, aggressive material removal | Heavy-duty grinding, rapid stock removal | + Fast grinding, durable – Rough finish, higher wear |

| Resin Bonded Carborundum | Resin binder for flexibility and shock resistance | Woodworking, soft metal grinding | + Flexible, less brittle – Lower heat resistance |

| Vitrified Bonded Stone | Ceramic bonding, high heat and wear resistance | High-precision grinding, tool sharpening | + Long-lasting, precise – Higher cost, brittle |

Standard Grit Carborundum

This type features a medium grit size that offers a balance between grinding speed and surface finish quality. It is the most commonly used variant, suitable for general-purpose grinding tasks in metalworking industries. For B2B buyers, this type represents a cost-effective choice with reliable performance, especially for operations requiring moderate precision without specialized demands. When sourcing, consider grit consistency and bonding quality to ensure longevity and uniform wear.

Fine Grit Carborundum

Fine grit stones provide a smoother finish and are ideal for precision grinding tasks where surface quality is critical, such as in aerospace component manufacturing or fine tool sharpening. These stones remove less material per pass but improve dimensional accuracy. Buyers focused on high-precision applications should prioritize suppliers offering consistent fine grit sizes and high-quality bonding to avoid premature wear and ensure uniformity.

Coarse Grit Carborundum

Designed for heavy-duty grinding, coarse grit carborundum stones enable rapid material removal, making them suitable for rough shaping and stock removal in foundries and construction tool manufacturing. Their aggressive cutting action speeds up workflows but can leave rough surfaces requiring secondary finishing. B2B buyers should assess grit size uniformity and stone hardness to balance removal rate with durability.

Resin Bonded Carborundum

These stones use a resin binder that imparts flexibility and shock resistance, making them well-suited for softer materials like wood and non-ferrous metals. They offer reduced brittleness compared to vitrified stones, lowering the risk of cracking under impact. Buyers in woodworking or light metal fabrication sectors should evaluate resin quality and bonding strength to optimize stone lifespan and performance under varying operational conditions.

Vitrified Bonded Stone

Vitrified bonding involves ceramic materials that provide excellent heat resistance and structural integrity, ideal for high-precision grinding and tool sharpening where consistent shape retention is crucial. Although more expensive and brittle, these stones deliver superior performance in demanding industrial environments. B2B purchasers should weigh the higher upfront cost against long-term benefits like reduced downtime and improved finishing quality.

Related Video: How to use a Carb Stone

| Industry/Sector | Specific Application of carborundum stone for grinder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Precision grinding of steel and iron components | Enhances surface finish quality, increases tool life, reduces rework costs | Consistent grit size, durability under high heat, supplier reliability |

| Automotive Manufacturing | Sharpening and finishing of engine parts and chassis components | Improves component performance and lifespan, ensures compliance with industry standards | Customizable stone shapes, abrasion resistance, compliance with export regulations |

| Construction & Mining | Grinding and shaping of hard materials like concrete and stone blocks | Increases operational efficiency, reduces downtime, supports heavy-duty usage | High wear resistance, availability of bulk orders, logistical support for heavy shipments |

| Aerospace | Fine grinding of turbine blades and aerospace alloys | Achieves tight tolerances and smooth finishes critical for safety and performance | Precision manufacturing standards, traceability, certifications (ISO, aerospace) |

| Tool & Die Making | Surface finishing and sharpening of cutting tools and dies | Extends tool life, improves cutting accuracy, reduces replacement frequency | Variety in grit grades, consistent hardness, supplier technical support |

Carborundum stones are essential in metal fabrication for grinding steel and iron parts to precise dimensions and smooth finishes. They address challenges such as surface imperfections and inconsistent finishes that can compromise assembly quality. For international buyers, especially in Africa and South America, sourcing stones with consistent grit size and high thermal resistance is crucial to withstand continuous grinding operations without degradation. Reliable supply chains and quality certifications help ensure production continuity and reduce costly downtime.

In automotive manufacturing, carborundum stones are utilized for sharpening engine components and finishing chassis parts to exact specifications. This application demands stones that maintain abrasion resistance under high-speed operations to enhance component durability and performance. Buyers in the Middle East and Europe should prioritize suppliers who can offer customizable shapes and sizes, along with compliance to export and safety standards, ensuring the grinding stones meet stringent automotive industry requirements.

The construction and mining sectors use carborundum stones for grinding and shaping hard materials like concrete and natural stone blocks. These stones must exhibit exceptional wear resistance to handle abrasive materials and heavy usage. For B2B buyers in regions like Indonesia and Colombia, sourcing bulk quantities with assured quality and reliable logistics is vital to maintain uninterrupted operations in remote or infrastructure-challenged areas, reducing operational downtime and costs.

In aerospace manufacturing, carborundum stones are employed for fine grinding of turbine blades and high-performance alloys, where precision and surface finish directly affect safety and efficiency. Buyers from Europe and the Middle East must ensure stones meet stringent aerospace quality standards, including traceability and ISO certifications. The ability to source stones with exacting manufacturing tolerances supports production of components that comply with international aerospace regulations.

Tool and die makers rely on carborundum stones for sharpening cutting tools and finishing dies to achieve high precision and extended tool life. This reduces tool replacement frequency and improves machining accuracy. International buyers should focus on suppliers offering a wide range of grit grades and consistent hardness levels, alongside technical support to optimize grinding processes. This is particularly important for markets in Africa and South America, where maximizing tool efficiency directly impacts production costs.

Key Properties: Silicon carbide is the primary material for carborundum stones, known for its exceptional hardness, high thermal conductivity, and excellent wear resistance. It withstands high temperatures (up to 1600°C) and maintains structural integrity under significant pressure. Its chemical inertness offers good corrosion resistance against most acids and alkalis.

Pros & Cons: Silicon carbide stones deliver outstanding durability and grinding efficiency, making them ideal for heavy-duty applications. However, manufacturing these stones requires precise sintering processes, which can increase production costs. They are relatively brittle, so impact resistance is moderate. The high hardness ensures long service life but can be costlier than other materials.

Impact on Application: Silicon carbide stones are versatile, compatible with a wide range of metals and alloys, and effective for grinding ferrous and non-ferrous materials. Their thermal stability makes them suitable for high-speed grinding operations without rapid wear or deformation.

International B2B Considerations: Buyers in Africa, South America, the Middle East, and Europe should verify compliance with ASTM B911 or DIN 6871 standards, which specify silicon carbide abrasives' quality. In regions like Colombia and Indonesia, sourcing from suppliers with recognized certifications ensures product consistency and performance. Import regulations often require detailed material certifications, so partnering with manufacturers who provide traceable quality documentation is critical.

Key Properties: Aluminum oxide offers good hardness and toughness, with excellent resistance to heat and chemical attack. It can operate effectively at temperatures up to 1200°C and exhibits moderate corrosion resistance. Alumina is less brittle than silicon carbide, providing better impact resistance.

Pros & Cons: Alumina stones are generally more affordable and easier to manufacture than silicon carbide, offering a good balance of performance and cost. However, they have slightly lower hardness, which can lead to faster wear when grinding very hard materials. Their toughness makes them suitable for applications requiring some flexibility.

Impact on Application: Ideal for grinding steels and other ferrous metals, alumina stones are preferred where moderate grinding speeds and pressures are used. They perform well in wet and dry grinding but may not be optimal for non-ferrous metals or very hard alloys.

International B2B Considerations: Compliance with ISO 8486 or JIS R6001 standards is common for alumina abrasives in Europe and Asia. Buyers in the Middle East and South America should consider regional preferences for alumina grades and ensure suppliers meet local import quality requirements. Alumina’s lower cost and ease of sourcing make it attractive for large-volume procurement in emerging markets.

Key Properties: Boron carbide is one of the hardest materials available, with exceptional wear resistance and a high melting point (~2763°C). It exhibits excellent chemical inertness and can withstand aggressive environments, including acidic and alkaline media.

Pros & Cons: While boron carbide stones offer superior durability and longevity, their high manufacturing complexity and raw material cost make them significantly more expensive. They are extremely brittle, requiring careful handling and specialized bonding techniques during production.

Impact on Application: Best suited for precision grinding of extremely hard materials, including ceramics and hardened steels. Boron carbide stones excel in high-pressure, high-temperature environments but are less common for general-purpose grinding due to cost.

International B2B Considerations: Given the premium nature of boron carbide stones, buyers in Europe and the Middle East often demand compliance with stringent quality standards like ASTM C799. For African and South American markets, cost-benefit analysis is crucial, as the upfront investment may be justified only for specialized industrial applications. Suppliers should provide detailed technical datasheets and certification to facilitate import clearance and quality assurance.

Key Properties: Synthetic diamond stones feature unmatched hardness and thermal conductivity, withstanding extreme temperatures and pressures. They resist chemical corrosion and maintain sharp cutting edges for prolonged periods.

Pros & Cons: PCD stones provide the highest grinding precision and longest lifespan but come at a premium price and require advanced manufacturing capabilities. They are less tolerant of impact shocks and need careful mounting to avoid chipping.

Impact on Application: Ideal for grinding very hard, abrasive materials such as carbides, composites, and advanced alloys. They are widely used in aerospace, automotive, and tooling industries where precision and surface finish are critical.

International B2B Considerations: European and Middle Eastern buyers often require compliance with ISO 9001 and ISO 14001 standards for environmental and quality management in diamond stone production. In Africa and South America, the high cost limits use to niche applications, but availability of certified suppliers with robust after-sales support is a key purchasing factor. Import duties and intellectual property rights for synthetic diamond technologies should be carefully reviewed.

| Material | Typical Use Case for carborundum stone for grinder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Heavy-duty grinding of ferrous and non-ferrous metals | High hardness and thermal stability | Moderate brittleness, higher cost | Medium |

| Aluminum Oxide | General-purpose grinding of steels and moderate hardness metals | Good toughness and lower cost | Faster wear on very hard materials | Low |

| Boron Carbide | Precision grinding of ceramics and hardened steels | Exceptional hardness and chemical resistance | High cost and brittleness | High |

| Synthetic Diamond | Ultra-precision grinding of carbides, composites, advanced alloys | Unmatched hardness and longevity | Very expensive, sensitive to impact | High |

The production of carborundum stones used in grinders involves a series of carefully controlled stages to ensure durability, consistency, and optimal abrasive performance. Understanding these stages helps B2B buyers evaluate supplier capabilities and product quality.

The primary raw material is silicon carbide (SiC), known commercially as carborundum, which is synthesized through a high-temperature reaction of silica sand and carbon. Suppliers typically source high-purity silicon carbide powders, then blend them with bonding agents such as phenolic resin or vitrified bonds, depending on the intended application of the grinding stone. Precise control of particle size distribution and bonding composition is critical to achieving the desired hardness and wear resistance.

Key considerations for buyers:

- Verify supplier raw material sourcing and purity certificates.

- Confirm the use of appropriate bonding agents for your grinding needs.

The mixed raw materials undergo molding to shape the grinding stone. This is often done using:

- Cold Pressing: The powder-bond mixture is compacted under high pressure at room temperature, suitable for standard shapes.

- Hot Pressing: Applies both heat and pressure, improving density and mechanical strength.

- Extrusion or Casting: For specialized shapes or large batches.

The formed stones are then subjected to a curing process (for resin-bonded stones) or sintering (for vitrified bonds), which solidifies the structure and enhances abrasive properties.

Key techniques:

- Uniform pressure application to avoid inconsistencies.

- Controlled temperature profiles during curing/sintering for optimal bonding.

Some grinding stones are mounted onto metal cores or fitted with threaded inserts to ensure compatibility with grinders. This stage also involves balancing the stone to minimize vibration during operation, crucial for safety and performance.

Buyer insight:

- Check if suppliers offer assembly customization to match your equipment specifications.

- Request information on balancing techniques and tolerances.

The finishing process includes grinding and dressing the stone surface to precise dimensions and surface texture. This ensures the abrasive surface is effective and that the stone fits correctly on the grinder.

Finishing may also include:

- Surface treatments to enhance durability.

- Marking for traceability (batch numbers, manufacturing dates).

B2B tip:

- Verify finishing tolerances and surface roughness to ensure compatibility with your grinding applications.

Quality assurance (QA) in manufacturing carborundum stones is critical for maintaining consistent performance and safety, especially in international B2B transactions. Buyers should be familiar with the relevant standards and QC practices suppliers employ.

Actionable advice:

- Request certificates demonstrating compliance with ISO 9001 and any applicable regional or industry-specific standards.

- Confirm the validity and scope of certifications, as some suppliers may hold general ISO certifications but not specific product compliance.

Quality control is typically segmented into three main checkpoints throughout the manufacturing process:

Buyers should ensure that suppliers maintain documented QC procedures and hold traceability records for each batch.

For buyers in Africa, South America, the Middle East, and Europe, due diligence on supplier quality systems is vital to mitigate risks associated with product inconsistencies and regulatory compliance.

Tip: Employ third-party inspection agencies familiar with local manufacturing landscapes to ensure impartiality.

By thoroughly assessing manufacturing and quality assurance frameworks, international B2B buyers can secure high-performance carborundum stones that meet their operational needs and regulatory obligations.

When sourcing carborundum stone for grinders, international B2B buyers must analyze several key cost components that collectively determine the final price:

Raw Materials: The primary expense is silicon carbide (carborundum) powder, whose quality and purity directly influence performance and cost. Variations in raw material sourcing—such as synthetic vs. natural silicon carbide—impact pricing significantly.

Labor Costs: Manufacturing involves skilled labor for shaping, bonding, and finishing the stones. Labor rates vary by country, with suppliers in Asia often offering competitive pricing, while European producers may charge a premium for craftsmanship and compliance with stricter labor standards.

Manufacturing Overhead: Includes energy consumption (high-temperature furnaces), machinery depreciation, and factory maintenance. Overhead costs fluctuate depending on production scale and technology used.

Tooling and Equipment: Custom molds and bonding equipment entail upfront investment, especially for specialized stone shapes or sizes. These costs are amortized over production runs, influencing unit cost based on order volume.

Quality Control (QC): Rigorous QC processes—such as hardness testing, dimensional accuracy, and surface finish inspections—add to costs but ensure product reliability, crucial for buyers targeting demanding industrial applications.

Logistics and Shipping: Freight charges, customs duties, and handling fees are vital considerations, especially for buyers in Africa, South America, and the Middle East, where transport routes and import tariffs can vary widely.

Supplier Margin: Profit margins depend on supplier market positioning, production efficiency, and negotiation leverage. Margins tend to be tighter in highly competitive markets.

Several factors determine the variability in pricing, which buyers should carefully evaluate:

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically attract volume discounts, reducing per-unit cost. However, smaller buyers must balance MOQ requirements against storage and cash flow constraints.

Specifications and Customization: Customized shapes, sizes, or bonding materials increase tooling and production complexity, driving prices upward. Standardized products are generally more cost-effective.

Material Grade and Quality Certifications: Higher-grade silicon carbide with certifications (ISO, REACH, RoHS) ensures performance and compliance but commands a premium price. Buyers must assess if certifications align with end-market regulations.

Supplier Location and Reputation: Established suppliers with proven quality records may price higher but reduce risks. Proximity also affects shipping costs and lead times.

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) shifts cost and risk responsibilities between buyer and supplier, impacting the landed cost. Favorable payment terms (e.g., letters of credit, net terms) can improve cash flow.

Negotiate Beyond Price: Engage suppliers on terms such as lead time, payment conditions, and after-sales support, which can improve total value.

Calculate Total Cost of Ownership (TCO): Factor in not just unit price, but also shipping, customs, storage, and potential downtime due to quality issues. A slightly higher-priced supplier with superior quality and reliability often yields lower TCO.

Leverage Regional Sourcing Hubs: For buyers in Africa and South America, sourcing from nearby hubs (e.g., Asia for Indonesia, Europe for Middle East) can reduce transit times and logistics costs.

Request Samples and Certifications: Validate quality through samples and review supplier certifications before committing to bulk orders, mitigating risk of costly returns or rejections.

Understand Pricing Nuances by Region: Be aware of local import tariffs, currency fluctuations, and regulatory compliance costs that affect landed cost in your market.

Use Consolidated Shipping Where Possible: Combining shipments with other orders can reduce freight costs, especially for smaller quantities.

Pricing for carborundum stone for grinders varies widely based on the factors outlined above. This section provides a framework for understanding cost drivers rather than exact figures. Buyers should request detailed quotations from multiple suppliers and consider total landed cost to make informed purchasing decisions.

When sourcing carborundum stones for grinders, understanding the critical technical properties and trade terminology is key to making informed purchasing decisions. These insights help buyers from diverse markets such as Africa, South America, the Middle East, and Europe evaluate product quality, ensure compatibility, and negotiate effectively with suppliers.

Illustrative Image (Source: Google Search)

Grain Size / Grit Size

Grain size defines the coarseness of the abrasive particles embedded in the stone, typically ranging from very coarse (24 grit) to very fine (600 grit). Coarser grits are used for rapid material removal, while finer grits provide smoother finishes. Selecting the appropriate grit size is crucial for optimizing productivity and achieving the desired surface quality.

Bond Type and Hardness

The bond holds the abrasive grains together and affects the stone’s hardness and durability. Common bond types include vitrified (ceramic-based) and resin bonds. Vitrified bonds offer high strength and heat resistance, ideal for precision grinding, whereas resin bonds provide flexibility and are often used for light-duty applications. Understanding bond type helps buyers match stones to specific grinding tasks and machine conditions.

Dimensional Tolerance

This refers to the permissible variation in the stone’s size and shape, such as diameter and thickness. Tight tolerance levels (e.g., ±0.02 mm) ensure the stone fits precisely on grinding machines, preventing vibration and uneven wear. Buyers should request detailed tolerance specifications to guarantee compatibility with their equipment.

Illustrative Image (Source: Google Search)

Density and Porosity

Density affects the stone’s strength and grinding efficiency, while porosity influences coolant flow and chip clearance during grinding. Stones with optimized porosity reduce heat buildup and extend tool life. For B2B buyers, evaluating density and porosity data can help avoid premature tool failure and improve overall process stability.

Maximum Operating Speed (RPM)

Each carborundum stone is rated for a maximum safe rotational speed, which must align with the grinder’s operating conditions to prevent accidents and damage. Confirming the maximum RPM rating is essential for buyer safety and compliance with international standards.

OEM (Original Equipment Manufacturer)

Refers to stones produced by or for the original maker of the grinding machine or tool. OEM products typically guarantee compatibility and quality but may come at a premium. Buyers should weigh the benefits of OEM-certified stones against third-party alternatives depending on budget and performance requirements.

MOQ (Minimum Order Quantity)

This is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is vital for inventory planning and cost management, especially for international buyers balancing shipping costs and storage capacity.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for price, lead time, and terms based on specified requirements. Crafting a detailed RFQ that includes technical specs like grit size, bond type, and tolerances ensures accurate and comparable offers from multiple vendors.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs clearance (e.g., FOB, CIF, DDP). Knowing Incoterms helps buyers clarify delivery obligations and calculate landed costs precisely.

Lead Time

The period between placing an order and receiving the goods. Lead time impacts production schedules and supply chain reliability, making it a critical factor for buyers operating in fast-moving or just-in-time manufacturing environments.

Certification and Compliance

Terms related to product quality and safety standards, such as ISO certifications or REACH compliance for chemical safety. Requesting certification documentation ensures the stones meet international regulations and buyer-specific quality benchmarks.

By mastering these technical properties and trade terms, international B2B buyers can effectively communicate requirements, evaluate supplier offerings, and negotiate terms that align with their operational needs. This approach reduces risk, optimizes costs, and supports long-term sourcing partnerships in the competitive carborundum stone market.

The global carborundum stone market, essential for producing high-performance grinding tools, is shaped by several dynamic forces that international B2B buyers must consider. Demand is primarily driven by the manufacturing, automotive, construction, and metalworking sectors, with rapid industrialization in regions such as Africa, South America, and Southeast Asia fueling growth. Countries like Colombia and Indonesia are emerging as critical markets due to expanding infrastructure projects and increasing mechanization, creating opportunities for suppliers specializing in durable grinding materials.

Technological advancements are influencing sourcing trends, with buyers increasingly seeking carborundum stones that offer enhanced precision, longevity, and compatibility with automated grinding machinery. Innovations such as nano-engineered abrasives and hybrid composite stones are gaining traction, delivering improved grinding efficiency and cost-effectiveness. Moreover, digital platforms and B2B marketplaces have streamlined procurement processes, enabling buyers in the Middle East and Europe to source directly from manufacturers, reducing intermediaries and lead times.

Market dynamics also reflect a growing emphasis on supply chain resilience amid geopolitical uncertainties and fluctuating raw material prices. Buyers from Africa and South America are prioritizing diversified sourcing strategies to mitigate risks associated with transportation delays and trade restrictions. Additionally, competitive pricing pressures are driving manufacturers to optimize production methods and adopt lean inventory management, benefiting buyers through more stable pricing and availability.

Sustainability is becoming a critical consideration in the carborundum stone sector, as environmental regulations tighten globally and buyers demand responsible sourcing. The production of carborundum (silicon carbide) involves energy-intensive processes, often relying on fossil fuels, which contribute to greenhouse gas emissions. For B2B buyers, particularly those committed to corporate social responsibility in Africa, the Middle East, and Europe, partnering with suppliers who implement energy-efficient manufacturing techniques is increasingly important.

Ethical supply chains are also under scrutiny, with international buyers seeking transparency regarding labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and adherence to Responsible Minerals Initiatives signal a supplier’s commitment to sustainable operations. Additionally, the rise of “green” carborundum products, manufactured using recycled materials or renewable energy sources, offers buyers an opportunity to reduce their carbon footprint and meet evolving regulatory standards.

For buyers targeting markets like Colombia and Indonesia, where environmental policies are progressively enforced, sourcing from suppliers with verifiable sustainability credentials can enhance brand reputation and compliance. Collaborative efforts between buyers and suppliers to implement circular economy principles—such as reclaiming and recycling worn grinding stones—are emerging as best practices that drive long-term value and reduce environmental impact.

Carborundum stones have a rich industrial heritage dating back to the late 19th century when silicon carbide was first synthesized as a superior abrasive material. Originally developed to replace natural abrasives like emery and corundum, carborundum quickly became the standard for grinding applications due to its exceptional hardness and thermal conductivity. Over the decades, the sector evolved from artisanal production methods to highly mechanized, precision-controlled manufacturing, enabling consistent quality and scale.

This evolution is significant for B2B buyers as it underscores the maturity and reliability of carborundum stones in industrial applications. Understanding this historical context helps buyers appreciate the technological sophistication behind modern products and informs their evaluation of supplier capabilities, especially when selecting partners in emerging markets with growing industrial bases.

1. How can I effectively vet suppliers of carborundum stone for grinders to ensure quality and reliability?

To vet suppliers, start by verifying their business credentials, including licenses and certifications such as ISO 9001 for quality management. Request detailed product specifications and samples to assess the stone’s hardness, grit consistency, and durability. Check references or client testimonials, especially from buyers in similar industries or regions. Use third-party inspection services for factory audits or product inspections if possible. Prioritize suppliers with transparent production processes and proven export experience to your region, as this reduces risks related to customs and logistics.

2. What customization options are typically available for carborundum stones, and how can I communicate my specific requirements?

Most manufacturers offer customization in grit size, shape, hardness, and bonding material to suit different grinding applications. Clearly specify your technical requirements in writing, including dimensions, tolerance levels, and performance standards. Providing samples or detailed drawings helps avoid miscommunication. Engage in technical discussions with supplier engineers to ensure feasibility. Custom orders may require longer lead times and higher MOQ, so confirm these details upfront. Establishing clear quality checkpoints during production helps maintain your standards.

3. What are the common minimum order quantities (MOQs) and lead times for international orders of carborundum stones?

MOQs can vary widely, typically ranging from 500 to 5,000 pieces depending on supplier capacity and customization. Lead times often span 4 to 8 weeks, influenced by order size, customization complexity, and production schedules. For first-time or smaller buyers, some suppliers may offer trial orders at higher per-unit costs. Plan your procurement well in advance to accommodate production and shipping timelines. Negotiate flexible MOQ terms where possible to align with your inventory needs and cash flow constraints.

4. Which payment terms are standard in international B2B transactions for carborundum stones, and how can I mitigate payment risks?

Common payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and escrow services. L/Cs are preferred for high-value orders as they provide security for both parties. Negotiate partial upfront payments (e.g., 30%) with the balance after inspection or delivery. Use escrow platforms or trade finance options to protect funds. Always confirm payment terms in the contract and avoid full advance payments without guarantees. Working with reputable suppliers and using verified payment channels reduces financial exposure.

5. What quality assurance certifications and testing standards should I look for when sourcing carborundum stones?

Look for suppliers with ISO 9001 certification, which indicates adherence to quality management systems. Additional certifications like RoHS or REACH compliance ensure environmental and safety standards, especially for European buyers. Request material composition reports and hardness testing results (e.g., Mohs scale rating). Some suppliers conduct batch-wise quality checks and provide inspection certificates. Consider third-party lab testing for critical applications to verify abrasiveness, durability, and bonding integrity before bulk purchase.

6. How can I optimize logistics and shipping for importing carborundum stones to regions like Africa, South America, or the Middle East?

Choose suppliers experienced in exporting to your target region to navigate customs efficiently. Consolidate shipments to reduce freight costs, and prefer suppliers near major ports or with established freight forwarding partnerships. Clarify Incoterms (e.g., FOB, CIF) to understand cost responsibilities. Use reliable carriers with proven transit times and track shipment status closely. Prepare all necessary import documentation in advance, including certificates of origin, commercial invoices, and compliance certificates, to avoid clearance delays.

7. What strategies can help resolve disputes related to product quality or delivery delays in international B2B transactions?

Draft clear contracts detailing product specifications, delivery schedules, payment terms, and dispute resolution mechanisms. Include clauses for quality inspections, penalties for delays, and arbitration procedures. If disputes arise, initiate dialogue promptly and use documented evidence such as inspection reports and correspondence. Engage neutral third-party mediators or arbitration bodies familiar with international trade laws. Maintaining open communication and establishing trust with suppliers reduces conflict likelihood and supports faster resolution.

8. Are there specific regulatory or environmental considerations when importing carborundum stones into Europe or the Middle East?

Yes, Europe enforces strict REACH regulations controlling hazardous substances in products, which may apply to abrasive materials. Ensure your supplier complies and provides necessary certification. The Middle East may require adherence to import standards regarding material safety and customs clearance protocols. Verify compliance with local environmental and occupational safety regulations to avoid penalties or shipment rejections. Collaborate with customs brokers knowledgeable about regional rules to ensure smooth import processes and stay updated on evolving regulatory requirements.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

The strategic sourcing of carborundum stones for grinders presents a significant opportunity for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. By prioritizing suppliers with consistent quality, reliable supply chains, and competitive pricing, buyers can enhance operational efficiency and product performance. Understanding regional market dynamics and forging strong partnerships with manufacturers—particularly in emerging hubs—can mitigate risks associated with supply disruptions and currency fluctuations.

Key takeaways for buyers include the importance of verifying material specifications, leveraging bulk purchasing for cost advantages, and incorporating sustainability criteria into supplier selection. Additionally, embracing digital procurement tools and transparent communication channels will facilitate smoother transactions and long-term collaboration.

Looking ahead, the demand for advanced abrasive materials like carborundum stones is expected to grow, driven by industrial modernization and increased manufacturing activities across target regions. Buyers who adopt a proactive and strategic sourcing approach will be well-positioned to capitalize on evolving market trends and secure a competitive edge. International purchasers are encouraged to engage early with trusted suppliers, explore innovative sourcing models, and continuously monitor market developments to future-proof their supply chains and maximize value.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina