Carborundum, known for its exceptional hardness and thermal conductivity, is a cornerstone material in industries ranging from abrasives and refractories to electronics and automotive manufacturing. For international B2B buyers, especially those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the complexities of sourcing high-quality carborundum is essential to maintaining competitive advantage and ensuring product reliability.

This guide offers a comprehensive exploration of the carborundum market, designed to equip procurement professionals with actionable insights. It covers the various types of carborundum, including synthetic and natural variants, and details the materials and manufacturing processes that influence product performance and cost-effectiveness. Emphasis is placed on quality control protocols to help buyers assess supplier reliability and product consistency.

Navigating the global supply chain can be challenging due to regional variations in availability, pricing, and regulatory standards. This resource provides a deep dive into supplier selection strategies, cost analysis, and market trends tailored to diverse international contexts such as those faced by buyers in Indonesia, Argentina, and other emerging economies. Additionally, a curated FAQ section addresses common concerns and technical queries to streamline decision-making.

By integrating market intelligence with practical sourcing advice, this guide empowers B2B buyers to make informed, strategic decisions that optimize procurement outcomes. Whether you are expanding your supplier base or seeking to enhance product quality, this resource is your essential partner in mastering the global carborundum marketplace.

Illustrative Image (Source: Google Search)

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Silicon Carbide | High hardness, dark color, sharp angular grains | Abrasive blasting, grinding, cutting | + Extremely hard and durable – Less chemical resistance |

| Green Silicon Carbide | Higher purity, harder than black, greenish tint | Precision grinding, polishing | + Superior hardness and thermal conductivity – Higher cost |

| Brown Silicon Carbide | Lower purity, contains iron oxides, brown color | General purpose abrasives, refractory | + Cost-effective – Lower hardness and wear resistance |

| Fused Silicon Carbide | Manufactured by fusing silica and carbon at high temp | High-performance abrasives, ceramics | + High purity and strength – More expensive production |

| Silicon Carbide Powder | Fine particle size, varying grades | Coatings, electronics, composites | + Versatile particle sizes – Requires precise handling |

Black Silicon Carbide is the most common and widely used variety, known for its exceptional hardness and sharp angular grains. It excels in abrasive blasting, cutting, and grinding applications, making it a staple for industries requiring durable abrasives. Buyers should consider its lower chemical resistance, which may limit its use in corrosive environments. Its cost-effectiveness and availability make it suitable for large-scale industrial use, especially in markets like Africa and South America where bulk abrasive materials are in demand.

Green Silicon Carbide offers higher purity and hardness compared to black silicon carbide, with a distinctive green tint. It is preferred for precision grinding and polishing, particularly in high-tech manufacturing sectors. The enhanced thermal conductivity and wear resistance justify its higher price point, making it ideal for buyers targeting advanced industries such as aerospace and electronics in Europe and the Middle East. Procurement should focus on supplier quality certifications to ensure consistent purity.

Brown Silicon Carbide is characterized by its lower purity and the presence of iron oxides, which impart a brown hue. It serves well in general-purpose abrasive applications and refractory materials, offering a budget-friendly option for buyers. While it lacks the hardness and wear resistance of black or green variants, its affordability makes it attractive for construction and foundry sectors in emerging markets like Indonesia and Argentina. Buyers must assess the trade-off between cost and performance for their specific industrial needs.

Fused Silicon Carbide is produced by high-temperature fusion of silica and carbon, resulting in a highly pure and strong abrasive material. It is used in high-performance abrasives and advanced ceramic manufacturing, where material integrity is critical. This type commands a premium price but delivers superior strength and consistency, appealing to specialized manufacturers in Europe and the Middle East. B2B buyers should evaluate suppliers’ production capabilities and quality control processes to ensure optimal product performance.

Silicon Carbide Powder comes in fine particle sizes and various grades, making it versatile for coatings, electronics, and composite materials. Its adaptability allows manufacturers to tailor particle size distribution for specific applications, such as thermal management in electronics or wear-resistant coatings. Buyers should focus on powder grade specifications and supplier reliability, especially when sourcing for high-precision industries in Africa and South America, where material consistency can significantly impact product quality.

| Industry/Sector | Specific Application of Carborundum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Metalworking | Abrasive cutting, grinding, and polishing tools | Enhances precision, durability, and surface finish quality | Ensure grain size and purity meet machinery specifications; reliable supply chain |

| Automotive | Brake pads and clutch materials | Improves wear resistance and heat dissipation | Consistency in particle hardness and thermal stability; certifications for safety |

| Electronics & Semiconductors | Substrate materials and heat sinks | Provides excellent thermal conductivity and electrical insulation | High purity grade and controlled particle morphology; compliance with industry standards |

| Construction & Ceramics | Abrasive powders for cutting tiles and shaping ceramics | Increases efficiency and reduces tool wear | Sourcing from suppliers with quality assurance and consistent particle size |

| Renewable Energy | Components for solar panels and wind turbine blades | Enhances durability and thermal management | Material grade suited for harsh environments; long-term supply agreements |

Manufacturing & Metalworking

Carborundum is widely used in manufacturing for abrasive cutting, grinding, and polishing tools due to its exceptional hardness and thermal stability. It enables businesses to achieve high precision and superior surface finishes on metals and other hard materials. For international buyers in regions such as Africa and South America, it is critical to select carborundum with appropriate grain size and purity to match their equipment requirements, ensuring consistent performance and minimizing downtime.

Automotive Industry

In automotive applications, carborundum is integral to brake pads and clutch materials where high wear resistance and heat dissipation are essential. This improves vehicle safety and component longevity. Buyers from the Middle East and Europe should prioritize suppliers offering carborundum with certified particle hardness and thermal stability, as these factors directly affect product safety and compliance with regulatory standards.

Electronics & Semiconductors

Carborundum’s excellent thermal conductivity and electrical insulation make it ideal for substrates and heat sinks in electronics. This helps manage heat in semiconductors, enhancing device reliability. International B2B buyers, particularly in technologically advanced markets like Europe and Indonesia, must ensure the carborundum supplied meets high purity grades and precise particle morphology to support sensitive electronic manufacturing processes.

Construction & Ceramics

In construction and ceramics, carborundum abrasive powders are used for cutting tiles and shaping ceramic products. This application benefits from increased efficiency and reduced tool wear, lowering operational costs. Buyers in emerging markets such as Argentina should focus on sourcing from manufacturers who provide consistent particle size and quality assurance to maintain production standards and reduce waste.

Renewable Energy Sector

Carborundum is increasingly used in renewable energy components such as solar panels and wind turbine blades, where durability and thermal management are critical. For international buyers from regions investing in green energy infrastructure, securing carborundum materials that withstand harsh environmental conditions is vital. Establishing long-term supply agreements with reputable producers ensures steady access to high-grade materials, supporting sustainable project development.

Related Video: Uses of Soil | Science | iKen | iKenEdu | iKenApp

Key Properties: Silicon Carbide, commonly referred to as carborundum, is renowned for its exceptional hardness, thermal conductivity, and chemical inertness. It can withstand temperatures up to 1600°C and exhibits excellent resistance to oxidation and corrosion, making it suitable for harsh industrial environments.

Pros & Cons: SiC offers outstanding durability and wear resistance, which translates into long service life and reduced maintenance costs. However, its manufacturing process is relatively complex and energy-intensive, leading to higher initial costs. The material’s brittleness can also pose challenges in applications involving mechanical shock.

Impact on Application: Silicon Carbide is ideal for abrasive media, high-temperature filtration, and mechanical seals in chemical processing. Its chemical inertness ensures compatibility with acidic and alkaline fluids, making it a versatile choice for diverse industrial processes.

International Buyer Considerations: Buyers from Africa, South America, the Middle East, and Europe should verify compliance with ASTM C799 and DIN EN 628 standards, which govern SiC abrasives and ceramics. Regions like Europe and the Middle East often demand adherence to stringent environmental and quality certifications, impacting supplier selection. In markets such as Argentina and Indonesia, cost-efficiency balanced with performance is critical, so negotiating bulk orders or sourcing from regional manufacturers can optimize procurement.

Key Properties: Aluminum Oxide is a widely used abrasive with excellent hardness and chemical stability. It tolerates temperatures up to 1200°C and offers good resistance to corrosion and wear, though it is less thermally conductive than SiC.

Pros & Cons: Al2O3 is more cost-effective and easier to manufacture than SiC, making it a popular choice for a broad range of applications. However, it is less hard than SiC and may wear faster under extreme conditions. Its moderate brittleness is manageable in most industrial settings.

Impact on Application: Aluminum Oxide is commonly used in grinding wheels, sandblasting, and polishing applications where moderate to high hardness is required. It performs well with metals and non-metallic materials but is less suitable for highly corrosive environments compared to SiC.

International Buyer Considerations: Compliance with ASTM B911 and DIN EN 13743 standards is typical for Al2O3 abrasives. Buyers in South America and Africa often prioritize cost and availability, so sourcing from local or regional suppliers who meet international quality standards can be advantageous. In Europe and the Middle East, certification and traceability are crucial, especially for automotive and aerospace sectors.

Key Properties: Boron Carbide is one of the hardest materials available, with excellent wear resistance and a melting point above 2450°C. It is chemically inert and resistant to oxidation, making it suitable for extreme environments.

Pros & Cons: The extreme hardness and low density of B4C provide superior performance in abrasive and ballistic applications. However, it is significantly more expensive and difficult to machine than SiC or Al2O3, limiting its use to specialized applications.

Impact on Application: Boron Carbide is preferred in high-performance cutting tools, armor plating, and abrasive blasting where maximum hardness and low weight are essential. Its chemical resistance also suits nuclear and chemical processing industries.

International Buyer Considerations: Standards such as ASTM C799 and ISO 9001 certification are important for B4C suppliers. For buyers in regions like the Middle East and Europe, where high-performance materials are in demand, ensuring supplier reliability and product certification is critical. In emerging markets like Africa and South America, the high cost may restrict use to niche applications or require strategic partnerships to justify investment.

Key Properties: Zirconia offers high fracture toughness, excellent wear resistance, and thermal stability up to 1400°C. It also exhibits good corrosion resistance and biocompatibility, making it useful in specialized industrial and medical applications.

Pros & Cons: Zirconia’s toughness reduces brittleness issues common in other ceramics, enhancing durability under mechanical stress. However, it is more expensive than Al2O3 and has a more complex manufacturing process. Its chemical resistance is good but not as broad as SiC.

Impact on Application: Zirconia is used in precision grinding, cutting tools, and applications requiring resistance to cracking under stress. It is suitable for wet and dry abrasive processes and is increasingly favored in high-tech industries.

International Buyer Considerations: Compliance with DIN EN ISO 13356 and ASTM standards is often required. European buyers especially value the material’s advanced properties for automotive and aerospace sectors. Buyers in the Middle East and South America should consider supply chain reliability and certification to ensure consistent quality, while African markets may focus on cost-benefit analysis given the higher price point.

| Material | Typical Use Case for carborundum. | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Abrasives, high-temp filtration, mechanical seals | Exceptional hardness and chemical inertness | Brittle, higher manufacturing complexity | High |

| Aluminum Oxide | Grinding wheels, sandblasting, polishing | Cost-effective with good hardness | Less hard and lower thermal conductivity | Low |

| Boron Carbide | High-performance cutting tools, armor plating | Extreme hardness and low density | Very expensive and difficult to machine | High |

| Zirconia | Precision grinding, cutting tools, high-stress applications | High fracture toughness and durability | Higher cost and complex manufacturing | Medium |

Carborundum, commonly known as silicon carbide, is a highly durable and versatile abrasive material widely used in industrial applications such as grinding, cutting, and polishing. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance (QA) protocols behind carborundum products is essential to ensuring reliable sourcing and optimal performance.

The production of carborundum involves several critical stages, each designed to achieve specific material properties such as hardness, thermal resistance, and particle size distribution. The main phases include:

The primary raw materials are silica sand and petroleum coke. These are carefully measured and mixed in precise proportions to optimize the chemical reaction. The quality and consistency of these inputs significantly influence the final product’s performance. Sourcing verified, high-purity raw materials is crucial for manufacturers to meet stringent industrial standards.

The core manufacturing technique for carborundum is the Acheson process, where the raw mix is heated to approximately 2000°C in an electric resistance furnace. This high-temperature environment facilitates the chemical reaction between silica and carbon, forming silicon carbide crystals. Key process controls include temperature uniformity, reaction time, and atmosphere control to ensure consistent crystal growth and purity.

Post-reaction, the solidified mass is broken down mechanically into smaller particles. This stage involves crushing, grinding, and screening to classify carborundum grains by size and grade. Precision in screening is vital to provide abrasives tailored for specific applications, such as fine powders for polishing or coarse grains for heavy-duty grinding.

Depending on the end-use, carborundum grains may be bonded into various forms such as grinding wheels, cutting tools, or abrasive papers. Bonding agents (resin, vitrified, metal) are selected based on application requirements. Assembly processes include molding, pressing, and curing under controlled conditions to ensure structural integrity and performance consistency.

Final finishing may involve surface treatments to enhance durability or specific performance characteristics. Packaging is designed to protect the product during transit, especially for exports to distant markets like Africa and South America, where environmental conditions can vary significantly.

Robust quality assurance is indispensable in carborundum manufacturing to meet international standards and buyer expectations. Quality control (QC) is integrated at multiple stages:

For international buyers, particularly those in emerging markets or regions with diverse regulatory environments, verifying supplier quality systems is critical to mitigating risks.

For international B2B buyers sourcing carborundum, a deep understanding of manufacturing processes and quality assurance practices is vital. By scrutinizing raw material sourcing, production techniques, QC protocols, and certification compliance, buyers can select suppliers who deliver reliable, high-performance products. Leveraging audits, independent testing, and thorough documentation review will further safeguard procurement decisions, ensuring that carborundum meets the exacting demands of diverse industrial applications across Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Carborundum pricing in the B2B landscape is influenced by a complex interplay of cost components and market dynamics, which international buyers must thoroughly understand to optimize procurement strategies. This analysis breaks down the key elements shaping cost structures and pricing, alongside actionable tips tailored for buyers from regions such as Africa, South America, the Middle East, and Europe.

Raw Materials

The primary input, silicon carbide (carborundum), is derived from quartz sand and petroleum coke. Fluctuations in raw material availability and quality directly impact base costs. Buyers should monitor global commodity trends, as prices can vary significantly depending on sourcing origin and purity requirements.

Labor Costs

Manufacturing carborundum involves energy-intensive processes like electric furnace heating. Labor costs vary widely by country and facility sophistication, affecting overall pricing. Regions with advanced automation may offer better price stability, while manual-intensive plants might reflect in higher labor cost components.

Manufacturing Overhead

Includes energy consumption (notably electricity), maintenance, and factory overheads. Energy costs are a major factor due to high-temperature production processes. Buyers should consider suppliers’ energy efficiency and local energy pricing, which can be notably higher in some regions (e.g., parts of South America and the Middle East).

Tooling and Equipment Depreciation

Specialized equipment for grinding and processing carborundum adds to fixed costs spread over production volumes. High initial tooling investments can influence minimum order quantities (MOQs) and pricing flexibility.

Quality Control (QC) and Certifications

Rigorous QC is essential to meet industrial standards, especially for applications in abrasives, refractories, and semiconductors. Suppliers offering internationally recognized certifications (ISO, REACH, RoHS) may command premium pricing but reduce risk and ensure compliance.

Logistics and Freight

Given the abrasive nature and weight of carborundum products, shipping costs can be substantial. Logistics expenses include inland transportation, port handling, and international freight, with variations depending on Incoterms and trade routes. Buyers from Africa and South America often face higher logistics costs due to longer transit times and less direct shipping lanes.

Supplier Margin

Margins vary based on supplier positioning, market competition, and customer relationships. Established suppliers with strong technical support may price at a premium, while newer entrants may offer aggressive pricing to capture market share.

Order Volume and MOQs: Larger orders typically yield lower unit prices due to economies of scale. However, buyers must balance inventory costs against discounts. Some suppliers set high MOQs to justify tooling and production runs, impacting smaller buyers.

Product Specifications and Customization: Customized grain sizes, purity levels, or specific forms (powders, grains, blocks) can increase costs. Standard grades are usually more cost-effective.

Material Quality: Higher purity and consistent grain size distribution are crucial for specialized applications, commanding price premiums.

Supplier Reliability and Certifications: Verified quality and timely delivery often come at higher prices but reduce downstream risks.

Incoterms and Payment Terms: Terms such as FOB, CIF, or DDP significantly affect landed costs. Buyers should carefully negotiate Incoterms to optimize control over logistics and cost transparency.

Negotiate Beyond Price: Engage suppliers on payment terms, lead times, and after-sales support. Volume commitments can unlock better pricing tiers.

Calculate Total Cost of Ownership (TCO): Evaluate not only the purchase price but also shipping, customs duties, storage, and potential quality failures. For example, cheaper carborundum with inconsistent quality may increase production downtime and waste.

Leverage Regional Trade Agreements: Buyers from Africa (e.g., South Africa), South America (e.g., Argentina), and the Middle East should explore regional trade agreements or free zones that can reduce tariffs and expedite customs clearance.

Consider Supplier Location and Logistics: Proximity to ports or industrial hubs can reduce lead times and freight costs. European buyers might prefer suppliers within the EU for quicker delivery and fewer customs complexities.

Assess Certification Requirements: Confirm that suppliers meet relevant certifications required by your industry and local regulations to avoid costly compliance issues.

Understand Pricing Volatility: Carborundum prices can fluctuate with energy costs and raw material markets. Locking in prices through contracts or hedging strategies can offer budget predictability.

Prices for carborundum vary widely based on grade, quantity, supplier, and logistics arrangements. This analysis provides general guidance; buyers should request detailed quotations and conduct due diligence tailored to their specific sourcing needs and regional market conditions.

By understanding these cost drivers and market nuances, international B2B buyers can strategically navigate carborundum procurement, achieving a balance between cost efficiency, quality assurance, and supply chain reliability.

Carborundum, a crystalline form of silicon carbide, is widely used across industrial applications for its exceptional hardness and thermal conductivity. For international B2B buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe, understanding its essential technical properties and common trade terms is crucial to making informed purchasing decisions. Below is a breakdown of key specifications and terminology that will help streamline your sourcing and procurement process.

Material Grade

Carborundum is available in different grades, typically categorized by purity and grain size. Higher-grade materials have fewer impurities and uniform grain distribution, which translates into superior hardness and wear resistance. For B2B buyers, selecting the right grade ensures optimal performance for applications like abrasives, refractory linings, or cutting tools, ultimately affecting product lifespan and operational efficiency.

Grain Size (Mesh Size)

Grain size, often indicated by mesh numbers, determines the fineness or coarseness of carborundum particles. Fine grains (higher mesh number) are used for precision grinding and polishing, while coarse grains (lower mesh number) are suited for heavy-duty cutting and blasting. Matching the grain size to your specific industrial application is essential to maximize productivity and minimize waste.

Tolerance and Dimensional Accuracy

Tolerance refers to the allowable deviation in the size and shape of carborundum products such as grinding wheels or abrasive sheets. Tight tolerances are critical in precision machining and manufacturing to ensure consistent quality and compatibility with machinery. Buyers should verify tolerance levels to avoid costly rework or equipment damage.

Hardness (Mohs Scale)

Carborundum ranks around 9-9.5 on the Mohs hardness scale, making it one of the hardest materials available for industrial use. This property is vital for applications requiring abrasion resistance, such as cutting, grinding, and polishing metals or ceramics. Understanding hardness helps buyers assess whether the carborundum grade meets the demands of their production environment.

Thermal Conductivity

High thermal conductivity allows carborundum to dissipate heat quickly, preventing overheating during high-speed machining or abrasive operations. This property extends tool life and maintains dimensional stability. For buyers in sectors like automotive or aerospace manufacturing, verifying thermal conductivity specifications can improve process reliability.

Chemical Stability

Resistance to oxidation and chemical corrosion ensures carborundum maintains its structural integrity in harsh environments. This is especially important for buyers in regions with varying climates or chemical exposure, such as mining operations in Africa or chemical manufacturing in the Middle East.

OEM (Original Equipment Manufacturer)

Refers to companies that produce carborundum-based components or tools under their own brand or specifications. Understanding OEM relationships helps buyers source customized products and ensure quality consistency aligned with their brand requirements.

MOQ (Minimum Order Quantity)

The smallest amount of carborundum a supplier is willing to sell in one order. MOQs vary by supplier and product type, impacting inventory planning and cost efficiency. Buyers from emerging markets should negotiate MOQs that align with their demand forecasts to optimize cash flow.

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain detailed pricing, delivery timelines, and terms for specific carborundum products. Crafting clear and detailed RFQs is essential for comparing offers and securing the best value deals internationally.

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms protects buyers from unexpected costs and clarifies logistics responsibilities.

Bulk Density

Indicates the mass of carborundum per unit volume, affecting packaging, shipping costs, and handling requirements. Buyers should consider bulk density when planning transportation, especially for long-distance shipments to minimize freight expenses.

Certification and Compliance

Certifications like ISO 9001 or REACH compliance assure buyers that carborundum products meet international quality and safety standards. Verifying certifications is particularly important for buyers in regulated industries or regions with strict import regulations.

Mastering these technical properties and trade terms empowers B2B buyers to select the right carborundum products, negotiate effectively, and ensure smooth international transactions tailored to their specific industrial needs.

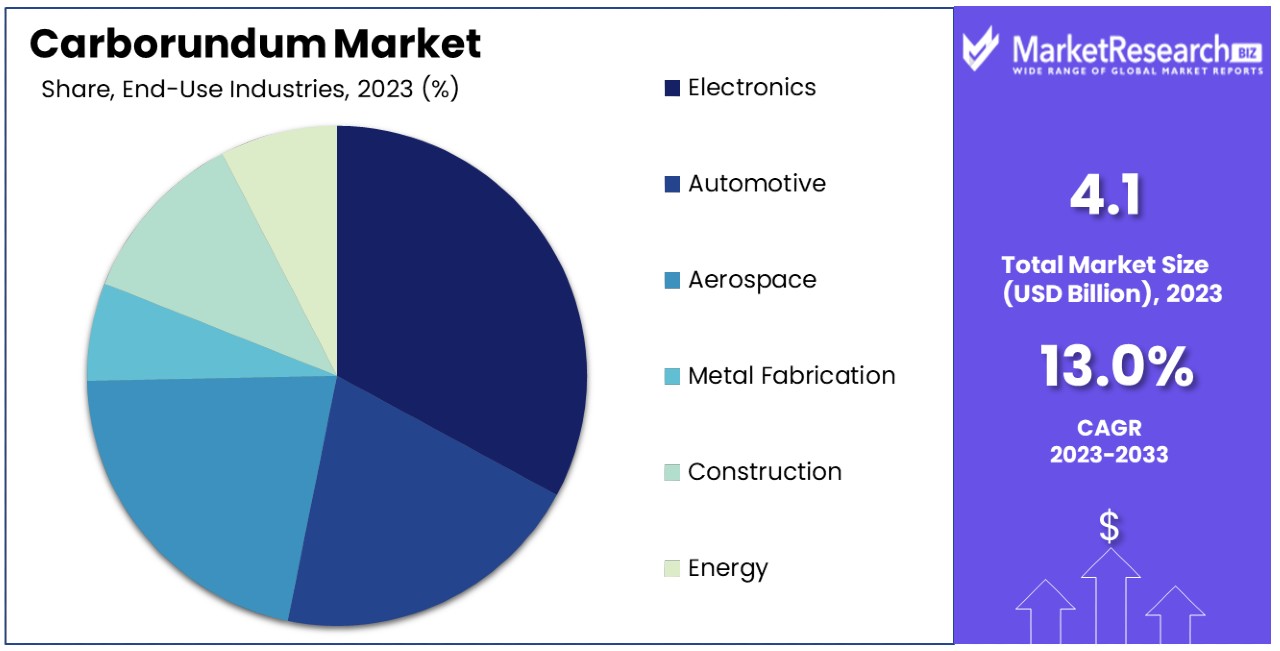

Carborundum, also known as silicon carbide, is a critical material widely used in industrial applications such as abrasives, refractories, semiconductors, and automotive components. The global demand for carborundum is driven by rapid industrialization, particularly in emerging markets across Africa, South America, and the Middle East, where infrastructure development and manufacturing sectors are expanding. Europe continues to be a major hub for high-value applications, especially in electronics and green technologies.

For international B2B buyers, understanding regional supply dynamics is crucial. Africa and South America, including countries like Nigeria and Argentina, are increasingly sourcing carborundum to support mining and automotive industries. Meanwhile, Middle Eastern markets are leveraging their strategic logistics capabilities to become important transit hubs for carborundum imports and exports. Indonesia and other Southeast Asian countries are also emerging as significant consumers, driven by their growing manufacturing sectors.

Key sourcing trends include:

- Shift towards synthetic carborundum: Synthetic variants offer higher purity and consistency, appealing to high-tech industries.

- Digital procurement platforms: Buyers are increasingly using online marketplaces and supply chain management tools to ensure transparency and optimize costs.

- Strategic partnerships and local sourcing: To mitigate supply chain disruptions, companies are forming closer ties with regional suppliers, particularly in Africa and South America.

- Focus on customization: Demand for tailored carborundum grades and particle sizes is growing to meet specific industrial requirements.

Market volatility, driven by raw material availability and energy costs, remains a challenge. Buyers must prioritize suppliers with robust logistics and flexible production capabilities to navigate fluctuations effectively.

Sustainability in the carborundum sector has gained prominence due to its energy-intensive manufacturing process and environmental footprint. The production of silicon carbide involves high-temperature furnaces that consume significant electricity, often derived from fossil fuels. For B2B buyers, especially in regions like Europe where regulatory frameworks are stringent, prioritizing suppliers committed to green manufacturing practices is essential.

Ethical sourcing also encompasses responsible mining of raw materials like quartz and petroleum coke, which are foundational to carborundum production. Buyers should seek suppliers who adhere to international environmental and labor standards, ensuring minimal ecological disruption and fair worker conditions.

Key sustainability considerations include:

- Energy sourcing: Preference for producers using renewable energy or implementing energy recovery systems.

- Waste management: Suppliers with advanced recycling and waste reduction processes reduce environmental impact.

- Certifications: Look for ISO 14001 (Environmental Management) and other green certifications that validate sustainable practices.

- Lifecycle transparency: Suppliers offering full material traceability and lifecycle assessments enable buyers to meet their own corporate social responsibility goals.

Adopting these criteria not only mitigates environmental risks but also enhances brand reputation and complies with increasingly strict import regulations in Europe and parts of the Middle East.

Carborundum’s origins date back to the late 19th century when Edward G. Acheson developed a process to synthesize silicon carbide as an abrasive alternative to natural materials. Initially revolutionizing grinding and cutting tools, carborundum’s role has since expanded dramatically alongside advancements in semiconductor and refractory technologies.

For B2B buyers, understanding this evolution highlights the material’s transition from a basic industrial commodity to a highly engineered product critical for modern manufacturing. Its adaptability and performance have made it indispensable across diverse sectors, reinforcing the importance of selecting suppliers who can provide both quality and innovation to meet evolving market demands.

Illustrative Image (Source: Google Search)

1. How can I effectively vet carborundum suppliers from different regions like Africa, South America, and the Middle East?

To vet suppliers effectively, start by verifying their business licenses and certifications related to product quality and safety. Request detailed product datasheets and samples for quality assessment. Use third-party inspection agencies to conduct factory audits, especially for new suppliers. Check references and client testimonials, focusing on those within your industry and region. Utilize international trade platforms with verified supplier programs. Understanding local market dynamics and regulatory compliance in regions like Africa or South America is crucial to avoid sourcing from unreliable or non-compliant suppliers.

2. Is customization of carborundum products available, and how can I ensure it meets my specific industrial needs?

Many manufacturers offer customization, including particle size, hardness grade, and form (e.g., grit, powder, or blocks). Clearly communicate your technical requirements and application details upfront. Request prototypes or small batch samples to validate performance before bulk ordering. Confirm the supplier’s capability to modify production processes and their flexibility in accommodating changes. Establish clear agreements on specifications, timelines, and costs. Collaborating with suppliers who have R&D capabilities or technical support teams can enhance product fit and reduce risk.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B purchases of carborundum?

MOQs vary widely depending on supplier scale and product type but often range from 500 kg to several tons. Lead times typically span 3 to 8 weeks, influenced by production schedules and shipping logistics. Payment terms commonly include 30-50% advance payment with the balance upon shipment or delivery. Letters of credit (LC) or escrow services are preferred for risk mitigation. Negotiate terms early, especially for first orders, to secure favorable conditions and avoid unexpected delays or cash flow constraints.

4. What quality assurance measures and certifications should I look for when sourcing carborundum internationally?

Look for suppliers with ISO 9001 certification, which ensures robust quality management systems. Additional certifications such as REACH compliance (for Europe), RoHS, and specific industrial standards relevant to abrasives (e.g., ANSI or ASTM) increase reliability. Request detailed quality control documentation, including batch test reports, particle size distribution, and hardness tests. Suppliers with traceability systems and third-party quality audits provide greater assurance. Always conduct your own incoming inspection upon receipt to verify conformance.

5. How can I optimize logistics and shipping when importing carborundum from distant regions like Indonesia or Argentina?

Choose suppliers near major ports with experience in international shipping to minimize transit times and handling risks. Consolidate shipments to reduce freight costs but balance against inventory holding costs. Use freight forwarders familiar with hazardous or abrasive material regulations, as carborundum may have special packaging or handling requirements. Factor in customs clearance times and local import regulations in your country. Establish clear Incoterms (e.g., FOB, CIF) to define responsibilities and reduce disputes.

6. What are common causes of disputes in international carborundum trade, and how can I proactively avoid them?

Disputes often arise from product quality discrepancies, delayed deliveries, or payment disagreements. Prevent these by having detailed contracts specifying technical specs, inspection protocols, delivery schedules, and payment terms. Use third-party inspections before shipment to verify quality and quantity. Maintain transparent communication channels and document all correspondence. Employ dispute resolution clauses such as arbitration or mediation, specifying jurisdiction and language to streamline conflict management.

7. How important is supplier location in sourcing carborundum for markets in Africa, South America, and Europe?

Supplier location impacts lead time, shipping costs, and regulatory compliance. Proximity to your market can reduce freight expenses and improve responsiveness. For example, sourcing from South America may benefit Argentine buyers due to regional trade agreements. However, quality and reliability should outweigh location alone. Consider suppliers in regions with established industrial infrastructure and export experience. Also, evaluate political stability and trade policies that might affect supply continuity.

8. What payment methods are safest and most efficient for international B2B transactions of carborundum?

Letters of Credit (LC) remain the safest for both buyers and sellers, ensuring payment only after meeting agreed terms. Bank transfers (TT) are common but require trust or escrow arrangements to minimize risk. Online trade platforms may offer secure payment gateways with escrow services. For new suppliers, consider partial advance payment combined with balance upon inspection or delivery. Always verify banking details independently to prevent fraud, and consult with trade finance experts to optimize currency risk management.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Carborundum remains a critical material across multiple industries, from abrasives to electronics, making its strategic sourcing a pivotal factor for international B2B buyers. For companies in Africa, South America, the Middle East, and Europe, understanding regional supply dynamics, supplier reliability, and quality standards is essential to securing competitive advantage and operational continuity.

Key takeaways for strategic sourcing include:

Looking ahead, the demand for carborundum is expected to grow in tandem with industrial modernization and green technologies. Buyers should proactively invest in market intelligence and supplier development to stay ahead. Embracing digital procurement tools and fostering cross-border partnerships will be key strategies to optimize sourcing outcomes.

For international buyers, particularly in emerging markets like Indonesia and Argentina, now is the time to deepen supplier networks and enhance strategic sourcing capabilities to unlock value and ensure resilient supply chains in a rapidly evolving global landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina