Navigating the complex landscape of sourcing ceramics boron carbide can pose significant challenges for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly turn to advanced materials for their unique properties, understanding the nuances of this market becomes essential. This guide offers a comprehensive overview of ceramics boron carbide, detailing its various types, applications in sectors such as defense, aerospace, and manufacturing, and critical factors for supplier vetting.

In today’s global economy, buyers must navigate fluctuating costs, varying quality standards, and the intricacies of international trade regulations. This guide empowers B2B buyers by providing actionable insights into the sourcing process. We will explore how to identify reputable suppliers, assess product specifications, and effectively negotiate prices to ensure optimal value for your organization.

By addressing these key areas, this guide serves as a vital resource for decision-makers looking to make informed purchasing decisions regarding ceramics boron carbide. Whether you are a buyer from Italy seeking high-performance materials for aerospace applications or a procurement officer in South Africa looking for cost-effective solutions, the insights provided here will help you navigate the global market with confidence and clarity.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Boron Carbide Ceramics | High hardness, low density, excellent wear resistance | Armor materials, grinding wheels | Pros: Exceptional hardness; Cons: Brittle nature can lead to cracking. |

| Boron Carbide Composites | Enhanced toughness through composite materials | Aerospace, automotive applications | Pros: Improved toughness; Cons: Higher production costs. |

| Boron Carbide Coatings | Thin layers providing surface hardness and protection | Industrial machinery, tooling | Pros: Cost-effective protection; Cons: Limited durability under extreme conditions. |

| Boron Carbide Powders | Fine particles used in various applications | Abrasives, nuclear shielding | Pros: Versatile use; Cons: Requires careful handling due to fine particle nature. |

| Boron Carbide Nanocomposites | Nano-sized particles for enhanced properties | Electronics, advanced ceramics | Pros: Superior mechanical properties; Cons: Complex manufacturing process. |

Boron carbide ceramics are renowned for their exceptional hardness, making them suitable for applications where wear resistance is crucial. They are commonly used in the production of armor materials and grinding wheels. However, buyers should consider their brittle nature, which can lead to cracking under stress, making them less ideal for applications where impact resistance is critical.

Boron carbide composites combine boron carbide with other materials to enhance toughness and impact resistance. This variation is particularly beneficial in aerospace and automotive applications, where structural integrity is paramount. While they offer improved mechanical properties, the higher production costs associated with composites can be a consideration for budget-conscious buyers.

Boron carbide coatings are thin layers applied to surfaces to enhance hardness and protect against wear. These coatings are widely used in industrial machinery and tooling to extend the lifespan of components. They are cost-effective and can be applied to existing tools, but their durability may be limited in extreme conditions, which buyers should evaluate based on their specific operational environments.

Boron carbide powders are finely milled particles that serve multiple functions, including use as abrasives and in nuclear shielding applications. Their versatility makes them a valuable resource in many industries. However, careful handling is essential due to the fine particle nature, which can pose health risks if not managed properly.

Boron carbide nanocomposites utilize nano-sized particles to enhance the mechanical properties of the material, making them suitable for cutting-edge applications in electronics and advanced ceramics. While they provide superior performance, the complexity of their manufacturing process can lead to higher costs, which may deter some buyers from considering them for bulk applications.

Related Video: Boron Carbide: Hardness Unleashed

| Industry/Sector | Specific Application of ceramics boron carbide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense and Military | Armor materials for ballistic protection | Enhanced protection against projectiles and shrapnel | Compliance with military standards and certifications |

| Aerospace | Thermal protection systems in spacecraft | High-temperature resistance and lightweight properties | Supplier reliability and material certification |

| Manufacturing | Abrasives in machining and grinding applications | Increased efficiency and reduced wear on tools | Quality control and consistency in material properties |

| Nuclear Energy | Control rods and neutron absorbers | Improved safety and efficiency in nuclear reactors | Regulatory compliance and sourcing of certified materials |

| Electronics | Semiconductor components and insulators | Enhanced performance and heat resistance | Supply chain transparency and material sourcing standards |

In the defense sector, ceramics boron carbide is primarily utilized for armor materials that offer ballistic protection. This advanced ceramic has a high hardness level, making it ideal for use in personal protective equipment (PPE) such as vests and helmets, as well as in vehicle armor. For international buyers, especially from regions like Africa and the Middle East, ensuring compliance with military standards is crucial. This involves sourcing materials that meet specific certifications and can withstand various threat levels, thus enhancing the safety of personnel and equipment.

In aerospace applications, ceramics boron carbide is employed in thermal protection systems for spacecraft. Its ability to withstand extreme temperatures while maintaining structural integrity makes it essential for re-entry vehicles and satellites. Buyers from Europe and South America should focus on suppliers that guarantee high-temperature resistance and lightweight properties, as these factors are critical for performance and fuel efficiency. Additionally, reliability in supply chains is vital to avoid delays in production schedules.

Within the manufacturing sector, ceramics boron carbide serves as an abrasive material in machining and grinding processes. Its exceptional hardness contributes to increased efficiency and reduced wear on tools, leading to lower operational costs and improved product quality. B2B buyers should prioritize sourcing materials with consistent quality control measures to ensure uniform performance across different manufacturing scenarios. This is particularly relevant for manufacturers in South America and Africa looking to enhance their competitive edge in global markets.

In the nuclear energy sector, ceramics boron carbide is utilized in control rods and neutron absorbers, playing a critical role in regulating nuclear reactions. Its unique properties allow for improved safety and efficiency within reactors. International buyers must consider regulatory compliance when sourcing these materials, as nuclear applications are subject to stringent safety standards. Sourcing from certified suppliers ensures that the materials used in nuclear facilities meet the necessary safety and performance criteria.

Ceramics boron carbide is also significant in the electronics industry, where it is used in semiconductor components and insulators. Its high thermal resistance and electrical insulating properties contribute to enhanced performance and reliability of electronic devices. For buyers in Europe, particularly in Italy, ensuring supply chain transparency is essential when sourcing these materials. This involves verifying the authenticity and quality of the boron carbide to prevent production disruptions and maintain product integrity.

The Problem:

B2B buyers, particularly in regions like Africa and South America, often face significant challenges in sourcing ceramics boron carbide due to unpredictable supply chain disruptions. These disruptions can stem from geopolitical issues, natural disasters, or even fluctuations in demand. For instance, manufacturers may experience delays in receiving raw materials, leading to production halts and unmet customer expectations. This not only affects the buyer's operational efficiency but can also tarnish their reputation in the marketplace.

The Solution:

To mitigate supply chain disruptions, buyers should establish relationships with multiple suppliers across different geographical regions. By diversifying the supply chain, buyers can reduce their dependency on a single source and ensure a more reliable flow of materials. Additionally, utilizing advanced inventory management systems can help in predicting demand trends and optimizing stock levels of ceramics boron carbide. Buyers should also consider investing in local suppliers to minimize shipping times and costs. Lastly, maintaining open communication with suppliers about potential risks and delivery timelines can help in planning and adjusting production schedules accordingly.

The Problem:

Quality inconsistency is a prevalent pain point for B2B buyers sourcing ceramics boron carbide. Variations in quality can arise from different manufacturing processes or standards adhered to by suppliers. This inconsistency can lead to product failures, increased costs due to rework, and ultimately, customer dissatisfaction. For instance, a company in Europe may receive subpar ceramics boron carbide that does not meet the required specifications for high-performance applications, resulting in operational setbacks.

The Solution:

To ensure high quality in ceramics boron carbide procurement, buyers should implement a rigorous supplier evaluation process. This includes assessing potential suppliers' manufacturing capabilities, quality control measures, and adherence to international standards such as ISO certifications. Establishing clear quality benchmarks and conducting regular audits can help maintain consistency. Additionally, buyers can request samples for testing before committing to large orders, allowing them to verify that the materials meet their specific performance criteria. Collaborating closely with suppliers to develop customized solutions can also enhance product quality and reliability.

The Problem:

Many B2B buyers struggle with understanding the technical specifications and appropriate applications of ceramics boron carbide, which can lead to misinformed purchasing decisions. For instance, a buyer in the Middle East may not fully grasp the differences between various grades of ceramics boron carbide and their suitability for applications like ballistic protection or industrial abrasives. This lack of knowledge can result in selecting inappropriate materials, causing inefficiencies and increased costs.

The Solution:

To navigate the complexities of ceramics boron carbide specifications, buyers should invest in training and resources that enhance their technical understanding. Engaging with industry experts and attending specialized workshops can provide invaluable insights into material properties and applications. Additionally, buyers should request detailed technical datasheets from suppliers, which outline specifications, performance characteristics, and application recommendations. Leveraging online resources, such as webinars or industry publications, can also be beneficial. Establishing a consultative relationship with suppliers can further assist buyers in making informed decisions tailored to their specific needs, ensuring they select the right materials for their projects.

When selecting materials for ceramics boron carbide, several options are commonly considered. Each material has unique properties, benefits, and drawbacks that can significantly impact performance in various applications. Here, we analyze four prevalent materials used in conjunction with boron carbide ceramics, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Key Properties: Silicon carbide is known for its exceptional hardness and thermal conductivity. It can withstand high temperatures (up to 1600°C) and has excellent corrosion resistance against acidic and alkaline environments.

Pros & Cons: The durability of SiC makes it suitable for high-wear applications, but its high cost can be a barrier for some buyers. Manufacturing complexity is moderate, as it requires specialized processes for shaping and sintering.

Impact on Application: SiC is particularly effective in applications involving abrasive materials or extreme thermal conditions, such as in aerospace or military applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the availability of SiC and the associated costs, as well as compliance with international standards such as ASTM or DIN.

Key Properties: Alumina is characterized by its high strength, wear resistance, and thermal stability. It can handle temperatures up to 1700°C and has good electrical insulating properties.

Pros & Cons: While alumina is relatively inexpensive and widely available, it is less tough compared to boron carbide and silicon carbide. The manufacturing process is well-established, making it easier to source.

Impact on Application: Alumina is often used in applications requiring insulation and wear resistance, such as in electrical components and cutting tools.

Considerations for International Buyers: Compliance with local and international standards is crucial, especially in Europe where regulations on materials can be stringent. Buyers should also evaluate the supply chain for alumina in their region.

Key Properties: Zirconia exhibits high fracture toughness and thermal stability, with a temperature tolerance of about 2400°C. It also has excellent resistance to corrosion and wear.

Pros & Cons: The primary advantage of zirconia is its toughness, making it suitable for demanding applications. However, it is more expensive than alumina and requires more complex manufacturing techniques.

Impact on Application: Zirconia is ideal for applications in the dental and medical fields, as well as in high-performance cutting tools.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for medical applications, particularly in Europe, where compliance with medical device regulations is strict.

Key Properties: Titanium diboride is known for its high hardness and excellent thermal and electrical conductivity. It can withstand temperatures up to 3000°C and has good wear resistance.

Pros & Cons: While TiB2 offers outstanding performance in extreme conditions, its high cost and the complexity of its manufacturing process can be significant drawbacks.

Impact on Application: TiB2 is often used in high-performance applications such as armor materials and cutting tools due to its hardness.

Considerations for International Buyers: Buyers should evaluate the cost-effectiveness of TiB2 for their specific applications and ensure compliance with relevant standards, particularly in defense-related industries.

| Material | Typical Use Case for ceramics boron carbide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Aerospace and military applications | Exceptional hardness and thermal conductivity | High cost and moderate manufacturing complexity | High |

| Aluminum Oxide (Alumina) | Electrical components and cutting tools | Inexpensive and widely available | Less tough compared to other materials | Medium |

| Zirconium Oxide (Zirconia) | Dental and medical applications | High fracture toughness and thermal stability | More expensive and complex to manufacture | High |

| Titanium Diboride (TiB2) | Armor materials and cutting tools | Outstanding performance in extreme conditions | High cost and complex manufacturing | High |

This analysis provides international B2B buyers with a comprehensive understanding of the materials used in ceramics boron carbide, enabling informed decisions based on performance, cost, and compliance with industry standards.

The manufacturing of ceramics boron carbide involves several crucial stages that ensure the material's quality and performance characteristics. Here’s a breakdown of the main stages involved:

Material Preparation:

The process begins with the selection and preparation of raw materials, primarily boron carbide powder. High-purity boron and carbon sources are combined in precise ratios, often using techniques like ball milling to achieve a homogeneous mixture. This step is critical as it influences the final properties of the ceramic.

Forming:

The prepared powder undergoes forming techniques, which can include uniaxial pressing, isostatic pressing, or slip casting. Uniaxial pressing involves compressing the powder in a single direction to create green bodies. Isostatic pressing applies pressure uniformly from all directions, resulting in denser components. The choice of forming technique affects the density and microstructure of the final product.

Assembly:

In some cases, multiple components may need to be assembled before the final sintering process. This can involve aligning and bonding various parts, which is particularly relevant for applications requiring complex geometries or multi-layered structures.

Finishing:

After forming, the green bodies are subjected to drying and then sintering, where they are heated to high temperatures in a controlled atmosphere to achieve densification. This process not only enhances mechanical properties but also reduces porosity. Following sintering, finishing processes such as machining, grinding, or polishing may be applied to achieve the desired tolerances and surface finishes.

Quality assurance (QA) is paramount in the production of ceramics boron carbide, as it directly impacts the performance and reliability of the final products. Here are the key aspects of QA in this industry:

International Standards and Certifications:

Adherence to international quality standards, such as ISO 9001, ensures a systematic approach to quality management. Additionally, industry-specific certifications like CE for European markets and API for oil and gas applications are crucial. These certifications provide a framework for consistent quality and safety.

Quality Control Checkpoints:

- Incoming Quality Control (IQC): This stage involves verifying the quality of raw materials before they enter the manufacturing process. Suppliers must provide certificates of analysis (CoA) for their materials, which should include details on purity and composition.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are performed to monitor parameters like temperature, pressure, and dimensional accuracy. This ensures that any deviations are promptly addressed.

- Final Quality Control (FQC): Once the ceramics are sintered and finished, they undergo final inspections, including visual checks and dimensional measurements. Testing methods such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) may be employed to assess the microstructure and phase composition.

Common Testing Methods for Ceramics Boron Carbide:

- Mechanical Testing: Hardness, wear resistance, and flexural strength tests are essential for determining material performance under operational conditions.

- Thermal Analysis: Techniques like differential thermal analysis (DTA) can assess thermal stability and phase transitions, which are critical for applications in harsh environments.

- Chemical Analysis: Ensuring the correct stoichiometry of boron and carbon is vital for the performance of the final product. Techniques like energy-dispersive X-ray spectroscopy (EDX) are used for compositional analysis.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to mitigate risks and ensure product reliability. Here are actionable strategies:

Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their documentation, quality management systems, and compliance with international standards.

Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of IQC, IPQC, and FQC tests. These reports should include data on testing methods, results, and any corrective actions taken in case of non-conformance.

Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of assurance. These agencies can perform independent audits and testing, providing unbiased assessments of the supplier’s quality control practices.

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their industry and region. For instance, understanding the significance of CE marking in Europe versus API certification in the oil and gas sector can help buyers make informed decisions.

When engaging in international transactions, particularly in sectors involving ceramics boron carbide, B2B buyers must be aware of several quality control nuances:

Cultural Differences in Quality Standards: Different regions may have varying expectations and standards for quality. Buyers should be proactive in understanding these differences and communicating their quality requirements clearly to suppliers.

Regulatory Compliance: Buyers must ensure that the products comply with the regulations of their respective countries. This might include import regulations, safety standards, and environmental considerations that differ across regions.

Traceability and Documentation: Maintaining detailed documentation of the entire supply chain is vital. This includes tracking raw material sources, production batches, and quality testing results. Such traceability can aid in resolving disputes and ensuring accountability.

Building Long-Term Relationships: Establishing strong partnerships with reliable suppliers can enhance quality assurance. Long-term relationships often lead to better communication and a deeper understanding of each other's quality expectations.

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can better navigate the complexities of sourcing ceramics boron carbide, ensuring they receive high-quality products that meet their operational needs.

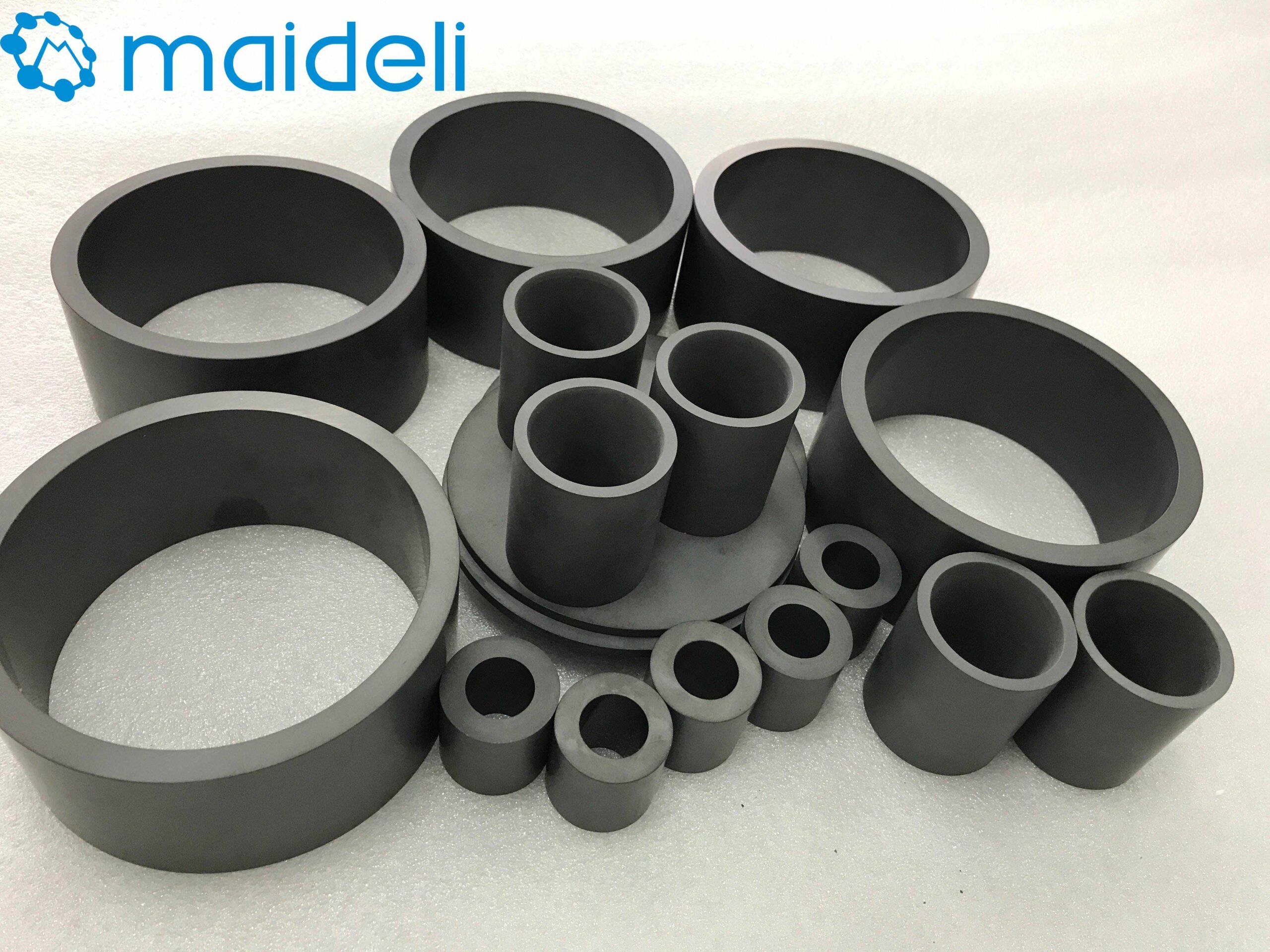

A stock image related to ceramics boron carbide.

The purpose of this guide is to provide B2B buyers with a practical checklist for sourcing ceramics boron carbide, a critical material known for its hardness and wear resistance. This structured approach will help you navigate the procurement process efficiently, ensuring that you select the right suppliers and products to meet your specific needs.

Before reaching out to suppliers, it’s essential to clearly define your technical requirements for ceramics boron carbide. This includes specifications such as the desired hardness, thermal conductivity, and the form (powder, rods, or plates) you need.

- Why it matters: Precise specifications will help suppliers understand your needs and provide accurate quotations.

- What to look for: Ensure that your specifications align with your application, whether it’s for military, industrial, or consumer use.

Investigate the current market landscape for ceramics boron carbide. This involves identifying potential suppliers, understanding pricing trends, and gathering insights on product availability.

- Why it matters: A comprehensive understanding of the market allows you to make informed decisions and negotiate better deals.

- What to look for: Pay attention to industry reports, supplier directories, and trade shows that can provide valuable information on leading manufacturers.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Why it matters: A reliable supplier is key to ensuring quality and timely delivery.

- What to look for: Check for certifications (ISO, ASTM) and industry experience, as these can indicate a supplier's reliability and quality assurance practices.

Once you have a shortlist of suppliers, request product samples to evaluate quality firsthand. This step is critical in assessing whether the material meets your specifications.

- Why it matters: Testing samples allows you to verify the supplier's claims and ensure the product performs as expected.

- What to look for: Pay attention to the material's density, texture, and any performance tests that may have been conducted.

Engage in discussions regarding pricing, delivery schedules, payment terms, and warranties. Clear communication at this stage can prevent misunderstandings later.

- Why it matters: Negotiating favorable terms can lead to cost savings and better service.

- What to look for: Ensure that all agreements are documented and include contingencies for potential issues like delays or quality discrepancies.

Understand the logistics involved in transporting ceramics boron carbide, especially if you are dealing with international suppliers.

- Why it matters: Efficient logistics can significantly affect your overall costs and project timelines.

- What to look for: Assess the supplier’s shipping capabilities and ensure they comply with international trade regulations.

Once you've made a purchase, set up a quality control procedure to monitor the incoming products. This could involve inspection upon arrival and regular checks during usage.

- Why it matters: Continuous monitoring ensures that you maintain high standards and can address any issues quickly.

- What to look for: Develop clear criteria for acceptance and procedures for handling defective materials.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing ceramics boron carbide effectively, ensuring they secure high-quality materials that meet their specific needs.

When sourcing ceramics boron carbide, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The raw materials for boron carbide can fluctuate significantly based on market demand and availability. Buyers should be aware that sourcing high-quality materials can lead to higher initial costs but can provide better long-term value.

Labor: Labor costs vary by region. In areas with lower wages, such as parts of Africa and South America, labor-intensive production can be more cost-effective. However, consider the trade-off with quality and expertise.

Manufacturing Overhead: This includes utilities, factory rent, and equipment maintenance. Manufacturers in regions with higher energy costs may pass these expenses onto buyers, affecting overall pricing.

Tooling: The cost of specialized tooling for producing ceramics boron carbide can be significant, particularly for customized products. This is often amortized over the production run, so larger orders can reduce the tooling cost per unit.

Quality Control (QC): Investing in rigorous quality control processes ensures product reliability, particularly for industries like defense or aerospace. While this adds to upfront costs, it can mitigate risks associated with defects.

Logistics: Shipping and handling costs can vary widely based on destination, volume, and chosen shipping method. Understanding logistics costs is essential, particularly for international buyers who must consider tariffs and import duties.

Margin: Suppliers typically include a profit margin in their pricing, which can vary significantly based on market conditions and competition.

Several factors influence the pricing of ceramics boron carbide, particularly for international B2B buyers:

Volume/MOQ: Suppliers often provide discounts for larger orders. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing.

Specifications and Customization: Customized products often incur higher costs due to additional tooling and processing requirements. Buyers should clearly define specifications to avoid unexpected costs.

Material Quality and Certifications: High-quality materials and necessary certifications (like ISO) can drive up costs. Buyers should assess whether these certifications are essential for their application.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better service and consistency.

Incoterms: The choice of Incoterms (International Commercial Terms) impacts overall costs and responsibilities related to shipping, insurance, and import duties. Buyers should select terms that align with their risk tolerance and logistical capabilities.

B2B buyers can adopt several strategies to optimize costs when sourcing ceramics boron carbide:

Negotiation: Building relationships with suppliers can lead to better pricing and terms. Effective negotiation often hinges on transparency regarding volume and specifications.

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors like durability and maintenance costs, which can significantly impact long-term expenses.

Market Research: Stay informed about market trends, material costs, and emerging suppliers. This knowledge can empower buyers during negotiations and help identify the best sourcing options.

Supplier Diversification: Engaging multiple suppliers can mitigate risks and provide leverage during negotiations, potentially leading to better pricing and service levels.

Understand Pricing Nuances: Familiarize yourself with the specific pricing structures and factors unique to the regions you are sourcing from, such as customs regulations in Europe or logistics challenges in Africa.

While indicative prices can offer a baseline, they can vary based on numerous factors. B2B buyers from Africa, South America, the Middle East, and Europe must conduct thorough research and engage in strategic planning to navigate the complexities of sourcing ceramics boron carbide effectively. Understanding cost components, pricing influencers, and optimization strategies will empower buyers to make informed decisions, ultimately leading to better procurement outcomes.

When considering materials for high-performance applications, it's crucial for B2B buyers to evaluate alternatives to ceramics boron carbide (B4C). This advanced ceramic is renowned for its hardness and resistance to wear, making it a popular choice in various industries, including aerospace, defense, and manufacturing. However, alternative materials may offer distinct advantages depending on the specific requirements of a project. This analysis compares ceramics boron carbide with two viable alternatives: silicon carbide (SiC) and aluminum oxide (Al2O3).

| Comparison Aspect | Ceramics Boron Carbide | Silicon Carbide (SiC) | Aluminum Oxide (Al2O3) |

|---|---|---|---|

| Performance | High hardness, excellent thermal stability | Superior thermal conductivity, lower density | Good hardness, excellent wear resistance |

| Cost | Higher manufacturing costs | Moderate costs, cost-effective for large volumes | Lower cost, widely available |

| Ease of Implementation | Requires specialized processes | Easier to machine and process | Simple to mold and process |

| Maintenance | Low maintenance, durable | Low maintenance, but can be brittle | Moderate maintenance, can wear over time |

| Best Use Case | Armor systems, nuclear applications | Semiconductor applications, high-temperature environments | General wear-resistant applications |

Silicon carbide (SiC) is a highly versatile material known for its superior thermal conductivity and strength. One of its main advantages is its ability to perform well at high temperatures, making it ideal for applications in the semiconductor industry and high-temperature environments. However, while SiC is generally easier to machine than ceramics boron carbide, it can be more brittle, which may lead to issues in applications requiring high toughness. Buyers should consider SiC for applications where thermal performance is critical and where cost-effectiveness is necessary.

Aluminum oxide (Al2O3) is another popular alternative that offers a good balance of performance and cost. It is widely used in applications requiring wear resistance, such as cutting tools and grinding media. One of its significant advantages is its lower cost and ease of manufacturing, making it an attractive option for bulk applications. However, while Al2O3 has good hardness, it may not provide the same level of thermal stability or wear resistance as ceramics boron carbide. B2B buyers should evaluate aluminum oxide when cost is a significant factor, and the application does not demand the highest performance levels.

Selecting the right material involves understanding the specific needs of your application, including performance requirements, budget constraints, and manufacturing capabilities. Ceramics boron carbide excels in high-performance environments where durability and thermal stability are paramount. In contrast, silicon carbide may be suitable for high-temperature applications, while aluminum oxide provides a cost-effective solution for general wear resistance. By carefully assessing these factors, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational goals and market demands.

When considering ceramics boron carbide, several technical properties are crucial for international B2B buyers, particularly in sectors such as aerospace, defense, and industrial manufacturing. Understanding these properties can guide purchasing decisions and ensure that the materials meet specific application requirements.

Material grade refers to the classification of boron carbide based on its purity and performance characteristics. Higher grades typically exhibit superior hardness and thermal stability, making them suitable for demanding applications such as ballistic armor and cutting tools. For B2B buyers, selecting the appropriate material grade is essential to ensure compliance with industry standards and performance expectations.

Boron carbide is known for its exceptional hardness, rated around 9.5 on the Mohs scale, making it one of the hardest materials available. This property is critical for applications requiring abrasion resistance, such as in grinding and cutting tools. Buyers should assess the hardness requirements of their specific applications to select the right grade of boron carbide that offers optimal durability.

The density of boron carbide affects its mechanical properties and weight, influencing its suitability for various applications. Lower density materials are often preferred in aerospace applications to reduce overall weight without compromising strength. Understanding the density specifications can help B2B buyers make informed decisions that align with project requirements.

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. In industries such as aerospace and automotive, precise tolerances are critical for ensuring compatibility and functionality. Buyers must communicate their tolerance requirements clearly to suppliers to avoid costly adjustments and delays in production.

Thermal conductivity is a measure of a material's ability to conduct heat. Boron carbide typically exhibits low thermal conductivity, making it an excellent insulator. This property is advantageous in applications where heat management is crucial, such as in nuclear applications or high-temperature environments. Buyers should consider thermal conductivity in conjunction with other properties to ensure the material is suitable for their specific needs.

Understanding trade terminology is vital for smooth communication and successful transactions in the ceramics boron carbide market. Here are some essential terms every B2B buyer should know.

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of ceramics boron carbide, OEMs often require specific formulations or grades for their products. B2B buyers should establish clear specifications to ensure that OEM suppliers can meet their needs effectively.

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Understanding the MOQ can help buyers negotiate better terms and avoid overstocking or stockouts.

An RFQ is a document sent to suppliers to solicit price quotes for specific products. For ceramics boron carbide, an RFQ should include detailed specifications, including material grade, quantity, and delivery timelines. This process allows buyers to compare offerings and select the best supplier based on price and capability.

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, risk, and insurance. Familiarity with these terms helps buyers understand their obligations and costs associated with international transactions, ensuring smoother logistics and financial planning.

Lead time refers to the time taken from placing an order until it is delivered. In the ceramics boron carbide sector, lead times can vary significantly based on material availability and production schedules. Buyers should inquire about lead times during negotiations to align their production schedules and avoid disruptions.

By understanding these technical properties and trade terminologies, international B2B buyers can make more informed decisions when purchasing ceramics boron carbide, ensuring that they select the right materials for their specific applications and maintain effective supplier relationships.

The ceramics boron carbide market is experiencing robust growth driven by several global factors. The increasing demand for lightweight and high-performance materials in industries such as aerospace, defense, and automotive is a significant catalyst. Additionally, the rise in the adoption of advanced ceramics for applications in ballistic armor and nuclear reactors is pushing the market forward. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are keen to leverage these advancements for enhanced product offerings.

Emerging sourcing trends indicate a shift towards digital procurement platforms that facilitate real-time supply chain visibility and enhance supplier collaboration. This technological evolution allows buyers to make informed decisions based on analytics and market intelligence. Furthermore, the trend towards customization in product specifications is gaining momentum, with manufacturers willing to adapt their offerings to meet specific buyer needs. Buyers from regions such as Italy and Australia are increasingly seeking partnerships with suppliers who can provide tailored solutions to enhance their competitive edge.

A stock image related to ceramics boron carbide.

In terms of market dynamics, fluctuating raw material prices, particularly for boron and silicon, pose challenges. However, the trend toward vertical integration, where manufacturers control the supply chain from raw materials to finished products, is gaining traction. This strategy not only mitigates risks associated with price volatility but also ensures quality and consistency in the final products.

Sustainability has emerged as a critical factor influencing B2B buying decisions in the ceramics boron carbide sector. The environmental impact of material extraction and processing cannot be overlooked, as industries are increasingly held accountable for their carbon footprint. Ethical sourcing practices are becoming essential for companies aiming to align with global sustainability goals and meet consumer expectations.

For international buyers, particularly in Europe and the Middle East, the importance of ethical supply chains is paramount. Buyers are now prioritizing suppliers who demonstrate transparency in their sourcing practices, including the use of responsibly sourced raw materials and adherence to fair labor practices. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are becoming prerequisites for supplier selection.

Moreover, the demand for 'green' certifications and materials is on the rise, with companies seeking alternatives that minimize environmental impact. In the ceramics boron carbide market, this includes sourcing materials that have lower carbon emissions during production and exploring innovative recycling methods. By integrating sustainability into their sourcing strategies, B2B buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

The evolution of ceramics boron carbide can be traced back to its initial development in the 1950s as a material for nuclear applications. Over the decades, its unique properties, including exceptional hardness and thermal stability, have led to its widespread use in various high-performance applications. The material gained significant traction in the defense sector for ballistic armor and protective gear.

As industries evolved, so did the applications of ceramics boron carbide. Today, it is not only utilized in military applications but also in aerospace, automotive, and even consumer electronics, where its lightweight and durable nature provides a competitive advantage. The historical context of ceramics boron carbide illustrates its transformation from a niche material to a critical component in advanced manufacturing, paving the way for innovative applications that meet modern challenges in various sectors.

In summary, understanding the market dynamics, prioritizing sustainability, and recognizing the historical evolution of ceramics boron carbide are crucial for international B2B buyers looking to make informed sourcing decisions and capitalize on emerging opportunities.

How do I solve quality assurance issues with ceramics boron carbide?

To address quality assurance issues when sourcing ceramics boron carbide, it's crucial to partner with suppliers who have robust quality control processes. Request detailed documentation, including certifications and test reports, to ensure compliance with international standards. Additionally, consider conducting third-party inspections or audits to verify product specifications before finalizing contracts. Establish clear communication with suppliers regarding your quality expectations and any specific standards that must be met.

What is the best payment method for importing ceramics boron carbide?

The best payment method for importing ceramics boron carbide often depends on the buyer-supplier relationship and the transaction size. Common methods include letters of credit (LC), which provide security for both parties, or telegraphic transfers (T/T) for quicker transactions. Ensure that payment terms are clearly defined in your contract, including milestones for partial payments based on delivery stages. Always assess the risk associated with the supplier and consider using escrow services for high-value transactions.

What are the minimum order quantities (MOQ) for ceramics boron carbide?

Minimum order quantities (MOQ) for ceramics boron carbide can vary widely among suppliers, typically ranging from a few hundred kilograms to several tons. When negotiating MOQs, consider your storage capacity, budget constraints, and demand forecasts. Some suppliers may offer flexibility on MOQs for first-time buyers or larger contracts, so it's advisable to discuss your needs openly to find a mutually beneficial arrangement.

How can I vet suppliers for ceramics boron carbide effectively?

Vetting suppliers for ceramics boron carbide involves several steps: research their market reputation through online reviews and industry forums, request references from previous clients, and verify their production capabilities. Additionally, assess their compliance with international standards, such as ISO certifications. A factory visit or virtual tour can provide insights into their operations and quality control processes, ensuring you select a reliable partner.

What customization options are available for ceramics boron carbide products?

Customization options for ceramics boron carbide can include variations in size, shape, and specific material properties tailored to your application. When discussing customization with suppliers, be clear about your requirements and any performance specifications needed for your end-use. Many manufacturers are willing to collaborate on research and development for bespoke solutions, particularly for high-value or specialized applications.

What logistics considerations should I be aware of when importing ceramics boron carbide?

When importing ceramics boron carbide, logistics considerations include transportation methods, customs clearance procedures, and warehousing needs. Evaluate the cost-effectiveness of air freight versus sea freight based on your delivery timelines. Ensure compliance with local regulations regarding import duties and taxes. Engaging a reliable freight forwarder can streamline the logistics process, ensuring timely delivery and minimizing disruptions.

How do I ensure compliance with international trade regulations for ceramics boron carbide?

To ensure compliance with international trade regulations, familiarize yourself with both exporting and importing country laws regarding ceramics boron carbide. This includes understanding tariffs, import quotas, and any specific documentation required, such as certificates of origin or quality. Collaborating with trade compliance experts or customs brokers can help navigate the complexities of international regulations and mitigate the risk of costly delays or penalties.

What are the common applications of ceramics boron carbide in industry?

Ceramics boron carbide is widely used in various industries due to its hardness and thermal stability. Common applications include armor plating for military and security purposes, abrasive materials for machining and grinding, and neutron absorbers in nuclear reactors. Understanding the specific needs of your industry can help in selecting the right type of boron carbide product that meets performance criteria and enhances operational efficiency.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the evolving landscape of ceramics boron carbide, strategic sourcing emerges as a pivotal element for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The key takeaways highlight the importance of establishing strong supplier relationships, leveraging local market insights, and embracing technological advancements to enhance procurement processes. Buyers should prioritize suppliers that demonstrate reliability, sustainability, and innovation, as these factors can significantly influence product quality and overall operational efficiency.

How can international buyers optimize their sourcing strategies for ceramics boron carbide? By adopting a data-driven approach to evaluate suppliers and continuously monitoring market trends, businesses can make informed decisions that align with their strategic goals. Additionally, exploring partnerships with regional suppliers can not only reduce lead times but also mitigate risks associated with global supply chain disruptions.

As the demand for high-performance materials continues to grow, it is imperative for buyers to remain proactive. The outlook for ceramics boron carbide is promising, with increasing applications across various industries. Embrace this opportunity to refine your sourcing strategy and position your business at the forefront of innovation and competitiveness in the global market.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina