The density of silicon carbide (SiC) is a fundamental property that directly impacts its performance in a wide array of industrial applications, from electronics and abrasives to high-temperature structural components. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding this characteristic is crucial for optimizing product quality, durability, and cost-efficiency.

In global supply chains, precise knowledge of SiC density enables buyers to evaluate material consistency, predict performance outcomes, and ensure compliance with industry standards. Given the diversity of SiC grades and manufacturing processes, sourcing the right density variant can significantly influence operational success—be it for semiconductor substrates in France or wear-resistant components in Kenya.

This comprehensive guide offers a deep dive into the nuances of SiC density, covering:

By equipping buyers with actionable insights and a clear framework for evaluating SiC density, this guide empowers businesses to make informed sourcing decisions that align with their technical requirements and market demands. Whether you are expanding your supplier network in Europe or navigating emerging markets in Africa and the Middle East, mastering the intricacies of SiC density is an indispensable step toward achieving competitive advantage and operational excellence.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bulk Density of SiC | Mass per unit volume including pores and voids | Ceramics manufacturing, refractory materials | + Cost-effective bulk assessment - Less precise for purity |

| Particle Density of SiC | Density of solid SiC particles excluding pores | Abrasives, polishing agents | + Accurate for material quality - Requires specialized testing |

| Apparent Density of SiC | Volume measured including inter-particle spaces | Powders handling, sintering processes | + Reflects packing efficiency - May vary with compaction |

| Tap Density of SiC | Density after mechanically tapping to reduce voids | Powder metallurgy, additive manufacturing | + Indicates flowability and packing - Sensitive to tapping method |

| True Density of SiC | Density of the SiC crystal lattice itself | High-performance composites, electronic substrates | + Highest accuracy for material integrity - Expensive testing |

Bulk Density of SiC

Bulk density measures the mass of silicon carbide per unit volume, including the space between particles and pores. This type is critical for industries like ceramics and refractory manufacturing where volume and weight impact furnace design and material handling. Buyers should consider that bulk density offers a cost-effective overview but may mask variations in purity or particle quality, which could affect product performance.

Particle Density of SiC

Particle density focuses solely on the solid material, excluding voids within particles. It is essential for applications requiring consistent abrasive quality, such as polishing and grinding. B2B buyers must invest in precise measurement techniques like pycnometry to ensure material consistency, which is crucial for maintaining product standards in competitive markets.

Apparent Density of SiC

Apparent density accounts for the volume including inter-particle spaces but excludes internal pores. It helps in assessing powder packing and sintering behavior, making it valuable for manufacturers working with powdered SiC. Buyers should evaluate how apparent density aligns with their compaction and sintering processes, as variations can affect final product strength and uniformity.

Tap Density of SiC

Tap density is measured after mechanically tapping the powder to reduce voids, reflecting how well the powder compacts and flows. This variation is particularly relevant for powder metallurgy and additive manufacturing sectors where powder handling characteristics impact production efficiency. Buyers should be aware that tap density results can vary based on tapping protocols, necessitating standardized testing for reliable comparisons.

True Density of SiC

True density represents the density of the pure SiC crystal lattice, excluding all pores and voids. It is the most accurate measure for high-performance applications like composites and electronic substrates, where material integrity is paramount. Although testing is more costly and complex, investing in true density measurements ensures optimal material selection and long-term reliability for advanced industrial applications.

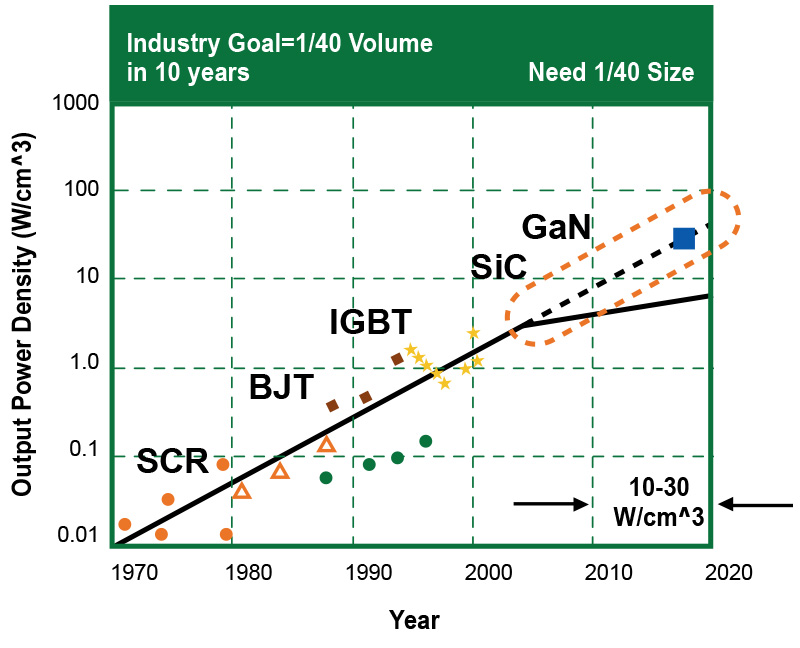

Related Video: Wide Bandgap SiC and GaN Devices - Characteristics & Applications

| Industry/Sector | Specific Application of density of sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics & Semiconductors | Substrate and heat sink materials for high-power devices | Enhanced thermal management and device reliability | Consistent density for thermal conductivity, purity levels, and batch uniformity; certification compliance important for Europe and Middle East markets |

| Automotive & Aerospace | Lightweight, high-strength composite reinforcements | Improved fuel efficiency and durability of components | Density uniformity critical for predictable mechanical properties; suppliers with robust quality control preferred, especially for export to EU and South America |

| Abrasives & Cutting Tools | High-performance abrasive grains and grinding wheels | Increased tool life and cutting precision | Precise density control ensures optimal hardness and wear resistance; sourcing from certified suppliers with traceable quality is essential |

| Energy & Power | SiC-based components in power electronics and thermal management | Higher efficiency and thermal stability in power converters | Buyers must verify density specifications to meet thermal and electrical performance; local regulations in Africa and Middle East may affect import requirements |

| Ceramics & Refractories | Manufacture of high-density SiC ceramics for industrial furnaces | Improved thermal shock resistance and extended service life | Consistent density impacts thermal conductivity and mechanical strength; sourcing partners with experience in tailored density ranges are advantageous |

Silicon carbide (SiC) density plays a pivotal role in electronics and semiconductor manufacturing, particularly in substrates and heat sinks for high-power devices. Consistent density ensures optimal thermal conductivity, critical for managing heat dissipation and improving device reliability. International buyers from Europe and the Middle East should prioritize suppliers offering certified purity and batch consistency to meet stringent quality and regulatory standards.

Illustrative Image (Source: Google Search)

In the automotive and aerospace sectors, SiC’s density directly influences the performance of composite reinforcements used to reduce weight while maintaining strength. Uniform density guarantees predictable mechanical behavior, which is essential for safety and durability. B2B buyers, especially in South America and Africa, must assess supplier quality control processes to ensure materials meet the rigorous demands of these industries.

For abrasives and cutting tools, the density of SiC grains determines hardness and wear resistance, directly affecting tool life and precision. Businesses sourcing these materials should focus on suppliers capable of delivering tightly controlled density specifications, backed by traceable quality certifications. This is particularly important for markets in Europe and the Middle East, where performance consistency is paramount.

In the energy and power industry, SiC components are increasingly used in power electronics and thermal management systems. The density of SiC affects thermal stability and electrical efficiency, making it a critical parameter for performance. Buyers in Africa and the Middle East should be mindful of local import regulations and verify that density specifications align with their application needs to optimize power converter efficiency.

Finally, in ceramics and refractories, high-density SiC ceramics are essential for industrial furnace linings due to their thermal shock resistance and longevity. The density impacts both thermal conductivity and mechanical strength, so sourcing from suppliers who understand and can tailor density ranges is beneficial. This is a key consideration for B2B buyers in all regions looking to enhance furnace performance and reduce maintenance costs.

Related Video: Fundamentals and applications of density functional theory

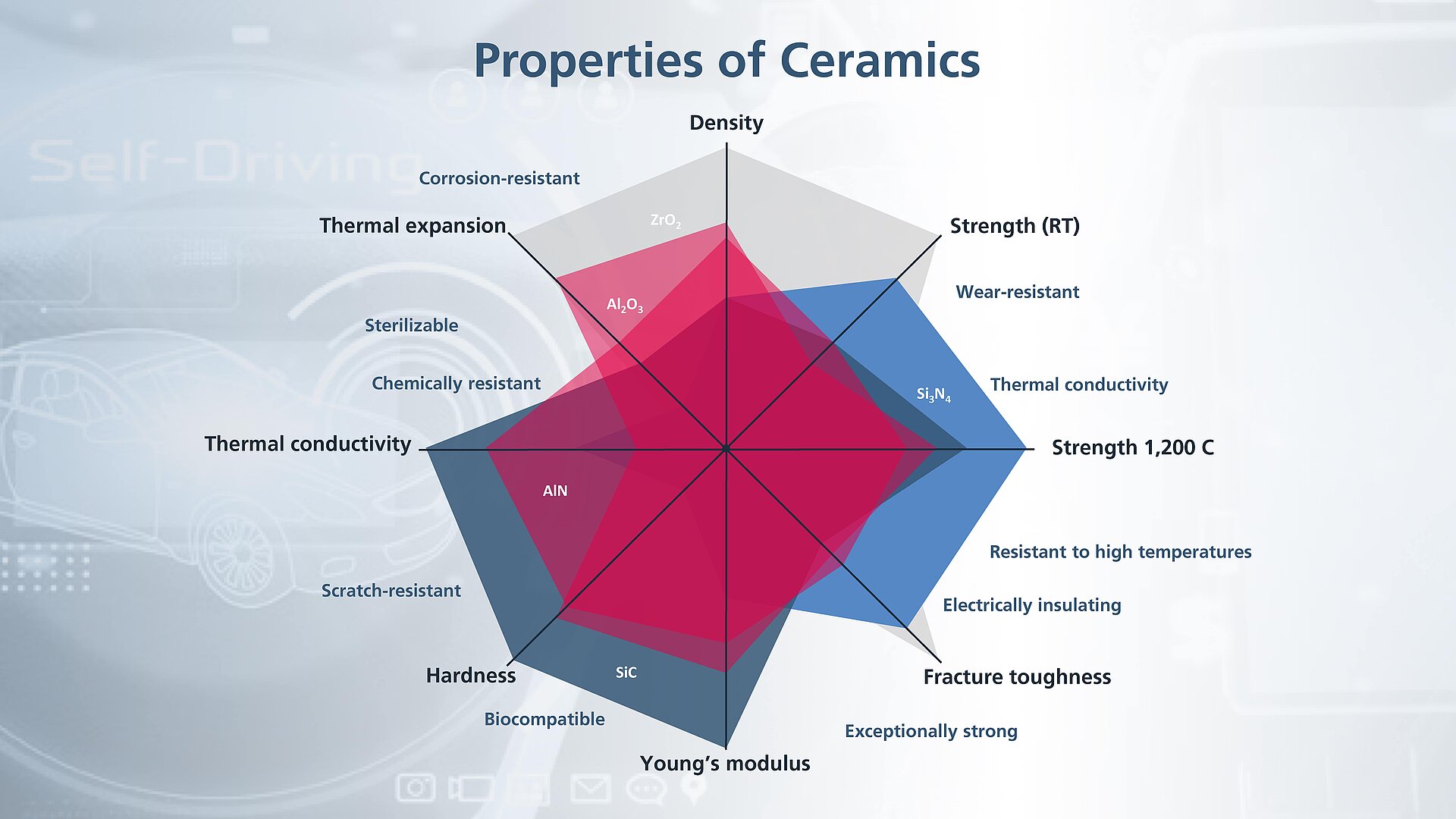

Silicon Carbide (SiC) is a critical material in various industrial applications due to its exceptional physical and chemical properties. When selecting materials based on the density of SiC, international B2B buyers must consider several common variants, each with distinct characteristics influencing their suitability for specific uses. Below is an in-depth analysis of four prevalent SiC materials from a strategic procurement perspective.

Key Properties:

RB-SiC exhibits a density typically around 3.10 g/cm³. It has excellent thermal conductivity and moderate mechanical strength, with a temperature resistance up to approximately 1400°C. Its porosity is relatively low, which enhances corrosion resistance but is less than that of fully sintered SiC.

Pros & Cons:

RB-SiC is cost-effective and easier to manufacture in complex shapes due to its reaction bonding process. However, it has lower strength and wear resistance compared to sintered SiC. Its moderate porosity can limit performance in highly corrosive environments.

Impact on Application:

Ideal for components exposed to moderate thermal and chemical stresses, such as furnace parts and wear-resistant linings. It performs well in dry and mildly corrosive media but is less suited for aggressive chemical environments.

International Buyer Considerations:

Buyers in regions like Africa and South America should evaluate local manufacturing capabilities, as RB-SiC’s production process is less complex and may be more readily sourced regionally. Compliance with ASTM C1205 and DIN EN 60672 standards is common. European buyers, particularly in France, often require certification aligned with ISO 9001 quality management due to stringent industrial regulations.

Key Properties:

SSiC has a higher density (~3.21 g/cm³), with superior hardness, strength, and thermal shock resistance. It withstands temperatures up to 1600°C and offers excellent corrosion resistance, especially against acids and alkalis.

Pros & Cons:

Its high durability and chemical inertness make it suitable for extreme environments. However, sintered SiC is more expensive and complex to manufacture, with limited machinability post-sintering.

Impact on Application:

SSiC is preferred for high-performance mechanical seals, pump components, and chemical reactors where durability under harsh conditions is critical.

International Buyer Considerations:

Middle Eastern and European buyers often prioritize SSiC for petrochemical and pharmaceutical industries, requiring adherence to ASTM C1464 and JIS R 1637 standards. Importers in Kenya and other African markets should consider the higher cost and potential supply chain lead times but benefit from the material’s longevity in corrosive applications.

Key Properties:

PSSiC offers a density close to that of sintered SiC (~3.20 g/cm³) but is produced without external pressure during sintering. It has excellent thermal stability and chemical resistance, with slightly lower mechanical strength than hot-pressed variants.

Pros & Cons:

The absence of pressure in manufacturing reduces tooling costs and allows for larger component sizes. However, mechanical properties can be less uniform, and porosity may be marginally higher, affecting wear resistance.

Impact on Application:

Suitable for large-scale industrial components like kiln furniture and heat exchangers where size and corrosion resistance are prioritized over maximum strength.

International Buyer Considerations:

European buyers, especially in Germany and France, value PSSiC for its balance of cost and performance in thermal processing industries. Buyers in South America should verify compliance with DIN 66301 and ASTM standards to ensure material consistency. African markets may find PSSiC an economical alternative for large parts but must assess supplier quality controls carefully.

Key Properties:

HPSiC features the highest density (~3.22 g/cm³) among SiC materials, combined with exceptional hardness, fracture toughness, and thermal shock resistance. It operates efficiently at temperatures exceeding 1600°C.

Pros & Cons:

The hot-pressing process yields superior mechanical properties and low porosity, enhancing durability and corrosion resistance. However, it is the most expensive SiC variant and limited to smaller component sizes due to manufacturing constraints.

Impact on Application:

Ideal for high-stress environments such as aerospace components, high-speed bearings, and semiconductor manufacturing equipment.

International Buyer Considerations:

Buyers in Europe and the Middle East often require HPSiC for cutting-edge applications, with strict adherence to ASTM C139 and JIS R 1637 standards. African and South American buyers should weigh the high cost against the critical performance benefits, especially where long-term reliability is paramount.

| Material | Typical Use Case for density of sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Reaction Bonded Silicon Carbide (RB-SiC) | Furnace parts, wear-resistant linings | Cost-effective, easy to manufacture complex shapes | Lower strength and wear resistance | Low |

| Sintered Silicon Carbide (SSiC) | Mechanical seals, chemical reactors | High durability, excellent corrosion resistance | Expensive, limited machinability | High |

| Pressureless Sintered Silicon Carbide (PSSiC) | Kiln furniture, heat exchangers | Allows large components, balanced cost-performance | Slightly lower mechanical strength, variable porosity | Medium |

| Hot-Pressed Silicon Carbide (HPSiC) | Aerospace parts, semiconductor equipment | Highest strength and thermal resistance | Highest cost, size limitations | High |

This guide equips international B2B buyers with actionable insights into selecting the optimal SiC material density variant, balancing performance requirements, cost considerations, and regional compliance standards. Strategic sourcing aligned with these factors ensures enhanced product longevity and operational efficiency across diverse industrial applications.

Understanding the manufacturing process behind silicon carbide (SiC) with controlled density is crucial for B2B buyers aiming to source high-quality materials tailored to specific industrial applications. The density of SiC significantly influences its mechanical strength, thermal conductivity, and electrical properties, making precise control during manufacturing essential.

The initial stage involves selecting high-purity raw materials, primarily silicon and carbon sources, often in the form of quartz sand and petroleum coke. The purity and particle size distribution of these inputs directly affect the final SiC density and performance. Advanced milling techniques ensure a uniform particle size, which is critical for consistent sintering behavior and density control.

Illustrative Image (Source: Google Search)

SiC powder is shaped into the desired form through various methods such as:

- Cold Pressing: Applying high pressure to compact the powder into molds.

- Hot Pressing: Combining pressure and heat to enhance densification during shaping.

- Injection Molding: For complex geometries, enabling uniform density distribution.

- Tape Casting: Used for thin layers or sheets, controlling thickness and density precisely.

Each method impacts the green body's density and porosity, which are critical precursors to the final density of the sintered product.

Sintering is a high-temperature process where compacted SiC particles bond together without melting, significantly increasing density and mechanical integrity. Techniques include:

- Pressureless Sintering: Common for bulk SiC, typically in inert atmospheres to prevent oxidation.

- Hot Isostatic Pressing (HIP): Applies uniform pressure from all directions at high temperature, achieving near-theoretical density and reducing internal defects.

- Reactive Sintering: Sometimes used to form SiC in situ from silicon and carbon powders, influencing microstructure and density.

Post-sintering, components may be assembled into larger units or integrated with other materials depending on the application.

Finishing involves grinding, machining, and surface treatments to achieve precise dimensions and surface quality. These steps are vital to maintain the integrity of the dense SiC structure and ensure performance under operational stresses. Advanced finishing methods such as laser machining or ultrasonic grinding are employed to minimize surface damage and maintain density-related properties.

For international B2B buyers, ensuring supplier adherence to rigorous quality standards is essential to guarantee the performance and reliability of SiC products. Quality assurance spans from raw material inspection through final product verification, supported by internationally recognized standards and systematic testing.

Compliance with these standards assures buyers of consistent quality and regulatory acceptance across regions.

Each checkpoint is vital for early detection of defects that could affect density and performance.

These methods allow precise quantification of density and its uniformity, crucial for high-performance applications.

Engaging in these verification steps reduces risk and ensures the material meets application-specific requirements.

B2B buyers from Africa, South America, the Middle East, and Europe face unique challenges and opportunities when sourcing SiC materials with specific density requirements.

By navigating these nuances effectively, international buyers can secure high-density SiC materials that meet their technical and regulatory needs while minimizing supply chain risks.

Summary: For B2B buyers, a thorough understanding of the SiC manufacturing stages and robust quality assurance frameworks is indispensable. Prioritizing suppliers with advanced densification techniques, adherence to international standards, and transparent QC practices will ensure the procurement of SiC materials with reliable density and performance suited to demanding industrial applications across diverse global markets.

When evaluating the cost structure for sourcing density of silicon carbide (SiC), it is essential to understand the multiple components that contribute to the final pricing:

Several factors beyond basic costs impact the final price when sourcing SiC density materials:

For buyers from Africa, South America, the Middle East, and Europe, navigating the complexities of SiC density sourcing requires strategic approaches:

All pricing insights provided are indicative and subject to change based on market conditions, supplier negotiations, and geopolitical factors. Buyers are encouraged to conduct thorough due diligence and obtain multiple quotations to ensure competitive and accurate pricing tailored to their specific sourcing needs.

Understanding the density of Silicon Carbide (SiC) is crucial for B2B buyers aiming to optimize product performance and cost-efficiency in applications such as abrasives, refractories, and semiconductors. Here are the critical technical properties related to SiC density that international buyers should consider:

Material Grade

SiC is available in various grades, such as alpha (α-SiC) and beta (β-SiC), each with distinct crystal structures affecting density and hardness. Higher-grade SiC typically exhibits greater density and purity, which translates to enhanced mechanical strength and thermal conductivity. For buyers, selecting the right grade ensures compatibility with intended industrial applications and longevity.

Bulk Density

Bulk density refers to the mass of SiC per unit volume, including the void spaces between particles. This property impacts packing, transportation costs, and the sintering behavior in manufacturing processes. Buyers should confirm bulk density values to optimize logistics and ensure consistent product quality.

True Density

True density measures the mass of SiC material excluding pores or voids. It is a direct indicator of material compactness and purity. Higher true density typically means fewer impurities and better structural integrity, which is vital for high-performance applications like electronic substrates.

Particle Size Distribution

Particle size influences the packing density and surface area of SiC powders. Finer particles generally increase density but may affect flowability. Understanding particle size distribution helps buyers specify materials that meet precise processing requirements and achieve desired end-product characteristics.

Density Tolerance

This defines the acceptable variation range in density values during production and quality control. Tight tolerance ensures consistency across batches, reducing risks of performance variability. Buyers should negotiate clear density tolerance limits in contracts to maintain product reliability.

Porosity

Porosity relates inversely to density and affects mechanical strength and thermal resistance. Low porosity (high density) SiC materials are preferred for applications demanding durability and heat resistance. Evaluating porosity helps buyers assess material suitability for harsh operating environments.

Navigating international SiC procurement requires familiarity with common trade terms that impact pricing, delivery, and contractual obligations. Below are key terms every B2B buyer should know:

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products using SiC materials. Understanding whether your supplier works with or is an OEM can influence product customization options, quality standards, and after-sales support.

MOQ (Minimum Order Quantity)

This is the smallest amount of SiC material a supplier is willing to sell in one order. MOQs affect inventory management and cost efficiency, especially for buyers in emerging markets like Kenya or smaller European enterprises. Negotiating MOQs can lead to better cash flow and reduced storage costs.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, delivery timelines, and technical specifications for SiC products. Crafting detailed RFQs with clear density and grade requirements helps buyers receive accurate, comparable offers and speeds up procurement decisions.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Selecting appropriate Incoterms ensures clarity in cost allocation and risk management during international shipment.

Certificate of Analysis (CoA)

A document provided by the supplier that details the physical and chemical properties of the SiC batch, including density measurements. Requesting a CoA guarantees transparency and helps buyers verify compliance with technical specifications.

Lead Time

The time interval from placing an order to receiving the SiC material. Knowing lead times is essential for production planning and meeting project deadlines, especially when sourcing from distant regions like South America or the Middle East.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize supply chain efficiency, and ensure the quality and reliability of Silicon Carbide products tailored to their specific industrial needs.

The market for silicon carbide (SiC) density materials is rapidly evolving, driven by the increasing demand for high-performance semiconductors and advanced power electronics. Globally, the push towards electrification, renewable energy integration, and electric vehicles (EVs) is a primary catalyst for SiC adoption. For B2B buyers from Africa, South America, the Middle East, and Europe—regions with diverse industrial needs—understanding these dynamics is crucial for strategic sourcing.

Key market drivers include:

Emerging sourcing trends to note:

For B2B buyers, aligning sourcing strategies with these trends ensures resilience and competitive advantage in a market characterized by rapid innovation and geopolitical complexities.

Sustainability has become a cornerstone in the procurement of silicon carbide density materials. The environmental impact of SiC production—especially energy-intensive processes like crystal growth and wafer slicing—necessitates a focus on reducing carbon footprints and promoting circular economy principles.

Key sustainability considerations include:

Buyers should prioritize suppliers with recognized green certifications such as ISO 14001 (Environmental Management) and adhere to frameworks like the Responsible Minerals Initiative (RMI). Additionally, emerging eco-labels specific to semiconductor materials are gaining traction, signaling commitment to sustainability.

Embedding sustainability into sourcing decisions not only mitigates risks associated with regulatory compliance and reputational damage but also aligns with global corporate responsibility goals. This approach is essential for long-term value creation in the SiC density sector.

The silicon carbide industry has evolved from niche abrasive applications to a critical enabler of next-generation electronics. Initially developed in the late 19th century for industrial uses, SiC's semiconductor potential was recognized only in the late 20th century with advances in crystal growth technologies.

Historically, the challenge was producing high-purity, defect-free SiC wafers with controlled density suitable for electronic applications. Breakthroughs in chemical vapor deposition (CVD) and physical vapor transport (PVT) methods in the 1990s and 2000s paved the way for commercial-scale production.

Today, the density of SiC materials is a key quality parameter directly influencing device performance and reliability. Understanding this evolution helps B2B buyers appreciate the complexity and value proposition of sourcing high-density SiC components tailored to their specific industrial needs.

How can I effectively vet suppliers of silicon carbide (SiC) density materials for international trade?

Begin by verifying the supplier’s certifications such as ISO 9001 for quality management and relevant industry-specific accreditations. Request product datasheets and independent lab test reports confirming density specifications. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers with a proven export track record to your region to ensure compliance with local import regulations. Utilize platforms like Alibaba, Global Sources, or industry trade shows to connect with reputable manufacturers. Conduct background checks on company financials and customer references to mitigate risks.

Is customization of SiC density possible, and how does it impact cost and lead times?

Yes, many manufacturers offer customization of SiC density based on your application needs, such as abrasives or semiconductors. Customization often requires adjustments in raw material sourcing and processing techniques, which can increase costs by 10-30%. Lead times may extend by 2-6 weeks depending on complexity and order volume. Early communication of your technical requirements and flexibility in minimum order quantities (MOQs) can help optimize both cost and delivery schedules.

What are typical minimum order quantities (MOQs) and lead times for international buyers of SiC density materials?

MOQs vary widely depending on the supplier and product grade but typically range from 500 kg to 5 metric tons. For first-time international buyers, some suppliers may offer lower MOQs to establish trust. Lead times for standard density SiC products usually span 3-6 weeks, including manufacturing and shipping. Planning ahead is crucial, especially when importing to regions with longer customs clearance times, such as parts of Africa and the Middle East.

Which payment terms are most common and secure for cross-border SiC density purchases?

Letters of Credit (LC) and Telegraphic Transfers (T/T) are standard payment methods in international B2B transactions. LCs provide security for both buyer and supplier by ensuring payment upon meeting agreed terms, while T/T is faster but requires trust. For new suppliers, consider escrow services or partial payments upfront with balance on delivery. Always confirm currency exchange considerations and potential banking fees when dealing with cross-border payments.

What quality assurance measures should I expect from SiC density suppliers?

Reputable suppliers implement stringent quality control processes, including raw material inspection, in-process monitoring, and final product testing for density, purity, and particle size. Request certificates of analysis (CoA) and compliance with international standards such as ASTM or ISO. Some suppliers also offer third-party lab verification. Regular audits or factory visits (virtual or physical) can help maintain quality consistency, especially for long-term contracts.

Are there specific certifications or standards I should require for SiC density products when importing into Europe, Africa, or the Middle East?

Compliance with REACH and RoHS is critical for European markets to ensure chemical safety and environmental standards. For Africa and the Middle East, certifications may include ISO 9001 and local regulatory approvals related to import and usage. Always verify if the product meets ASTM or JIS standards for density and purity. Obtaining documentation that supports customs clearance and environmental compliance will reduce delays and penalties.

What logistics considerations should I keep in mind when importing SiC density materials internationally?

Due to the abrasive and sometimes hazardous nature of SiC powders, ensure suppliers provide proper packaging compliant with international shipping regulations (e.g., IMO for sea freight). Choose freight forwarders experienced with chemical or mineral shipments and verify shipping routes that minimize transit time to your region. Consider Incoterms carefully—FOB or CIF terms are common, but clarity on responsibilities for customs clearance and insurance is essential to avoid unexpected costs.

How should I handle disputes or quality issues with SiC density suppliers across different regions?

Establish clear contractual terms covering product specifications, inspection rights, and remedies before purchase. If disputes arise, initiate communication promptly and provide detailed evidence such as photos, test reports, and delivery documents. Utilize arbitration clauses or third-party mediation to resolve conflicts efficiently. Maintaining a good relationship with suppliers through transparency and regular feedback can prevent many issues. For buyers in emerging markets, engaging local trade chambers or export promotion agencies can provide additional support.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of silicon carbide (SiC) density materials presents a critical opportunity for international B2B buyers aiming to enhance product performance and operational efficiency. Understanding the precise density characteristics of SiC enables informed supplier selection, quality assurance, and cost optimization—key factors for industries ranging from electronics to automotive manufacturing.

Key takeaways for buyers include:

Looking ahead, strategic sourcing in the SiC density domain will increasingly benefit from advancements in material science and digital procurement platforms, fostering greater supply chain transparency and agility. For B2B buyers in markets such as France, Kenya, and beyond, proactive engagement with trusted suppliers and ongoing market intelligence will be essential to capitalize on emerging opportunities.

Actionable next steps: Establish strategic partnerships with SiC manufacturers prioritizing density quality, invest in supplier audits focusing on material characterization, and adopt data-driven sourcing strategies to future-proof your supply chain in this dynamic sector.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina