In today's competitive landscape, sourcing high-quality einkristalle (crystal glass) can be a significant challenge for international B2B buyers. With an increasing demand for innovative materials across various industries, including automotive, electronics, and decorative arts, understanding the nuances of the einkristalle market is essential for making informed purchasing decisions. This guide offers a comprehensive overview, covering the different types of einkristalle, their diverse applications, and effective supplier vetting strategies to ensure you partner with reliable manufacturers.

The complexities of sourcing einkristalle extend beyond just identifying suppliers. Buyers must navigate considerations such as cost factors, quality standards, and regional availability, which can vary significantly across continents. This guide aims to empower B2B buyers from Africa, South America, the Middle East, and Europe—such as those in Argentina and South Africa—by providing actionable insights tailored to their specific market needs.

By delving into the intricacies of einkristalle, this resource equips you with the knowledge needed to optimize your sourcing strategy, mitigate risks, and ultimately enhance your product offerings. Whether you are looking to integrate einkristalle into new designs or seeking to streamline your supply chain, this guide serves as a vital tool for making strategic, informed decisions in the global market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monocrystalline | High purity, single crystal structure | Electronics, solar cells | Pros: Excellent conductivity; Cons: Higher cost and more fragile. |

| Polycrystalline | Multiple crystal grains, less uniform | Solar panels, metals | Pros: Cost-effective; Cons: Lower efficiency compared to monocrystalline. |

| Amorphous | Non-crystalline, flexible material | Thin-film solar cells, flexible electronics | Pros: Lightweight, versatile; Cons: Lower efficiency and durability. |

| Czochralski | Grown using Czochralski process, high quality | High-end electronics, optical devices | Pros: High purity and uniformity; Cons: Complex and expensive production. |

| Float Zone | Zone melting process, minimal impurities | Specialty materials, semiconductor applications | Pros: Superior electrical properties; Cons: Limited scalability and higher costs. |

Monocrystalline einkristalle are recognized for their high purity and single-crystal structure. This uniformity provides exceptional electrical conductivity, making them ideal for high-performance applications such as electronics and solar cells. B2B buyers should consider the higher initial investment required for monocrystalline options, balanced against their long-term efficiency and performance benefits.

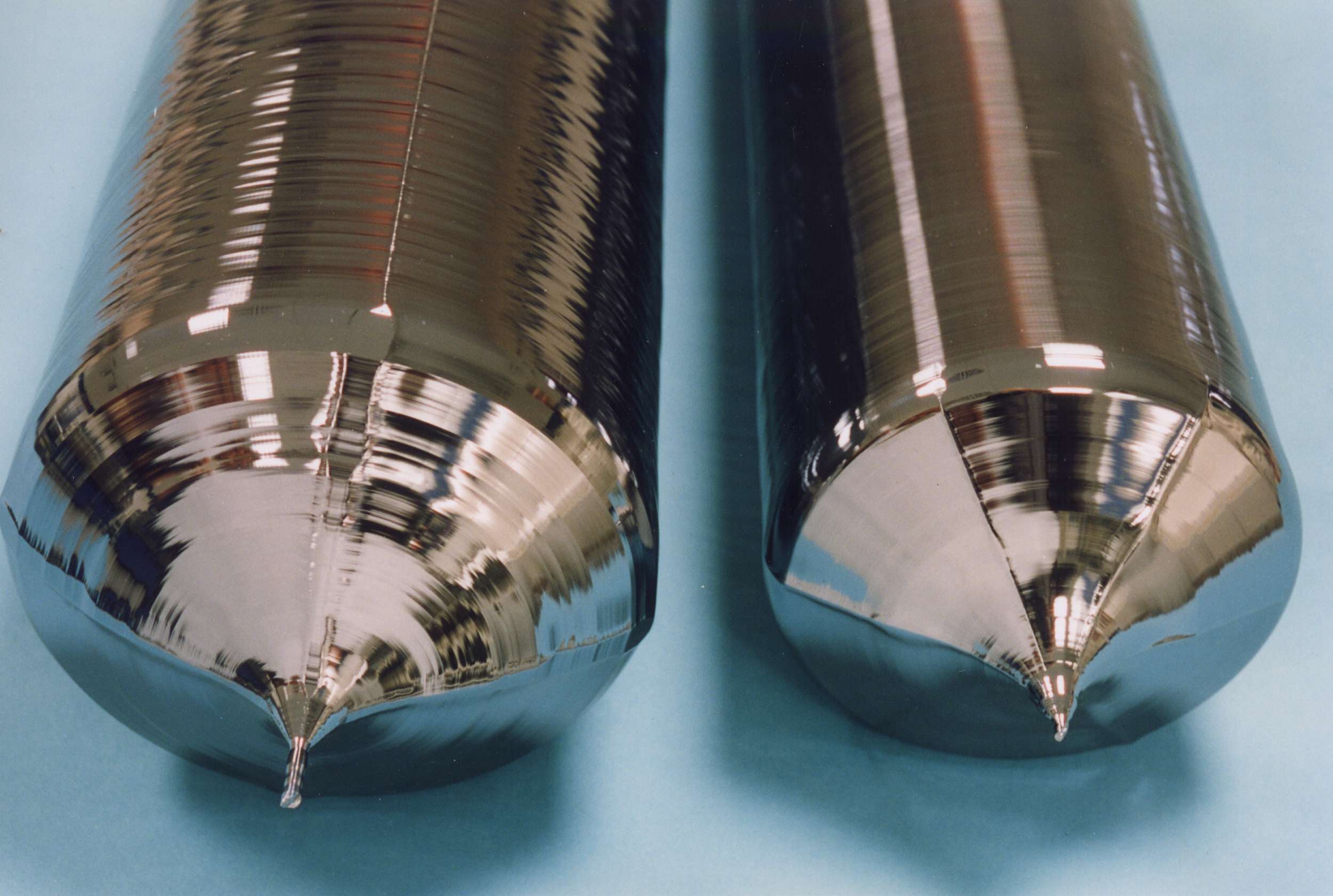

A stock image related to einkristalle.

Polycrystalline einkristalle consist of multiple crystal grains, leading to a less uniform structure compared to monocrystalline types. They are widely used in the production of solar panels and various metal applications due to their cost-effectiveness. Buyers should weigh the lower efficiency against the reduced manufacturing costs, particularly in applications where budget constraints are significant.

Amorphous einkristalle lack a defined crystal structure, resulting in flexible and lightweight materials. This characteristic makes them suitable for thin-film solar cells and flexible electronic devices. B2B buyers should note that while amorphous einkristalle offer versatility, they typically exhibit lower efficiency and durability, which may limit their application scope in high-demand environments.

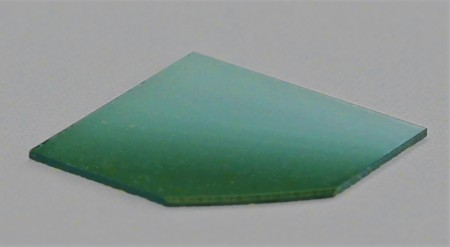

A stock image related to einkristalle.

Czochralski einkristalle are produced through a specific growth process that yields high-quality crystals with minimal impurities. This makes them ideal for high-end electronics and optical devices, where performance is critical. However, the complexity and cost of production may deter some buyers, making it essential to assess the application requirements against the potential return on investment.

Float zone einkristalle are created using a zone melting technique that results in minimal impurities, offering superior electrical properties. They are particularly valuable in specialty materials and semiconductor applications. Buyers should consider the limited scalability and higher production costs, ensuring that the benefits align with their operational needs and product specifications.

| Industry/Sector | Specific Application of einkristalle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Display Technology in Smartphones and Tablets | Enhanced display clarity and energy efficiency | Ensure compatibility with existing technologies and suppliers' reliability. |

| Automotive | Advanced Sensor Systems in Vehicles | Improved safety and performance | Focus on sourcing materials that meet stringent automotive standards. |

| Renewable Energy | Solar Panel Manufacturing | Increased energy conversion efficiency | Look for suppliers with proven technology and certifications. |

| Healthcare | Medical Imaging Devices | Higher resolution imaging for accurate diagnostics | Verify compliance with medical regulations and quality standards. |

| Consumer Goods | Smart Home Devices | Improved functionality and user experience | Assess the scalability of supply to meet growing consumer demand. |

In the electronics sector, einkristalle are pivotal in display technology for smartphones and tablets. They enhance display clarity while also improving energy efficiency, which is crucial for battery-operated devices. For international B2B buyers, especially in regions like Africa and South America, sourcing einkristalle requires ensuring compatibility with existing technologies and confirming the reliability of suppliers. This includes verifying the quality of the einkristalle to meet consumer expectations in a competitive market.

Einkristalle are utilized in advanced sensor systems within vehicles, contributing to enhanced safety features such as collision detection and lane-keeping assistance. These sensors improve overall vehicle performance, which is increasingly demanded in the automotive industry. Buyers from the Middle East and Europe should prioritize sourcing materials that comply with stringent automotive standards to ensure durability and reliability in their applications.

In renewable energy, particularly in solar panel manufacturing, einkristalle significantly boost energy conversion efficiency. This improvement is essential for maximizing the output of solar energy systems. International buyers, particularly in regions with growing renewable energy initiatives like Africa and South America, should seek suppliers with proven technology and relevant certifications to ensure the quality and sustainability of the einkristalle used in their solar panels.

Einkristalle are integral to medical imaging devices, providing higher resolution images that facilitate accurate diagnostics. This application is critical in healthcare settings where precision is paramount. B2B buyers from Europe and the Middle East need to verify that their suppliers comply with medical regulations and quality standards, ensuring that the einkristalle used in imaging devices meet the necessary safety and efficacy requirements.

In the realm of consumer goods, einkristalle improve the functionality and user experience of smart home devices. This includes applications in smart thermostats, security systems, and connected appliances. For international buyers, particularly in rapidly growing markets, assessing the scalability of supply is crucial to meet increasing consumer demand while maintaining product quality and innovation.

Related Video: Uses of Metals and Non Metals

The Problem:

B2B buyers often struggle to find reliable suppliers of einkristalle (single crystals) that meet their specific quality standards. This challenge is particularly pronounced for companies in regions like Africa and South America, where access to premium materials can be limited. Poor quality einkristalle can lead to defective products, increased production costs, and ultimately, a negative impact on customer satisfaction. The lack of transparency in the supply chain can further exacerbate these issues, leaving buyers uncertain about the origins and quality of the crystals they procure.

The Solution:

To effectively source high-quality einkristalle, buyers should establish relationships with reputable suppliers that have a proven track record in the industry. It's essential to conduct thorough due diligence by requesting samples, certifications, and documentation that verifies the quality and origin of the crystals. Utilizing platforms like Alibaba or industry-specific trade fairs can also help buyers identify trustworthy suppliers. Additionally, consider investing in a quality assurance process that includes regular inspections and audits of suppliers to ensure compliance with your standards. Engaging with local chambers of commerce or trade associations can provide further insights into reliable suppliers in your region.

The Problem:

B2B buyers frequently face challenges in determining the correct type of einkristalle needed for specific applications. With various types of crystals available, each with unique properties and uses, the risk of selecting the wrong type can lead to project delays and increased costs. This is especially critical in industries such as electronics and optics, where the performance of the final product heavily depends on the characteristics of the crystals used.

The Solution:

To mitigate this issue, buyers should invest time in understanding the different types of einkristalle and their specific applications. Collaborating with technical experts or consultants can provide valuable insights into the best materials suited for particular projects. Additionally, creating a comprehensive requirements document that outlines the desired properties, such as thermal conductivity, optical clarity, or piezoelectric characteristics, can guide the selection process. Suppliers often have technical support teams that can assist in matching the right type of einkristalle to your needs, so don't hesitate to leverage their expertise.

The Problem:

Another common pain point for B2B buyers is ensuring the consistent quality of einkristalle during production and usage. Variations in quality can arise due to factors such as improper handling, subpar storage conditions, or fluctuations in the supply chain. This inconsistency can result in significant production setbacks, impacting timelines and budgets.

The Solution:

To ensure consistent quality, buyers should implement strict handling and storage protocols for einkristalle. This includes maintaining optimal temperature and humidity levels in storage facilities to prevent degradation of the crystals. Additionally, training staff on proper handling techniques can minimize the risk of damage during transport and usage. Establishing a robust quality control system, including regular testing and validation of the crystals before use in production, is essential. Consider partnering with suppliers that offer warranties or guarantees on their products, which can provide an added layer of assurance regarding the quality of the einkristalle you are sourcing.

When selecting materials for einkristalle, it is essential for international B2B buyers to understand the properties, advantages, and limitations of various materials. The choice of material can significantly impact product performance, manufacturing processes, and compliance with regional standards. Below, we analyze four common materials used in einkristalle applications, focusing on their key properties, pros and cons, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Glass is a widely used material in the production of einkristalle due to its excellent optical properties and versatility.

Polycarbonate is another popular choice, especially in applications requiring impact resistance.

Metals, particularly stainless steel and aluminum, are also utilized in certain einkristalle applications.

Ceramics are increasingly being explored for their unique properties in einkristalle applications.

| Material | Typical Use Case for einkristalle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Optical components | Low cost and good transparency | Brittle and prone to breakage | Low |

| Polycarbonate | Protective covers | High impact resistance | Expensive and UV degradation | Medium |

| Metals | Structural components | Excellent strength and durability | Heavier and complex manufacturing | High |

| Ceramics | High-temperature applications | Thermal stability and hardness | Brittle and limited flexibility | Medium to High |

This analysis provides a comprehensive overview of the materials commonly used in einkristalle applications, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

The manufacturing of einkristalle, or single crystals, involves several critical stages that ensure high quality and performance. Understanding these processes is essential for B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, where sourcing quality materials is paramount.

The first step in the manufacturing process is material preparation. This involves selecting high-purity raw materials, typically silicon or other semiconductor materials. The quality of these materials directly impacts the final product's performance. Suppliers must ensure that the materials meet specific purity standards, often verified through supplier certifications and third-party testing.

Once the materials are selected, they undergo thorough cleaning and treatment to remove any contaminants. This step is critical as even minor impurities can affect the electrical and optical properties of the einkristalle. Buyers should inquire about the supplier’s cleaning protocols and the purity levels of the raw materials used.

The forming process for einkristalle typically employs techniques such as the Czochralski method or the Bridgman method.

Czochralski Method: In this technique, a seed crystal is dipped into a molten material. As the seed is slowly pulled upwards, the material solidifies on the seed, forming a single crystal. This method is favored for its ability to produce large crystals with controlled dimensions.

Bridgman Method: This involves the controlled cooling of a molten material in a crucible. As the material cools, it solidifies into a single crystal. This method is useful for specific applications where the crystal structure needs to be precisely controlled.

Buyers should assess whether suppliers use advanced forming technologies and maintain strict temperature controls, as variations can lead to defects in the crystals.

Following forming, the crystals undergo assembly and finishing processes. This stage includes cutting, grinding, and polishing to achieve the desired specifications. Techniques such as laser cutting and precision grinding are employed to ensure high accuracy.

Finishing processes also include coating and surface treatments that enhance the crystal's properties, such as optical clarity or electrical conductivity. B2B buyers should verify the capabilities of suppliers in executing these processes to meet specific application needs.

Quality assurance is crucial in the manufacturing of einkristalle. Various international standards govern the quality and safety of these products, including:

ISO 9001: This standard focuses on quality management systems and is applicable across industries. Suppliers adhering to ISO 9001 demonstrate a commitment to quality and customer satisfaction.

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. B2B buyers in Europe should prioritize suppliers with CE certification.

API Standards: In sectors like pharmaceuticals and oil & gas, adherence to API (American Petroleum Institute) standards is essential. This is particularly relevant for applications involving einkristalle in these industries.

Quality control (QC) is typically structured around several key checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival. Suppliers should perform thorough tests to ensure materials meet specified standards before production begins.

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor processes and detect any deviations from quality standards. This ensures that any defects are identified early, minimizing waste and rework.

Final Quality Control (FQC): Before shipment, finished einkristalle undergo a final inspection. This includes functionality tests, dimensional checks, and surface quality evaluations. Buyers should request FQC reports to verify compliance with specifications.

Several testing methods are essential for ensuring the quality of einkristalle:

B2B buyers should ensure that suppliers provide detailed testing reports and certifications that confirm the results of these tests.

To ensure supplier reliability, B2B buyers should consider the following verification methods:

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality certification. Different regions may have varying standards and expectations regarding quality assurance.

Regional Standards: Buyers should familiarize themselves with local regulations and standards that may impact product acceptance. For example, products sold in the EU must comply with specific directives that may not apply elsewhere.

Language and Documentation: Ensure that all quality documentation is available in a language that is understandable. This is crucial for verifying compliance with local regulations.

Cultural Considerations: Building strong relationships with suppliers can help facilitate better communication regarding quality expectations. Understanding cultural differences can play a role in establishing trust and ensuring quality compliance.

By thoroughly understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing einkristalle, ensuring that they receive high-quality products that meet their specific needs.

In the competitive landscape of international B2B procurement, sourcing high-quality einkristalle (crystal) requires a systematic approach. This guide provides a step-by-step checklist tailored for buyers from diverse regions, ensuring you navigate the complexities of the sourcing process effectively.

What specifications do you need for einkristalle?

Understanding your requirements is critical. Define the size, purity, and type of einkristalle you need, as different applications may demand specific characteristics. This clarity will help you communicate effectively with suppliers and avoid mismatches.

How can you find reliable suppliers for einkristalle?

Conduct thorough research to identify potential suppliers. Utilize industry-specific directories, trade shows, and online platforms such as Alibaba or Global Sources. Focus on suppliers with a solid reputation and experience in exporting to your target region, ensuring they understand local regulations and market dynamics.

Why are supplier certifications important?

Before proceeding, ensure that your potential suppliers hold relevant certifications, such as ISO 9001 or industry-specific quality assurance standards. These certifications indicate adherence to quality management practices and can significantly reduce the risk of sourcing inferior products.

How can you assess product quality before bulk ordering?

Request samples of the einkristalle from shortlisted suppliers. This step is vital for evaluating the quality, clarity, and consistency of the crystals. Assess the samples under different lighting conditions and in various applications to ensure they meet your standards.

What should you consider regarding pricing structures?

Compare pricing from multiple suppliers, keeping in mind that the lowest price does not always guarantee the best value. Analyze payment terms, including deposit requirements and payment methods. Favor suppliers who offer flexible payment options and transparent pricing structures to facilitate smoother transactions.

What logistics should you consider when sourcing from abroad?

Discuss shipping options, delivery timelines, and associated costs with your suppliers. Ensure they have experience in international shipping and can provide tracking information. Understanding the logistics will help you plan your inventory and manage lead times effectively.

How can effective communication improve your sourcing experience?

Establish clear communication channels with your suppliers. Regular updates, feedback mechanisms, and responsiveness can foster a collaborative relationship. Ensure you have a dedicated contact person to address any queries or concerns promptly throughout the sourcing process.

By following this checklist, international B2B buyers can streamline their procurement of einkristalle, ensuring quality products and effective supplier relationships.

When sourcing einkristalle, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

Materials: The quality and type of raw materials directly influence the cost of einkristalle. Higher-quality materials will generally incur higher costs, but they may also offer better performance and durability.

Labor: Labor costs vary significantly by region. In countries like South Africa and Argentina, labor costs may be lower than in Europe. However, skilled labor for quality control and production processes can raise costs.

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

Tooling: Custom tooling for specific specifications can add to the initial cost. Buyers should assess whether standard tooling can suffice to keep costs down.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to overall costs. Buyers should weigh the benefits of enhanced quality against the added expenses.

Logistics: Shipping and handling costs can vary widely based on the distance and mode of transport. International buyers must consider customs duties and tariffs as additional logistical costs.

Margin: Suppliers typically include a profit margin, which can vary based on market conditions and competition. Understanding the supplier's pricing strategy is essential for negotiations.

Several factors influence the pricing of einkristalle that international buyers should consider:

Volume/MOQ: Minimum order quantities (MOQs) often determine pricing. Larger orders typically lead to lower per-unit costs, making it advantageous for buyers to consolidate orders.

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should evaluate the necessity of customization against the potential increase in price.

Materials: The choice of materials can affect not only the base price but also long-term performance and maintenance costs. Ensure that material choices align with intended use.

Quality and Certifications: Products that meet specific quality certifications may carry a premium. However, these certifications often translate into higher reliability and customer satisfaction.

Supplier Factors: Supplier reputation, reliability, and financial stability can impact pricing. Established suppliers may charge more due to their proven track record.

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics costs and responsibilities. Understanding these terms can help in negotiating better shipping terms and costs.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Negotiate Effectively: Leverage your purchasing power, especially if placing large orders. Use market research to justify your pricing expectations during negotiations.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, warranty, and potential downtime. A lower upfront cost may lead to higher TCO.

Understand Pricing Nuances: Be aware of local market conditions and currency fluctuations that can affect pricing. This is particularly important for buyers in regions with volatile economies.

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers may offer discounts or improved service for repeat business.

Stay Informed on Market Trends: Keep abreast of industry trends, material costs, and technological advancements that may affect pricing. This knowledge can provide leverage in negotiations.

It is essential for buyers to note that prices can vary significantly based on the aforementioned factors. The information provided is for indicative purposes only and should not be taken as fixed pricing. Always conduct thorough market research and supplier evaluations to get the most accurate and up-to-date pricing information.

When considering solutions for specific applications, it's essential to evaluate the available alternatives to ensure optimal performance and cost-effectiveness. In this analysis, we will compare Einkristalle with two alternative solutions that serve similar purposes, helping B2B buyers from diverse regions like Africa, South America, the Middle East, and Europe make informed decisions.

| Comparison Aspect | Einkristalle | Alternative 1: Traditional Crystals | Alternative 2: Synthetic Polymers |

|---|---|---|---|

| Performance | High stability and durability | Moderate stability | High adaptability |

| Cost | Moderate | Low to moderate | High |

| Ease of Implementation | Requires specialized handling | Easy to source | Moderate complexity |

| Maintenance | Low maintenance needs | Regular maintenance required | Variable maintenance based on use |

| Best Use Case | Long-term applications in electronics | Short-term decorative uses | Versatile applications in packaging |

Traditional Crystals offer a low-cost alternative that is easily sourced, making them appealing for short-term applications or decorative purposes. However, they lack the high stability and durability of Einkristalle, which can lead to more frequent replacements. Additionally, the need for regular maintenance can be a drawback for businesses looking to minimize operational interruptions. These crystals are best suited for applications where aesthetic appeal is prioritized over long-term performance.

Synthetic Polymers provide a highly adaptable solution that can be tailored for various applications, including packaging and electronics. Their versatility allows them to be engineered for specific requirements, but this often comes at a higher cost. While they can outperform traditional crystals in specific use cases, they may require more complex implementation and varying maintenance levels depending on the material used. Businesses may find synthetic polymers beneficial in scenarios where adaptability and customization are crucial.

When selecting between Einkristalle and its alternatives, B2B buyers should carefully assess their specific needs, budget constraints, and application requirements. Einkristalle stand out for their durability and low maintenance, making them suitable for long-term applications, especially in electronics. In contrast, traditional crystals may be more appropriate for aesthetic-focused projects with shorter lifespans, while synthetic polymers excel in adaptability but come with a higher price point. By weighing these factors, businesses can make informed decisions that align with their operational goals and financial strategies.

Einkristalle, or crystalline materials, have unique technical properties that make them essential in various applications, especially in electronics, optics, and energy sectors. Understanding these properties is crucial for international B2B buyers looking to make informed purchasing decisions.

Material Grade

- Definition: Material grade refers to the classification of the einkristalle based on their purity, composition, and intended application. Higher grades typically indicate better performance and reliability.

- Importance: Selecting the correct material grade is vital for ensuring product longevity and efficacy, particularly in high-stakes industries such as telecommunications and healthcare. Buyers should verify the grade to meet specific regulatory standards.

Tolerance

- Definition: Tolerance denotes the allowable deviation from specified dimensions in the manufacturing of einkristalle. This can include size, shape, and structural integrity.

- Importance: For B2B buyers, understanding tolerance is essential as it directly impacts the compatibility of components in assemblies. Tight tolerances are often necessary in precision applications, whereas broader tolerances may suffice for less critical uses.

Thermal Conductivity

- Definition: Thermal conductivity measures a material's ability to conduct heat. For einkristalle, this property is crucial in applications where temperature management is vital.

- Importance: High thermal conductivity is necessary in electronic devices to prevent overheating and ensure optimal performance. Buyers should assess thermal properties to avoid failures in high-temperature environments.

Dielectric Strength

- Definition: Dielectric strength indicates the maximum electric field a material can withstand without breaking down. This is particularly relevant for electrical insulation applications.

- Importance: In sectors such as energy and telecommunications, high dielectric strength can prevent electrical failures and improve safety. Buyers need to ensure that the einkristalle selected can handle the electrical demands of their specific applications.

Crystallinity

- Definition: Crystallinity refers to the degree to which a material has a well-ordered structure. High crystallinity typically leads to superior optical and electronic properties.

- Importance: B2B buyers should consider crystallinity, especially when sourcing materials for optical devices or high-performance electronics, as it can significantly affect the end product’s quality and functionality.

Familiarity with industry-specific terminology is essential for B2B buyers to navigate contracts and negotiations effectively. Here are some key terms to know:

OEM (Original Equipment Manufacturer)

- Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of einkristalle, it often refers to suppliers that provide these materials for integration into larger systems.

- Importance: Understanding OEM relationships can help buyers identify reliable sources for quality materials tailored to their specific needs.

MOQ (Minimum Order Quantity)

- Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers who need to manage inventory and production costs.

- Importance: Knowing the MOQ allows buyers to assess whether a supplier’s offerings fit their budget and demand forecasts, especially for smaller companies.

RFQ (Request for Quotation)

- Definition: An RFQ is a document sent to suppliers requesting pricing and other details for specific quantities of products. This is a standard practice in B2B transactions.

- Importance: Using RFQs effectively can help buyers gather competitive pricing and terms, enabling better negotiation outcomes.

Incoterms (International Commercial Terms)

- Definition: Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They clarify responsibilities regarding shipping, insurance, and tariffs.

- Importance: Understanding Incoterms is crucial for managing logistics and ensuring that responsibilities are clearly defined in international transactions.

Lead Time

- Definition: Lead time refers to the time taken from placing an order to receiving the goods. It encompasses manufacturing and shipping durations.

- Importance: Buyers should consider lead time in their planning to avoid production delays and ensure timely project execution.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing einkristalle, ensuring they select the right materials for their applications while effectively managing supply chain dynamics.

The einkristalle sector is currently experiencing dynamic growth driven by technological advancements, increasing global demand, and the need for innovative applications across various industries. Key drivers include the rising adoption of advanced materials in electronics, pharmaceuticals, and sustainable energy solutions. International B2B buyers from Africa, South America, the Middle East, and Europe, particularly Argentina and South Africa, are keenly observing these shifts. The emergence of smart technologies, such as AI and IoT, is further influencing sourcing strategies, as companies seek suppliers who can deliver high-quality einkristalle products that integrate seamlessly with these technologies.

Moreover, the trend towards digital transformation in supply chain management is reshaping sourcing practices. Buyers are increasingly leveraging data analytics and AI tools to make informed decisions about suppliers and materials. This shift not only enhances efficiency but also supports better risk management and cost-effectiveness. Additionally, as companies strive for competitive advantage, there is a growing focus on collaborative partnerships with suppliers that can offer innovative solutions and flexibility in production.

Sustainability has become a cornerstone of sourcing strategies in the einkristalle sector, with increasing awareness of environmental impacts prompting companies to reevaluate their supply chains. Ethical sourcing is not merely a trend but a necessity, as international buyers are prioritizing suppliers that adhere to sustainable practices. This includes minimizing carbon footprints, reducing waste, and ensuring responsible sourcing of raw materials.

B2B buyers should consider suppliers that hold certifications for sustainability, such as ISO 14001 or LEED, which demonstrate a commitment to environmentally friendly practices. Furthermore, using 'green' materials in production can enhance brand reputation and appeal to eco-conscious consumers. As regulations tighten globally, especially in Europe, aligning with sustainable and ethical sourcing practices will not only mitigate risks but also open new market opportunities.

The einkristalle sector has evolved significantly over the past few decades, transitioning from traditional production methods to more advanced, technology-driven processes. Initially focused on basic applications, the sector has expanded into specialized areas such as nanotechnology and advanced materials, catering to the demands of diverse industries. This evolution has been marked by increased investment in research and development, leading to innovations that enhance product performance and sustainability.

For B2B buyers, understanding this historical context is crucial, as it highlights the importance of choosing suppliers that are not only technologically adept but also committed to continuous improvement and innovation. This knowledge can empower buyers to make strategic decisions that align with long-term goals and market demands.

How do I solve quality issues when sourcing einkristalle?

To mitigate quality issues when sourcing einkristalle, start by conducting thorough supplier vetting. Request samples from multiple suppliers to assess quality firsthand. Implement a clear quality assurance (QA) protocol that outlines your standards and expectations. Additionally, consider third-party inspections during production to ensure compliance with your specifications. Establish ongoing communication with suppliers to address any concerns promptly, and maintain detailed documentation of quality checks.

What is the best way to identify reliable suppliers of einkristalle?

Identifying reliable suppliers of einkristalle involves a multi-step approach. Start by researching industry-specific trade shows and online marketplaces where reputable suppliers showcase their products. Utilize platforms like Alibaba or Global Sources, but be sure to check reviews and ratings. Additionally, consider joining industry associations or networking groups that can provide referrals. Always conduct due diligence, including checking business licenses, certifications, and customer testimonials.

What are the typical minimum order quantities (MOQ) for einkristalle?

Minimum order quantities for einkristalle can vary widely among suppliers, typically ranging from 100 to 1000 units. Smaller suppliers may offer lower MOQs, while larger manufacturers often have higher thresholds. When negotiating, clarify your needs and explore potential flexibility in MOQs, especially for first-time orders. Some suppliers may offer sample orders or trial runs to accommodate smaller businesses, allowing you to test the market without a significant upfront investment.

What payment terms should I expect when sourcing einkristalle?

Payment terms for einkristalle vary by supplier and region, but common practices include a 30-50% deposit upfront, with the balance due upon delivery or before shipment. Some suppliers may offer net terms, allowing payment within 30-90 days after receipt of goods. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Always ensure that the payment method is secure, and consider using escrow services for added protection during international transactions.

How can I customize einkristalle for my specific needs?

Customization of einkristalle often depends on the supplier's capabilities. When discussing your requirements, be specific about the desired dimensions, colors, or finishes. Many suppliers offer customization options, but this may come with increased costs or longer lead times. Request a detailed quote for any customization and ensure that you have a clear understanding of the production timeline. It’s advisable to obtain a sample of the customized product before placing a full order to ensure it meets your expectations.

What logistics considerations should I keep in mind when importing einkristalle?

When importing einkristalle, logistics play a crucial role in ensuring timely delivery. Consider factors such as shipping methods (air vs. sea), customs clearance procedures, and potential tariffs. Collaborate with a reliable freight forwarder familiar with your destination market to navigate these complexities. Additionally, factor in lead times for production and shipping, and ensure that your supplier provides tracking information for real-time updates on your shipment.

How do I ensure compliance with international trade regulations when sourcing einkristalle?

Compliance with international trade regulations is essential when sourcing einkristalle. Familiarize yourself with the import regulations of your country, including tariffs, duties, and product standards. Consult with a trade compliance expert to understand any specific certifications or documentation required. Additionally, ensure that your supplier adheres to international quality standards and has the necessary export licenses. Keeping abreast of changes in trade agreements can also help mitigate potential compliance issues.

What are the best practices for maintaining supplier relationships in the einkristalle market?

Maintaining strong supplier relationships in the einkristalle market involves consistent communication, trust, and mutual respect. Regularly provide feedback on product quality and delivery performance, and acknowledge their efforts when they meet or exceed expectations. Establishing long-term contracts can also foster loyalty and better pricing. Attend industry events or trade shows to engage with suppliers in person, and be open to discussing future collaboration opportunities, which can lead to better terms and innovative solutions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing of einkristalle presents significant opportunities for international B2B buyers across Africa, South America, the Middle East, and Europe. By leveraging local suppliers and fostering partnerships, businesses can enhance supply chain resilience while ensuring access to high-quality products. It is crucial to assess the unique market dynamics and regulatory landscapes in each region, as these factors can greatly influence sourcing decisions.

What are the key benefits of strategic sourcing for your business? First, it reduces costs through competitive pricing and bulk purchasing, ultimately leading to better profit margins. Additionally, establishing strong relationships with suppliers can lead to improved quality and reliability of einkristalle, which is essential for maintaining customer satisfaction.

As we look to the future, the demand for einkristalle is expected to grow, driven by innovations in various industries. B2B buyers are encouraged to stay proactive in evaluating their sourcing strategies. By embracing a forward-thinking approach and adapting to market trends, businesses can position themselves for success. Engage with suppliers, explore new technologies, and remain agile in your sourcing efforts to maximize the benefits of einkristalle in your operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina