Navigating the global market for grit rock tumblers presents unique challenges for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality grit rock tumblers that meet specific operational needs—whether for hobbyist use or industrial applications—requires a nuanced understanding of product specifications, supplier reliability, and market trends.

This comprehensive guide will delve into various types of grit rock tumblers, their applications across different industries, and critical factors for supplier vetting. It will also address cost considerations, enabling buyers to balance quality and budget effectively. By providing in-depth insights and actionable strategies, this guide empowers B2B buyers to make informed purchasing decisions, ensuring they select the right products that align with their business objectives.

International buyers from countries like Nigeria and Spain will find tailored information that speaks directly to their unique market conditions and procurement processes. This guide not only simplifies the sourcing journey but also enhances the potential for successful supplier partnerships, fostering long-term growth in the competitive landscape of grit rock tumblers. Whether you are a seasoned buyer or new to the market, the insights contained herein will equip you with the knowledge needed to navigate the complexities of global sourcing with confidence.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Tumblers | Utilizes a rotating barrel; suitable for bulk processing. | Jewelry making, stone polishing | Pros: High volume output, easy to use. Cons: Slower polishing time compared to vibratory types. |

| Vibratory Tumblers | Employs vibration to achieve faster results; smaller footprint. | Industrial applications, metal parts | Pros: Quick processing, effective for small items. Cons: Limited capacity; may require more maintenance. |

| Dual Barrel Tumblers | Features two barrels for simultaneous processing of different materials. | Educational tools, hobbyists | Pros: Versatile, can handle various materials at once. Cons: More expensive, complex setup. |

| Magnetic Tumblers | Uses magnetic fields to polish small metal parts efficiently. | Manufacturing, automotive parts | Pros: Fast and efficient for small components. Cons: Limited to specific materials; requires careful handling. |

| Mini Tumblers | Compact design for small batches; often portable. | Jewelry makers, hobbyists | Pros: Space-saving, ideal for small operations. Cons: Limited capacity and slower processing times. |

Rotary tumblers are the most common type used in both commercial and hobbyist settings. They consist of a rotating barrel that holds the rocks and abrasive grit. This design allows for bulk processing, making it ideal for businesses that need to polish large quantities of stones or jewelry components. When considering a rotary tumbler, B2B buyers should evaluate the barrel size and material, as these factors influence durability and the quality of the finish.

Vibratory tumblers utilize vibration to create a more aggressive polishing action, which significantly reduces processing time compared to rotary tumblers. This type is particularly well-suited for industrial applications, such as polishing metal parts or small components. B2B buyers should assess the vibrational frequency and amplitude settings, as these will impact the effectiveness for specific materials and desired finishes.

Dual barrel tumblers allow users to process two different types of materials simultaneously, making them a versatile choice for educational purposes or hobbyists who work with various stones. Their capacity for multitasking can be a significant advantage for businesses that want to maximize efficiency. However, buyers should consider the complexity of the setup and the potential for higher costs when investing in this type of tumbler.

Magnetic tumblers leverage magnetic fields to polish small metal parts, making them an efficient choice for the manufacturing and automotive sectors. They are particularly effective for intricate components that require a high level of precision. B2B buyers should keep in mind the material compatibility and the specific requirements for handling and processing, as magnetic tumblers may have limitations based on the size and type of parts being polished.

Mini tumblers are designed for small batches and are often portable, making them ideal for individual artisans or small businesses. Their compact size allows for easy storage and transport, but they generally have limited processing capabilities. Buyers in the B2B space should weigh the benefits of convenience against the slower processing times and capacity constraints, ensuring that the mini tumbler aligns with their operational needs.

Related Video: What Is the Optimal Amount of Grit to Use in a Rock Tumbler?

| Industry/Sector | Specific Application of grit rock tumbler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Jewelry Manufacturing | Polishing gemstones and metals | Enhances aesthetic appeal and market value | Sourcing high-quality grit and ensuring compatibility with materials |

| Mineral Processing | Preparing minerals and ores for analysis | Improves accuracy in assays and quality control | Evaluating grit size and hardness for specific mineral types |

| Ceramic Production | Smoothing ceramic components before firing | Reduces defects, improving product quality | Ensuring grit compatibility with ceramic materials and firing processes |

| Automotive Industry | Deburring and polishing metal parts | Increases component lifespan and performance | Sourcing durable tumblers that can handle various metal alloys |

| Educational Institutions | Demonstrating geological processes in geology classes | Enhances learning through practical applications | Ensuring availability of educational kits and support materials |

In the jewelry manufacturing sector, grit rock tumblers are essential for polishing gemstones and metals. By using various grades of grit, manufacturers can achieve a high gloss finish that enhances the aesthetic appeal of their products, ultimately increasing their market value. For international B2B buyers, especially from regions like Africa and South America, sourcing high-quality grit that is compatible with specific gemstones or metals is crucial. Additionally, buyers should consider the reliability and efficiency of the tumblers to ensure consistent results in their production processes.

In mineral processing, grit rock tumblers are used to prepare minerals and ores for analysis. The tumbling process helps to break down larger particles, ensuring a homogenous sample that improves the accuracy of assays and quality control measures. For buyers in the Middle East and Europe, it’s vital to evaluate the grit size and hardness to match the specific mineral types being processed. This ensures that the tumblers can handle the abrasive nature of certain ores while providing accurate results for further processing.

Ceramic production involves the smoothing of components before firing, which is where grit rock tumblers come into play. They help reduce surface defects, leading to improved product quality and durability. For B2B buyers, particularly in Europe, ensuring compatibility of the tumbler grit with various ceramic materials is critical, as it can affect the final product’s performance during the firing process. Additionally, sourcing tumblers that can handle the specific shapes and sizes of ceramic pieces is essential for operational efficiency.

In the automotive industry, grit rock tumblers are utilized for deburring and polishing metal parts, which is vital for increasing the lifespan and performance of components. By effectively removing sharp edges and surface imperfections, tumblers enhance the overall quality of the automotive parts. For international buyers, particularly those in Africa and South America, sourcing durable tumblers that can accommodate various metal alloys is crucial. They should also consider the operational costs and efficiency of the tumblers to maximize their investment.

Educational institutions employ grit rock tumblers to demonstrate geological processes, providing hands-on learning experiences for students in geology classes. This practical application enhances learning by allowing students to observe the effects of erosion and sedimentation in real-time. For B2B buyers from educational sectors in Europe, ensuring the availability of educational kits, including tumblers and support materials, can significantly enrich the learning environment. Additionally, sourcing tumblers that are user-friendly and safe for student use is paramount for successful educational outcomes.

The Problem:

B2B buyers often face challenges in achieving the desired finish quality when using grit rock tumblers for polishing stones or metals. Inconsistent results can stem from various factors such as the type of grit used, the duration of tumbling, and the quality of the tumbler itself. This inconsistency not only impacts the aesthetic appeal of the final product but can also lead to increased operational costs due to wasted materials and time. Buyers may find themselves frustrated as they attempt to balance grit coarseness and tumbling time to achieve optimal results.

The Solution:

To overcome this challenge, B2B buyers should carefully select the appropriate type of grit for their specific materials and desired finish. For instance, using a finer grit for the final stages of polishing can enhance the luster of the stones. Additionally, buyers should maintain a consistent tumbling schedule by investing in timers or programmable tumblers that allow for precise control over tumbling duration. Regular maintenance of the tumbler itself is crucial; ensuring that it operates at the correct speed and that the rubber lining is in good condition will significantly improve the quality of the finish. Furthermore, conducting small batch tests with different grit combinations can help establish the best methodology for achieving the desired finish.

The Problem:

Another common issue faced by international B2B buyers of grit rock tumblers is the high wear and tear of the equipment, especially in environments with heavy usage. Tumblers subjected to continuous operation can experience significant wear on their motors, rubber barrels, and internal components, leading to costly repairs and downtime. This situation is particularly pressing for buyers in regions with limited access to spare parts or repair services, creating a need for reliable and durable tumbling solutions.

The Solution:

To mitigate wear and tear, buyers should prioritize the purchase of high-quality tumblers that are specifically designed for heavy-duty use. Investing in models with robust motors and reinforced barrels can lead to better longevity. Regular maintenance routines should be established, including routine checks of the motor, seals, and barrel integrity. Additionally, implementing a rotation system for tumblers can reduce the workload on any single unit, thereby extending the lifespan of each piece of equipment. For buyers in regions with limited access to repairs, sourcing tumblers from suppliers who offer comprehensive warranties and after-sales support can provide peace of mind and facilitate smoother operations.

The Problem:

Many B2B buyers, especially those new to the industry, struggle with understanding the compatibility of different grits and their proper usage in rock tumbling processes. This lack of knowledge can lead to improper grit selection, resulting in ineffective polishing or even damage to the materials being tumbled. The confusion is compounded by the variety of grit types available on the market, each with specific properties that cater to different applications.

The Solution:

To address this knowledge gap, buyers should seek out educational resources or training programs that focus on grit compatibility and effective tumbling practices. Suppliers often provide technical support and detailed product descriptions that can guide buyers in selecting the right grit for their applications. It can be beneficial to engage in community forums or industry groups where users share their experiences and tips on grit usage. Additionally, conducting experiments with different grit types in small batches can help buyers gain hands-on experience and better understand how each grit interacts with various materials. By becoming more informed about grit characteristics and their applications, buyers can optimize their tumbling processes, leading to improved results and increased efficiency.

When selecting materials for grit rock tumblers, international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in grit rock tumblers: stainless steel, plastic, ceramic, and rubber. Each material has unique properties and implications for use in different markets, particularly in Africa, South America, the Middle East, and Europe.

Stainless steel is a popular choice for grit rock tumblers due to its excellent strength and resistance to corrosion. Typically, grades like 304 and 316 are utilized, which can withstand high temperatures and pressures. Stainless steel's non-reactive nature makes it suitable for various media, ensuring that the tumbling process does not contaminate the rocks.

Pros and Cons:

- Pros: High durability, excellent corrosion resistance, and long service life.

- Cons: Higher initial cost and potential for scratching softer materials during the tumbling process.

Impact on Application:

Stainless steel tumblers are compatible with various abrasive materials, making them versatile for different types of rocks. However, they may not be ideal for softer stones, as they can cause wear.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with ASTM standards for material quality. In Africa and South America, sourcing from local suppliers may reduce shipping costs and support regional economies.

Plastic tumblers, often made from high-density polyethylene (HDPE), offer a lightweight alternative to metal options. They are resistant to many chemicals and can handle a variety of tumbling media.

Pros and Cons:

- Pros: Lower cost, lightweight, and good chemical resistance.

- Cons: Less durable than metal options and can warp under high temperatures.

Impact on Application:

Plastic tumblers are best suited for softer materials and delicate stones, where the risk of damage is higher. They are not recommended for heavy-duty tumbling applications.

Considerations for International Buyers:

International buyers should verify that the plastic complies with relevant safety standards, especially in Europe where regulations may be stricter. In regions like Nigeria, ensuring local availability of replacement parts can be crucial.

Ceramic tumblers are known for their hardness and ability to produce a high-quality finish on rocks. They can withstand high temperatures and provide excellent wear resistance.

Pros and Cons:

- Pros: Excellent finish quality, high durability, and suitable for a wide range of media.

- Cons: Higher fragility compared to metals and potential for cracking under stress.

Impact on Application:

Ceramic tumblers are ideal for producing polished finishes on harder stones. However, their fragility can be a limiting factor in rough tumbling applications.

Considerations for International Buyers:

Buyers should assess the ceramic's compliance with international standards, particularly in Europe where quality assurance is critical. In South America, understanding local sourcing options for ceramics can enhance supply chain efficiency.

Rubber tumblers are often used as liners for metal tumblers, providing a cushioning effect that protects both the tumbler and the rocks. They are particularly effective in reducing noise during operation.

Pros and Cons:

- Pros: Noise reduction, cushioning effect, and lower risk of damage to delicate stones.

- Cons: Limited durability and potential degradation over time due to exposure to chemicals.

Impact on Application:

Rubber liners are beneficial in applications where noise reduction is critical or where softer stones are being processed. However, they may require more frequent replacement compared to metal options.

Considerations for International Buyers:

In regions like the Middle East, buyers should ensure that rubber materials meet local environmental regulations. For buyers in Africa, sourcing durable rubber from local manufacturers can be economically advantageous.

| Material | Typical Use Case for grit rock tumbler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty tumbling of various rocks | High durability and corrosion resistance | Higher initial cost | High |

| Plastic | Tumbling softer materials | Lightweight and cost-effective | Less durable under high temperatures | Low |

| Ceramic | Polishing hard stones | Excellent finish quality | Fragility under stress | Medium |

| Rubber | Liner for metal tumblers | Noise reduction and cushioning | Limited durability | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions tailored to specific applications and regional considerations.

The manufacturing of grit rock tumblers involves several critical stages that ensure the final product meets quality and performance standards. Here’s a breakdown of the main stages:

The process begins with selecting high-quality materials. Most grit rock tumblers are made from durable metals such as stainless steel or heavy-duty plastic. The material is carefully sourced to ensure it meets specific properties like corrosion resistance and strength. Before manufacturing begins, raw materials undergo inspection to confirm they meet the required specifications.

Once the materials are prepared, they are subjected to various forming techniques. Common methods include:

These forming techniques ensure that each component of the grit rock tumbler is made to exact specifications, which is crucial for its overall performance.

After forming, the components are assembled into the final product. This stage typically involves:

The finishing stage enhances the aesthetic appeal and functionality of the grit rock tumbler. This may include:

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that each grit rock tumbler meets international standards and customer expectations. Here are some key elements of QA:

International standards play a significant role in maintaining the quality of grit rock tumblers. Key standards include:

These certifications not only enhance the credibility of the manufacturer but also provide assurance to B2B buyers regarding product quality.

Quality control (QC) checkpoints are implemented throughout the manufacturing process to catch defects early. The main checkpoints include:

Several testing methods are utilized to ensure the quality and performance of grit rock tumblers:

These testing methods provide a thorough understanding of the product's reliability and longevity.

For international B2B buyers, verifying a supplier's quality control processes is essential. Here are actionable steps to ensure supplier reliability:

Regular audits of suppliers can help assess their manufacturing practices and compliance with quality standards. Auditors can evaluate processes, equipment, and employee training to ensure adherence to quality protocols.

Requesting detailed QC reports from suppliers allows buyers to gain insights into the quality assurance processes used. These reports should include information on inspections, testing results, and any non-conformance issues.

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct inspections at various stages of production and provide certification that the products meet required standards.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

By paying attention to these aspects, international B2B buyers can make informed decisions and ensure they source high-quality grit rock tumblers that meet their operational needs.

In today’s competitive market, sourcing a high-quality grit rock tumbler is essential for businesses involved in jewelry making, mineralogy, or lapidary work. This guide provides a step-by-step checklist to help international B2B buyers streamline their procurement process, ensuring they make informed decisions and secure the best equipment for their needs.

Before beginning your search for a grit rock tumbler, clearly outline your technical requirements. Consider factors such as the desired capacity, rotation speed, and material durability. This will help you narrow down options and ensure that the tumbler meets your specific operational needs.

Conduct thorough research to identify established manufacturers of grit rock tumblers. Look for companies with a strong reputation in the industry, verified by customer reviews and testimonials. This step is crucial to ensure that you are sourcing from a reliable supplier.

Verify that potential suppliers possess the necessary certifications and compliance with international standards. This not only ensures product quality but also confirms that the supplier adheres to safety regulations, which is vital for operational integrity.

Before making a bulk purchase, request samples of the grit rock tumbler. Testing a sample allows you to evaluate performance, durability, and suitability for your specific applications. This step can prevent costly mistakes down the line.

Collect quotes from multiple suppliers to compare pricing structures and terms. Look beyond the base price to consider factors such as shipping costs, warranty offers, and after-sales support. This comprehensive view will help you find the best value.

Evaluate the level of customer support offered by the supplier. A supplier who provides excellent after-sales support and a robust warranty can save you time and money in the long run.

Once you've selected a supplier, finalize the purchase agreement, ensuring all terms discussed are documented. Include details such as delivery timelines, payment schedules, and return policies. This ensures clarity and protects your interests.

By following these structured steps, B2B buyers can efficiently navigate the sourcing process for grit rock tumblers, ensuring they acquire quality equipment that meets their operational needs while fostering strong supplier relationships.

When considering the sourcing of grit rock tumblers, it's essential to understand the various cost components that contribute to the overall pricing. The primary cost components include:

Materials: The quality and type of materials used directly influence the cost. High-grade abrasives and durable components will typically cost more but can enhance the tumbler's performance and longevity.

Labor: Labor costs vary significantly depending on the region of manufacture. Countries with higher labor costs may produce higher-quality products, but this will be reflected in the final price.

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and rent. Efficient manufacturing processes can help reduce these overheads, impacting overall pricing.

Tooling: The initial investment in tools and molds is significant, especially for custom designs. These costs can be amortized over large production runs, making them less impactful on per-unit pricing as volume increases.

Quality Control (QC): Implementing strict QC measures ensures that the tumblers meet the required specifications and certifications. This can involve additional costs but is crucial for maintaining product quality, especially in international markets.

Logistics: Shipping costs can be substantial, particularly for international buyers. Factors such as distance, shipping method, and Incoterms can significantly affect logistics expenses.

Margin: Suppliers will typically add a margin to cover their costs and profit. This varies based on market competition and supplier reputation.

Several factors influence the pricing of grit rock tumblers, particularly for B2B buyers:

Volume/MOQ: Minimum Order Quantities (MOQs) can dictate pricing. Larger orders often lead to lower per-unit costs, making it advantageous for buyers to consolidate purchases.

Specifications and Customization: Custom designs or specific requirements can increase costs. Clear communication of needs can help suppliers provide accurate quotes.

Materials and Quality Certifications: High-quality materials and compliance with international standards can lead to higher costs. Buyers should weigh the benefits of investing in certified products against their budget.

Supplier Factors: The reputation, location, and experience of the supplier can impact pricing. Established suppliers may charge more due to their track record, while emerging suppliers may offer competitive pricing to gain market share.

Incoterms: Understanding Incoterms is crucial for cost management. Different terms can shift responsibility for shipping costs and risks, affecting the total landed cost.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation is key to achieving cost efficiency:

Research Market Prices: Familiarize yourself with current market prices and trends for grit rock tumblers. This knowledge will empower you during negotiations.

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the TCO, which includes maintenance, operation, and disposal costs. This holistic view can justify a higher upfront investment if long-term savings are evident.

Be Transparent About Your Needs: Clearly communicate your specifications and budget constraints. Suppliers may offer tailored solutions that fit your needs better when they understand your requirements.

Leverage Volume Discounts: If possible, commit to larger orders or long-term contracts to negotiate better pricing. Suppliers are often willing to provide discounts for guaranteed business.

Evaluate Multiple Suppliers: Don’t settle for the first quote. Obtaining multiple quotes can provide leverage in negotiations and help you identify the best deal.

Understanding the cost structure and pricing dynamics of grit rock tumblers is vital for international B2B buyers. By considering the key cost components, price influencers, and adopting effective negotiation strategies, buyers can make informed decisions that align with their budgetary and operational needs. Always remember to approach each supplier relationship with a clear understanding of your requirements and market conditions to achieve the best possible outcomes.

In the realm of rock polishing and stone finishing, the grit rock tumbler stands as a popular choice among manufacturers and hobbyists alike. However, several alternative solutions exist that cater to similar polishing needs. This section will evaluate these alternatives, allowing B2B buyers to make informed decisions based on their specific operational requirements and constraints.

| Comparison Aspect | Grit Rock Tumbler | Vibratory Tumbler | Hand Polishing Techniques |

|---|---|---|---|

| Performance | High-quality finish in a consistent time frame | Excellent for intricate shapes; faster than tumbling | Labor-intensive, time-consuming, variable results |

| Cost | Moderate initial investment | Higher initial cost but faster output | Low cost, requires minimal investment |

| Ease of Implementation | Easy to use, minimal setup required | Moderate complexity, may require training | Requires skilled labor, dependent on individual skill |

| Maintenance | Low maintenance needs; occasional grit replacement | Moderate maintenance; requires regular cleaning | No maintenance, but labor-intensive |

| Best Use Case | Suitable for larger batches of stones | Ideal for detailed polishing and smaller batches | Best for custom or one-off pieces |

The vibratory tumbler is an alternative that offers distinct advantages. It excels in polishing intricate shapes due to its ability to use a combination of vibration and abrasive media. This method can produce a high-quality finish in a shorter time frame compared to grit rock tumblers. However, it typically involves a higher initial investment and can require more training for effective operation. Maintenance is also a consideration, as the equipment needs regular cleaning to maintain optimal performance.

Hand polishing techniques represent the most traditional method of stone finishing. This approach involves skilled labor to achieve the desired finish, making it highly customizable. While the initial investment is minimal, the process is labor-intensive and can lead to variable results depending on the operator's skill level. Additionally, it is not suitable for large batches due to time constraints, making it less efficient for businesses that require high-volume output.

When selecting between a grit rock tumbler and its alternatives, B2B buyers should assess their specific needs. Factors such as the volume of stones to be polished, the intricacy of the shapes, budget constraints, and available labor should guide the decision. A grit rock tumbler may be ideal for businesses looking for efficiency and consistency in larger batches, while vibratory tumblers may be more suitable for detailed polishing jobs. Hand polishing can be advantageous for artisanal projects requiring a personalized touch but may not be feasible for mass production.

Ultimately, understanding these alternatives and their respective advantages and disadvantages will empower international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—to make choices that align with their operational goals and financial strategies.

When considering a grit rock tumbler for your business, understanding its technical properties is crucial. Here are some essential specifications to keep in mind:

The material grade of a grit rock tumbler refers to the quality of the materials used in its construction, typically stainless steel or high-impact plastic. Stainless steel offers durability and corrosion resistance, which is vital for long-term use, especially in wet environments. High-grade materials ensure that the tumbler can withstand the abrasive action of grit and stones without degrading.

Tolerance levels indicate the precision of the tumbler's components, such as the drum's thickness and the fit of the motor. High tolerance levels are essential for ensuring that the tumbler operates smoothly without excessive wear or vibration, which could lead to premature failure. For B2B buyers, understanding these specifications can help in selecting a reliable product that minimizes maintenance costs.

Drum capacity is measured in liters and determines how much material can be processed at one time. A larger drum capacity allows for more efficient batch processing, which is particularly beneficial for businesses that require high volume output. Choosing the right capacity is crucial for optimizing operational efficiency and meeting production demands.

The motor power rating, often measured in watts or horsepower, affects the tumbler's performance. A more powerful motor can handle heavier loads and operate at higher speeds, resulting in quicker polishing times. For international buyers, especially in regions with varying energy costs, understanding motor efficiency can lead to significant savings.

Noise level, measured in decibels (dB), is a critical factor for workplaces. Many grit rock tumblers operate at high speeds, which can generate considerable noise. Selecting a model with a lower noise level can enhance workplace comfort and compliance with local regulations regarding industrial noise.

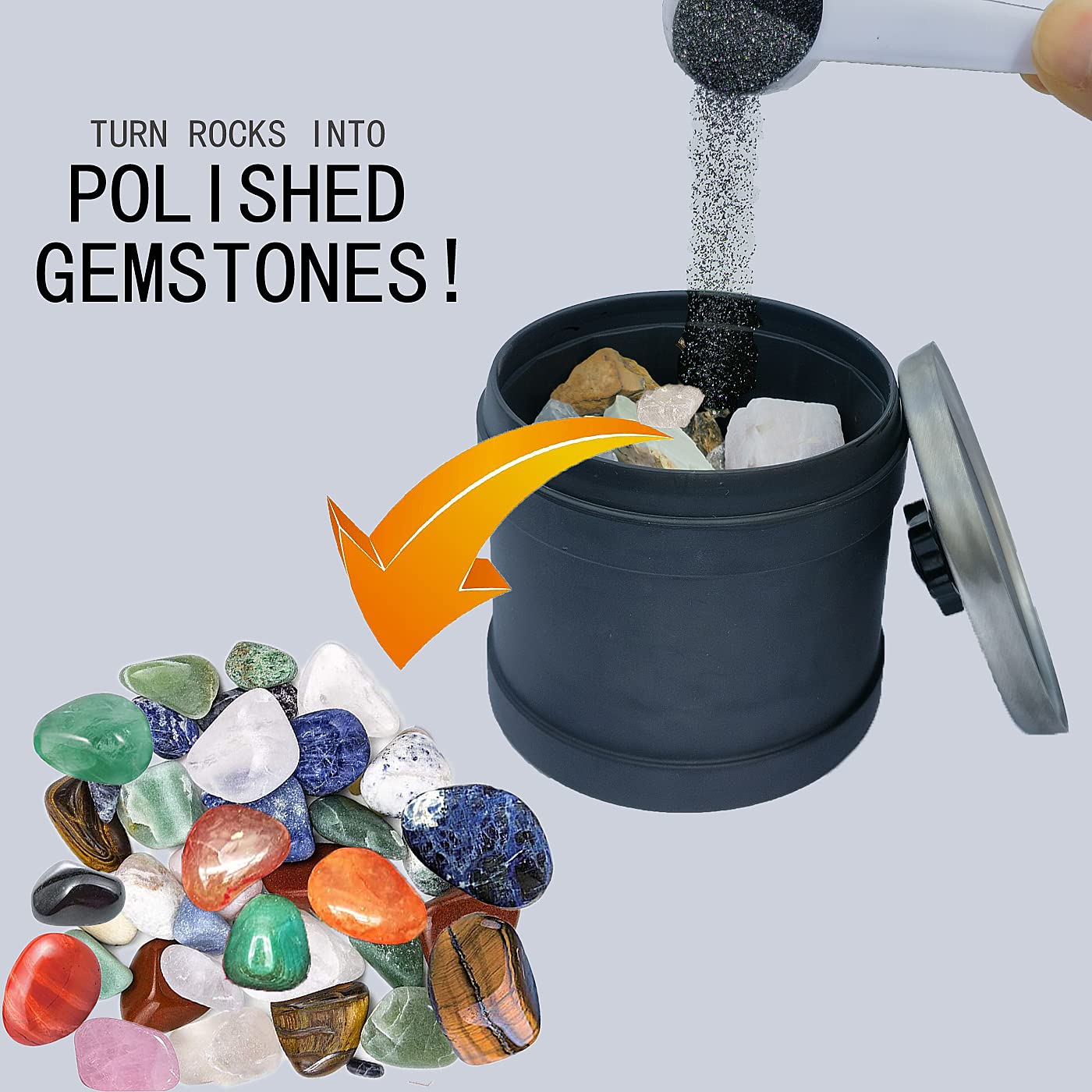

A stock image related to grit rock tumbler.

Speed settings allow operators to adjust the rotational speed of the tumbler, which can affect the polishing process. Different materials may require specific speeds for optimal results, making this feature important for versatility in processing various types of stones.

Understanding trade terminology is essential for navigating the procurement process effectively. Here are some common terms you should be familiar with:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of grit rock tumblers, working with an OEM can provide access to specialized models tailored to your specific needs.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, understanding MOQ is crucial for budgeting and inventory management. It can influence your purchasing strategy, especially when dealing with manufacturers from different regions.

An RFQ is a document sent to suppliers to request pricing for specific products. When sourcing grit rock tumblers, submitting an RFQ can help you obtain competitive pricing and clarify specifications, ensuring you make informed purchasing decisions.

A stock image related to grit rock tumbler.

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms is essential for understanding shipping costs, risk management, and delivery responsibilities, ensuring smoother transactions across borders.

Lead time refers to the amount of time from placing an order to receiving the product. For businesses, especially in fast-paced markets, knowing the lead time is vital for planning inventory and production schedules.

A warranty is a promise from the manufacturer regarding the condition of the product. Understanding warranty terms can help mitigate risks associated with purchasing equipment like grit rock tumblers, providing peace of mind regarding potential defects or issues.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market conditions.

The grit rock tumbler market is experiencing significant growth, driven by increased consumer interest in DIY projects, gemstone crafting, and jewelry making. International B2B buyers are noticing a surge in demand, particularly in regions like Africa, South America, the Middle East, and Europe, where hobbies related to stone polishing and crafting have gained popularity. The rise of e-commerce platforms is also facilitating access to a broader range of suppliers and products, allowing buyers to source grit rock tumblers directly from manufacturers around the globe.

Emerging technologies, such as 3D printing and automation, are influencing product design and manufacturing processes within the grit rock tumbler sector. These technologies not only enhance product quality but also reduce production costs, making it easier for suppliers to offer competitive pricing. Furthermore, the integration of IoT (Internet of Things) capabilities in tumblers allows for better monitoring and control during the tumbling process, appealing to tech-savvy consumers.

B2B buyers must stay informed about regional trends and preferences to make strategic sourcing decisions. For example, buyers from Nigeria may prioritize local suppliers to reduce shipping costs, while those in Spain may seek high-quality, European-manufactured tumblers that emphasize design and durability. Understanding these dynamics can help international buyers optimize their sourcing strategies.

Sustainability is becoming a core focus in the grit rock tumbler sector, driven by increasing consumer awareness of environmental issues and the importance of ethical sourcing. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste during production. The environmental impact of sourcing raw materials for grit rock tumblers, such as abrasives and plastics, is under scrutiny, making it essential for suppliers to adopt greener alternatives.

Buyers should look for suppliers who hold certifications like ISO 14001, which indicates a commitment to environmental management. Additionally, sourcing tumblers made from biodegradable or recycled materials can enhance a company's sustainability profile. By aligning with suppliers that prioritize ethical practices, B2B buyers not only improve their brand reputation but also contribute positively to the global push for sustainability.

The grit rock tumbler sector has evolved significantly since its inception in the mid-20th century. Initially popularized by hobbyists in the United States, tumblers were primarily used for polishing rocks and stones for personal collections. Over the decades, advancements in technology have led to the development of more efficient and user-friendly tumblers, expanding their appeal to a wider audience, including jewelers and artisans.

As consumer interests have shifted towards sustainable and ethical practices, the grit rock tumbler market has adapted, focusing on environmentally friendly materials and manufacturing processes. This evolution reflects broader market trends, where B2B buyers are increasingly looking for products that align with their values and the expectations of their customers. Understanding this historical context can guide international buyers in making informed sourcing decisions that resonate with current market demands.

How do I choose the right grit rock tumbler for my business needs?

Selecting the right grit rock tumbler involves considering the material you will be polishing, the desired finish, and the tumbler's capacity. For larger operations, a high-capacity tumbler is recommended to maximize efficiency. Additionally, evaluate the machine's durability and ease of maintenance. Research suppliers who offer detailed specifications and customer reviews to ensure the tumbler meets your operational requirements. It’s beneficial to request samples or demonstrations to assess performance before making a bulk purchase.

What are the common applications of grit rock tumblers in various industries?

Grit rock tumblers are widely used in jewelry making, mineral processing, and crafting. In jewelry, they polish stones to enhance their aesthetic appeal. In mineral processing, tumblers are employed to refine raw materials and ensure uniformity in size and texture. Crafting industries utilize them for creating decorative items from various materials, including glass and ceramics. Understanding the specific application can guide you in selecting the appropriate grit and tumbler specifications.

What should I consider when vetting suppliers for grit rock tumblers?

When vetting suppliers, prioritize their experience in the industry and reputation for quality. Verify certifications and compliance with international standards, especially if you are importing to regions like Africa or South America. Request references from previous clients to gauge reliability and service quality. Additionally, assess their customer support and after-sales service, which is crucial for maintenance and troubleshooting. A supplier with a solid track record can significantly impact your operational success.

What customization options are available for grit rock tumblers?

Customization options for grit rock tumblers can include size, capacity, and design features such as variable speed settings or integrated cooling systems. Some manufacturers offer bespoke solutions tailored to specific industry needs, such as jewelry polishing or industrial applications. Discuss your requirements with suppliers to explore the possibilities, including branding options for promotional purposes. Understanding customization can lead to better alignment with your operational workflow and product outcomes.

What is the minimum order quantity (MOQ) for grit rock tumblers?

Minimum order quantities (MOQs) for grit rock tumblers can vary significantly among suppliers, typically ranging from one unit for smaller manufacturers to several dozen for larger companies. MOQs may also depend on the level of customization required. Always clarify MOQs before finalizing agreements to ensure they align with your purchasing strategy and budget. If you are testing the market, consider negotiating lower MOQs for initial orders or sample units.

What payment terms should I expect when sourcing grit rock tumblers internationally?

Payment terms for international transactions can vary widely, but common options include partial payment upfront and the balance upon delivery. Suppliers may also offer letters of credit or payment through platforms like PayPal or bank transfers. Be sure to discuss payment terms during negotiations to find a mutually agreeable solution. Understanding the terms can help mitigate risks and ensure a smoother transaction process.

How can I ensure quality assurance for grit rock tumblers?

To ensure quality assurance, request detailed product specifications and compliance certifications from suppliers. It’s advisable to conduct inspections during production and before shipment. Consider third-party quality assurance services to verify that the tumblers meet your standards. Establishing a clear communication channel with your supplier can also facilitate prompt resolution of any quality issues that arise post-delivery.

What logistics considerations should I keep in mind when importing grit rock tumblers?

Logistics for importing grit rock tumblers involve selecting reliable shipping partners, understanding customs regulations, and planning for potential delays. Ensure that your suppliers provide accurate shipping documentation to facilitate smooth customs clearance. Additionally, consider insurance for your shipment to protect against loss or damage during transit. Evaluating the overall logistics process can help minimize disruptions and ensure timely delivery of your equipment.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the competitive landscape of grit rock tumblers, international B2B buyers must prioritize strategic sourcing to ensure optimal quality and cost-effectiveness. By leveraging supplier networks across regions such as Africa, South America, the Middle East, and Europe, businesses can access a diverse range of products that meet their specific operational needs. Establishing strong relationships with suppliers not only enhances negotiation power but also fosters innovation and sustainability in sourcing practices.

What are the key considerations for sourcing grit rock tumblers effectively? Buyers should assess supplier reliability, product specifications, and compliance with international standards. Additionally, understanding regional market trends can help in forecasting demand and mitigating risks associated with supply chain disruptions.

Looking ahead, the grit rock tumbler market is poised for growth as industries increasingly prioritize quality finishing processes. B2B buyers are encouraged to explore emerging technologies and sustainable practices within their sourcing strategies. By doing so, they can not only optimize their operations but also contribute to a more responsible and resilient supply chain. Engage with your suppliers today to secure your competitive advantage in this evolving market landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina