In the quest for sourcing high-quality boron, international B2B buyers face significant challenges, especially when evaluating the hardness of boron for various industrial applications. This guide delves into the multifaceted nature of boron hardness, providing insights into its types, applications, and the critical factors influencing supplier selection and cost. With the growing demand for boron in sectors such as electronics, ceramics, and metallurgy, understanding its hardness properties becomes essential for making informed purchasing decisions.

Navigating the global market for boron can be daunting, particularly for buyers from Africa, South America, the Middle East, and Europe, including Turkey and Indonesia. This comprehensive resource not only outlines the various forms of boron and their respective hardness characteristics but also emphasizes practical strategies for vetting suppliers. Additionally, it addresses pricing structures and market trends, enabling buyers to align their sourcing strategies with current industry demands.

By leveraging the information provided in this guide, B2B buyers will be empowered to make informed decisions that enhance their procurement processes. Whether you are looking to improve product quality, reduce costs, or ensure compliance with international standards, understanding the hardness of boron is crucial to achieving your business objectives in a competitive global landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Amorphous Boron | Non-crystalline structure, high surface area | Electronics, Chemical Catalysts | Pros: Versatile, can enhance reactivity. Cons: Less stable than crystalline forms. |

| Crystalline Boron | Ordered atomic structure, high thermal conductivity | Aerospace, Defense, Cutting Tools | Pros: Superior hardness, excellent thermal properties. Cons: Higher cost and brittleness. |

| Boron Carbide | Extremely hard, used in abrasives | Armor, Industrial Machinery | Pros: Exceptional wear resistance. Cons: Limited availability and can be costly. |

| Boron Nitride | Exists in multiple forms (cubic, hexagonal), lubricating | Electronics, High-Temperature Applications | Pros: High thermal stability, excellent electrical insulator. Cons: May require special handling. |

| Boron-Doped Silicon | Enhanced electrical properties due to boron doping | Semiconductor Manufacturing | Pros: Improves conductivity and efficiency. Cons: Requires precise doping processes. |

Amorphous boron is characterized by its non-crystalline structure, which results in a high surface area that enhances its reactivity. This type of boron is particularly suitable for applications in electronics and as a catalyst in chemical processes. For B2B buyers, the versatility of amorphous boron is a significant advantage; however, its stability can be a concern, making it less ideal for long-term storage or high-temperature applications.

Crystalline boron features a well-ordered atomic structure, contributing to its exceptional hardness and thermal conductivity. This type is widely used in industries such as aerospace and defense, where high-performance materials are essential. B2B buyers should consider the higher costs associated with crystalline boron, along with its brittleness, which may impact its usability in certain applications where flexibility is required.

Boron carbide is known for its extreme hardness, making it a preferred choice for abrasive materials and armor applications. Its outstanding wear resistance is a key feature that appeals to industries involved in manufacturing machinery and protective gear. However, B2B buyers should be aware of its limited availability and potentially higher costs, which may affect procurement decisions.

Boron nitride exists in various forms, with the cubic and hexagonal forms being the most notable for their thermal and electrical properties. It is particularly valuable in electronics and high-temperature applications due to its thermal stability and excellent insulating capabilities. Buyers should consider the special handling requirements and costs associated with boron nitride, as these factors can influence overall project budgets.

Boron-doped silicon is crucial in the semiconductor industry, as the addition of boron significantly enhances the electrical properties of silicon. This doping process improves conductivity and efficiency, making it a vital component in modern electronics. For B2B buyers, understanding the precision required in the doping process is essential, as it can impact both performance and production costs in semiconductor manufacturing.

Related Video: The Mohs Scale of Hardness Explained

| Industry/Sector | Specific Application of hardness of boron | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Boron carbide composites for armor | Enhanced protection against ballistic threats | Ensure compliance with aerospace standards and certifications |

| Automotive | Hardening agents in brake systems | Improved wear resistance and safety performance | Evaluate compatibility with existing materials and processes |

| Electronics | Semiconductor fabrication | Enhanced thermal stability and efficiency | Source high-purity boron for consistent quality |

| Construction and Mining | Boron-based additives in concrete | Increased durability and reduced cracking | Assess local regulations and environmental impact |

| Energy (Nuclear) | Boron neutron capture materials | Improved safety in nuclear reactors | Consider sourcing from certified suppliers for quality assurance |

In the aerospace sector, boron carbide composites are increasingly used for armor applications. The hardness of boron makes it an ideal material for lightweight yet robust protective gear against ballistic threats. This application addresses safety concerns while minimizing weight, which is crucial in aerospace design. International buyers must consider compliance with aerospace standards and certifications, ensuring that the sourced materials meet rigorous safety and performance criteria.

Boron compounds serve as hardening agents in automotive brake systems, significantly enhancing wear resistance. This application is vital for improving the longevity and safety performance of braking components. For B2B buyers in this sector, it is essential to evaluate the compatibility of boron additives with existing materials and manufacturing processes, as well as to ensure they meet industry safety standards.

In the electronics industry, the hardness of boron is leveraged in semiconductor fabrication, where boron is used to enhance thermal stability and efficiency. This is particularly relevant in high-performance electronic devices that require reliable operation under varying conditions. Buyers should prioritize sourcing high-purity boron to maintain consistent quality and performance in their products, as impurities can significantly affect semiconductor functionality.

In the construction and mining sectors, boron-based additives are incorporated into concrete to increase durability and reduce cracking. This application is crucial for infrastructure projects that demand long-lasting materials. International buyers need to assess local regulations regarding boron usage and its environmental impact, ensuring compliance while maximizing the benefits of enhanced material performance.

Boron plays a critical role in nuclear energy as a neutron capture material, enhancing safety in nuclear reactors. Its hardness contributes to the effectiveness of boron-based materials in controlling neutron flux, thereby improving reactor safety. For B2B buyers in the energy sector, sourcing from certified suppliers is essential to ensure quality assurance and compliance with stringent safety regulations, particularly in international markets.

Related Video: Boron Carbide: Hardness Unleashed

The Problem: Many B2B buyers, especially in the manufacturing and materials sector, struggle with inconsistencies in the hardness levels of boron-based materials. This inconsistency can lead to product failures, increased production costs, and ultimately, dissatisfied customers. For instance, a manufacturer producing boron carbide components for cutting tools may find that variations in hardness lead to premature wear, impacting the tool's lifespan and performance.

The Solution: To overcome this challenge, buyers should prioritize sourcing boron materials from suppliers that provide detailed certifications and testing results for hardness levels. It's essential to establish clear specifications for hardness before placing orders, ensuring that suppliers can meet these requirements consistently. Implementing a robust quality assurance process, including in-house testing of incoming materials, can also help identify discrepancies early in the production process. Additionally, collaborating with suppliers to understand their production processes can lead to better alignment and assurance of quality.

The Problem: B2B buyers, particularly those new to using boron in their products, often lack comprehensive knowledge about the specific applications and advantages of boron hardness. This gap can result in underutilization of boron materials, missing out on potential performance improvements in their products. For example, a company in the automotive industry might overlook the benefits of using boron steel for parts that require high strength and durability, leading to suboptimal product performance.

The Solution: To address this issue, buyers should engage in educational initiatives, such as attending industry conferences, webinars, and workshops focused on advanced materials. Developing a relationship with knowledgeable suppliers can also provide insights into how boron hardness can enhance specific applications. Creating internal resources or guides that outline the benefits and use cases of boron in various industries can empower decision-makers within the organization to make informed choices. Encouraging cross-functional collaboration within the company can help integrate this knowledge into product development strategies.

The Problem: For many B2B buyers, the costs associated with testing the hardness of boron materials can be a significant pain point. This is particularly relevant for companies that require frequent quality assurance checks to maintain compliance with industry standards. A manufacturing firm may find that the expenses related to third-party testing laboratories or in-house testing equipment become burdensome, impacting their overall profitability.

The Solution: To mitigate these costs, buyers can explore partnerships with suppliers that offer integrated testing services as part of their product offerings. This can reduce the need for separate testing contracts and streamline the supply chain. Additionally, investing in training for in-house personnel to perform basic hardness testing can reduce reliance on external labs, allowing for quicker and cost-effective assessments. Utilizing advanced testing technologies, such as portable hardness testers, can further minimize expenses while ensuring that quality remains uncompromised. Establishing a clear testing schedule aligned with production cycles can also help manage costs and ensure that only necessary tests are conducted.

When selecting materials for applications involving the hardness of boron, international B2B buyers must consider various factors, including material properties, advantages and disadvantages, and compliance with regional standards. Below is an analysis of four common materials used in conjunction with boron hardness, tailored for buyers from Africa, South America, the Middle East, and Europe.

Boron Carbide (B4C) is one of the hardest materials known, often used in applications requiring high wear resistance. It has excellent properties such as high-temperature stability and low density, making it suitable for armor applications and abrasive tools.

Pros: Its exceptional hardness and chemical resistance make it ideal for tough environments. Additionally, it is relatively lightweight, which is advantageous in applications where weight is a concern.

Cons: The primary drawback is its brittleness, which can lead to failure under certain stress conditions. Manufacturing boron carbide can also be complex and costly due to the high purity requirements.

Impact on Application: Boron carbide is compatible with various media, including corrosive substances, making it suitable for industries like defense and aerospace.

Silicon Carbide (SiC) is another material frequently used for its hardness and thermal conductivity. It is particularly effective in high-temperature applications and environments where oxidation is a concern.

Pros: SiC offers excellent thermal stability and is highly resistant to chemical attack, making it suitable for harsh environments. Its high hardness also translates to superior wear resistance.

Cons: While it performs well under high temperatures, silicon carbide can be more expensive than other materials. Additionally, its brittleness can limit its use in certain applications.

Impact on Application: SiC is often used in semiconductor applications and high-performance ceramics, where its thermal properties are essential.

Tungsten is renowned for its high melting point and density, making it a preferred choice in applications requiring strength and durability. It is often used in cutting tools and heavy machinery.

Pros: Tungsten's high density provides excellent wear resistance and durability, making it ideal for heavy-duty applications. It also maintains its hardness at elevated temperatures.

Cons: The main disadvantages include its high cost and the complexity of machining due to its hardness. Additionally, tungsten can be prone to corrosion in certain environments.

Impact on Application: Tungsten is compatible with various media, including high-pressure systems, making it suitable for applications in mining and drilling.

Boron Nitride (BN) is a versatile material that exhibits properties similar to those of diamond, making it useful in various applications requiring high hardness and thermal stability.

Pros: BN is chemically inert and has excellent thermal conductivity, making it suitable for high-temperature applications. It also has a lower density than diamond, which can be advantageous in specific applications.

Cons: The primary limitation of boron nitride is its cost, as it can be more expensive than other materials. Additionally, its mechanical properties can vary significantly depending on the form (e.g., hexagonal vs. cubic).

Impact on Application: Boron nitride is often used in lubricants and coatings due to its excellent thermal properties and low friction coefficient.

Here is a summary of the materials analyzed, highlighting their typical uses, advantages, disadvantages, and relative costs.

| Material | Typical Use Case for hardness of boron | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Boron Carbide | Armor applications and abrasive tools | Exceptional hardness and chemical resistance | Brittleness and high manufacturing costs | High |

| Silicon Carbide | Semiconductor applications and ceramics | Excellent thermal stability and wear resistance | Higher cost and brittleness | High |

| Tungsten | Cutting tools and heavy machinery | High density and durability | High cost and complex machining | Med |

| Boron Nitride | Lubricants and coatings | Chemically inert with excellent thermal conductivity | Higher cost and variable mechanical properties | High |

This guide serves as a strategic resource for international B2B buyers, helping them navigate the complexities of material selection related to the hardness of boron while considering regional standards and compliance requirements.

The manufacturing of boron products that exhibit hardness involves several critical stages. Understanding these stages is essential for B2B buyers seeking reliable and high-quality materials.

Material Preparation

The first step involves sourcing high-purity boron or boron-containing compounds. Suppliers often utilize boron oxide (B2O3) or boron carbide (B4C) as starting materials. The selection of raw materials is crucial, as impurities can significantly affect the hardness and overall quality of the final product. Buyers should verify the purity levels through supplier documentation and certifications.

Forming Techniques

Once the materials are prepared, they undergo forming processes. Common techniques include:

- Pressing: For boron carbide, pressing is often used to create dense shapes. The powder is compacted under high pressure to achieve the desired density and hardness.

- Sintering: This is a vital step where the pressed materials are heated to a temperature below their melting point, allowing particles to bond. This process enhances hardness and structural integrity.

- Molding: For specific applications, boron products can be shaped using injection molding, which allows for complex geometries.

Assembly

In cases where boron is used as a component in larger systems (e.g., composite materials), assembly processes come into play. This may include layering boron with other materials to enhance properties like thermal resistance or mechanical strength.

Finishing Processes

After assembly, finishing processes are applied to achieve the required surface quality. Techniques such as grinding, polishing, or coating may be employed. The finishing stage is essential for ensuring that the product meets specific industry standards for hardness and durability.

Quality assurance (QA) is critical in the manufacturing of boron products to ensure that they meet international standards and customer specifications.

What Are the International Standards Relevant to Boron Manufacturing?

International standards such as ISO 9001 are pivotal for ensuring consistent quality management systems. These standards help manufacturers maintain a systematic approach to quality, thereby reducing defects and enhancing customer satisfaction. Industry-specific standards, like CE marking for European markets or API standards for oil and gas applications, also play a significant role in product acceptance.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This step involves verifying the quality of incoming raw materials against established specifications.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor parameters such as temperature, pressure, and density. This ensures that any deviations are corrected promptly.

- Final Quality Control (FQC): Once products are completed, final inspections and testing are conducted to ensure they meet hardness and other relevant specifications.

What Testing Methods Are Commonly Used?

Various testing methods are employed to assess the hardness of boron products:

- Hardness Testing: Techniques such as Vickers or Rockwell hardness tests provide quantitative measures of hardness.

- Microstructural Analysis: Scanning Electron Microscopy (SEM) and X-ray Diffraction (XRD) can be used to analyze the microstructure and phases present in the boron material.

- Mechanical Testing: Tensile strength and impact resistance tests are also performed to evaluate performance under stress.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial for ensuring product reliability.

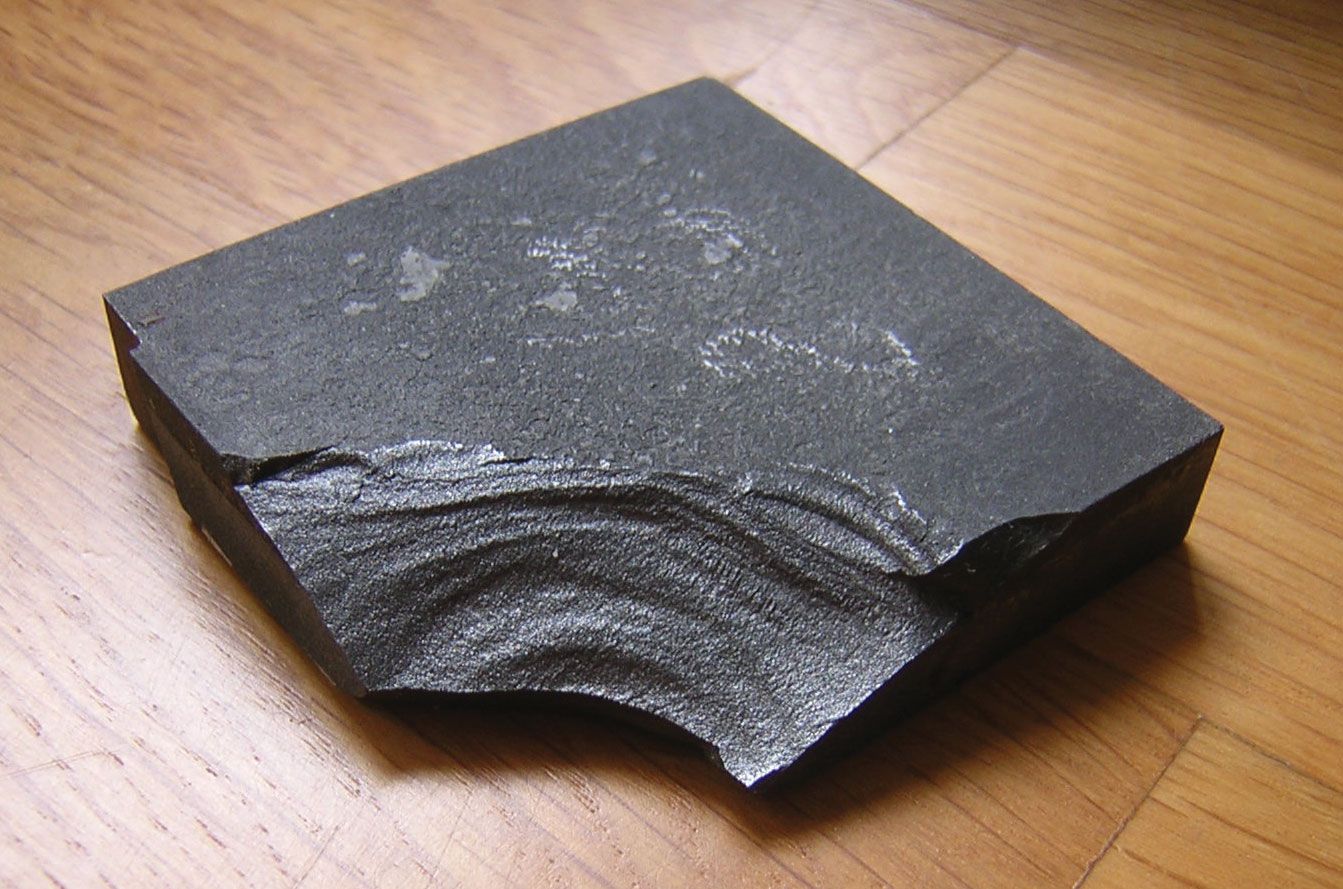

A stock image related to hardness of boron.

Supplier Audits

Conducting audits of potential suppliers can provide valuable insights into their quality management systems. Buyers should look for evidence of compliance with ISO standards and other relevant certifications. Audits can also reveal the effectiveness of their QC checkpoints and testing methods.

Quality Reports and Documentation

Requesting detailed quality reports, including test results and compliance certifications, is essential. This documentation should outline the results of IQC, IPQC, and FQC processes, providing transparency in the supplier's quality assurance.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the supplier's capabilities. These inspections can validate the supplier’s adherence to quality standards and provide additional assurance of product quality.

Understanding the specific quality control nuances can significantly impact the purchasing decisions of international B2B buyers.

Differences in Regulatory Standards

Different regions may have varying regulatory standards for boron products. Buyers in Europe may need to comply with CE marking requirements, while those in the Middle East may focus on local standards. It’s essential to be aware of these differences to avoid compliance issues.

Cultural and Communication Considerations

Engaging with suppliers from diverse regions may involve navigating cultural differences in business practices and communication. Clear communication about quality expectations and requirements is vital to avoid misunderstandings.

Logistics and Supply Chain Considerations

Quality assurance extends beyond manufacturing to include logistics and supply chain management. Ensuring that transportation and storage conditions meet quality standards is crucial for maintaining product integrity during shipment.

By understanding the manufacturing processes and quality assurance practices associated with boron hardness, international B2B buyers can make informed decisions that align with their quality expectations and industry standards.

This practical sourcing guide is designed to assist international B2B buyers in procuring materials related to the hardness of boron. Understanding the unique properties and applications of boron, particularly its hardness, is vital for industries ranging from manufacturing to electronics. This checklist outlines actionable steps to streamline your sourcing process, ensuring you find reliable suppliers that meet your specifications.

Before initiating the sourcing process, it's crucial to clearly define your technical specifications for boron hardness. This includes understanding the specific hardness levels required for your application, whether it's for abrasives, glass production, or other industrial uses.

Conduct thorough research to identify potential suppliers of boron hardness materials, particularly those located in Africa, South America, the Middle East, and Europe. Local suppliers may offer advantages in terms of logistics and cultural understanding.

It is essential to verify that your potential suppliers hold the necessary certifications and comply with industry standards. This step helps mitigate risks associated with quality and safety.

Once you have shortlisted suppliers, request product samples for testing. This step is critical to ensure that the hardness of the boron meets your specifications and quality expectations.

Understanding pricing structures and payment terms is vital for budgeting and financial planning. Engage in discussions with suppliers to clarify these aspects.

Before making a final decision, seek references from other businesses that have sourced boron hardness materials from your shortlisted suppliers. Customer feedback can provide valuable insights into supplier reliability and service quality.

After selecting a supplier, finalize contracts that clearly outline all agreed-upon terms, including delivery schedules and quality assurance measures. Continuous monitoring of supplier performance is essential for long-term success.

By following this checklist, B2B buyers can streamline the sourcing process for boron hardness materials, ensuring they make informed decisions that align with their technical requirements and business objectives.

When sourcing hardness of boron, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The quality and type of boron used can significantly impact costs. Higher purity boron typically commands a premium, while bulk purchases may reduce unit prices.

Labor: Labor costs vary by region. In regions like Africa and South America, lower wage rates can lead to cost savings, but this may come at the expense of skill levels and efficiency.

Manufacturing Overhead: This includes costs associated with production facilities, maintenance, and utilities. Efficient operations can lower overhead, making sourcing more cost-effective.

Tooling: Investment in tooling can be substantial, especially for custom specifications. The initial cost can be spread over larger production runs, reducing the per-unit cost.

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the overall cost. Buyers should evaluate the necessity of such measures based on their specific needs.

Logistics: Transportation and handling fees can vary widely, especially for international shipments. Incoterms play a crucial role in determining who bears these costs.

Margin: Suppliers typically factor in a profit margin, which can vary based on market demand, competition, and the buyer's negotiation power.

Several factors influence pricing in the hardness of boron market:

Volume and Minimum Order Quantity (MOQ): Larger orders generally reduce the cost per unit due to economies of scale. Negotiating favorable terms regarding MOQs can lead to significant savings.

Specifications and Customization: Custom requirements can increase costs. Buyers should be clear about their specifications to avoid unnecessary expenses.

Materials Quality and Certifications: Certifications (e.g., ISO, ASTM) can enhance product value but may also increase costs. Buyers must weigh the benefits against the additional costs.

Supplier Factors: The supplier's reputation, location, and production capabilities can all influence pricing. Established suppliers may charge more but offer better reliability and quality.

Incoterms: Understanding Incoterms can help buyers avoid unexpected costs. For example, choosing FOB (Free on Board) can shift shipping costs to the buyer, which may impact overall pricing.

Negotiation Strategies: Establish a strong relationship with suppliers to foster open communication. Use market research to leverage competitive pricing during negotiations.

Focus on Cost-Efficiency: Evaluate not just the initial price but the total cost of ownership (TCO). This includes maintenance, logistics, and potential downtime, which can drastically affect long-term costs.

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and trade agreements that may impact pricing. Engaging with local experts can provide insights into regional market dynamics.

Inquire About Volume Discounts: Always ask about discounts for larger orders or long-term contracts. Suppliers may be more willing to negotiate if they see a long-term commitment.

Monitor Market Trends: Stay informed about market trends and price fluctuations in the boron industry. This knowledge can empower buyers during negotiations and help them make timely purchasing decisions.

Prices for hardness of boron can vary significantly based on numerous factors, including market conditions, supplier agreements, and geographic location. It is essential for buyers to conduct thorough research and obtain multiple quotes to understand the current pricing landscape before making purchasing decisions.

When it comes to materials used for enhancing hardness, boron is a well-regarded option due to its unique properties. However, international B2B buyers must also consider other viable alternatives that could meet their specific requirements. This analysis provides a comparative look at boron's hardness against two alternative solutions: titanium carbide and tungsten carbide.

| Comparison Aspect | Hardness of Boron | Titanium Carbide | Tungsten Carbide |

|---|---|---|---|

| Performance | High hardness (9.3 Mohs) | High hardness (9 Mohs) | Very high hardness (9.5 Mohs) |

| Cost | Moderate | Moderate to high | High |

| Ease of Implementation | Easy to integrate | Moderate | Complex |

| Maintenance | Low maintenance | Moderate | Low |

| Best Use Case | General industrial applications | Cutting tools, wear-resistant coatings | Mining, drilling applications |

Titanium carbide is known for its excellent hardness and wear resistance, making it a popular choice in the manufacturing of cutting tools and protective coatings. It offers a performance level slightly below boron, but its ability to withstand high temperatures adds to its appeal. However, titanium carbide is generally more expensive and requires a more complex installation process. Maintenance needs are moderate, necessitating regular checks in high-stress environments.

Tungsten carbide stands out for its superior hardness, often cited as one of the hardest materials available. With a Mohs hardness of 9.5, it excels in demanding applications like mining and drilling. While it offers low maintenance requirements, the initial cost is significantly higher compared to boron and titanium carbide. The complexity of its implementation can also deter some buyers, especially in industries where quick integration is vital.

A stock image related to hardness of boron.

Selecting the right hardness solution requires careful consideration of various factors, including performance, cost, ease of implementation, and maintenance. While boron offers a balanced approach for general industrial applications, titanium carbide and tungsten carbide provide specialized benefits that may better suit specific use cases. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should evaluate their operational requirements and budget constraints to make an informed choice. By weighing the pros and cons of each alternative, companies can ensure they select the most appropriate material for their applications, ultimately enhancing efficiency and productivity.

Understanding the technical properties of boron hardness is essential for B2B buyers, particularly in industries requiring high-performance materials. Here are some critical specifications that influence purchasing decisions:

Material Grade

- Definition: Material grades indicate the composition and quality of boron used in manufacturing. Common grades include amorphous boron and crystalline boron.

- B2B Importance: Choosing the right grade affects the hardness and durability of the final product. Buyers must align the material grade with application requirements, ensuring optimal performance and longevity.

Hardness Value

- Definition: Hardness is quantified using scales such as Mohs or Vickers, measuring a material's resistance to deformation or scratching.

- B2B Importance: A higher hardness value signifies superior wear resistance, making it vital for applications in cutting tools and abrasives. Buyers should assess hardness in relation to operational conditions to avoid premature failure.

Tolerance Levels

- Definition: Tolerance refers to the allowable variation in dimensions and physical properties during manufacturing.

- B2B Importance: Precise tolerances ensure that components fit correctly in assemblies. For international buyers, understanding tolerance specifications can mitigate costly rework or delays in production.

Density

- Definition: Density measures the mass per unit volume, impacting the weight and overall performance of boron materials.

- B2B Importance: Higher density often correlates with improved hardness and durability. Buyers should evaluate density in conjunction with other properties to select materials that meet specific engineering requirements.

Thermal Stability

- Definition: This property indicates how well a material retains its hardness and structural integrity under elevated temperatures.

- B2B Importance: In industries like aerospace and automotive, thermal stability is crucial. Buyers should consider thermal resistance when evaluating boron for high-heat applications.

Familiarity with industry-specific terminology enhances effective communication between buyers and suppliers. Here are some commonly used terms:

OEM (Original Equipment Manufacturer)

- Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

- Relevance: For B2B buyers, partnering with OEMs ensures access to high-quality boron products that meet specific industry standards.

MOQ (Minimum Order Quantity)

- Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

- Relevance: Understanding MOQ is essential for budget planning. Buyers should negotiate MOQs to align with their production needs without overcommitting resources.

RFQ (Request for Quotation)

- Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

- Relevance: Utilizing RFQs can streamline the procurement process, ensuring competitive pricing and clarity on specifications for boron hardness products.

Incoterms (International Commercial Terms)

- Definition: Incoterms are a set of rules that define the responsibilities of sellers and buyers regarding the delivery of goods.

- Relevance: For international transactions, understanding Incoterms is crucial to avoid misunderstandings about shipping, insurance, and tariffs, particularly when dealing with boron hardness materials.

Lead Time

- Definition: Lead time refers to the period from placing an order to receiving the product.

- Relevance: Knowing lead times helps buyers plan their inventory and production schedules, particularly in industries with tight deadlines.

Certification

- Definition: Certification indicates that a product meets specific industry standards or regulations.

- Relevance: Buyers should prioritize sourcing certified boron hardness materials to ensure compliance and quality assurance in their applications.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that optimize their procurement strategies and align with their operational goals.

The hardness of boron sector is experiencing transformative shifts influenced by global demand and technological advancements. As industries increasingly seek materials that enhance durability and performance, boron’s unique properties, such as high hardness and resistance to wear, have become highly sought after. Key markets driving this demand include the aerospace, automotive, and electronics sectors, particularly in regions like Europe, the Middle East, and parts of Africa and South America.

Emerging B2B tech trends are reshaping sourcing strategies. Digital platforms are facilitating more transparent and efficient procurement processes, enabling buyers to connect directly with suppliers across borders. Additionally, data analytics tools are being used to predict market trends, allowing buyers to make informed decisions regarding price fluctuations and material availability. For instance, the rise of e-commerce in B2B transactions is enabling companies from Turkey and Indonesia to access global suppliers and diversify their sourcing options.

International B2B buyers must also navigate various market dynamics, including fluctuating raw material prices and geopolitical factors that can impact supply chains. Understanding these elements is crucial for maintaining competitive advantage and ensuring timely access to high-quality boron products.

Sustainability is becoming a critical concern in the hardness of boron sector, as environmental impacts from mining and processing operations come under scrutiny. Buyers are increasingly prioritizing suppliers that adhere to sustainable practices, which may include responsible sourcing of raw materials and minimizing ecological footprints.

The importance of ethical supply chains cannot be overstated, particularly for international buyers who are often held accountable for their sourcing decisions. Certifications such as ISO 14001 for environmental management and Fair Trade practices can be indicators of a supplier's commitment to sustainability.

Additionally, the movement towards "green" materials is gaining traction. Buyers should consider suppliers that offer boron products derived from recycled or low-impact processes, which can provide a competitive edge in markets that are moving towards more sustainable consumption patterns. By aligning with ethical sourcing practices, companies can enhance their brand reputation and attract customers who value corporate responsibility.

The hardness of boron has a rich history that dates back to its discovery in the early 19th century. Initially utilized in glass and ceramics, its applications have expanded significantly with advancements in technology. The industrial revolution marked a turning point, as boron’s hardness became essential in manufacturing processes, particularly in the production of abrasives and cutting tools.

Over the decades, research has uncovered additional benefits of boron, such as its role in enhancing the mechanical properties of metals and ceramics. Today, the hardness of boron is integral to various high-tech applications, including aerospace components and advanced electronics, highlighting its evolution from a niche material to a cornerstone of modern engineering. This historical context underscores the material's growing importance in contemporary B2B markets, offering insights into future trends and opportunities for international buyers.

How do I determine the hardness of boron for my applications?

To accurately assess the hardness of boron for your specific applications, consider conducting standardized tests such as the Mohs hardness test or the Vickers hardness test. These methods will provide quantitative measurements that can guide your material selection process. Additionally, consult technical datasheets from suppliers to compare hardness values in relation to other materials. If custom specifications are needed, communicate your requirements clearly with potential suppliers to ensure they can meet your hardness criteria.

What is the best grade of boron for industrial applications?

The ideal grade of boron for industrial applications largely depends on the intended use. For example, boron carbide is often preferred in abrasive applications due to its high hardness and chemical stability. Conversely, boron nitride is favored in high-temperature applications because of its thermal properties. Evaluate your specific requirements such as thermal resistance, chemical reactivity, and mechanical strength to choose the best grade that aligns with your operational needs.

What are the typical minimum order quantities (MOQs) for boron hardness products?

Minimum order quantities for boron hardness products can vary significantly among suppliers. Generally, MOQs range from 10 kg to several tons, depending on the supplier's capacity and the product type. When sourcing, inquire about flexible options for smaller orders, especially if you are testing the material for the first time. Establishing a relationship with suppliers may also lead to negotiated terms that accommodate your purchasing needs.

How can I vet suppliers of boron hardness products effectively?

To vet suppliers effectively, start by checking their certifications, such as ISO or ASTM, which indicate compliance with international standards. Request references or case studies from previous clients to gauge their reliability and product quality. Additionally, evaluate their production capabilities and quality assurance processes. Conducting site visits or third-party audits can provide further assurance of their operational integrity and adherence to quality standards.

What payment terms should I expect when sourcing boron products internationally?

Payment terms for international transactions can vary, but common options include letters of credit, advance payments, or net 30/60 days terms depending on the supplier’s policies. It's advisable to discuss payment terms upfront to avoid any surprises. Ensure that the terms align with your cash flow needs and risk management strategies. Also, consider the implications of currency exchange rates and transaction fees when negotiating these terms.

What logistics considerations should I keep in mind when importing boron products?

When importing boron products, pay attention to shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with the regulations in your country and the supplier's location. Additionally, consider the lead times for shipping and ensure that your inventory management aligns with these timelines. Finally, ensure that all necessary documentation, including customs declarations and certificates of origin, are prepared to facilitate smooth customs clearance.

How can I customize boron products to meet specific hardness requirements?

Customizing boron products often involves collaborating closely with suppliers to define your specific hardness requirements. This may include adjusting the boron content or altering the manufacturing process to achieve desired properties. Communicate your application needs clearly and request samples to evaluate performance before committing to larger orders. Establishing a strong partnership with your supplier can enhance their ability to meet your customization needs effectively.

What quality assurance measures should I expect from suppliers of boron hardness products?

Quality assurance measures from suppliers should include regular testing of material properties, adherence to industry standards, and comprehensive documentation of test results. Ask for details about their quality control processes, including any certifications they hold. Additionally, inquire whether they offer warranties or guarantees on their products, as this can provide additional assurance of material reliability and performance in your applications.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of boron, particularly in its application for hardness enhancement, presents significant opportunities for international B2B buyers across Africa, South America, the Middle East, and Europe. By understanding the unique properties of boron and its role in various industries—such as manufacturing, electronics, and materials science—businesses can make informed decisions that enhance product quality and performance.

The foremost takeaway is the importance of establishing strong relationships with reliable suppliers. Conducting thorough market research, considering local sourcing options, and evaluating supplier capabilities can mitigate risks associated with supply chain disruptions. Additionally, leveraging technological advancements in boron processing can lead to cost efficiencies and improved product outcomes.

As the demand for boron-based materials continues to rise, especially in innovative applications like energy storage and advanced ceramics, buyers should stay ahead by investing in strategic sourcing practices. Emphasizing sustainability and ethical sourcing will not only align with global standards but also enhance brand reputation.

In a rapidly evolving market, proactive engagement with suppliers and continuous assessment of sourcing strategies will be crucial. International B2B buyers are encouraged to act now—embrace the potential of boron and secure your competitive advantage in your respective industries.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina