In the ever-evolving global market, sourcing materials that meet specific performance criteria is a significant challenge for international B2B buyers. Among these materials, silicon carbide (SiC) stands out due to its exceptional hardness, making it a preferred choice in various applications, from abrasives to semiconductor devices. However, understanding the nuances of SiC hardness, including its types, applications, and the implications for supplier selection, is crucial for making informed purchasing decisions.

This comprehensive guide will delve into the different types of silicon carbide, exploring their unique characteristics and applications across industries. Additionally, we will address critical factors such as supplier vetting processes, cost analysis, and market trends, all tailored specifically for B2B buyers from Africa, South America, the Middle East, and Europe. By equipping buyers with actionable insights and strategic frameworks, this guide empowers you to navigate the complexities of sourcing high-quality SiC effectively.

Whether you are looking to enhance your production capabilities or seeking reliable suppliers, understanding the hardness of SiC can significantly impact your decision-making process. With this guide, you will gain the knowledge needed to make strategic purchasing choices that align with your business objectives, ensuring that you remain competitive in the global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microhardness | Measured at a micro-scale, often using Vickers or Knoop tests. | Semiconductor manufacturing, ceramics. | Pros: Precise measurement; Cons: Requires specialized equipment. |

| Macrohardness | Evaluated with larger scale tests like Rockwell or Brinell. | Heavy machinery, metal fabrication. | Pros: Quick results; Cons: Less precision than microhardness. |

| Indentation Hardness | Based on the depth of indentation under a specific load. | Material quality testing, coatings. | Pros: Simple to perform; Cons: May not reflect true material performance. |

| Scratch Hardness | Assessed by the ability to resist scratching, often using Mohs scale. | Jewelry, mineral testing. | Pros: Easy assessment; Cons: Limited to surface properties. |

| Ceramic Hardness | Specific to ceramics, indicating resistance to deformation. | Aerospace, automotive industries. | Pros: High temperature resistance; Cons: Brittle nature can limit applications. |

Microhardness testing involves measuring the hardness of materials at a microscopic level, typically using Vickers or Knoop indentation methods. This type of hardness is particularly relevant for materials that require precision, such as semiconductors and ceramics. B2B buyers should consider the need for specialized equipment and expertise in interpreting results, as microhardness testing often involves complex procedures. This testing is ideal for applications where material properties at small scales are critical, ensuring high-quality standards in production.

Macrohardness is assessed using larger-scale tests like Rockwell or Brinell, making it suitable for evaluating the hardness of bulk materials. Industries such as heavy machinery and metal fabrication frequently utilize macrohardness testing due to its efficiency in providing quick results. Buyers should weigh the advantages of fast testing against the potential loss of precision compared to microhardness methods. Understanding the specific hardness requirements of their materials will guide businesses in selecting the appropriate testing method.

Indentation hardness testing measures the depth of an indentation produced by a specific load, providing valuable insights into a material's resistance to deformation. This method is widely used in quality control for various industries, particularly in assessing coatings and surface treatments. B2B buyers should consider the simplicity of this testing method, which can be performed with relatively low-cost equipment. However, they must also recognize that indentation hardness may not fully reflect a material's overall performance, prompting a comprehensive evaluation of material characteristics.

Scratch hardness is determined by a material's ability to resist scratching, often assessed using the Mohs scale. This type of hardness is particularly useful in industries like jewelry and mineral testing, where surface durability is crucial. Buyers should appreciate the ease of assessing scratch hardness, which can be performed without specialized equipment. However, it is essential to remember that this method primarily focuses on surface properties and may not provide a complete picture of material performance under varying conditions.

Ceramic hardness reflects a material's resistance to deformation, making it critical in high-performance applications such as aerospace and automotive industries. Ceramics are known for their excellent hardness and high-temperature resistance, which are essential for components exposed to extreme conditions. B2B buyers should consider the brittleness of ceramics, which can limit their application in dynamic environments. Understanding the balance between hardness and brittleness will help buyers make informed decisions when selecting materials for their projects.

Related Video: Types of hardness(lecture 2)by Anu sambyal

| Industry/Sector | Specific Application of hardness of sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine components and turbine blades | Enhanced durability and reduced wear in high-temperature environments | Suppliers must meet stringent aerospace standards and certifications. |

| Electronics | Semiconductor substrates | Improved thermal conductivity and reliability in electronic devices | Focus on purity levels and defect-free materials during sourcing. |

| Automotive | Brake systems and wear-resistant components | Increased safety and longer lifespan of critical automotive parts | Ensure compliance with automotive industry regulations and testing. |

| Manufacturing | Cutting tools and abrasives | Higher efficiency and precision in manufacturing processes | Consider sourcing from manufacturers with advanced quality control. |

| Construction | High-performance concrete additives | Improved strength and longevity of construction materials | Evaluate suppliers based on their experience in construction applications. |

In the aerospace sector, the hardness of silicon carbide (SiC) is crucial for manufacturing engine components and turbine blades. Its exceptional wear resistance and ability to withstand high temperatures ensure that these components maintain performance under extreme conditions. International buyers, especially from regions like Europe and the Middle East, must prioritize suppliers who adhere to rigorous aerospace quality standards and possess the necessary certifications to guarantee safety and reliability.

Silicon carbide's hardness makes it an ideal material for semiconductor substrates in electronic devices. Its high thermal conductivity and thermal stability help improve the reliability and efficiency of various electronic applications, particularly in high-power and high-frequency devices. Buyers from Africa and South America should focus on sourcing SiC with low defect levels and high purity to ensure optimal performance in their electronic products.

In the automotive industry, hardness of SiC is utilized in brake systems and wear-resistant components. The material's durability enhances safety by reducing wear and tear on critical automotive parts, ultimately leading to longer service life and reduced maintenance costs. Buyers should ensure that their suppliers meet automotive industry regulations and conduct thorough testing to verify the quality and performance of SiC components.

Manufacturers leverage the hardness of SiC in cutting tools and abrasives to achieve higher efficiency and precision in their production processes. The material's toughness allows for extended tool life and better performance in machining operations. When sourcing SiC for manufacturing, it is vital for buyers to consider suppliers with advanced quality control measures to ensure the consistency and reliability of the materials provided.

In construction, the hardness of SiC is used in high-performance concrete additives, which significantly improve the strength and longevity of construction materials. This enhancement is particularly beneficial in regions prone to harsh environmental conditions. Buyers should evaluate potential suppliers based on their experience and success in providing SiC solutions tailored to construction applications, ensuring they meet the specific needs of the project.

Related Video: Brinell Hardness Test

The Problem:

Many B2B buyers, especially those in manufacturing sectors across Africa, South America, the Middle East, and Europe, struggle with accurately assessing the hardness of silicon carbide (SiC) for their specific applications. This challenge often arises from the varying hardness grades of SiC available on the market, which can lead to incorrect material selection. If the hardness is too low, the material may wear out quickly, while overly hard materials can lead to increased brittleness, resulting in premature failures during use. This confusion can result in costly production delays, increased waste, and ultimately affect the bottom line.

The Solution:

To effectively navigate the hardness specifications of SiC, buyers should first engage with reputable suppliers who provide detailed technical datasheets that include hardness values (often measured on the Mohs or Vickers scales). It's essential to ask for sample materials to conduct preliminary testing in their specific conditions before making bulk purchases. Furthermore, leveraging the expertise of material scientists or engineers familiar with SiC can help in understanding how varying hardness levels affect performance in specific applications. Collaborating with suppliers on tailored material solutions can also lead to better outcomes, ensuring that the chosen SiC fits the operational requirements precisely.

The Problem:

Another prevalent issue faced by international B2B buyers is the inconsistency in the quality and hardness of SiC from different suppliers. This discrepancy can arise from variations in production processes, raw material sources, and quality control measures. Buyers may receive materials that do not meet the required hardness specifications, leading to product failures and customer dissatisfaction. This inconsistency can disrupt supply chains, particularly for companies that depend on reliable material performance for high-stakes applications.

The Solution:

To mitigate risks associated with quality inconsistency, buyers should establish strong relationships with a select few suppliers known for their stringent quality control processes. Requesting third-party certifications or laboratory test results for hardness can provide additional assurance of the material's quality. Implementing a robust supplier evaluation process, including audits and regular performance reviews, can help maintain high standards. Additionally, adopting a just-in-time inventory system can reduce the impact of any quality discrepancies by allowing companies to respond quickly to supply chain challenges.

The Problem:

Integrating silicon carbide with existing manufacturing processes poses significant challenges for many B2B buyers. Companies often face difficulties in machining or processing SiC due to its extreme hardness, which can lead to increased tool wear and higher operational costs. Moreover, without proper knowledge of suitable processing techniques and equipment, buyers may find themselves unable to effectively utilize SiC in their applications, resulting in inefficiencies and wasted resources.

The Solution:

To effectively integrate SiC into their manufacturing processes, companies should invest in training for their engineering and production teams on the best practices for working with hard materials. Collaborating with manufacturers who specialize in SiC machining can provide valuable insights into the latest techniques and tools designed for this purpose. Additionally, investing in high-quality diamond tools specifically designed for machining SiC can significantly reduce wear and improve efficiency. Networking with industry peers and participating in workshops or seminars focused on SiC applications can also enhance knowledge and skills, ensuring that the transition to using SiC is as smooth as possible.

Silicon carbide (SiC) is renowned for its exceptional hardness, making it a preferred choice in various industrial applications. The material exhibits high thermal conductivity, excellent wear resistance, and remarkable chemical stability, which are critical for high-performance applications. SiC can withstand extreme temperatures, typically up to 1,600°C, and high pressures, making it suitable for environments where other materials may fail. Additionally, its corrosion resistance allows it to perform well in harsh chemical environments, which is vital for industries such as aerospace, automotive, and semiconductor manufacturing.

When considering SiC, it is essential to weigh its advantages against its limitations. One of the primary benefits is its durability; SiC components can last significantly longer than those made from traditional materials like metals or ceramics. This longevity translates into lower maintenance costs and improved efficiency in operations. However, the manufacturing complexity of SiC can be a drawback. Producing high-quality SiC components often requires sophisticated processing techniques, which can lead to higher initial costs.

SiC’s unique properties make it particularly suitable for applications involving high-speed and high-temperature operations, such as in power electronics and high-performance motors. Its compatibility with various media, including aggressive chemicals, enhances its utility in industries like oil and gas, where equipment must resist wear and corrosion. For international B2B buyers, understanding the specific media compatibility of SiC is crucial for ensuring that the material meets the operational demands of their applications.

For buyers in Africa, South America, the Middle East, and Europe, several factors come into play when selecting SiC for hardness applications. Compliance with international standards such as ASTM, DIN, and JIS is vital to ensure that the materials meet safety and performance benchmarks. Additionally, regional preferences may influence material selection; for example, buyers in Europe might prioritize sustainability and environmental impact, while those in the Middle East may focus on cost-effectiveness and availability. Understanding these nuances can help buyers make informed decisions that align with their operational needs.

| Material | Typical Use Case for hardness of sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Semiconductor devices | High thermal conductivity | High manufacturing complexity | High |

| Alumina | Abrasives and cutting tools | Good wear resistance | Lower thermal conductivity than SiC | Medium |

| Tungsten Carbide | Mining and drilling applications | Exceptional hardness | Brittle nature can lead to cracking | High |

| Boron Carbide | Armor materials | Lightweight yet very hard | Limited availability and higher cost | High |

This analysis provides a comprehensive overview of the materials relevant to hardness applications of SiC, emphasizing their properties, advantages, and considerations for international B2B buyers. Understanding these factors will enable buyers to make strategic decisions that optimize performance and cost-effectiveness in their operations.

The manufacturing of Silicon Carbide (SiC) components, particularly those requiring high hardness, involves several critical stages. Understanding these processes is essential for B2B buyers aiming to ensure product quality and performance.

The first step in the manufacturing process involves sourcing high-purity raw materials, including silicon and carbon. These materials undergo rigorous quality checks to ensure they meet the required specifications. The preparation stage often includes:

Once the materials are prepared, the next phase involves shaping them into desired forms. Various forming techniques are employed based on the final application:

Finishing processes are vital to enhance the surface quality and dimensional accuracy of SiC products. Common finishing techniques include:

Quality assurance (QA) is critical in ensuring that SiC components meet international standards and customer specifications. Here are key aspects of QA in the manufacturing process:

B2B buyers should look for manufacturers that comply with recognized international standards. Key certifications include:

The quality control (QC) process typically includes several checkpoints throughout the manufacturing cycle:

Several testing methods are employed to assess the hardness and overall quality of SiC products:

Verifying a supplier's quality control processes is crucial for international B2B buyers. Here are actionable steps to ensure supplier credibility:

For B2B buyers operating in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital:

Understanding the manufacturing processes and quality assurance measures associated with the hardness of SiC is crucial for international B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and robust QC practices, buyers can ensure they procure high-quality SiC components that meet their specific needs. Engaging in thorough supplier verification and understanding regional nuances will further enhance the likelihood of successful transactions in the global market.

When sourcing materials like silicon carbide (SiC), particularly focusing on its hardness properties, it’s essential to follow a structured approach to ensure quality and reliability. This guide outlines actionable steps to assist international B2B buyers from regions such as Africa, South America, the Middle East, and Europe in making informed procurement decisions.

A stock image related to hardness of sic.

Begin by establishing the precise hardness requirements for your application. Different applications, such as abrasives or semiconductor devices, may require varying hardness levels. Clearly outlining these specifications will help you communicate effectively with potential suppliers and ensure that the materials meet your needs.

Understanding the market landscape is crucial for identifying potential suppliers. Investigate suppliers that specialize in silicon carbide and assess their market reputation.

Before making a commitment, conduct thorough evaluations of potential suppliers. This step is critical to ensure that the suppliers can consistently meet your specifications.

Ensure that your suppliers have the necessary certifications to confirm the quality of their products. Certifications can provide assurance of compliance with international standards.

Before placing a bulk order, obtain samples of the silicon carbide material. Testing these samples allows you to verify that the hardness and other properties meet your specifications.

Once you have identified a suitable supplier, it’s time to negotiate pricing and terms. Transparent negotiations can lead to long-term partnerships that benefit both parties.

Implement a quality control process to regularly assess the quality of the silicon carbide materials received. This helps maintain consistency and addresses any issues promptly.

By following this practical sourcing guide, B2B buyers can enhance their procurement process for silicon carbide materials, ensuring they receive high-quality products that meet their hardness requirements.

When sourcing hardness of silicon carbide (SiC), understanding the cost structure is critical for effective budgeting and decision-making. The primary cost components include:

Materials: The cost of SiC raw materials varies significantly based on purity and sourcing location. High-purity SiC typically commands a premium, impacting overall cost.

Labor: Labor costs can fluctuate based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can be offset by quality concerns.

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

Tooling: Initial tooling costs for custom SiC products can be substantial. Buyers should factor in these costs when evaluating suppliers, especially for unique specifications.

Quality Control (QC): Investing in robust QC processes ensures product reliability but can add to the overall cost. Certifications such as ISO or specific industry standards may also incur additional expenses.

Logistics: Shipping costs, including freight and insurance, are influenced by distance, mode of transport, and Incoterms. Effective logistics management can lead to significant savings.

Margin: Supplier margins vary based on market conditions and competition. Understanding the typical margins in your region can aid in negotiations.

Several factors can influence the pricing of SiC products significantly:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs against suppliers' MOQ requirements.

Specifications and Customization: Custom specifications can increase costs due to the need for specialized production processes. It’s crucial to communicate your requirements clearly to avoid unexpected charges.

Material Quality and Certifications: Higher quality materials and certifications typically incur additional costs. Buyers should weigh the necessity of these factors against potential benefits in performance and reliability.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Well-established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

Incoterms: The choice of Incoterms affects the distribution of costs and risks between buyers and suppliers. Understanding these terms can help in negotiating better pricing and terms.

B2B buyers can adopt several strategies to enhance their negotiation power and achieve cost efficiency:

Conduct a Total Cost of Ownership (TCO) Analysis: Evaluate not just the purchase price, but also logistics, maintenance, and disposal costs. A lower upfront cost may lead to higher long-term expenses.

Negotiate Based on Volume: Leverage larger order sizes to negotiate better pricing. Suppliers are often willing to provide discounts for bulk purchases.

Seek Multiple Quotes: Gathering quotes from multiple suppliers can provide leverage in negotiations and help buyers understand the market price range.

Understand Pricing Nuances: Familiarize yourself with regional pricing trends, particularly if sourcing from different continents. For instance, suppliers in Africa may have different pricing strategies compared to those in Europe.

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing, improved service, and priority during supply shortages.

A stock image related to hardness of sic.

While indicative prices can provide a baseline for budgeting, they often fluctuate due to market conditions, supplier capacities, and geopolitical factors. It’s essential for buyers to remain flexible and prepared for price changes. Regularly updating pricing information and maintaining open communication with suppliers can mitigate the impact of unexpected cost increases.

When evaluating materials for industrial applications, understanding the hardness of Silicon Carbide (SiC) is crucial. However, there are several alternative solutions that may also meet your hardness requirements while offering distinct advantages. This analysis aims to compare the hardness of SiC with other viable alternatives, helping international B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Hardness of SiC | Alternative 1: Boron Carbide | Alternative 2: Tungsten Carbide |

|---|---|---|---|

| Performance | High hardness (9-10 Mohs scale) | Extremely high hardness (9.3-9.5 Mohs scale) | High hardness (8.5-9 Mohs scale) |

| Cost | Moderate | High | Moderate to High |

| Ease of Implementation | Requires specialized handling | Requires specialized handling | Widely available and easier to work with |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | High-temperature applications, abrasives | Armor, industrial applications | Tool manufacturing, mining |

Boron Carbide (B4C) is one of the hardest materials known and is often used in armor plating and industrial applications. Its exceptional hardness makes it suitable for environments where resistance to wear and abrasion is critical. However, the cost of Boron Carbide can be significantly higher than SiC, which may deter some buyers. Additionally, like SiC, it requires specialized handling during manufacturing, which could complicate the supply chain.

Tungsten Carbide (WC) is another durable alternative known for its hardness and versatility. It is widely used in the manufacturing of cutting tools and mining equipment due to its excellent wear resistance. While it is slightly less hard than SiC, its availability and ease of processing make it a popular choice. Maintenance requirements can be moderate, and the initial investment is often lower than that of Boron Carbide, making it accessible for various industrial applications.

Selecting the right hardness solution involves evaluating your specific application requirements, budget constraints, and long-term maintenance expectations. If high-performance and extreme hardness are paramount, Boron Carbide may be the best option despite its higher cost. Conversely, if you prioritize ease of implementation and moderate costs, Tungsten Carbide could be more suitable. Ultimately, B2B buyers should conduct a thorough analysis of their operational needs and consider not only the hardness but also the overall lifecycle costs and logistical challenges associated with each material. This comprehensive approach will ensure that you invest in a solution that aligns with your business objectives.

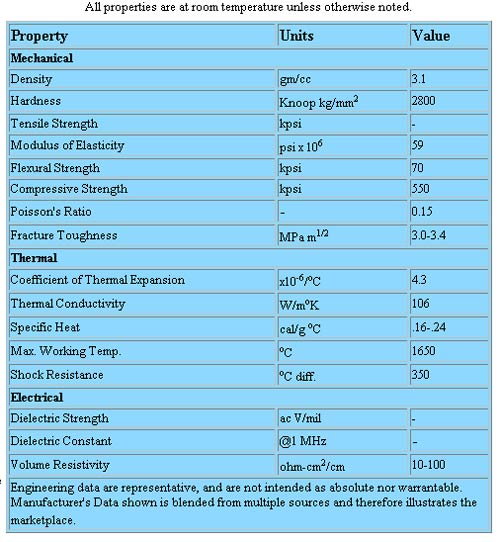

When dealing with silicon carbide (SiC), understanding its hardness and related technical properties is crucial for B2B buyers, particularly in sectors like manufacturing, electronics, and automotive. Here are essential specifications to consider:

Material grades of SiC can vary significantly based on purity and crystal structure. Common grades include 6H, 4H, and 3C, which refer to different polytypes of SiC. The grade impacts hardness, thermal conductivity, and overall performance in applications. For buyers, selecting the appropriate grade ensures compatibility with their intended use, whether it's in abrasives or semiconductor devices.

The hardness of SiC is often quantified using the Mohs hardness scale, where it typically rates between 9 and 9.5. This high hardness level makes SiC an excellent choice for wear-resistant applications. Understanding the hardness measurement allows buyers to assess how SiC will perform under stress and in abrasive environments, ensuring longevity and durability in their products.

Tolerance refers to the allowable deviation from a specified dimension in the manufacturing process. In the context of SiC, tight tolerances are critical, especially when producing components for high-precision applications like semiconductor wafers. Buyers should look for suppliers who can consistently meet these tolerance levels to ensure product reliability and performance.

Thermal conductivity measures how well a material can conduct heat. SiC boasts high thermal conductivity, making it suitable for high-temperature applications. Buyers must consider this property to ensure their components can withstand operational temperatures without degrading, especially in industries like power electronics and aerospace.

The density of SiC typically ranges from 3.1 to 3.2 g/cm³, affecting its weight and structural integrity. Understanding the density is vital for applications where weight is a consideration, such as in automotive parts or aerospace components. Buyers should evaluate density in conjunction with other properties to determine the overall suitability of SiC for their specific needs.

Navigating the international B2B landscape involves understanding specific trade terminology, which facilitates smoother transactions and clearer communication. Here are some key terms relevant to SiC:

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of SiC, OEMs often require specific grades and tolerances, making it essential for suppliers to meet these criteria to establish partnerships.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For SiC products, understanding MOQ is crucial for buyers, especially smaller companies that may not need large quantities but still seek quality materials.

An RFQ is a standard business process where a buyer requests a price quote from suppliers for specific products or services. When sourcing SiC materials, an RFQ helps buyers compare prices, quality, and delivery timelines from multiple suppliers, enabling informed decision-making.

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with these terms is essential for international B2B transactions involving SiC, as they specify who is responsible for shipping, insurance, and tariffs.

The American Society for Testing and Materials (ASTM) sets international standards for materials, including SiC. Understanding these standards is crucial for buyers to ensure that the materials they procure meet quality and performance expectations.

By comprehensively understanding the technical properties and trade terminology associated with the hardness of SiC, international B2B buyers can make informed decisions, ensuring they select the right materials for their specific applications.

The global market for Silicon Carbide (SiC), recognized for its hardness and thermal stability, is witnessing robust growth driven by several factors. The increasing demand for energy-efficient technologies and the push for electric vehicles (EVs) are major catalysts. With a global shift towards renewable energy sources, SiC's application in power electronics is becoming increasingly vital. Furthermore, the automotive sector's growing focus on lightweight materials enhances SiC's appeal, as it contributes to fuel efficiency and performance.

Emerging technologies such as artificial intelligence and IoT are reshaping sourcing trends. B2B buyers are leveraging advanced analytics to optimize supply chains, making data-driven decisions that enhance procurement efficiency. Additionally, the rise of digital platforms is facilitating better supplier connectivity and real-time tracking of materials, which is particularly advantageous for international buyers from regions like Africa, South America, and the Middle East. As these markets develop, establishing relationships with reliable suppliers who understand local regulations and market nuances is critical.

The demand for customized solutions is also on the rise, pushing suppliers to innovate and differentiate themselves in the SiC space. Buyers should prioritize partnerships with manufacturers who can provide tailored products that meet specific industry needs, thus ensuring competitive advantage.

Sustainability is becoming a non-negotiable aspect of sourcing strategies in the SiC sector. The environmental impact of production processes is under scrutiny, and buyers are increasingly favoring suppliers who adopt eco-friendly practices. Companies are now required to demonstrate their commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems.

Ethical sourcing is another crucial consideration. Buyers must ensure that their supply chains do not contribute to environmental degradation or exploit labor. This means sourcing SiC from manufacturers who prioritize responsible mining practices and have transparent supply chains. Additionally, the use of 'green' materials in production processes is gaining traction. For instance, suppliers incorporating recycled SiC or employing less harmful chemicals in their processes can enhance their marketability to environmentally conscious buyers.

Incorporating sustainability into procurement strategies not only aligns with global trends but also mitigates risks associated with regulatory changes and consumer preferences for ethical products.

The hardness of Silicon Carbide has made it a material of choice since its introduction in the early 20th century, initially used in abrasives and cutting tools. Over the decades, its applications have expanded significantly, particularly in high-temperature and high-voltage environments such as semiconductor devices and power electronics.

In recent years, the evolution of SiC technology has been marked by advancements in manufacturing processes, such as the development of silicon carbide wafers. These innovations have enhanced the material's performance in various applications, from automotive to renewable energy sectors. For B2B buyers, understanding this historical context is essential as it highlights the material's adaptability and relevance in modern applications, ensuring they are well-informed when making sourcing decisions.

As the SiC market continues to evolve, staying abreast of technological advancements and emerging applications will be crucial for international buyers seeking to leverage the material's unique properties in their industries.

How do I determine the hardness of silicon carbide (SiC) for my application?

To determine the hardness of silicon carbide for your specific application, you should refer to standardized testing methods like the Mohs scale or Vickers hardness test. These tests provide quantitative measures of hardness, which can help you assess whether SiC meets your requirements for abrasion resistance or wear performance. Consult with suppliers to ensure they provide detailed hardness specifications and consider conducting your own tests on samples to validate the data.

What is the best grade of silicon carbide for high-temperature applications?

For high-temperature applications, the best grade of silicon carbide is typically the Beta-SiC variant. This form has superior thermal stability and maintains its hardness at elevated temperatures, making it ideal for use in environments like aerospace, automotive, and semiconductor manufacturing. Be sure to confirm the specific temperature thresholds and mechanical properties with your supplier to ensure compatibility with your operational conditions.

How can I verify the quality of silicon carbide suppliers?

To verify the quality of silicon carbide suppliers, request certifications such as ISO 9001, which indicates compliance with quality management standards. Conduct audits, if possible, to assess their production processes and quality control measures. Additionally, seek references from other international buyers in your region to gauge their experiences. Reviewing customer feedback and performance histories can also provide insights into supplier reliability and product quality.

What are the typical minimum order quantities (MOQs) for silicon carbide products?

Minimum order quantities for silicon carbide products can vary significantly based on the supplier and product type. Typically, MOQs range from 100 kg to several tons. It's advisable to communicate your specific needs directly with suppliers, as many are willing to accommodate smaller orders, especially for custom formulations. Establishing a solid relationship with your supplier can also lead to more flexible terms.

What payment terms should I expect when purchasing silicon carbide internationally?

Payment terms for international purchases of silicon carbide often range from 30% upfront and 70% upon delivery to 100% payment in advance, depending on the supplier's policies and your negotiation. Some suppliers may offer letters of credit or escrow services as secure payment options. Always clarify payment terms in your contract to avoid misunderstandings and ensure financial security throughout the transaction.

How do I ensure the silicon carbide I purchase meets international quality standards?

To ensure that the silicon carbide you purchase meets international quality standards, request documentation such as Material Safety Data Sheets (MSDS), technical data sheets, and compliance certificates for relevant industry standards like ASTM or ISO. Conducting thorough supplier audits and requiring batch testing results can further verify quality. Engage with suppliers who demonstrate transparency in their production processes and quality assurance measures.

What logistics considerations should I keep in mind when sourcing silicon carbide?

When sourcing silicon carbide, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Evaluate the total cost of logistics, including freight, tariffs, and handling fees, to ensure they fit within your budget. Collaborating with suppliers who have experience in international shipping can streamline the process and help you navigate any potential challenges related to delivery timelines or regulatory compliance.

Can silicon carbide be customized for specific applications?

Yes, silicon carbide can be customized for specific applications by adjusting its composition, grain size, and bonding methods during production. Many suppliers offer tailored solutions to meet unique performance requirements, such as specific hardness levels or thermal properties. Discuss your application needs with potential suppliers to explore customization options, ensuring that the final product aligns with your technical specifications and operational goals.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing for silicon carbide (SiC) hardness is essential for international B2B buyers aiming to optimize procurement processes. Buyers should focus on understanding material specifications, supplier capabilities, and market trends to enhance product quality and reduce costs. By fostering strong relationships with suppliers, businesses can ensure a consistent supply of high-quality SiC materials that meet their technical requirements.

The value of strategic sourcing extends beyond mere cost savings; it encompasses risk management, innovation, and sustainability. By adopting a proactive sourcing strategy, companies from Africa, South America, the Middle East, and Europe can navigate geopolitical uncertainties and fluctuating market conditions more effectively. Engaging in collaborative partnerships with suppliers can also lead to innovative solutions that drive competitive advantage.

Looking ahead, it is crucial for international B2B buyers to remain adaptable and informed about emerging technologies and market shifts. As the demand for SiC materials continues to grow, leveraging data analytics and digital tools will be vital for making informed sourcing decisions. By staying ahead of the curve, businesses can not only meet current demands but also position themselves for future growth in the SiC landscape. Act now to enhance your strategic sourcing approach and secure a competitive edge in this evolving market.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina