Hollow aluminium balls have emerged as essential components across diverse industrial sectors, including automotive, aerospace, construction, and decorative applications. Their unique combination of lightweight properties, corrosion resistance, and structural strength makes them invaluable for manufacturers and suppliers aiming to optimize product performance while reducing material costs. For B2B buyers operating in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of hollow aluminium balls is crucial to securing reliable, cost-effective, and high-quality supply chains.

This comprehensive guide is designed to equip international buyers—from Kenya to the UK—with actionable insights that streamline the sourcing process. It covers a wide spectrum of critical topics: from the various types and alloys of hollow aluminium balls available, to advanced manufacturing techniques and stringent quality control measures that ensure durability and consistency. Additionally, the guide delves into supplier evaluation strategies, cost factors influenced by global market trends, and regional considerations impacting logistics and compliance.

By consolidating market intelligence and technical knowledge, this resource empowers procurement professionals to make informed decisions that align with their operational goals and regional demands. Whether you are navigating supplier negotiations, assessing material specifications, or managing supply chain risks, this guide offers a clear roadmap to optimize your investment in hollow aluminium balls and maintain a competitive edge in the global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seamless Hollow Aluminium Balls | Manufactured without welding seams; uniform thickness | Aerospace, precision instruments, decorative elements | Pros: Superior strength and aesthetics; Cons: Higher cost, limited size range |

| Welded Hollow Aluminium Balls | Constructed by joining two hemispheres via welding | Industrial machinery, structural components, signage | Pros: Cost-effective; customizable sizes; Cons: Potential weak points at welds, less uniformity |

| Anodized Hollow Aluminium Balls | Surface treated for enhanced corrosion resistance and color options | Outdoor installations, marine equipment, architectural design | Pros: Improved durability and appearance; Cons: Additional processing cost, limited thickness options |

| Perforated Hollow Aluminium Balls | Feature strategically placed holes or patterns | Ventilation systems, lighting fixtures, artistic installations | Pros: Lightweight, functional airflow; Cons: Reduced structural integrity, specialized production |

| Powder-Coated Hollow Aluminium Balls | Coated with a durable, colored finish for protection | Automotive parts, outdoor furniture, commercial displays | Pros: Enhanced weather resistance, aesthetic versatility; Cons: Potential for coating wear over time |

Seamless Hollow Aluminium Balls

Seamless hollow aluminium balls are prized for their uniform wall thickness and absence of weld seams, which ensures high structural integrity and a smooth finish. These qualities make them ideal for aerospace applications and precision instruments where strength and reliability are paramount. For B2B buyers, the trade-off is a higher price point and limited availability in larger diameters. When purchasing, consider your tolerance for cost versus quality and the critical nature of the application.

Welded Hollow Aluminium Balls

Welded variants are produced by joining two hemispheres, offering greater flexibility in size and shape customization at a lower cost. They are commonly used in industrial machinery, signage, and structural components where aesthetic perfection is less critical. Buyers should evaluate the welding quality carefully, as weld seams can be potential weak points, impacting durability under stress. This type suits projects with budget constraints but requires inspection for weld integrity.

Anodized Hollow Aluminium Balls

Anodizing enhances corrosion resistance and allows for a range of colors, making these balls well-suited for outdoor and marine environments, as well as architectural projects demanding both durability and visual appeal. B2B buyers should factor in the added processing time and cost but gain significant longevity and reduced maintenance. This option is valuable for clients in coastal regions or harsh climates, such as parts of Africa and the Middle East.

Perforated Hollow Aluminium Balls

Featuring engineered perforations, these balls serve dual functions of lightweight design and airflow, making them ideal for ventilation systems, lighting fixtures, and artistic installations. The perforations, however, reduce overall strength, so buyers must assess load-bearing requirements carefully. This type is best for decorative or functional uses where weight reduction and air passage are priorities, common in innovative architectural and industrial applications.

Powder-Coated Hollow Aluminium Balls

Powder coating provides a robust, colorful finish that enhances weather resistance, making these balls suitable for automotive parts, outdoor furniture, and commercial displays. B2B buyers benefit from the aesthetic versatility and protection against environmental damage, though coatings may degrade over time under extreme conditions. When sourcing, consider the coating quality and environmental exposure to ensure longevity, particularly in outdoor markets across Europe and South America.

| Industry/Sector | Specific Application of hollow aluminium balls | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight structural components and insulation fillers | Reduced aircraft weight leading to fuel efficiency and cost savings | Compliance with aerospace-grade certifications and material standards; reliable supply chain for timely delivery |

| Oil & Gas | Buoyancy modules for subsea pipelines and equipment | Enhanced operational safety and reduced maintenance costs | Corrosion resistance specifications; certification for marine environment use; durability under high pressure |

| Automotive | Crash absorption elements and lightweight vehicle parts | Improved fuel efficiency and enhanced safety performance | Material quality for impact resistance; customization options; compliance with regional automotive standards |

| Construction | Lightweight filler material for concrete and facade panels | Reduction in structural load and improved thermal insulation | Consistent size and quality; local availability to reduce shipping costs; environmental compliance |

| Renewable Energy | Components in wind turbine blades and solar panel mounts | Improved durability and reduced weight for easier installation | Resistance to weathering; long-term durability; certifications for renewable energy equipment |

Aerospace Applications

Hollow aluminium balls are widely used in aerospace for lightweight structural components and insulation fillers. Their low density helps reduce overall aircraft weight, directly contributing to fuel efficiency and operational cost savings. For international buyers, especially in Europe and the Middle East, sourcing must prioritize compliance with strict aerospace material standards such as AMS or ASTM, ensuring reliability and safety. Timely delivery and traceability in the supply chain are critical due to the high precision and certification requirements in this sector.

Oil & Gas Industry Uses

In subsea oil and gas operations, hollow aluminium balls serve as buoyancy modules attached to pipelines and equipment, preventing sinking and damage. Their corrosion resistance and ability to withstand high underwater pressures improve operational safety and reduce costly maintenance. Buyers from Africa and South America should focus on materials certified for marine environments and verify the supplier’s capacity to provide consistent quality under harsh conditions, considering the logistical challenges of remote offshore sites.

Automotive Sector

Automotive manufacturers incorporate hollow aluminium balls in crash absorption systems and lightweight components to enhance safety and fuel economy. These balls help absorb impact energy while reducing vehicle weight, which is crucial for meeting stringent emissions regulations in regions like the UK and Europe. Buyers must ensure the material meets regional automotive standards and can be customized to specific design needs, with a focus on high impact resistance and durability.

Construction Industry

In construction, hollow aluminium balls are used as lightweight filler materials in concrete and facade panels, reducing structural load and improving thermal insulation. This application is particularly valuable in regions with extreme climates, such as parts of Africa and the Middle East, where energy efficiency is a priority. B2B buyers should consider the consistency in size and quality of the balls to maintain structural integrity, as well as local availability to minimize shipping costs and comply with environmental regulations.

Renewable Energy Applications

Renewable energy companies use hollow aluminium balls in components of wind turbine blades and solar panel mounts to reduce weight and enhance durability against weathering. This facilitates easier installation and longer service life. Buyers from Europe and South America should prioritize suppliers offering products with certifications for long-term UV and corrosion resistance, ensuring the materials can withstand diverse climatic conditions and contribute to sustainable energy solutions.

Related Video: How Is Aluminium Extruded? - Aluminium Casting and Extrusion

Key Properties: Aluminium 6061 is a versatile alloy known for its excellent strength-to-weight ratio, good corrosion resistance, and moderate temperature tolerance up to approximately 150°C. It offers good weldability and machinability, making it a popular choice for hollow aluminium balls requiring structural integrity.

Pros & Cons: The alloy’s durability and corrosion resistance make it suitable for outdoor and marine applications, especially in humid or mildly corrosive environments. However, it has moderate cost and manufacturing complexity due to heat treatment requirements. It is less suitable for extremely high-temperature or highly corrosive chemical environments.

Impact on Application: 6061 aluminium balls are ideal for applications involving water, air, and mild chemical exposure, such as buoyancy aids, decorative elements, or lightweight structural components. Its compatibility with common industrial fluids makes it a practical choice for many industries.

Considerations for International Buyers: Buyers in regions like Africa and South America, where environmental conditions can be harsh, will benefit from 6061’s corrosion resistance. Compliance with ASTM B209 and ISO 209-1 standards is common, and European buyers often look for EN 573-3 certification. For markets like the UK and Middle East, ensuring conformity to local standards and certifications (e.g., BS EN) is critical for procurement and regulatory approval.

Key Properties: Aluminium 5052 is highly regarded for its superior corrosion resistance, especially against saltwater and marine environments. It has good formability and moderate strength, with temperature resistance typically up to 120°C.

Pros & Cons: Its excellent resistance to seawater and industrial chemicals makes it ideal for marine and chemical processing applications. However, it has lower tensile strength compared to 6061, which may limit its use in high-stress environments. Manufacturing complexity is moderate, with good weldability but limited heat-treating options.

Impact on Application: 5052 hollow aluminium balls are frequently used in offshore, marine, and chemical industries where exposure to saltwater and corrosive agents is common. Its chemical compatibility ensures longevity and reduced maintenance costs.

Considerations for International Buyers: For African coastal regions and Middle Eastern countries with saline environments, 5052 is a preferred choice. Buyers should verify compliance with ASTM B209 and JIS H4000 standards. European buyers often require adherence to EN 485-2 for sheet and plate products. Cost considerations are important as 5052 tends to be slightly more expensive than 6061 due to its specialized corrosion properties.

Key Properties: Aluminium 3003 is an alloy with excellent corrosion resistance and good workability but lower strength compared to 6061 and 5052. It has good resistance to atmospheric corrosion and moderate temperature tolerance up to 100°C.

Pros & Cons: This alloy is cost-effective and easy to manufacture, making it suitable for large-scale production. However, its lower mechanical strength limits use in high-load or high-pressure applications. It is less suitable for aggressive chemical environments.

Impact on Application: 3003 alloy hollow aluminium balls are well-suited for decorative purposes, lightweight floatation devices, and applications where corrosion resistance is required without significant mechanical stress.

Considerations for International Buyers: Buyers in South America and Africa often prioritize cost-effectiveness, making 3003 attractive for non-critical applications. Compliance with ASTM B209 and DIN 1725 standards is common. European buyers may require additional certifications for food-grade or architectural uses, depending on the end application.

Key Properties: Anodizing is a surface treatment that enhances corrosion resistance, surface hardness, and aesthetic appeal of aluminium alloys. It does not change the base metal’s mechanical properties but adds a durable oxide layer.

Pros & Cons: Anodized hollow aluminium balls offer superior protection against corrosion and wear, extending service life in harsh environments. The process adds cost and complexity but improves product value. Color customization is possible, which is beneficial for branding or design purposes.

Impact on Application: Anodized aluminium balls are ideal for decorative, architectural, and outdoor applications where appearance and durability are critical. They also perform well in mildly corrosive environments.

Considerations for International Buyers: Buyers in Europe and the Middle East often require anodized finishes to meet aesthetic and durability standards, such as Qualanod certification in Europe. In Africa and South America, anodizing can be a value-added feature for premium applications. Ensuring the anodizing process complies with ISO 7599 or equivalent standards is important for quality assurance.

| Material | Typical Use Case for hollow aluminium balls | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminium 6061 | Structural components, buoyancy aids, outdoor fittings | High strength-to-weight ratio, good corrosion resistance | Moderate cost, limited high-temp tolerance | Medium |

| Aluminium 5052 | Marine, chemical processing, offshore applications | Excellent corrosion resistance, especially in saltwater | Lower tensile strength, higher cost | Medium-High |

| Aluminium 3003 | Decorative, lightweight floatation, non-critical parts | Cost-effective, excellent workability | Lower mechanical strength, limited chemical resistance | Low |

| Anodized Aluminium | Architectural, outdoor decorative, wear-resistant parts | Enhanced corrosion resistance and surface hardness | Added processing cost and complexity | Medium-High |

The production of hollow aluminium balls involves several critical stages that ensure the final product meets stringent quality and performance requirements. Understanding these stages helps B2B buyers assess supplier capabilities and production reliability.

Material Preparation

The process begins with selecting high-grade aluminium alloys, often 6061 or 7075, known for their strength-to-weight ratio and corrosion resistance. Raw aluminium is sourced in forms such as sheets, strips, or tubes depending on the forming technique. Prior to forming, the material undergoes cleaning and sometimes heat treatment to improve malleability and remove surface contaminants, which is essential for subsequent forming and finishing.

Forming Techniques

There are several forming methods employed to create hollow aluminium spheres, each with distinct advantages:

- Deep Drawing and Spinning: This technique involves shaping aluminium sheets into hemispherical shells using dies and mandrels. Two hemispheres are then welded or joined to form a hollow ball.

- Hydroforming: A high-pressure fluid is used to shape aluminium blanks inside a mold, allowing for uniform thickness and smooth surface finish. This method is favored for complex shapes and precision.

- Metal Injection Molding (MIM): For smaller, high-precision hollow balls, MIM can be used, combining powdered aluminium with binders to create intricate shapes, followed by sintering to achieve strength.

- Casting (Less common): Gravity or centrifugal casting can produce hollow forms but often with less uniformity and surface finish compared to other methods.

Assembly and Joining

When hemispheres are formed separately, they require joining via welding techniques such as TIG (Tungsten Inert Gas) welding or laser welding. These methods provide strong, clean joints with minimal distortion. In some cases, adhesives or mechanical locking methods are used, but welding remains the standard for structural integrity.

Finishing Processes

Finishing ensures corrosion resistance, aesthetic appeal, and dimensional accuracy:

- Surface Treatment: Anodizing is common to enhance corrosion resistance and surface hardness. Alternative coatings include powder coating or painting for specific environmental protections.

- Machining: Final machining may be performed to refine dimensions or add features such as holes or threaded inserts.

- Polishing: For applications requiring high reflectivity or smooth surfaces, polishing or buffing is applied.

Robust quality assurance (QA) and quality control (QC) systems are critical for ensuring hollow aluminium balls meet international standards and customer specifications. Suppliers typically implement multiple QC checkpoints and testing methods.

International Standards and Certifications

- ISO 9001: Most reputable manufacturers maintain ISO 9001 certification, which ensures a structured quality management system covering all production phases.

- Industry-Specific Certifications: Depending on application sectors, compliance with standards such as CE marking (for European markets), API (American Petroleum Institute) standards (for oil & gas applications), or ASTM specifications may be required. These certifications confirm product safety, reliability, and performance under defined conditions.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Verifies raw material quality through chemical composition analysis and mechanical property testing before production begins.

- In-Process Quality Control (IPQC): Includes dimensional checks, welding inspections (e.g., non-destructive testing such as ultrasonic or X-ray), and surface finish verification during forming and assembly stages.

- Final Quality Control (FQC): Comprehensive inspection of the finished product, including dimensional accuracy, surface integrity, and functional testing.

Common Testing Methods

- Dimensional Inspection: Utilizes coordinate measuring machines (CMM) or laser scanning to verify spherical geometry and tolerances.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing, dye penetrant inspection, or radiography detect internal defects or weld flaws without damaging the product.

- Mechanical Testing: Tensile strength, hardness, and impact resistance tests confirm material properties.

- Corrosion Testing: Salt spray or humidity chamber tests assess surface treatment effectiveness.

- Leak Testing: For hollow balls used in fluid or gas applications, pressure tests ensure the absence of leaks.

Ensuring supplier reliability and product quality is paramount for international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, where import regulations and standards compliance are strict.

Supplier Audits:

Conduct on-site audits or hire third-party inspection agencies to evaluate manufacturing facilities, observe production processes, and verify QA/QC systems. Audits should assess certification validity, staff qualifications, equipment calibration, and traceability systems.

Review of Quality Documentation:

Request and review key documents such as ISO certificates, material test reports (MTRs), welding procedure specifications (WPS), and inspection reports. These documents provide transparency about the supplier’s adherence to standards.

Third-Party Inspection and Testing:

Engage independent inspection bodies to perform pre-shipment inspections or sample testing. This is especially critical for buyers from regions with strict import controls (e.g., CE marking for Europe or local regulatory requirements in Kenya or the UAE).

Sample Approval:

Before bulk orders, obtain and test product samples to verify compliance with specifications and performance criteria.

Traceability and Batch Control:

Ensure suppliers provide full traceability for each batch of hollow aluminium balls, linking raw materials to finished products, which is vital for quality accountability and future audits.

Regional Standards Alignment:

Buyers in Europe must ensure CE marking compliance and adherence to REACH regulations concerning chemical substances used in coatings. Middle Eastern buyers should verify compliance with Gulf Cooperation Council (GCC) standards. African and South American buyers may face varying local standards and should confirm that supplier certifications meet both international and local regulatory requirements.

Import Documentation:

Proper documentation, including certificates of conformity, customs declarations, and test reports, is essential for smooth clearance. Buyers should work with suppliers familiar with export regulations to avoid delays.

Environmental and Sustainability Considerations:

Increasingly, buyers in Europe and South America are demanding environmentally responsible manufacturing practices. Certifications such as ISO 14001 (environmental management) and adherence to sustainable sourcing policies can be differentiators.

Language and Communication:

Clear communication regarding technical specifications and QC expectations is crucial. Buyers should insist on detailed, bilingual documentation where necessary and confirm understanding of quality standards.

By thoroughly understanding the manufacturing processes and quality assurance mechanisms for hollow aluminium balls, B2B buyers can make informed procurement decisions, mitigate risks, and foster long-term supplier partnerships that meet the specific demands of their regional markets.

Understanding the cost structure and pricing dynamics for hollow aluminium balls is crucial for international B2B buyers aiming to optimize procurement strategies while ensuring product quality and reliability. This section breaks down key cost components, identifies critical price influencers, and offers actionable tips tailored for buyers from regions including Africa, South America, the Middle East, and Europe.

Raw Materials:

Aluminium alloy grades significantly impact material costs. Higher-grade alloys or specialty treatments (e.g., corrosion-resistant coatings) increase expenses but enhance product durability. Global aluminium price fluctuations, driven by supply-demand imbalances and energy costs, also affect pricing.

Labor Costs:

Labor intensity varies depending on production methods—whether automated casting or manual finishing. Countries with lower labor costs may offer more competitive pricing but require scrutiny of quality standards.

Manufacturing Overhead:

Overhead includes factory utilities, machine depreciation, and indirect labor. Efficient manufacturers optimize these costs through lean production and automation, which can translate into better pricing.

Tooling and Setup:

Initial tooling for molds or specialized equipment is a fixed cost that manufacturers amortize over production volumes. Custom designs or smaller runs increase per-unit tooling costs.

Quality Control (QC):

Rigorous QC processes, including dimensional inspections and material certifications, add to costs but reduce risks of defects and returns—critical for B2B reliability.

Logistics and Freight:

Shipping costs depend on origin, destination, mode (sea, air, road), and volume. International freight charges, customs duties, and insurance must be factored into landed cost calculations.

Supplier Margin:

Profit margins vary based on market competition, supplier positioning, and contract terms. Negotiation can influence margins, especially for large or repeat orders.

Order Volume and Minimum Order Quantities (MOQ):

Larger volumes typically unlock economies of scale, reducing per-unit prices. However, buyers with smaller needs should explore suppliers offering flexible MOQs or consolidated shipments.

Specifications and Customization:

Tailored sizes, wall thicknesses, or surface finishes often increase costs due to specialized tooling and quality assurance requirements.

Material Quality and Certifications:

Compliance with international standards (e.g., ISO, ASTM) or certifications for aerospace, automotive, or marine applications commands premium pricing but assures performance.

Supplier Location and Reputation:

Established suppliers with proven track records may charge more but provide reliability and better after-sales support. Regional suppliers can reduce shipping time and costs.

Incoterms Selection:

Terms like FOB, CIF, or DDP determine which party bears transportation and customs risks, directly affecting pricing and total landed cost.

Negotiate Beyond Price:

Discuss payment terms, lead times, and volume discounts. Establishing long-term partnerships can secure better pricing and priority production slots.

Analyze Total Cost of Ownership (TCO):

Consider not just unit price but also shipping, customs fees, potential rework costs, and inventory holding expenses. For African or South American buyers, factoring in port handling and inland transport is vital.

Leverage Local and Regional Suppliers:

European buyers (e.g., UK) might benefit from suppliers within the EU to avoid tariffs and simplify compliance, while Middle Eastern buyers may explore nearby manufacturing hubs to reduce logistics costs.

Verify Quality and Certifications Early:

Request samples and certification documents upfront to avoid costly quality issues downstream.

Understand Pricing Nuances by Region:

Currency volatility and differing import regulations can affect landed costs. Employ hedging strategies or local currency contracts where possible.

Use Incoterms Wisely:

For first-time importers, opting for DDP (Delivered Duty Paid) can simplify customs clearance but may come at a premium. Experienced buyers may prefer FOB or EXW to control logistics.

Pricing for hollow aluminium balls varies widely based on specifications, order size, and market conditions. The figures discussed herein are indicative and should be validated through direct supplier quotations and market research tailored to the buyer’s specific requirements and region.

By carefully dissecting cost components and understanding pricing drivers, B2B buyers can develop informed sourcing strategies that balance cost efficiency with product quality and supply chain reliability, essential for competitive advantage in global markets.

Understanding the critical technical specifications of hollow aluminium balls is essential for making informed purchasing decisions that align with your industry requirements and quality standards.

Material Grade

The aluminium alloy grade (e.g., 6061, 5052) dictates the ball’s mechanical strength, corrosion resistance, and suitability for specific environments. For B2B buyers, selecting the correct grade ensures durability and performance, especially in harsh climates found in regions like the Middle East and coastal Africa.

Diameter and Wall Thickness

Precise control over diameter and wall thickness affects the ball’s weight, strength, and functionality. Tighter tolerances (e.g., ±0.1 mm) are crucial for applications requiring high precision, such as aerospace components or decorative architectural elements.

Surface Finish

Surface treatments (anodizing, polishing, powder coating) impact corrosion resistance and aesthetic appeal. Buyers targeting high-end markets in Europe or South America should specify finishes that meet both functional and visual standards.

Tolerance Levels

Tolerance refers to the allowable deviation in size or shape from the specified dimensions. For hollow aluminium balls, low tolerance values ensure consistency and interchangeability, which are vital for mass production and OEM partnerships.

Weight Consistency

Uniform weight distribution affects balance and performance, particularly in applications like bearings or decorative installations. Reliable suppliers will provide detailed weight specifications to meet these needs.

Corrosion Resistance

Aluminium’s natural oxide layer offers some corrosion resistance, but additional treatments enhance longevity. This is critical for buyers in humid or salty environments such as coastal South America or the Middle East.

Familiarity with industry jargon streamlines communication and negotiation processes with suppliers and manufacturers.

OEM (Original Equipment Manufacturer)

Refers to companies that produce products or components used in another company’s end product. For buyers, partnering with OEMs can offer customization and adherence to specific technical standards.

MOQ (Minimum Order Quantity)

The smallest amount a supplier is willing to sell per order. Understanding MOQ helps buyers manage inventory and cash flow, especially important for emerging markets in Africa where demand may be variable.

RFQ (Request for Quotation)

A formal document sent to suppliers requesting pricing and terms based on specified requirements. Crafting detailed RFQs ensures accurate quotes and reduces the risk of misunderstandings.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers. Examples include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Knowing Incoterms helps buyers control costs and logistics efficiently.

Lead Time

The time from order placement to delivery. Shorter lead times improve supply chain agility, which is crucial for buyers in fast-growing markets or industries with tight project schedules.

Batch Number

A unique identifier for a production run. Tracking batch numbers aids quality control and traceability, especially for compliance with international standards and certifications.

By mastering these technical properties and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can negotiate better contracts, ensure product quality, and optimize supply chain operations when sourcing hollow aluminium balls.

The global hollow aluminium balls market is experiencing steady growth driven by their lightweight, corrosion-resistant, and durable properties, making them ideal for diverse industrial applications such as aerospace, automotive, construction, and decorative sectors. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these market dynamics is essential to optimize sourcing strategies and capitalize on emerging opportunities.

Key Market Drivers:

- Lightweight & Performance Efficiency: Hollow aluminium balls reduce material weight without compromising strength, which aligns with increasing demand for fuel efficiency and sustainability in transportation and manufacturing sectors.

- Technological Advancements: Innovations in casting and machining technologies have improved the precision and quality of hollow aluminium balls, enabling tailored solutions for complex industrial requirements.

- Regional Industrial Growth: Emerging economies in Africa and South America are expanding their manufacturing and infrastructure capabilities, increasing demand for aluminium components. Meanwhile, Europe’s focus on lightweight materials for automotive and aerospace sectors sustains steady consumption.

Sourcing Trends:

- Digital Procurement Platforms: Buyers are increasingly leveraging digital marketplaces and e-sourcing tools to identify reliable suppliers offering competitive pricing and quality certifications. This trend enhances transparency and shortens lead times, especially critical for buyers in geographically distant markets like Kenya or Brazil.

- Customization & Value-Added Services: Suppliers offering customization options, such as specific alloy grades or surface treatments, are preferred as they add value and improve integration into end-use products.

- Nearshoring & Regional Partnerships: In response to supply chain disruptions, some European and Middle Eastern buyers are exploring nearshoring options or forming strategic partnerships with regional manufacturers to ensure consistent supply and reduce logistics costs.

Market Challenges:

- Raw Material Price Volatility: Fluctuations in aluminium prices can impact procurement budgets, requiring buyers to adopt flexible contract terms or hedging strategies.

- Quality Assurance: Ensuring consistent quality across international suppliers necessitates rigorous due diligence, including factory audits and third-party inspections.

Sustainability considerations are becoming increasingly critical in the procurement of hollow aluminium balls, driven by stricter environmental regulations and growing corporate responsibility commitments. Aluminium production is energy-intensive, but the metal’s recyclability offers significant opportunities for reducing the environmental footprint.

Environmental Impact & Mitigation:

- Energy Consumption: Primary aluminium production consumes substantial energy, often derived from fossil fuels. Buyers should prioritize suppliers utilizing renewable energy sources or secondary (recycled) aluminium to minimize carbon emissions.

- Recycling & Circular Economy: Hollow aluminium balls manufactured from recycled aluminium scrap significantly lower environmental impact while maintaining material integrity. This aligns with circular economy principles gaining traction globally.

Ethical Supply Chains:

- Conflict-Free Sourcing: Ensuring aluminium raw materials are sourced from conflict-free zones is essential, especially for buyers in regions sensitive to ethical concerns. Transparent supply chains supported by certifications help mitigate reputational risks.

- Labor Standards & Compliance: Buyers must verify that suppliers adhere to fair labor practices and international standards, reinforcing corporate social responsibility mandates.

Green Certifications & Standards:

- ISO 14001: Environmental management system certification demonstrates supplier commitment to sustainable practices.

- Aluminium Stewardship Initiative (ASI): ASI certification ensures responsible production, sourcing, and stewardship of aluminium, providing buyers with confidence in ethical and sustainable supply chains.

- Cradle to Cradle (C2C): This certification assesses product sustainability, including recyclability and environmental health, relevant for buyers targeting green product portfolios.

By integrating these sustainability criteria into procurement policies, B2B buyers can enhance brand value, comply with regulatory requirements, and contribute to global environmental goals.

The use of hollow aluminium balls traces back several decades as industries sought lightweight alternatives to steel and other heavy metals. Initially, these components were predominantly used in aerospace and high-performance engineering sectors due to aluminium’s favorable strength-to-weight ratio. Over time, advancements in metallurgical processes and precision manufacturing expanded their applications into automotive, architecture, and decorative industries.

For B2B buyers, understanding this evolution highlights the increasing sophistication and diversification of hollow aluminium balls. Early production focused on standard sizes and basic alloys, but today’s market offers a wide array of customizable options meeting stringent technical and environmental requirements. This progression underscores the importance of partnering with suppliers who invest in innovation and sustainability to meet modern industrial demands.

How can I effectively vet suppliers of hollow aluminium balls to ensure reliability and quality?

To vet suppliers, start by verifying their business licenses and certifications such as ISO 9001. Request product samples to evaluate quality firsthand. Check their track record by seeking client references and reviews, especially from similar industries or regions like Africa or Europe. Assess their manufacturing capabilities and inquire about quality control processes. Additionally, use third-party inspection services for on-site audits if possible. Building a strong communication channel with the supplier helps clarify expectations and detect potential red flags early.

What customization options are typically available for hollow aluminium balls, and how can I specify my requirements clearly?

Most manufacturers offer customization in size, wall thickness, surface finish, and alloy composition. Some can also provide specific treatments like anodizing or powder coating. To ensure your requirements are met, provide detailed technical drawings, precise measurements, and material standards. Specify the intended application to help suppliers recommend suitable options. Clear, written communication and confirmation of specifications before production reduce misunderstandings and ensure that the product aligns with your project needs.

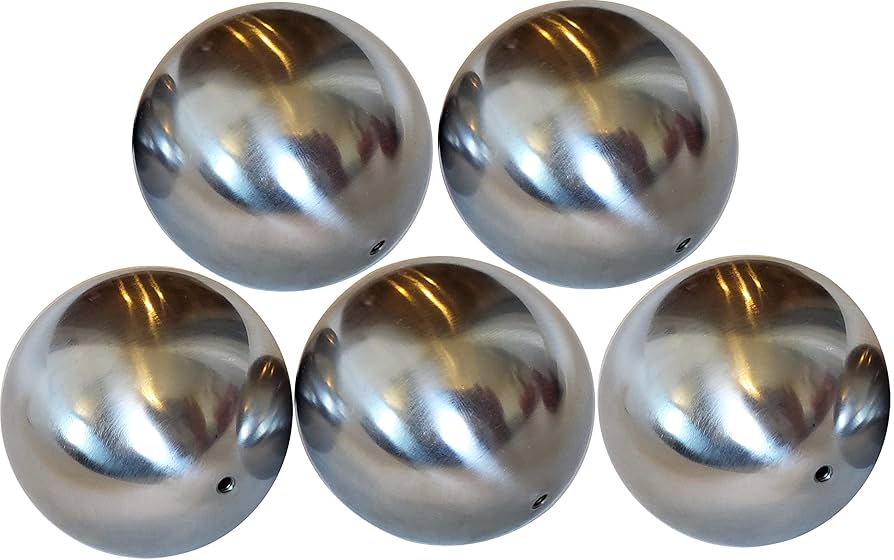

Illustrative Image (Source: Google Search)

What are common minimum order quantities (MOQs) and lead times for hollow aluminium balls, especially when ordering internationally?

MOQs vary widely depending on supplier scale and customization level, typically ranging from 100 to 1,000 units. Lead times generally span 4 to 12 weeks, factoring in manufacturing, customization, and shipping. For buyers in Africa, South America, or the Middle East, additional transit time and customs clearance should be considered. Negotiating with suppliers for smaller initial orders can be possible but may affect pricing. Planning procurement timelines with these factors in mind avoids project delays.

Which payment terms are standard in international B2B transactions for hollow aluminium balls, and how can I mitigate financial risks?

Common payment terms include 30-50% advance payment with the balance upon shipment or delivery. Letters of credit (LC) and escrow services provide added security. To mitigate risks, conduct due diligence on suppliers, use trusted payment platforms, and avoid full upfront payments unless the supplier has a proven track record. Structuring payments around verified milestones, such as sample approval and production completion, also protects your investment.

What quality assurance certifications should I look for to ensure compliance and product reliability?

Key certifications include ISO 9001 for quality management and ASTM or EN standards specific to aluminium alloys. Suppliers with RoHS or REACH compliance demonstrate environmental and safety adherence. For European buyers, CE marking might be relevant depending on application. Request documentation and third-party test reports verifying mechanical properties and dimensional accuracy. Certifications provide assurance that the product meets international standards, reducing risks of defects and regulatory issues.

How should I approach logistics and shipping for hollow aluminium balls to regions like Kenya, Brazil, or the UAE?

Choose suppliers experienced with international freight, and clarify Incoterms (e.g., FOB, CIF) upfront to define responsibility and costs. Hollow aluminium balls are lightweight but may require protective packaging to avoid damage. Sea freight is cost-effective for large volumes but slower, while air freight suits urgent, smaller shipments. Factor in customs clearance times and local import regulations. Collaborating with freight forwarders knowledgeable about your destination market streamlines the process and helps avoid unexpected delays or fees.

What steps can I take to resolve disputes related to product quality or delivery delays in cross-border transactions?

First, maintain detailed contracts specifying quality standards, delivery schedules, and penalties for non-compliance. In case of disputes, engage in direct communication to seek amicable solutions, supported by evidence such as inspection reports and correspondence. If unresolved, consider mediation or arbitration clauses included in contracts, which are common in international trade agreements. Leveraging trade bodies or chambers of commerce in your region can also provide assistance. Proactive documentation and transparent communication are key to minimizing conflicts.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of hollow aluminium balls presents a compelling opportunity for international buyers aiming to optimize cost, quality, and supply chain resilience. Key takeaways include the importance of vetting suppliers for material certifications, manufacturing expertise, and adherence to international standards. Buyers from Africa, South America, the Middle East, and Europe should leverage regional trade agreements and emerging manufacturing hubs to access competitive pricing without compromising on quality.

Illustrative Image (Source: Google Search)

Emphasizing strategic sourcing enables businesses to:

Looking ahead, the growing demand for lightweight, corrosion-resistant materials in sectors such as automotive, aerospace, and construction will drive innovation and supply chain evolution. International buyers are encouraged to proactively engage with suppliers who demonstrate agility, sustainability commitments, and advanced production technologies.

For B2B buyers in Kenya, the UK, and beyond, the call to action is clear: invest in comprehensive supplier assessments and cultivate strategic partnerships that align with long-term business goals. This approach will not only ensure supply continuity but also position your enterprise at the forefront of industry advancements in hollow aluminium ball applications.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina