The demand for homemade grit for rock tumblers is steadily growing as businesses worldwide seek cost-effective, customizable solutions for polishing and shaping stones, minerals, and jewelry components. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the nuances of homemade grit production is critical to sourcing quality materials that meet specific project requirements and regulatory standards.

This guide offers an in-depth exploration of the homemade grit market, covering essential aspects such as the variety of grit types and raw materials, manufacturing processes, quality control measures, and supplier evaluation. It also provides detailed insights into pricing structures and cost optimization strategies, enabling buyers to make data-driven procurement decisions. By addressing common challenges and answering frequently asked questions, the guide serves as a comprehensive resource to mitigate risks and maximize value.

For buyers in diverse markets like Italy and the UAE, where quality and compliance are paramount, this guide emphasizes practical sourcing tips tailored to regional trade dynamics and logistics considerations. Whether you are a wholesaler, manufacturer, or distributor, the knowledge shared here equips you to navigate global supply chains confidently, forge reliable partnerships, and secure competitive advantages in the niche yet vital segment of rock tumbler grit.

Empower your procurement strategy with a clear understanding of homemade grit’s specifications and market trends, ensuring your business delivers superior products while optimizing costs and supply reliability.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicon Carbide Grit | Sharp, angular particles; available in coarse to fine grades | Precision polishing of hard stones and metals | Pros: High efficiency, widely available; Cons: Can be abrasive for delicate materials |

| Aluminum Oxide Grit | Durable, reusable grit with a uniform grain size | Polishing softer stones and glass | Pros: Cost-effective, consistent results; Cons: Slower cutting action than silicon carbide |

| Crushed Glass Grit | Made from finely ground recycled glass; eco-friendly | Budget-friendly polishing, hobbyist markets | Pros: Sustainable, low cost; Cons: Variable particle size, less consistent finish |

| Homemade Sand Grit | Natural sand crushed and sieved for particle size control | Entry-level tumbling, educational use | Pros: Easily sourced, low cost; Cons: Inconsistent grit size, limited polishing quality |

| Ceramic Grit | Manufactured grit with high hardness and toughness | Industrial polishing requiring high precision | Pros: Long-lasting, excellent finish; Cons: Higher upfront cost, less common in homemade setups |

Silicon carbide grit is prized for its sharpness and versatility, making it ideal for polishing a wide range of hard materials including rocks, metals, and ceramics. For B2B buyers, particularly in regions with access to industrial abrasives like Europe and the Middle East, silicon carbide offers a reliable balance between cost and performance. When sourcing homemade silicon carbide grit, quality control on particle size is essential to ensure consistent tumbling results. Bulk purchasing agreements can reduce costs significantly for manufacturers and distributors.

Illustrative Image (Source: Google Search)

Aluminum oxide grit is favored for polishing softer stones such as quartz and glass. It is durable and reusable, providing cost savings over time. For buyers in Africa and South America, where cost efficiency and material availability are crucial, aluminum oxide grit is a practical choice. B2B buyers should consider suppliers that offer uniform particle sizing and packaging options suitable for scaling production or retail distribution. Its slower cutting action compared to silicon carbide makes it preferable for delicate polishing tasks.

Crushed glass grit is a sustainable option made from recycled glass, appealing to eco-conscious buyers. It is typically used in hobbyist and budget markets where environmental impact and low cost are priorities. B2B buyers in regions with strong recycling industries, such as parts of Europe, can leverage local supply chains to reduce costs. However, the variability in particle size requires careful sieving to maintain polishing consistency. This grit type is ideal for entry-level tumblers and educational kits.

Natural sand grit is the most accessible and affordable option for homemade grit production. It is widely used in educational settings and by small-scale tumbling businesses. The inconsistency in grit size and abrasive quality means it is less suitable for professional-grade polishing. B2B buyers should focus on suppliers who can provide sieved and graded sand to improve performance. This grit is attractive in markets with limited access to industrial abrasives, such as rural areas in Africa and South America.

Ceramic grit is a manufactured abrasive known for its hardness and durability, often used in industrial polishing applications requiring high precision and long-lasting performance. For B2B buyers in advanced manufacturing hubs like Italy or the UAE, ceramic grit represents a premium option for achieving superior finishes. Despite a higher initial investment, its longevity and consistent results justify the cost for high-volume operations. Sourcing from reputable manufacturers with quality certifications is critical for ensuring performance standards.

Related Video: Homemade Rock Tumbler

| Industry/Sector | Specific Application of homemade grit for rock tumbler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Jewelry Manufacturing | Polishing and smoothing semi-precious and precious stones | Enhances product quality and finish, reducing labor costs | Consistent grit size and abrasiveness, purity, and cost-efficiency |

| Geological and Mineralogy | Preparing rock samples for analysis and display | Provides uniform surface finish for accurate analysis and aesthetic display | Availability of various grit grades, contamination-free materials |

| Decorative Arts & Crafts | Finishing and refining ornamental stones and glass pieces | Improves visual appeal and marketability of crafted items | Customizable grit blends, eco-friendly sourcing, and supply reliability |

| Industrial Tooling | Surface preparation of small metal parts and prototypes | Increases durability and precision of tools | Abrasion rate control, grit hardness, and bulk supply capability |

| Educational Institutions | Hands-on training in geology and materials science laboratories | Enables cost-effective, repeatable sample preparation | Safety standards compliance, ease of use, and batch consistency |

In the jewelry sector, homemade grit for rock tumblers is crucial for polishing semi-precious and precious stones. B2B buyers from Europe and the Middle East, where artisanal jewelry production is significant, benefit from grit that delivers consistent abrasion without damaging delicate stones. This application reduces manual labor and enhances product finish, leading to higher customer satisfaction. Buyers must prioritize grit uniformity and purity to avoid contamination that could affect stone clarity or color.

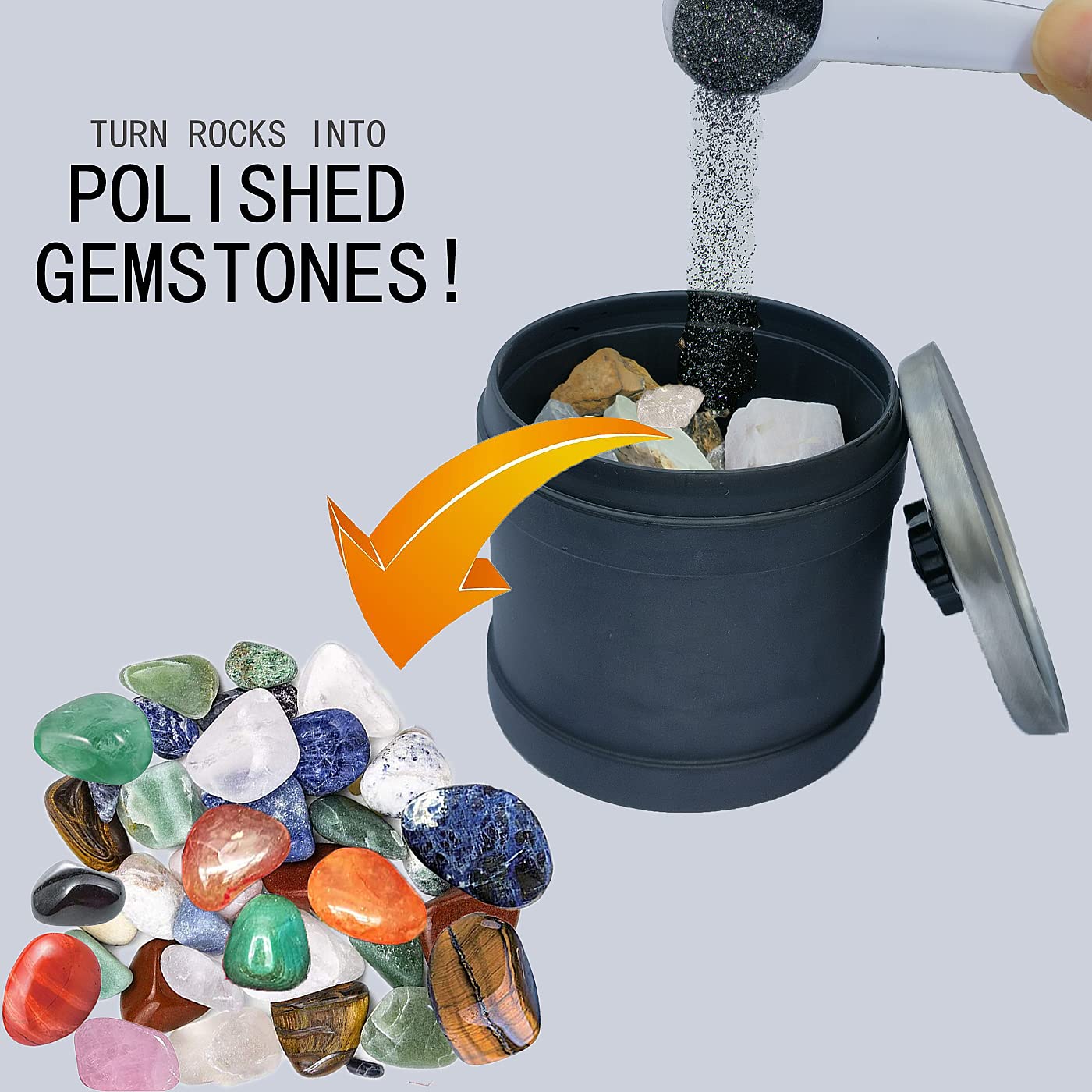

Illustrative Image (Source: Google Search)

Geological labs and mineralogy businesses use homemade grit to prepare rock samples for microscopic examination or museum displays. Uniform grit size ensures smooth surfaces, critical for accurate mineral identification and aesthetic presentation. International buyers, especially in Africa and South America with rich mineral resources, should source grit free from impurities that could interfere with analytical results. Availability of multiple grit grades allows for tailored sample preparation workflows.

Illustrative Image (Source: Google Search)

Artisans and manufacturers in decorative arts employ homemade grit to refine ornamental stones and glass. This enhances the visual appeal of products destined for luxury markets in Italy and the UAE. Custom grit blends, often eco-friendly, are preferred to meet sustainability goals while ensuring consistent finishing quality. Reliable supply chains are essential for maintaining production schedules in competitive craft industries.

Small-scale industrial tooling companies utilize homemade grit to prepare metal parts and prototypes by smoothing surfaces and removing burrs. This process improves tool precision and lifespan, critical for manufacturers in Europe and emerging industrial hubs in the Middle East. Buyers must assess grit hardness and abrasion rates to match specific tooling materials and ensure bulk availability for continuous operations.

Schools and universities incorporate homemade grit in geology and materials science labs for practical training. It offers a cost-effective solution for repeated sample preparation, essential for hands-on learning. B2B buyers in Africa and South America should focus on sourcing grit that meets safety standards and provides batch consistency to support effective teaching and research activities.

Related Video: Homemade DIY Custom Built High Capacity Rock Tumbler MUST SEE****

Key Properties:

Silicon carbide is an extremely hard and sharp abrasive material with excellent thermal stability and chemical inertness. It withstands high temperatures (up to ~1600°C) and is resistant to corrosion, making it ideal for abrasive applications. Its hardness is near diamond on the Mohs scale, enabling efficient grinding and polishing.

Pros & Cons:

SiC offers superior durability and fast cutting action, resulting in high-quality surface finishes. It is widely available and relatively cost-effective for industrial-grade abrasive grit. However, manufacturing SiC grit requires high-temperature processes, which can increase production complexity and energy costs. Additionally, SiC dust can be hazardous if inhaled, requiring proper handling.

Impact on Application:

SiC grit is compatible with a broad range of rock types and tumbling media, including metals and glass. It is particularly effective for hard stones like quartz and jasper. Its sharp edges maintain cutting efficiency over multiple cycles, reducing the need for frequent grit replacement.

Considerations for International B2B Buyers:

Buyers in Africa, South America, the Middle East, and Europe should verify compliance with international standards such as ASTM F1003 (for abrasive grains) and DIN EN 13236. European buyers, especially in Italy, often prioritize eco-friendly sourcing and consistent particle size distribution. In the UAE and Middle East, suppliers must consider import regulations and certification for chemical safety due to strict customs controls.

Key Properties:

Aluminum oxide is a hard, chemically stable abrasive with moderate thermal resistance (~1200°C) and excellent corrosion resistance. It is less brittle than silicon carbide, offering a slightly gentler abrasive action.

Pros & Cons:

Aluminum oxide is cost-effective and easier to produce than SiC, with a well-established supply chain worldwide. It provides good durability and is less likely to cause excessive wear on softer stones. However, it is less effective on very hard materials and may require longer tumbling times to achieve the desired polish.

Impact on Application:

This grit is suitable for softer stones such as agate and jasper, and for polishing metals with less aggressive abrasion. It works well with water-based tumbling media and is less likely to cause contamination or staining.

Considerations for International B2B Buyers:

In regions like South America and Africa, where cost-efficiency is critical, aluminum oxide offers a balanced option. Buyers should ensure grit particle size meets ISO 6344 standards for abrasives. European buyers may demand compliance with REACH regulations for chemical safety. Middle Eastern markets require documentation for chemical handling and import clearance.

Key Properties:

Crushed glass grit is an economical, environmentally friendly abrasive made from recycled glass. It has moderate hardness (~5.5-6.5 Mohs) and is chemically inert but less heat resistant than synthetic abrasives.

Pros & Cons:

The primary advantage of crushed glass grit is its low cost and sustainability profile, appealing to eco-conscious markets. It is easy to produce locally in many regions, reducing logistics costs. However, its abrasive efficiency is lower, and it may not produce as fine a polish on very hard stones. Additionally, particle shape can be irregular, affecting consistency.

Impact on Application:

Crushed glass grit is best suited for softer stones and initial rough grinding stages. It is compatible with water-based tumbling but may require careful screening to maintain particle size uniformity. It is less suitable for high-precision polishing.

Considerations for International B2B Buyers:

African and South American buyers can benefit from locally sourced crushed glass grit to reduce import dependency. European buyers, including Italy, may require certification regarding recycled content and safety standards (e.g., CE marking). In the UAE and Middle East, importers should verify compliance with environmental and health regulations.

Key Properties:

Garnet is a natural mineral abrasive with good hardness (~6.5-7.5 Mohs) and excellent chemical stability. It has moderate heat resistance and is non-toxic.

Pros & Cons:

Garnet grit offers a natural, consistent abrasive suitable for fine polishing and finishing. It is less brittle than synthetic abrasives, reducing dust generation and wear on equipment. However, garnet is generally more expensive and less widely available than synthetic options. Its supply can be affected by mining regulations and geopolitical factors.

Impact on Application:

Garnet is ideal for delicate polishing stages and works well with a variety of rock types, including softer and medium-hard stones. It is often preferred in applications requiring minimal contamination and environmental impact.

Considerations for International B2B Buyers:

European buyers value garnet for its natural origin and compliance with sustainability standards. Buyers in Africa and South America should consider local garnet deposits to reduce costs. In the Middle East, importers must ensure garnet meets ASTM standards and is free from contaminants. Certification of origin and purity is often requested.

| Material | Typical Use Case for homemade grit for rock tumbler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Efficient grinding and polishing of hard stones | Extremely hard and durable; fast cutting action | Higher manufacturing complexity; health risks | Medium |

| Aluminum Oxide | Polishing softer stones and metals | Cost-effective; good chemical stability | Less effective on very hard materials | Low |

| Crushed Glass | Eco-friendly, low-cost rough grinding | Sustainable and locally producible | Lower abrasive efficiency; inconsistent shape | Low |

| Garnet | Fine polishing and finishing of delicate stones | Natural, consistent abrasive; low dust generation | Higher cost; supply variability | High |

The production of homemade grit for rock tumblers involves several carefully controlled stages to ensure the grit performs effectively in polishing and shaping stones. For B2B buyers, understanding these manufacturing stages and techniques is critical for evaluating suppliers and ensuring consistent product quality.

1. Material Preparation

The foundation of high-quality grit lies in the selection and preparation of raw materials. Typically, abrasive minerals such as silicon carbide, aluminum oxide, or quartz are sourced in bulk. These materials undergo crushing and grinding to achieve the desired particle size distribution. Precision sieving and classification are employed to separate grit into coarse, medium, and fine grades, tailored to different stages of rock tumbling.

2. Forming and Processing

Once raw materials are prepared, the grit may undergo further processing such as blending with binders or additives that enhance abrasive properties or reduce dust. In some cases, granulation techniques are used to form more uniform granules to improve handling and dispersion in tumblers. The grit is then dried and cured if binders are applied, ensuring durability and consistent performance.

3. Assembly and Packaging

After processing, grit is carefully packaged to maintain quality and prevent contamination. Packaging options vary from bulk sacks for industrial buyers to smaller, resealable bags for retail. Proper labeling with grit size, composition, and safety information is essential, especially for international shipments.

4. Finishing and Quality Enhancements

Some manufacturers add finishing steps such as coating grit particles with anti-caking agents or moisture barriers to improve shelf life and usability. This stage can also include blending different grit sizes to create custom polishing blends that meet specific customer requirements.

Ensuring consistent quality in homemade grit production demands robust QA/QC systems aligned with international standards and industry best practices. B2B buyers, especially those sourcing for diverse markets such as Africa, South America, the Middle East, and Europe, must prioritize suppliers who demonstrate stringent quality controls.

Relevant International Standards

- ISO 9001: The global benchmark for quality management systems, emphasizing process consistency, continuous improvement, and customer satisfaction.

- CE Marking: Important for European markets, indicating compliance with EU safety, health, and environmental requirements.

- API Standards: While typically for petroleum-related abrasives, some grit products used in industrial polishing may require adherence to API or similar certifications depending on end use.

By thoroughly understanding the manufacturing and quality assurance processes for homemade grit, international B2B buyers can make informed sourcing decisions, mitigate risks, and secure consistent, high-performance abrasive products for their rock tumbling operations.

When sourcing homemade grit for rock tumblers, understanding the detailed cost components is crucial for effective budgeting and supplier negotiations. The primary cost elements include:

Pricing for homemade grit is not static and is influenced by several factors:

For buyers across Africa, South America, the Middle East, and Europe (including Italy and UAE), the following insights can optimize sourcing outcomes:

Prices for homemade grit for rock tumblers vary widely based on materials, specifications, volumes, and supplier factors. Typical unit prices may range from $1.50 to $5.00 per kilogram, excluding freight and duties. Buyers should treat these figures as indicative and conduct supplier-specific negotiations and due diligence to obtain accurate, competitive pricing aligned with their sourcing requirements.

By carefully analyzing cost components, understanding pricing influencers, and applying strategic sourcing tactics, international B2B buyers can achieve cost-efficient procurement of homemade grit tailored to their operational needs and market conditions.

For B2B buyers sourcing homemade grit for rock tumblers, understanding essential technical properties ensures product quality and consistency, which directly impacts the tumbling process and final gemstone finish. Here are the critical specifications to consider:

Material Grade and Purity

Homemade grit is typically made from abrasive minerals such as silicon carbide or aluminum oxide. The grade refers to the purity and composition of these materials. Higher purity grit provides consistent abrasive action and reduces contamination risks. For industrial buyers, specifying material grade helps ensure durability and predictable performance in polishing cycles.

Particle Size and Grit Consistency

Particle size is crucial and usually measured in microns or mesh size. Common grit sizes range from coarse (60-100 mesh) to fine (500-600 mesh), affecting the speed and finish quality of rock tumbling. Uniform particle size distribution prevents uneven abrasion, essential for maintaining product standards in professional lapidary operations.

Tolerance and Granularity Uniformity

Tolerance defines the allowable variation in particle size. Tight tolerances (±5-10%) mean more uniform grit, leading to smoother polishing and less product waste. B2B buyers should request detailed tolerance specs to avoid inconsistent batches that can disrupt production workflows.

Moisture Content

Moisture affects grit flowability and shelf life. Lower moisture content (<1%) is preferred to prevent clumping and ensure ease of mixing with tumbling media. This property is vital for buyers in humid regions (e.g., parts of Africa and the Middle East) where storage conditions can impact grit quality.

Bulk Density

Bulk density influences packing, shipping costs, and how grit behaves during tumbling. Consistent bulk density ensures that the grit mixes properly with rocks and water in the tumbler. Buyers should confirm bulk density to optimize handling and transportation logistics.

Contaminant Levels

Homemade grit may contain impurities like dust, unwanted minerals, or metallic particles. Specifying maximum contaminant thresholds guarantees product safety and compliance with quality standards, especially important for European and South American markets with strict import regulations.

Navigating international B2B transactions requires familiarity with key trade terms and industry jargon. Here are essential terms to facilitate smooth communication and procurement processes:

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce grit specifically tailored for another company’s brand or product line. OEM arrangements allow buyers to customize grit specifications and packaging, enhancing brand differentiation.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ helps buyers from emerging markets like Africa or South America plan inventory and cash flow effectively, avoiding overstocking or excessive costs.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed price and specification information. RFQs are critical in sourcing grit, enabling buyers to compare offers and negotiate terms before committing.

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities, costs, and risk transfer points between buyers and sellers. Knowledge of Incoterms is essential for international buyers in regions such as the UAE and Europe to manage shipping logistics and customs clearance efficiently.

Batch Number

A unique code assigned to a production run of grit. Batch numbers enable traceability and quality control, allowing buyers to track product origin and manage potential recalls or complaints.

Lead Time

The period between order placement and delivery. Accurate lead time estimates help buyers coordinate production schedules and avoid downtime, especially when sourcing grit from distant suppliers.

By focusing on these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring high-quality homemade grit supplies that meet regional market demands and operational requirements.

The global market for homemade grit used in rock tumblers is influenced by increasing interest in artisanal crafts, lapidary arts, and gemstone finishing. International B2B buyers from Africa, South America, the Middle East, and Europe—regions with rich mineral deposits and thriving craft industries—are driving demand for high-quality, customizable grit solutions. These buyers seek reliable, cost-effective sources that offer both raw and processed grit materials tailored to various tumbling stages, from coarse shaping to fine polishing.

Key market dynamics include a growing preference for localized sourcing to reduce supply chain complexity and costs. For example, African and South American buyers often look for grit sourced from their own mineral-rich regions to ensure authenticity and sustainability. European buyers, especially from countries like Italy, emphasize precision and quality control, favoring suppliers who can meet stringent specifications for grit particle size and consistency.

Emerging B2B trends show an increased adoption of digital platforms for sourcing and procurement, enabling buyers to access a broader range of suppliers and negotiate better terms. Additionally, technological advancements in particle grading and quality assurance allow suppliers to offer more consistent and effective grit products. Buyers in the UAE and other Middle Eastern markets are increasingly focused on premium grit blends that combine natural abrasives with synthetic additives to enhance efficiency and reduce processing times.

Strategic partnerships between grit producers and rock tumbler manufacturers are becoming more common, facilitating co-development of custom grit formulas that meet specific industry needs. This trend is particularly relevant for markets emphasizing innovation and product differentiation.

Sustainability is rapidly becoming a critical factor in the homemade grit sector. The extraction and processing of abrasive materials can have significant environmental impacts, including habitat disruption, water consumption, and energy use. International B2B buyers are increasingly scrutinizing suppliers for adherence to environmental standards and ethical sourcing practices.

Ethical supply chains are vital to ensure that grit materials do not contribute to conflict minerals or exploit vulnerable labor forces, especially in regions like Africa and South America where mining activities may lack transparency. Buyers from Europe and the Middle East are often required to comply with regulations such as the EU’s Conflict Minerals Regulation and UAE’s sustainability mandates, making supplier due diligence indispensable.

“Green” certifications and eco-labels are emerging as important differentiators in this sector. Certifications related to responsible mining, low carbon footprint production, and recyclable packaging appeal to buyers aiming to enhance their sustainability profiles. Suppliers who invest in cleaner extraction technologies, water recycling, and waste minimization stand to gain a competitive edge.

Moreover, the use of natural and biodegradable binders or additives in grit production aligns with global efforts to reduce plastic and chemical residues. Some suppliers are exploring renewable abrasive materials derived from agricultural byproducts or recycled minerals, which resonate well with environmentally conscious buyers.

The use of grit in rock tumbling dates back centuries, with early practitioners relying on naturally occurring sand and crushed stones to smooth and polish minerals. Traditionally, grit was sourced locally with minimal processing, limiting consistency and effectiveness. Over time, industrial advances introduced graded abrasives like silicon carbide and aluminum oxide, significantly improving tumbling results.

In recent decades, the homemade grit market has evolved to include more specialized formulations tailored to different rock types and tumbling stages. This evolution reflects a shift from purely artisanal methods to semi-industrial processes that combine traditional knowledge with modern material science.

For B2B buyers, understanding this history underscores the importance of selecting suppliers who blend heritage expertise with contemporary quality standards. This approach ensures grit products that not only meet performance expectations but also respect the craft’s cultural and environmental context.

How can I effectively vet suppliers of homemade grit for rock tumblers in international markets?

To vet suppliers, start by requesting detailed product samples and technical specifications to assess grit quality and consistency. Verify the supplier’s business licenses, certifications, and export history, particularly for compliance with international trade regulations. Check references or reviews from other B2B buyers, especially within your region (Africa, South America, Middle East, Europe). Conduct virtual or on-site factory audits if feasible. Prioritize suppliers who demonstrate transparency in sourcing raw materials and production processes, ensuring reliability and product safety.

Is customization of grit particle size and composition possible for bulk orders?

Yes, many homemade grit suppliers offer customization to meet specific polishing requirements or rock tumbler models. Discuss your desired grit particle size, abrasive material type, and mixture ratios upfront. Customization may require minimum order quantities (MOQs) and slightly longer lead times due to formulation adjustments. Clear communication on technical needs and sample approvals is essential to ensure the final product meets your quality standards and customer expectations in your local market.

What are typical minimum order quantities (MOQs) and lead times for international B2B orders?

MOQs vary widely depending on the supplier’s production capacity and customization level but typically range from 50 to 500 kilograms per shipment. Lead times average between 2 to 6 weeks, factoring in production, quality control, and international shipping. For buyers in regions like the Middle East or Africa, consider additional time for customs clearance. Establishing long-term relationships can help negotiate better MOQs and expedited lead times. Always confirm these terms in the contract before finalizing orders.

What payment terms are commonly accepted for international purchases of homemade grit?

Suppliers often accept a range of payment methods including wire transfers (T/T), letters of credit (L/C), PayPal, or escrow services for added security. Standard terms might include a 30-50% deposit upfront with the balance paid upon shipment or delivery. For new buyers, letters of credit provide risk mitigation. Negotiating payment terms that balance supplier trust and your cash flow needs is critical, especially when dealing with international suppliers across different continents and currencies.

How can I ensure the quality and safety of homemade grit products? Are certifications important?

Quality assurance starts with supplier selection—choose those who implement rigorous in-house testing for grit size uniformity, abrasiveness, and contaminant-free composition. Certifications such as ISO 9001 (quality management) or specific environmental and safety standards can be strong indicators of a reliable supplier. While homemade grit may not always have formal certifications, request detailed quality control reports and third-party lab testing results to verify compliance with your country’s import regulations and industry standards.

What logistical considerations should B2B buyers keep in mind when importing homemade grit?

Plan for appropriate packaging that prevents moisture and contamination, as grit quality can degrade if exposed to humidity. Confirm the supplier’s experience with international shipping modes (sea freight, air freight) and documentation compliance, including customs declarations and material safety data sheets. For buyers in Africa, South America, or the Middle East, factor in local port handling times, import duties, and potential regulatory inspections. Partnering with freight forwarders experienced in abrasive materials can streamline delivery and reduce delays.

How should disputes or quality issues be handled with international grit suppliers?

Establish clear contractual terms outlining product specifications, inspection protocols, and dispute resolution mechanisms before order confirmation. If quality issues arise, document them thoroughly with photos and independent lab test results. Engage in direct communication with the supplier to negotiate returns, replacements, or refunds. Utilizing third-party arbitration or trade mediation services can be effective if amicable solutions fail. Maintaining detailed records and adhering to Incoterms minimizes misunderstandings and supports legal claims if necessary.

Are there regional differences in sourcing homemade grit that B2B buyers should be aware of?

Yes, sourcing homemade grit can vary significantly by region due to raw material availability, manufacturing practices, and regulatory environments. For example, European suppliers may offer higher consistency and certifications but at higher costs, while African or South American producers might provide more competitive pricing with variable quality control. Understanding regional logistics challenges, such as longer shipping times or customs complexities in the Middle East or South America, helps tailor your sourcing strategy. Building diversified supplier networks across regions can mitigate risks and optimize supply continuity.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of homemade grit for rock tumblers presents a unique opportunity for international B2B buyers to optimize cost efficiency, quality control, and supply chain resilience. By leveraging local raw materials and artisanal production methods, buyers in regions such as Africa, South America, the Middle East, and Europe can reduce dependency on imported abrasives, customize grit specifications, and support sustainable practices. Key considerations include thorough supplier evaluation, quality consistency, and logistics planning to ensure timely delivery and cost-effectiveness.

For B2B buyers, the value of strategic sourcing lies in:

Looking ahead, international buyers are encouraged to deepen supplier relationships and invest in innovative grit formulations that enhance tumbling efficiency and end-product quality. Embracing strategic partnerships across continents will be crucial in navigating evolving market dynamics and achieving competitive advantage. Engage proactively with trusted suppliers to unlock new growth avenues in the rock tumbling industry.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina