Industrial rock tumblers are indispensable tools across a variety of sectors, including mining, manufacturing, and materials processing. For B2B buyers in Africa, South America, the Middle East, and Europe—regions marked by diverse industrial demands and growth trajectories—securing the right industrial rock tumblers is critical to optimizing operational efficiency and product quality. These machines facilitate the smoothing, polishing, and shaping of rocks and minerals, playing a pivotal role in producing market-ready materials and components.

This comprehensive guide delves into every essential aspect of industrial rock tumblers to empower international buyers with actionable insights. It covers the different types of tumblers available, tailored to specific industrial applications, and explores the key materials used in their construction to ensure durability and performance under rigorous conditions. Additionally, the guide examines manufacturing standards and quality control protocols that distinguish reliable suppliers from less dependable ones.

Understanding supplier landscapes, pricing structures, and market dynamics across continents such as Africa, South America, the Middle East, and Europe is another cornerstone of this resource. Whether sourcing from established manufacturers in the UK or emerging suppliers in Brazil, buyers will find strategies to negotiate competitive costs without compromising quality. The inclusion of a detailed FAQ section addresses common concerns and technical queries, streamlining the decision-making process.

By consolidating industry expertise and market intelligence, this guide enables B2B buyers to make well-informed sourcing decisions, mitigate risks, and secure industrial rock tumblers that align perfectly with their operational goals and regional market requirements.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Drum Tumblers | Large cylindrical drums rotating on a horizontal axis | Polishing, deburring large batches of stones | Pros: High capacity, uniform finish; Cons: High energy use, bulky |

| Vibratory Tumblers | Vibrate in a circular or elliptical motion | Fast polishing and cleaning of small to medium stones | Pros: Faster processing, energy efficient; Cons: Limited batch size |

| Centrifugal Tumblers | Use centrifugal force via spinning bowls | Precision finishing of small, delicate stones | Pros: Quick, high precision; Cons: Smaller capacity, higher cost |

| Barrel Tumblers | Simple barrel shape, often with media and rocks inside | General purpose tumbling, cost-effective | Pros: Low cost, easy maintenance; Cons: Slower, less uniform finish |

| Continuous Flow Tumblers | Continuous loading and unloading system | High-volume industrial polishing and finishing | Pros: Continuous operation, high throughput; Cons: Complex setup, high initial investment |

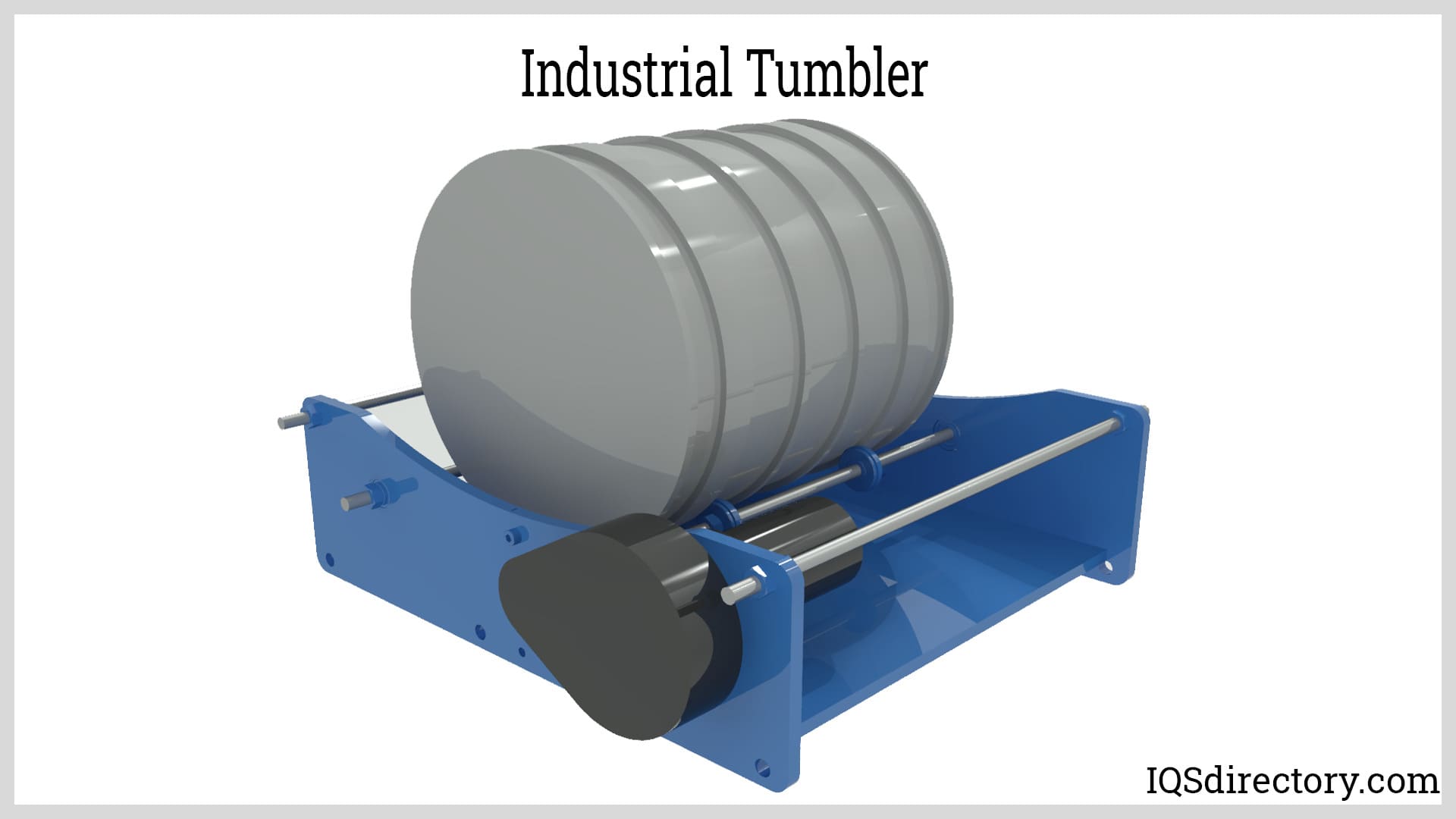

Rotary Drum Tumblers

Rotary drum tumblers feature large drums rotating horizontally, making them ideal for processing large volumes of rocks or stones uniformly. They are best suited for industries requiring consistent surface finishes on bulk materials. B2B buyers should consider space availability and energy costs, as these machines tend to be bulky and power-intensive. However, their robust design and scalability make them a solid investment for enterprises with high-volume polishing needs.

Vibratory Tumblers

These tumblers operate by vibrating the container in circular or elliptical motions, accelerating the polishing and cleaning process. They are favored in industries handling small to medium-sized stones requiring fast turnaround times. Buyers from regions with energy cost sensitivity, such as Africa or South America, will appreciate their energy efficiency. However, the batch size limitation means they may not suit operations with very high volume demands.

Centrifugal Tumblers

Centrifugal tumblers spin bowls at high speeds to apply centrifugal force, delivering precise and rapid finishing for small, delicate stones. This type is common in sectors where fine detail and surface quality are paramount, such as jewelry manufacturing. While their speed and precision are advantageous, buyers should weigh the higher acquisition and maintenance costs against their production needs and expected output volume.

Barrel Tumblers

Barrel tumblers are the most basic and cost-effective type, consisting of a simple barrel where stones and abrasive media rotate together. They serve well for general-purpose tumbling where budget constraints exist, especially for smaller businesses or startups in emerging markets. Their slower processing time and less uniform finish are trade-offs for their affordability and ease of maintenance.

Continuous Flow Tumblers

Designed for uninterrupted operation, continuous flow tumblers allow for constant loading and unloading of materials, making them suitable for very high-volume industrial applications. Buyers in Europe or the Middle East with advanced manufacturing setups will find these tumblers beneficial for optimizing throughput. The initial investment and operational complexity require careful consideration, but the long-term productivity gains can justify the cost for large-scale operations.

Related Video: Rock Tumbling Tutorial for Rotary Tumblers and Ceramic Media

| Industry/Sector | Specific Application of Industrial Rock Tumblers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining and Mineral Processing | Polishing and cleaning raw minerals and gemstones | Enhances product quality and market value by improving appearance and purity | Durability for heavy loads, corrosion resistance, and energy efficiency |

| Jewelry Manufacturing | Smoothing and polishing precious and semi-precious stones | Produces high-quality finished stones with consistent surface finish | Precision control, noise reduction, and compatibility with various media |

| Construction Materials | Finishing aggregates and decorative stones for architectural use | Improves aesthetic appeal and surface texture of building materials | Capacity to handle large volumes, robust construction, and ease of maintenance |

| Metalworking and Tooling | Deburring and polishing metal parts and tools | Increases lifespan and performance of metal components | Adjustable speed settings, abrasive media compatibility, and safety features |

| Geological Research | Sample preparation for analysis and study of rock specimens | Provides uniform, contamination-free samples for accurate testing | Gentle tumbling action, contamination control, and adaptability to sample size |

Industrial rock tumblers play a vital role in the mining and mineral processing industry, where they are used to polish and clean raw minerals and gemstones. This process removes impurities and improves the visual and structural quality of the raw materials, making them more attractive for downstream processing or direct sale. For buyers in regions like South America and Africa, sourcing tumblers that can withstand abrasive materials and heavy loads is crucial, alongside energy-efficient models to reduce operational costs.

In the jewelry manufacturing sector, industrial rock tumblers are essential for smoothing and polishing precious and semi-precious stones. They ensure a consistent, high-quality finish that enhances the stones' market value. B2B buyers from the Middle East and Europe, such as the UK, should prioritize tumblers with precise speed control and noise reduction features to maintain a high standard of production while ensuring workplace comfort.

The construction materials industry utilizes rock tumblers to finish aggregates and decorative stones used in architecture. Tumblers help improve the texture and appearance of these materials, increasing their appeal for use in premium construction projects. For international buyers, particularly in Africa and Europe, tumblers with high capacity and robust build quality are preferred to handle large volumes efficiently and withstand harsh working environments.

In metalworking and tooling, industrial rock tumblers are employed to deburr and polish metal parts and tools. This application enhances the durability and performance of metal components by removing sharp edges and surface imperfections. Buyers should consider tumblers with adjustable speed settings and compatibility with various abrasive media to accommodate different metal types and processing requirements.

Finally, in geological research, tumblers are used to prepare rock samples for analysis, ensuring uniformity and preventing contamination. This application demands gentle tumbling action and easy cleaning features to maintain sample integrity. Research institutions and labs in Europe and South America benefit from tumblers that can handle varying sample sizes and provide contamination control to support accurate scientific results.

Related Video: Rotary & Vibratory Rock Tumblers Explained

Key Properties: Stainless steel tumblers typically offer excellent corrosion resistance, high tensile strength, and can withstand elevated temperatures (up to 800°C depending on grade). They are resistant to chemical attack and mechanical wear, making them suitable for aggressive polishing media and abrasive materials.

Pros & Cons: Stainless steel is highly durable and easy to clean, supporting long operational cycles with minimal maintenance. However, it has a higher upfront cost and manufacturing complexity due to precision welding and finishing requirements. The weight of stainless steel tumblers can also impact shipping costs, especially for international buyers.

Impact on Application: Stainless steel tumblers are ideal for wet tumbling processes involving water-based media or chemical additives, common in jewelry and precision parts finishing. Their resistance to rust ensures consistent performance in humid climates, which is advantageous for buyers in tropical regions of Africa and South America.

International Considerations: Buyers in Europe (e.g., UK) and the Middle East often require compliance with ASTM A240 or EN 10088 standards for stainless steel, ensuring material traceability and quality. African and South American buyers should verify supplier certifications and consider import tariffs on stainless steel products. The material’s recyclability is a plus for environmentally conscious markets.

Key Properties: Polyurethane tumblers provide excellent abrasion resistance and impact cushioning. They operate effectively at moderate temperatures (up to 80°C) and resist many solvents and oils. Their flexibility reduces damage to delicate stones or metals during tumbling.

Pros & Cons: Polyurethane tumblers are lightweight and cost-effective, with relatively simple manufacturing processes. However, they have limited temperature tolerance and can degrade under UV exposure or harsh chemicals over time. Their lifespan is shorter compared to metals, requiring more frequent replacement.

Impact on Application: Best suited for dry tumbling or light wet tumbling applications where gentle polishing is required, such as in gemstone finishing or soft metal parts. The cushioning effect reduces chipping and surface damage.

International Considerations: For buyers in regions with high ambient temperatures like the Middle East and parts of Africa, polyurethane’s thermal limitations must be considered. Compliance with ISO 22768 or regional standards related to polymer safety and chemical resistance is important. Brazil and European buyers often prioritize materials free from harmful plasticizers or VOCs, aligning with environmental regulations.

Key Properties: Cast iron tumblers are known for their robustness and ability to handle heavy loads and high-pressure tumbling. They have good thermal conductivity but are prone to rust if not properly coated or maintained.

Pros & Cons: Cast iron is relatively low cost and easy to manufacture in large volumes. However, it is heavy and susceptible to corrosion, which can shorten equipment lifespan without adequate surface treatment. Maintenance costs can increase due to rust prevention needs.

Impact on Application: Cast iron tumblers are preferred for heavy-duty dry tumbling applications, such as deburring large metal parts or rough stone shaping. They are less suitable for wet tumbling where corrosion risk is higher.

International Considerations: Buyers in humid or coastal regions (e.g., parts of Africa and South America) must assess corrosion risks and consider protective coatings or stainless alternatives. Compliance with DIN EN 1561 or ASTM A48 standards ensures casting quality. Cast iron’s weight can affect freight costs, important for international procurement logistics.

Illustrative Image (Source: Google Search)

Key Properties: HDPE tumblers offer excellent chemical resistance, low moisture absorption, and good impact strength. They operate well at temperatures up to 120°C and are resistant to many acids and alkalis.

Pros & Cons: HDPE is lightweight, cost-effective, and easy to mold into complex shapes. It has a longer lifespan than polyurethane and is less prone to cracking. However, it is less abrasion-resistant than metals and can deform under heavy loads.

Impact on Application: HDPE tumblers are suitable for chemical polishing and light to moderate tumbling tasks, especially in wet processes involving acidic or alkaline media. Their chemical resistance makes them popular in industries processing minerals or delicate components.

International Considerations: European and Middle Eastern buyers often require compliance with REACH and RoHS regulations for plastic materials. Brazilian and African buyers should verify local chemical resistance standards and consider HDPE’s recyclability benefits. HDPE’s lighter weight reduces shipping costs, an advantage for international buyers.

| Material | Typical Use Case for industrial rock tumblers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Wet tumbling of jewelry, precision metal parts | High corrosion resistance and durability | High initial cost and weight | High |

| Polyurethane | Dry or light wet tumbling of gemstones and soft metals | Lightweight with good impact cushioning | Limited temperature tolerance and UV degradation | Low |

| Cast Iron | Heavy-duty dry tumbling of large metal parts | Robust and cost-effective | Prone to rust, heavy, requires maintenance | Low |

| High-Density Polyethylene (HDPE) | Chemical polishing and moderate wet tumbling | Excellent chemical resistance and lightweight | Lower abrasion resistance, potential deformation under heavy loads | Medium |

Industrial rock tumblers are precision-engineered machines designed to polish and finish rocks, minerals, and metals at scale. Their manufacturing involves several critical stages to ensure durability, performance, and safety.

1. Material Preparation

The process begins with selecting high-grade raw materials such as stainless steel, heavy-duty plastics, and durable rubber compounds. Metals are typically procured in sheets, rods, or castings, then inspected for defects. Material preparation includes cutting raw metal to size using CNC laser cutting or water jet technology to ensure precision and reduce waste.

2. Forming and Fabrication

Key components such as the drum, motor housing, and frame are shaped through processes like stamping, bending, and forging. The drum, often the most critical part, is formed to exact tolerances to withstand continuous abrasion. Advanced forming techniques such as CNC machining ensure consistent dimensions and surface finishes, which are vital for smooth operation.

3. Assembly

Assembly is a meticulous stage where subcomponents—motors, belts, drums, control panels, and safety guards—are integrated. Industrial rock tumblers often require precision alignment of rotating parts to minimize vibration and wear. Automated assembly lines combined with skilled manual labor help maintain consistency. During assembly, components like bearings and seals are installed to ensure longevity and operational efficiency.

4. Finishing and Surface Treatment

Finishing processes include deburring, polishing, and applying protective coatings such as powder coating or anodizing. These treatments enhance corrosion resistance and aesthetic appeal. For tumblers exposed to harsh environments, additional sealing or rust-proofing may be applied.

Quality assurance (QA) is paramount in manufacturing industrial rock tumblers to meet international buyer expectations and regulatory requirements.

Relevant International Standards:

- ISO 9001: The foundational quality management system standard ensuring consistent product quality and continuous improvement.

- CE Marking: Mandatory for selling within the European Economic Area, indicating compliance with EU safety, health, and environmental requirements.

- API (American Petroleum Institute) Standards: Relevant if tumblers are used in petrochemical applications for abrasive finishing of metal parts.

- RoHS and REACH Compliance: Important for European buyers concerned with hazardous substances.

B2B buyers should understand the typical QC checkpoints manufacturers implement:

For international buyers from Africa, South America, the Middle East, and Europe, verifying supplier QA is essential to mitigate risks:

Middle East and Africa: Import regulations vary widely; some countries require SASO certification (Saudi Arabia) or SONCAP (Nigeria). Buyers should verify if suppliers have experience navigating these regional requirements.

Language and Documentation: Ensure all technical documents, manuals, and certification paperwork are provided in languages understandable to the buyer’s team or customs officials. English is commonly accepted, but translations may be necessary.

After-Sales Support and Warranty: Quality assurance extends beyond manufacturing. Buyers should confirm the supplier’s warranty terms, availability of spare parts, and technical support, especially for markets with limited local service infrastructure.

By thoroughly understanding the manufacturing processes and quality assurance frameworks of industrial rock tumblers, international B2B buyers can make informed procurement decisions that align with their operational needs and regulatory environments.

When sourcing industrial rock tumblers, understanding the detailed cost structure is essential for accurate budgeting and negotiation. Key cost components typically include:

Several factors shape the final price for industrial rock tumblers:

Buyers from Africa, South America, the Middle East, and Europe should be aware of regional nuances:

Prices for industrial rock tumblers vary widely based on specifications, supplier capabilities, and market conditions. The figures discussed here serve as indicative guidance. Buyers are encouraged to conduct direct supplier engagement and market research to obtain accurate, up-to-date quotations tailored to their specific requirements.

By carefully analyzing these cost components and pricing influencers, international B2B buyers can optimize procurement strategies, achieve cost efficiencies, and secure industrial rock tumblers that meet both budget and operational goals.

When sourcing industrial rock tumblers, understanding key technical specifications ensures the equipment meets your operational needs and quality standards. Here are the essential properties to evaluate:

Material Grade of the Barrel

The barrel material, often stainless steel or heavy-duty plastic, determines durability and resistance to corrosion or chemical reactions with tumbling media. For international buyers, especially in humid or saline environments like coastal Africa or the Middle East, opting for high-grade stainless steel (e.g., 304 or 316 grade) extends equipment life and minimizes maintenance.

Drum Capacity and Load Tolerance

Capacity is measured in liters or kilograms and indicates the maximum volume or weight of rocks and media the tumbler can process per batch. Overloading can reduce polishing efficiency and damage the machine. Knowing your production volume helps in selecting a tumbler with suitable capacity, balancing throughput with energy consumption.

Motor Power and Speed Control

Motor power (typically in kilowatts) affects the tumbler’s ability to rotate heavy loads consistently. Speed control options allow customization of rotation speed to optimize polishing quality for different rock types. Variable speed is especially beneficial for buyers processing diverse materials, enabling flexibility without multiple machines.

Noise Level and Vibration Dampening

Industrial tumblers can generate significant noise and vibration, impacting workplace safety and comfort. Machines with built-in vibration dampening and noise reduction features comply better with international workplace standards, a critical consideration for buyers in regions with strict occupational health regulations like the EU or UK.

Tolerance and Precision of Rotation

Tolerance refers to how consistently the tumbler maintains its rotational speed and alignment. High-precision tumblers ensure uniform polishing results, reducing batch variability. This is crucial for industries requiring consistent surface finishes, such as jewelry manufacturing or geological sample preparation.

Energy Efficiency Rating

Energy consumption is a key cost driver in industrial operations. Tumblers with energy-efficient motors and optimized design reduce operational expenses and environmental impact. For buyers in regions with high energy costs or sustainability mandates, prioritizing energy efficiency can yield significant long-term savings.

Navigating the industrial rock tumbler market requires familiarity with trade terminology that shapes procurement and negotiation processes:

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce tumblers that other companies rebrand or resell. Buyers may seek OEM products for customization or cost advantages. Understanding OEM relationships can help negotiate better pricing or request specific design modifications.

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. MOQs vary widely and impact inventory planning and cash flow. International buyers, especially SMEs in Africa or South America, should clarify MOQs upfront to avoid overcommitment.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting price and delivery terms for specified equipment. RFQs are critical for comparing multiple vendors and securing competitive bids. Including detailed technical requirements in your RFQ improves response accuracy and speeds up the procurement cycle.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting appropriate Incoterms influences total landed cost and risk management, especially when importing tumblers into regions with complex customs procedures.

Lead Time

The period between placing an order and receiving the equipment. Lead times can vary due to manufacturing complexity or shipping logistics. Buyers should factor lead times into project timelines and negotiate realistic delivery schedules to avoid operational delays.

After-Sales Support

Services provided post-purchase, including installation, maintenance, and warranty. For industrial tumblers, reliable after-sales support is essential to minimize downtime. International buyers should verify supplier capabilities for remote support or local service partnerships in their region.

By focusing on these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring the selected industrial rock tumblers align with their operational requirements and procurement strategies. This clarity helps mitigate risks, optimize costs, and build strong supplier relationships across diverse markets.

The industrial rock tumblers market is experiencing steady growth driven by increasing demand from sectors such as mining, metallurgy, jewelry manufacturing, and materials science. Globally, the push towards automation and enhanced process efficiency is encouraging manufacturers to invest in advanced tumbling equipment with improved capacity and energy efficiency. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, this translates into a need for machines that can handle diverse rock types and volumes while maintaining operational reliability under varied environmental conditions.

Key market dynamics include the rising demand for customizable tumblers that integrate with digital monitoring systems to optimize cycle times and reduce manual oversight. Buyers from emerging markets such as Brazil and South Africa are increasingly prioritizing suppliers who offer scalable solutions adaptable to local raw material characteristics. In Europe and the UK, the focus is on precision, durability, and compliance with stringent industrial standards, pushing suppliers to innovate with advanced materials and modular designs.

Illustrative Image (Source: Google Search)

Sourcing trends reflect a shift towards partnerships with manufacturers that emphasize local support services and supply chain transparency. The growing influence of digital procurement platforms enables buyers to compare specifications, certifications, and pricing more efficiently, supporting informed decision-making. Additionally, cross-border trade agreements and regional trade blocs are facilitating smoother import/export processes, which is vital for buyers in the Middle East and Africa aiming to reduce lead times and costs.

Sustainability has become a critical consideration in the industrial rock tumblers sector as companies worldwide strive to minimize environmental impact and meet corporate social responsibility goals. Industrial tumblers traditionally consume significant energy and water resources, so buyers are increasingly evaluating equipment based on energy efficiency ratings and water recycling capabilities. Selecting tumblers with variable frequency drives (VFDs) and optimized motor systems can substantially reduce electricity consumption, aligning with sustainability objectives.

Ethical sourcing is also paramount, especially for buyers in regions sensitive to supply chain risks, such as Africa and South America. Ensuring that suppliers adhere to fair labor practices and environmental regulations mitigates reputational risks and supports compliance with international trade standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are indicators of responsible manufacturing practices. Additionally, some suppliers offer tumblers made with recycled or sustainably sourced materials, reducing the carbon footprint associated with production.

For B2B buyers, engaging with vendors who provide transparent supply chain documentation and lifecycle assessments enables better evaluation of a product's environmental credentials. Green procurement policies are increasingly adopted by governments and large enterprises in Europe and the Middle East, making sustainability not just a preference but often a procurement requirement.

Industrial rock tumblers have evolved significantly since their inception as simple rotary barrels used for polishing and smoothing rocks and metals. Initially designed for small-scale gemstone processing, their application expanded into heavy industries such as mining and metal finishing as demand for automated, high-throughput equipment grew. Over the decades, advancements in motor technology, materials science, and control systems have transformed tumblers from purely mechanical devices into sophisticated machines capable of precise process control.

This evolution is particularly relevant for B2B buyers today as it highlights the availability of highly specialized tumblers tailored to specific industrial needs. Understanding this progression helps buyers appreciate the technological improvements that enhance durability, efficiency, and versatility — essential factors when sourcing equipment for diverse and demanding industrial environments globally.

How can I effectively vet industrial rock tumbler suppliers internationally?

To vet suppliers, start by requesting company profiles, certifications, and client references to verify legitimacy and quality standards. Utilize platforms like Alibaba or Global Sources with verified supplier badges. Conduct virtual factory tours or onsite audits if possible. Check their compliance with international standards (ISO, CE) and review their export history, especially with buyers in Africa, South America, the Middle East, and Europe. Assess communication responsiveness and after-sales support capabilities, which are critical for cross-border transactions.

What customization options are typically available for industrial rock tumblers, and how can I negotiate them?

Suppliers often offer customization in drum size, motor power, material composition, and automation features to suit specific industrial needs. Discuss your application requirements clearly upfront and ask for tailored solutions. Negotiate customization costs by comparing multiple suppliers and requesting prototypes or samples. For international buyers, ensure that customizations comply with local regulations and power standards (e.g., voltage differences between Brazil and the UK). Always confirm lead times for customized orders as they tend to be longer than standard models.

What are typical Minimum Order Quantities (MOQs), lead times, and payment terms for international B2B purchases?

MOQs vary widely but generally range from 5 to 50 units for industrial rock tumblers. Lead times can span from 4 to 12 weeks depending on customization and production capacity. Payment terms often require a 30%-50% deposit upfront with the balance paid before shipment or upon delivery. For buyers in emerging markets like Africa or South America, negotiating flexible payment terms such as Letter of Credit (L/C) or escrow services can mitigate risk. Confirm these terms early to avoid delays.

Which quality assurance certifications and standards should I prioritize when sourcing industrial rock tumblers internationally?

Prioritize internationally recognized certifications such as ISO 9001 for quality management and CE marking for European market compliance. UL or CSA certifications may be relevant depending on electrical safety standards in your region. For buyers in the Middle East and Africa, certifications related to durability and environmental compliance can be critical due to harsh operational conditions. Request test reports and inspection certificates to ensure batch consistency and adherence to contract specifications.

What are the best practices for managing logistics and shipping of industrial rock tumblers across continents?

Work closely with suppliers to determine the most cost-effective shipping methods—sea freight is common for heavy machinery but can be slow; air freight is faster but more expensive. Confirm packaging standards to prevent damage during transit, especially for long routes to Africa or South America. Use freight forwarders familiar with customs clearance in your destination country and consider insurance to cover potential losses. Plan shipments well in advance to accommodate possible delays due to customs or port congestion.

How can I handle disputes or quality issues with overseas suppliers effectively?

Establish clear contractual terms covering quality expectations, inspection rights, and dispute resolution mechanisms before purchase. Use third-party inspection agencies to verify product quality pre-shipment. In case of disputes, communicate promptly and document all correspondence. Leverage international trade arbitration bodies or mediation services if necessary. Maintaining good supplier relationships helps in amicable resolution, which is preferable to costly legal battles. For buyers in regions with complex import regulations, involving local trade experts can be beneficial.

Are there specific considerations for sourcing industrial rock tumblers for markets with variable power supplies?

Yes, electrical compatibility is crucial. Ensure tumblers are designed for the local voltage and frequency standards (e.g., 220V/50Hz in Europe and parts of Africa, 110V/60Hz in some regions). Request suppliers to provide models with voltage adaptability or recommend transformers. Additionally, inquire about energy efficiency ratings, as power reliability varies in many African and Middle Eastern countries. Investing in robust, energy-efficient machines can reduce operational costs and downtime.

Illustrative Image (Source: Google Search)

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of industrial rock tumblers demands a nuanced understanding of supplier capabilities, regional manufacturing strengths, and evolving technological trends. For B2B buyers across Africa, South America, the Middle East, and Europe, it is crucial to prioritize suppliers who demonstrate consistent quality, compliance with international standards, and flexible customization options tailored to diverse industrial applications. Leveraging local and global supply chain networks can optimize cost-efficiency and minimize lead times, especially when considering logistics challenges unique to emerging markets.

Key takeaways for effective sourcing include:

Looking ahead, industrial rock tumblers will continue evolving with advancements in automation and materials science. International buyers are encouraged to engage proactively with manufacturers who invest in R&D and demonstrate agility in meeting customized demands. By embracing strategic sourcing principles today, companies can secure competitive advantage and drive sustainable growth in their respective markets. Act now to align your procurement strategy with the future trajectory of industrial finishing technologies.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina