Navigating the global market for kalziniert (calcined products) poses a significant challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the nuances of sourcing high-quality calcined materials, which are essential in various industries such as construction, metallurgy, and agriculture, can be overwhelming. This guide is designed to streamline the procurement process, offering insights into the different types of kalziniert, their applications, and strategies for effective supplier vetting.

In this comprehensive resource, we delve into the intricacies of kalziniert, covering everything from product specifications and quality standards to cost considerations and market trends. By offering actionable insights and expert advice, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are a buyer in South Africa seeking reliable suppliers or a procurement manager in Colombia looking to optimize your supply chain, this guide will equip you with the knowledge necessary to navigate the complexities of the global kalziniert market. Prepare to enhance your sourcing strategies and strengthen your competitive edge through informed decision-making.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Calcium Carbonate | Natural mineral, white powder, high purity | Pharmaceuticals, food additives | Pros: Widely available, cost-effective. Cons: Limited in specific applications. |

| Calcium Oxide | Produced by calcining limestone, highly reactive | Steel production, chemical manufacturing | Pros: High reactivity, essential for various processes. Cons: Can be hazardous without proper handling. |

| Calcium Hydroxide | Slaked lime, soluble in water, used in various reactions | Water treatment, construction | Pros: Versatile, effective in pH regulation. Cons: Requires careful storage to maintain quality. |

| Quicklime | Anhydrous form of calcium oxide, exothermic reaction when mixed with water | Construction, agriculture | Pros: Strong alkaline properties, useful in soil stabilization. Cons: Risk of burns if mishandled. |

| Calcined Clay | Fine powder obtained from heating clay, enhances cement properties | Cement production, ceramics | Pros: Improves durability, eco-friendly alternative. Cons: May require specific processing equipment. |

Calcium carbonate is a naturally occurring mineral often utilized in its powdered form. It is characterized by its high purity and versatility across various industries, including pharmaceuticals and food additives. B2B buyers should consider sourcing calcium carbonate for applications that require a cost-effective filler or a pH regulator. Its widespread availability makes it an attractive option, although its limited functionality in specialized applications may be a drawback for certain industries.

Calcium oxide, or quicklime, is produced through the calcination of limestone and is known for its high reactivity. This type is essential in steel production and chemical manufacturing, where it serves as a flux and reagent. For B2B buyers, the key consideration is its effectiveness in various processes, although it poses safety risks due to its corrosive nature. Proper handling and storage are critical for maximizing its benefits while minimizing hazards.

Calcium hydroxide, commonly known as slaked lime, is produced by adding water to calcium oxide. It is soluble in water and plays a significant role in water treatment and construction. Its ability to regulate pH levels makes it a valuable asset for B2B buyers involved in environmental management or construction projects. While it is versatile, careful storage is necessary to maintain its quality, which could be a concern for some buyers.

Quicklime is the anhydrous form of calcium oxide and is recognized for its strong alkaline properties. It is widely used in construction and agricultural applications, particularly for soil stabilization. B2B buyers should evaluate quicklime for its effectiveness in enhancing soil quality and building materials. However, the risk of burns and other hazards necessitates stringent safety measures during handling and application.

Calcined clay is a fine powder derived from heating clay and is known for its ability to improve the properties of cement. It offers an eco-friendly alternative to traditional cement additives, enhancing durability and performance. B2B buyers in the construction and ceramics industries should consider calcined clay for its sustainability benefits. However, specific processing equipment may be required, which could be a barrier for some buyers.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of kalziniert | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Use in cement and concrete production | Enhances durability and strength of materials | Quality control of raw materials, regional availability |

| Agriculture | Soil amendment and pH adjustment | Improves soil fertility and crop yield | Certification of product purity, local agricultural practices |

| Chemical Manufacturing | Production of calcium-based chemicals | Essential for various chemical reactions | Compliance with international standards, sourcing reliability |

| Water Treatment | Treatment of drinking and wastewater | Removes impurities and improves water quality | Regulatory compliance, sourcing from certified suppliers |

| Metallurgy | Production of metallurgical lime | Crucial for steelmaking and other metal processes | Consistency in chemical composition, supplier reputation |

In the construction sector, kalziniert is primarily utilized in the production of cement and concrete. The calcination process enhances the properties of calcium carbonate, yielding a material that significantly improves the durability and strength of construction materials. For international buyers in regions like Africa and South America, ensuring the quality of raw materials is critical due to varying local standards. Additionally, sourcing from reputable suppliers who can guarantee consistent quality and compliance with construction regulations is essential.

Kalziniert serves as an effective soil amendment, helping to adjust pH levels and improve soil fertility. This application is particularly beneficial for farmers looking to enhance crop yield in regions with poor soil quality. Buyers from the Middle East and Africa should prioritize sourcing kalziniert that is certified for agricultural use to ensure safety and efficacy. Understanding local agricultural practices and soil conditions is also crucial for maximizing the benefits of this product.

In chemical manufacturing, kalziniert is a key ingredient in the production of various calcium-based chemicals, which are crucial for numerous industrial processes. The versatility of kalziniert allows it to be used in applications ranging from plastics to pharmaceuticals. International buyers must consider compliance with global chemical safety standards and ensure reliable sourcing to avoid disruptions in production. Establishing relationships with suppliers who can provide consistent quality and timely delivery is vital for operational efficiency.

Kalziniert is employed in water treatment processes to remove impurities and enhance the overall quality of drinking and wastewater. By acting as a flocculating agent, it helps in sedimentation, making it invaluable for municipalities and industries focused on water safety. Buyers in Europe and Africa should focus on suppliers who comply with local and international water treatment regulations to ensure that the kalziniert they source meets the necessary safety standards. Evaluating the supplier’s track record and certifications can also provide assurance of quality.

In metallurgy, kalziniert is primarily used to produce metallurgical lime, which is essential in steelmaking and other metal production processes. Its role in removing impurities and facilitating chemical reactions makes it indispensable in the metallurgical industry. For international B2B buyers, particularly in regions like South America and Europe, sourcing high-quality kalziniert that maintains consistent chemical composition is crucial. Engaging with reputable suppliers who have a strong reputation in the metallurgy sector can help ensure the quality needed for successful operations.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem:

B2B buyers often encounter significant challenges when sourcing 'kalziniert' materials, especially when quality control measures are inconsistent. For companies in regions like Africa or South America, where local suppliers may not adhere to international standards, ensuring that the 'kalziniert' product meets specific requirements becomes a daunting task. This inconsistency can lead to production delays, increased costs, and ultimately, a negative impact on overall business operations.

The Solution:

To mitigate quality control issues, buyers should establish clear specifications and standards before engaging with suppliers. It is essential to conduct thorough research on potential suppliers, including their certifications and track record in producing 'kalziniert' products. Consider implementing a supplier qualification process that includes requesting sample products for testing. Additionally, using third-party inspection services can provide an unbiased assessment of product quality. By prioritizing quality verification, businesses can ensure that the 'kalziniert' materials sourced meet the necessary performance criteria, thus preventing costly disruptions in production.

The Problem:

Another common pain point is the misunderstanding of how 'kalziniert' products should be applied in specific processes or industries. Buyers may struggle to find accurate information on the best practices for utilizing 'kalziniert' in their operations, leading to inefficient use or even product failure. This is particularly prevalent in sectors such as construction or agriculture, where the application of 'kalziniert' directly affects the project's success.

The Solution:

To address this issue, B2B buyers should engage in comprehensive training and consultation with industry experts. This could involve arranging workshops or webinars with manufacturers or consultants who specialize in 'kalziniert' products. Additionally, creating a detailed application guide, outlining different uses and best practices, can serve as a reference tool for teams. Collaboration with suppliers to develop customized solutions that cater to specific application needs can also enhance understanding and usage efficiency. By investing in education and support, companies can maximize the benefits of 'kalziniert' and avoid costly mistakes.

The Problem:

Managing costs while procuring 'kalziniert' materials is a critical concern for many B2B buyers, especially in competitive markets in the Middle East and Europe. Fluctuations in market prices and unanticipated expenses can lead to budget overruns, impacting overall profitability. Furthermore, buyers may struggle with understanding the total cost of ownership, which includes not just the purchase price but also logistics, storage, and potential wastage.

The Solution:

To gain better control over costs, buyers should develop a comprehensive procurement strategy that includes detailed budgeting and forecasting. Implementing a total cost of ownership (TCO) analysis can provide insights into all costs associated with 'kalziniert' procurement, enabling businesses to make informed decisions. Additionally, negotiating long-term contracts with suppliers can lock in prices and mitigate the risk of price fluctuations. Utilizing data analytics tools can also help buyers track and predict market trends, allowing for timely purchasing decisions that align with budget constraints. By adopting a strategic approach to procurement, companies can ensure they remain competitive while managing costs effectively.

When selecting materials for kalziniert applications, international B2B buyers must consider various factors, including the material's properties, advantages, limitations, and compliance with industry standards. Below, we analyze four common materials used in kalziniert processes, providing insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Steel is a widely used material in kalziniert applications due to its strength and versatility. Key properties include high tensile strength, excellent temperature resistance (up to 600°C), and good corrosion resistance when treated. Steel's ability to withstand high pressures makes it suitable for various industrial applications.

Pros & Cons:

- Advantages: Steel is durable, relatively low-cost, and can be manufactured in various forms (e.g., sheets, tubes). It is also easily weldable, which simplifies fabrication.

- Disadvantages: The primary limitation is its susceptibility to corrosion unless properly coated or treated, which can increase maintenance costs.

Impact on Application: Steel is compatible with many media, including gases and liquids, making it suitable for diverse industries, from construction to chemical processing.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like South Africa and Colombia, understanding local regulations regarding material specifications is crucial.

Aluminum is another popular choice for kalziniert applications, particularly in environments where weight reduction is essential. It boasts excellent corrosion resistance and a lower density compared to steel, which can be advantageous in specific applications.

Pros & Cons:

- Advantages: Aluminum is lightweight, resistant to corrosion, and offers good thermal conductivity. It can be anodized for enhanced surface protection.

- Disadvantages: The primary drawback is its lower strength compared to steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum is ideal for applications in the automotive and aerospace industries, where weight savings are critical.

Considerations for International Buyers: Compliance with JIS standards is essential for buyers in Asia, while European buyers may prefer EN standards. Understanding the specific alloy grades and their properties is vital for ensuring suitability.

Stainless steel is renowned for its corrosion resistance and durability, making it an excellent choice for kalziniert applications where exposure to harsh environments is expected. It maintains its integrity at high temperatures and is compatible with a wide range of chemicals.

Pros & Cons:

- Advantages: Stainless steel is highly durable, resistant to corrosion, and requires minimal maintenance. Its aesthetic appeal also makes it suitable for visible applications.

- Disadvantages: It is generally more expensive than carbon steel and can be more challenging to machine.

Impact on Application: Stainless steel is particularly effective in food processing and pharmaceutical applications, where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Buyers should be aware of the need for compliance with health and safety regulations, particularly in the food and pharmaceutical sectors. Familiarity with local standards, such as the FDA in the U.S. or EFSA in Europe, is essential.

Composite materials, often made from a combination of polymers and fibers, are increasingly used in kalziniert applications due to their unique properties. They offer high strength-to-weight ratios and excellent corrosion resistance.

Pros & Cons:

- Advantages: Composites are lightweight, resistant to corrosion, and can be tailored for specific applications. They also provide excellent thermal insulation.

- Disadvantages: The primary limitation is the higher cost and complexity of manufacturing, which can deter some buyers.

Impact on Application: Composites are ideal for applications in the aerospace and automotive industries, where weight and performance are critical.

Considerations for International Buyers: Buyers must consider the specific certifications required for composites in their industry and region. Understanding the differences in manufacturing processes and material properties is crucial for making informed decisions.

| Material | Typical Use Case for kalziniert | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and versatility | Susceptible to corrosion | Medium |

| Aluminum | Lightweight frames | Excellent corrosion resistance | Lower strength compared to steel | Medium |

| Stainless Steel | Food processing equipment | Highly durable and corrosion resistant | Higher cost than carbon steel | High |

| Composite | Aerospace components | Lightweight and customizable | Higher manufacturing complexity | High |

This strategic material selection guide provides a comprehensive overview of materials for kalziniert applications, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

Kalziniert, or calcined materials, are produced through a series of intricate manufacturing processes that ensure the final product meets industry standards and specific customer needs. The key stages involved in the manufacturing process include material preparation, forming, assembly, and finishing. Each of these stages plays a critical role in determining the quality and characteristics of the final product.

The first stage in the manufacturing process is material preparation, which involves selecting and processing raw materials. For kalziniert, the primary raw materials often include limestone, clays, and other minerals. These materials must undergo crushing and milling to achieve the desired particle size and uniformity.

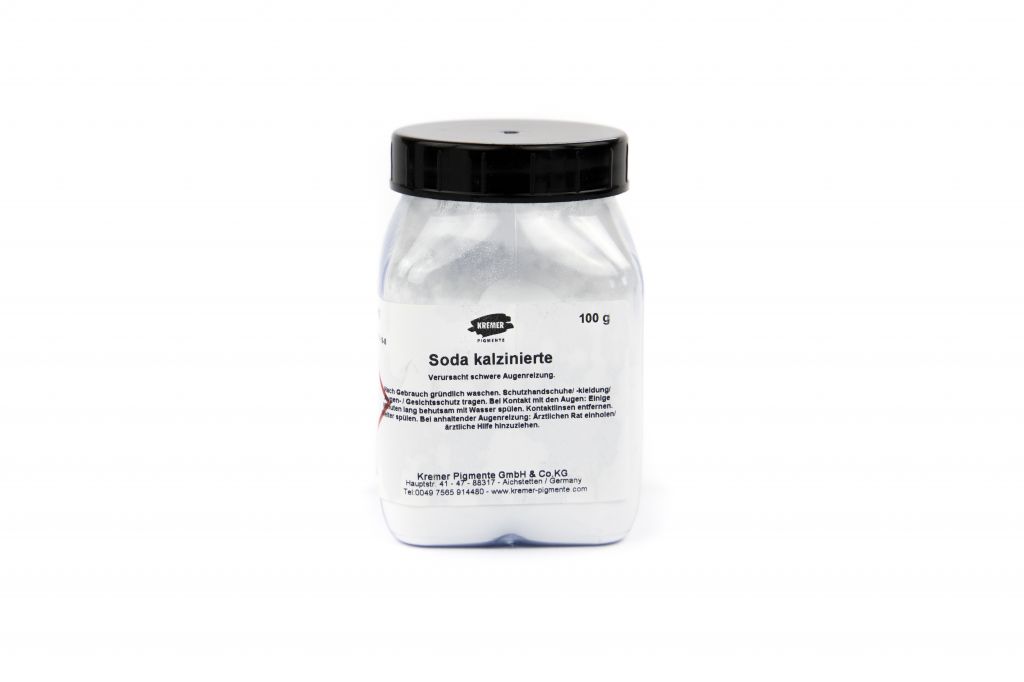

A stock image related to kalziniert.

After milling, the materials are subjected to drying to eliminate moisture content, ensuring that the calcination process is efficient. This stage is crucial because excess moisture can lead to incomplete calcination, affecting the final product's quality. B2B buyers should look for suppliers who use advanced drying techniques, such as rotary dryers or fluidized bed dryers, to ensure optimal moisture removal.

Once the materials are prepared, the next step is forming. This involves shaping the material into the desired form before it undergoes calcination. Common techniques include pressing, extruding, or molding.

For instance, in the production of refractory materials, the mixture may be pressed into molds to form bricks or shapes that will withstand high temperatures. The choice of forming technique can influence the density and strength of the final product, making it essential for buyers to understand these processes when evaluating suppliers.

In some cases, multiple components need to be assembled before the final calcination process. This might involve combining different types of minerals or additives to enhance specific properties, such as thermal resistance or chemical stability.

During this assembly stage, it is vital to maintain consistent proportions of each component to ensure uniformity in the final product. Buyers should inquire about the supplier's methods for ensuring consistency, such as automated batching systems or manual checks.

After calcination, the finishing stage includes grinding, polishing, or coating the product to enhance its performance characteristics. This stage may also involve additional quality control checks to ensure that the product meets the required specifications.

Finishing techniques may vary depending on the intended application of the kalziniert product. For example, materials intended for construction may require a rough surface finish for better adhesion, while those used in electronics may need a smooth, polished surface. Buyers should assess the supplier's capabilities in finishing to ensure they can meet specific project requirements.

Quality assurance is a critical aspect of kalziniert manufacturing, as it ensures that the products meet international standards and customer expectations. There are various quality control (QC) checkpoints and international standards that buyers should be aware of.

One of the most recognized international quality standards is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality and continual improvement.

In addition to ISO 9001, industry-specific standards may apply, such as CE marking for products sold within the European Union or API standards for petroleum and natural gas industries. Buyers from Africa, South America, the Middle East, and Europe should verify that their suppliers adhere to relevant standards to avoid compliance issues.

Quality control in kalziniert manufacturing typically involves several checkpoints throughout the production process:

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter production. It is crucial for ensuring that only high-quality materials are processed.

In-Process Quality Control (IPQC): During production, ongoing checks are performed to monitor critical parameters such as temperature, pressure, and material consistency.

Final Quality Control (FQC): After production, the finished products undergo rigorous testing to ensure they meet specified requirements. This may involve physical inspections, chemical analyses, and performance testing.

B2B buyers should inquire about the specific QC protocols their suppliers follow and request evidence of compliance with these checkpoints.

To ensure that suppliers maintain high-quality standards, B2B buyers can take several actions:

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational standards of their suppliers.

Quality Assurance Reports: Requesting regular quality assurance reports provides insight into the supplier's performance over time and highlights any potential issues.

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

Certifications: Buyers should look for suppliers with relevant certifications that demonstrate adherence to international quality standards.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. These may include different regulatory requirements, cultural attitudes toward quality, and logistics considerations that can affect product delivery and performance.

It's essential for buyers to establish clear communication channels with their suppliers, ensuring that expectations regarding quality are understood and met. Additionally, recognizing the local market conditions and standards can help buyers make informed decisions when selecting suppliers.

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can better navigate the complexities of sourcing kalziniert products while ensuring they receive high-quality materials that meet their operational needs.

To successfully procure kalziniert, a step-by-step approach can streamline your sourcing process. This guide provides actionable steps to ensure you find the right suppliers and products that meet your specific needs.

Define Your Technical Specifications

Clearly outline the technical requirements for the kalziniert you intend to purchase. This includes chemical composition, grain size, and intended use. Having precise specifications helps avoid misunderstandings with suppliers and ensures that you receive the right product for your applications.

Conduct Market Research for Suppliers

Investigate potential suppliers in the regions of interest, such as Africa, South America, the Middle East, and Europe. Use platforms like trade directories, industry forums, and LinkedIn to gather information. Understanding the market landscape will help you identify reliable suppliers and assess their capabilities.

Evaluate Potential Suppliers

Before committing to a supplier, it's crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who have experience with kalziniert and can demonstrate their expertise through past projects or certifications.

Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and compliance with international standards. For instance, ISO certifications can indicate a commitment to quality management. This step is vital to ensure that the product meets safety and quality benchmarks, especially in regulated industries.

Request Samples for Quality Assessment

Before making a large order, request samples of the kalziniert. This allows you to evaluate the quality and suitability of the product for your specific needs. Pay attention to factors such as consistency, purity, and performance under operational conditions.

Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, delivery schedules, and after-sales support. Clear agreements can prevent disputes and enhance the purchasing experience.

Establish a Reliable Logistics Plan

Consider the logistics involved in the procurement of kalziniert, including shipping methods, customs clearance, and delivery timelines. Work with your supplier to develop a logistics plan that aligns with your project timelines and ensures timely delivery. Efficient logistics can significantly impact your supply chain efficiency.

A stock image related to kalziniert.

By following this checklist, international B2B buyers can navigate the procurement process for kalziniert effectively, ensuring they select the right suppliers and products that meet their technical and operational needs.

When sourcing kalziniert, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The quality and type of raw materials significantly influence the price. High-purity limestone or specific additives can increase costs but may be necessary for specific applications.

Labor: Labor costs vary by region and can be influenced by local wage standards and skill levels. Countries with lower labor costs may provide competitive pricing but could compromise quality if not managed properly.

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead and, consequently, the final price.

Tooling: Initial costs for molds and machinery can be substantial, especially for custom specifications. Buyers should factor in these costs when evaluating suppliers.

Quality Control (QC): Implementing stringent QC measures ensures product consistency and reliability. This may increase costs but is essential for maintaining product standards.

Logistics: Shipping and handling costs can vary widely based on the origin and destination of the products. Buyers should consider the total logistics cost, including any tariffs or duties.

Margin: Supplier profit margins can vary based on market demand and competition. Understanding a supplier’s pricing strategy is essential for effective negotiation.

Several factors influence the pricing of kalziniert, making it essential for buyers to consider these when negotiating:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, as suppliers can spread fixed costs over more units. Buyers should assess their needs to optimize order sizes.

Specifications and Customization: Custom requirements can significantly increase costs. Buyers should clearly define their needs upfront to avoid unexpected price hikes.

Materials and Quality Certifications: The use of certified materials or adherence to specific industry standards can increase costs. Buyers should weigh the benefits of certifications against their budget.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding the agreed terms of shipment can impact costs. For instance, choosing a delivery term that includes all freight and duty costs can simplify budgeting but may also lead to higher upfront prices.

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies are vital:

Research and Benchmarking: Gather market intelligence on pricing and terms. Understanding what others pay for similar products can provide leverage in negotiations.

Emphasize Total Cost of Ownership (TCO): When discussing pricing, include all associated costs such as logistics, tariffs, and quality assurance. This holistic view can help justify higher initial prices if long-term savings are evident.

Build Relationships: Establishing a strong rapport with suppliers can lead to better terms and pricing. Long-term partnerships often yield more favorable conditions.

Be Flexible: Be open to adjusting order quantities or delivery schedules to accommodate the supplier’s constraints. This flexibility can lead to better pricing.

International buyers must navigate various pricing nuances when sourcing kalziniert:

Currency Fluctuations: Exchange rate volatility can impact pricing. Buyers should consider hedging strategies or negotiating prices in a stable currency.

Regulatory Compliance: Different regions have varying regulations that can affect pricing. Ensure compliance with local standards to avoid additional costs.

Cultural Sensitivity: Understanding cultural differences in negotiation styles can aid in securing favorable terms. Tailor your approach to the region’s business etiquette.

Navigating the costs and pricing of kalziniert requires a thorough understanding of the various components involved. By recognizing key influencers and employing effective negotiation strategies, international B2B buyers can optimize their sourcing decisions and achieve better value. Always remember that prices are indicative and subject to change based on market conditions and supplier circumstances.

When evaluating solutions for industrial processes, it’s essential to explore various options that may meet specific operational needs. Kalziniert, a method involving the thermal treatment of materials, has specific advantages; however, alternative solutions may also provide valuable benefits depending on the application context. This section will compare kalziniert with alternative methods to help international B2B buyers make informed decisions.

| Comparison Aspect | Kalziniert | Alternative 1: Roasting | Alternative 2: Calcination |

|---|---|---|---|

| Performance | High efficiency in material transformation | Effective for mineral extraction | Suitable for carbonate materials |

| Cost | Moderate capital investment | Lower initial investment | Higher operational costs |

| Ease of Implementation | Requires specialized equipment | Easier to implement in existing setups | Complex setup and operational requirements |

| Maintenance | Moderate maintenance needs | Low maintenance | High maintenance due to equipment wear |

| Best Use Case | Chemical processing in industries like ceramics and glass | Mining and metallurgy | Cement production and mineral processing |

Roasting is a widely used thermal treatment method, primarily in the mining and metallurgy sectors. One of its significant advantages is the lower initial investment compared to kalziniert. Roasting is easier to implement in existing setups, making it a practical choice for operations looking to minimize disruption. However, it may not achieve the same high efficiency in material transformation as kalziniert, particularly in processes requiring precise chemical alterations.

Calcination is another method that shares similarities with kalziniert but is distinct in its application. It is primarily used for carbonate materials and is effective in producing quicklime from limestone. While calcination may offer specific advantages in processing certain minerals, it typically incurs higher operational costs due to the complexity of its equipment and processes. Furthermore, the maintenance needs are more significant than those associated with kalziniert, which may deter some buyers from choosing this option.

When selecting between kalziniert and its alternatives, international B2B buyers should consider several factors, including the specific application, budget constraints, and operational capabilities. Understanding the unique requirements of their processes will guide buyers in selecting the most suitable method. For instance, companies in the ceramics industry may find kalziniert to be the best fit due to its efficiency in transforming materials, while those in mining might prefer roasting for its cost-effectiveness and ease of implementation. Ultimately, the choice should align with long-term operational goals and resource availability.

Understanding the technical properties of kalziniert is essential for international B2B buyers, particularly in industries such as construction, manufacturing, and agriculture. Here are some critical specifications to consider:

Material Grade

Material grade refers to the specific classification of the kalziniert based on its chemical composition and physical properties. This specification is crucial as it affects the material's strength, durability, and suitability for various applications. B2B buyers must ensure that the material grade meets their project requirements to avoid complications during production.

Particle Size Distribution

The particle size distribution of kalziniert influences its reactivity and performance in applications such as construction and chemical processes. A finer particle size generally increases the surface area, enhancing reactivity. Buyers should assess particle size specifications to align with their processing needs, as this can significantly impact the effectiveness of the final product.

Tolerance Levels

Tolerance levels define the acceptable variations in dimensions and properties of kalziniert. In B2B transactions, precise tolerances are vital to ensure compatibility with other materials and components. Buyers must specify tolerance requirements to maintain product quality and consistency, minimizing the risk of defects in production.

Thermal Stability

Thermal stability indicates how well kalziniert can withstand high temperatures without decomposing or losing its properties. This characteristic is particularly important for applications in high-temperature environments, such as manufacturing and energy production. Buyers should inquire about thermal stability to ensure that the kalziniert will perform reliably under their operating conditions.

Chemical Purity

The level of impurities in kalziniert can significantly affect its performance in various applications. High chemical purity is often required for products used in food, pharmaceuticals, or high-tech industries. Buyers should request certificates of analysis to verify the chemical purity levels and ensure compliance with industry standards.

Familiarity with industry jargon can enhance communication and streamline negotiations in the B2B marketplace. Here are some essential terms:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of kalziniert, buyers may deal with OEMs when sourcing customized products. Understanding OEM relationships can help buyers negotiate better pricing and quality assurances.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and overall costs. Knowing the MOQ can help buyers plan their purchases effectively to avoid excess inventory or stock shortages.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ can lead to better pricing and conditions, as it allows suppliers to compete for their business. It is advisable for buyers to include detailed specifications in their RFQs to receive accurate quotes.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping costs, risks, and delivery timelines. Buyers should familiarize themselves with the relevant Incoterms to ensure clarity in their contracts.

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For B2B buyers, understanding lead times is critical for project planning and inventory management. Buyers should discuss lead times upfront to align expectations and ensure timely delivery of kalziniert.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing kalziniert more effectively, ensuring that they make informed decisions that align with their business needs.

The kalziniert sector is experiencing significant shifts driven by globalization and technological advancements. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, must navigate these market dynamics to optimize their sourcing strategies. A primary driver is the increasing demand for high-quality materials, which kalziniert products often represent due to their enhanced properties. This demand is particularly evident in industries such as construction, agriculture, and manufacturing.

Emerging technologies are reshaping sourcing trends, with digital platforms facilitating better supplier visibility and collaboration. For instance, blockchain technology is being adopted to enhance transparency and traceability in the supply chain. Additionally, artificial intelligence (AI) and machine learning are being utilized to predict market trends, allowing buyers to make informed decisions. This technological integration is vital for companies looking to maintain competitive advantages in a rapidly evolving marketplace.

Another significant trend is the rise of regional sourcing, as buyers seek to reduce lead times and transportation costs. This approach not only optimizes logistics but also supports local economies, aligning with the growing emphasis on corporate social responsibility. For example, B2B buyers from South Africa and Colombia are increasingly looking for local kalziniert suppliers to meet their specific needs, resulting in a more localized supply chain strategy.

Sustainability is a critical consideration for B2B buyers in the kalziniert sector. The environmental impact of sourcing practices is under scrutiny, prompting businesses to prioritize ethical supply chains. Buyers are increasingly interested in suppliers who demonstrate commitment to sustainable practices, such as reducing carbon footprints and minimizing waste. This shift is driven by both consumer preferences and regulatory pressures, making it essential for international buyers to align their sourcing strategies with sustainability goals.

Ethical sourcing is not just a trend; it is becoming a prerequisite for doing business. Certifications such as ISO 14001 (Environmental Management) and specific 'green' certifications for kalziniert materials are gaining importance. These certifications provide assurance to buyers that their suppliers adhere to environmental standards, which can enhance brand reputation and customer loyalty. Additionally, using sustainably sourced kalziniert materials can lead to cost savings in the long run, as companies may benefit from reduced energy consumption and waste management costs.

Moreover, the focus on sustainability is influencing product innovation. Suppliers are increasingly developing eco-friendly kalziniert options, such as those made from recycled materials or processes that utilize less energy. For buyers in regions like the Middle East and Europe, integrating these sustainable options into their procurement strategies can provide a competitive edge in an increasingly eco-conscious market.

Understanding the evolution of the kalziniert sector can provide valuable insights for international B2B buyers. Historically, kalziniert materials were primarily used in traditional industries, but the last few decades have seen a significant transformation. Advances in production technologies have improved the quality and applications of kalziniert products, expanding their use across various sectors.

In the early 2000s, the push for more efficient production methods led to innovations that reduced costs and increased availability. This made kalziniert materials more accessible to a broader range of industries, including automotive and aerospace. As these sectors evolved, the demand for high-performance materials also increased, further driving innovation in the kalziniert sector.

Today, the historical context of kalziniert materials emphasizes the importance of adaptability and innovation in sourcing strategies. B2B buyers must be aware of these trends and historical shifts to effectively align their procurement practices with market demands and technological advancements. This awareness will enable them to make informed decisions that not only meet current needs but also anticipate future developments in the kalziniert sector.

How can I ensure the quality of kalziniert products before purchasing?

To guarantee quality, start by requesting product samples from potential suppliers. Conduct thorough inspections upon arrival, checking for consistency in texture, size, and chemical composition. Establish clear quality assurance protocols, including certifications like ISO or relevant industry standards. Additionally, consider third-party testing for independent verification. Building strong relationships with suppliers who prioritize quality control can also help ensure that you receive kalziniert products that meet your specifications.

What are the best practices for sourcing kalziniert in international markets?

When sourcing kalziniert internationally, conduct comprehensive market research to identify reliable suppliers. Utilize platforms like Alibaba or industry-specific trade fairs to connect with potential vendors. Ensure you understand the regulatory requirements in your target market regarding importation. Engage in direct communication with suppliers to clarify product specifications, pricing, and lead times. Finally, consider visiting suppliers’ facilities if feasible, as this can provide valuable insights into their operations and quality control measures.

What customization options are available for kalziniert products?

Many suppliers offer customization for kalziniert products, including variations in particle size, purity levels, and packaging types. Discuss your specific requirements with potential suppliers to determine their capabilities. Some manufacturers may also provide tailored formulations to suit unique applications in industries like construction, agriculture, or manufacturing. Be clear about your needs during negotiations to ensure that the final product aligns with your business objectives.

What is the typical minimum order quantity (MOQ) for kalziniert?

The MOQ for kalziniert can vary significantly between suppliers, often ranging from 500 kg to several tons. Factors influencing MOQ include production capabilities, product specifications, and your geographical location. Always inquire about MOQs during your initial discussions with suppliers. If your order volume is lower than their MOQ, consider negotiating a compromise or exploring alternative suppliers who may accommodate smaller orders.

What payment terms should I expect when sourcing kalziniert?

Payment terms for kalziniert can differ based on the supplier's policies and your business relationship. Common practices include payment in advance, letters of credit, or net 30/60 terms upon delivery. It’s crucial to establish clear payment terms before finalizing any contracts to avoid misunderstandings. Additionally, consider using escrow services for large transactions to protect both parties until the goods are delivered and inspected.

How can I effectively vet potential suppliers of kalziniert?

To vet suppliers effectively, start by researching their background and reputation in the industry. Check for customer reviews, testimonials, and any certifications they hold. It’s beneficial to request references from previous clients and follow up with them to gauge satisfaction. Additionally, consider conducting site visits or audits to evaluate their production capabilities and quality control processes. A thorough vetting process can help you identify reliable partners for your kalziniert sourcing needs.

What logistics considerations should I keep in mind when importing kalziniert?

When importing kalziniert, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose reliable freight forwarders experienced in handling your specific products. Be aware of import duties and taxes that may apply in your country. Additionally, ensure proper documentation is in place, including bills of lading and import permits, to facilitate a smooth customs clearance process. Planning logistics effectively can help avoid delays and unexpected costs.

How can I establish a long-term partnership with kalziniert suppliers?

Building a long-term partnership with kalziniert suppliers involves clear communication, mutual trust, and consistent performance. Start by setting clear expectations regarding quality, delivery schedules, and pricing. Regularly engage with your suppliers to provide feedback and discuss any challenges. Consider establishing a formal agreement that outlines the terms of your partnership. Showing commitment through consistent orders and timely payments can foster goodwill and encourage suppliers to prioritize your business.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of kalziniert presents numerous advantages for international B2B buyers across Africa, South America, the Middle East, and Europe. Understanding the specific applications and benefits of kalziniert can enhance product quality and reduce costs. Buyers should prioritize establishing reliable supplier relationships, focusing on quality assurance and compliance with local regulations to mitigate risks associated with sourcing.

The importance of strategic sourcing cannot be overstated; it not only optimizes procurement processes but also fosters innovation and sustainability in operations. As global markets continue to evolve, leveraging insights from regional suppliers will be critical in adapting to changing demands and enhancing competitiveness.

Looking ahead, B2B buyers should actively engage with suppliers to explore new opportunities and innovations in kalziniert applications. By staying informed about industry trends and technological advancements, buyers can position themselves for long-term success. Take the initiative to connect with potential suppliers and industry experts to foster partnerships that drive mutual growth and success in the dynamic landscape of international trade.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina