Navigating the global market for korund-struktur presents significant challenges for international B2B buyers, particularly those seeking reliable sourcing solutions for high-quality materials. As industries increasingly demand durable and versatile components, understanding the properties and applications of korund becomes essential. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe—countries like Germany and Saudi Arabia—with the knowledge necessary to make informed purchasing decisions.

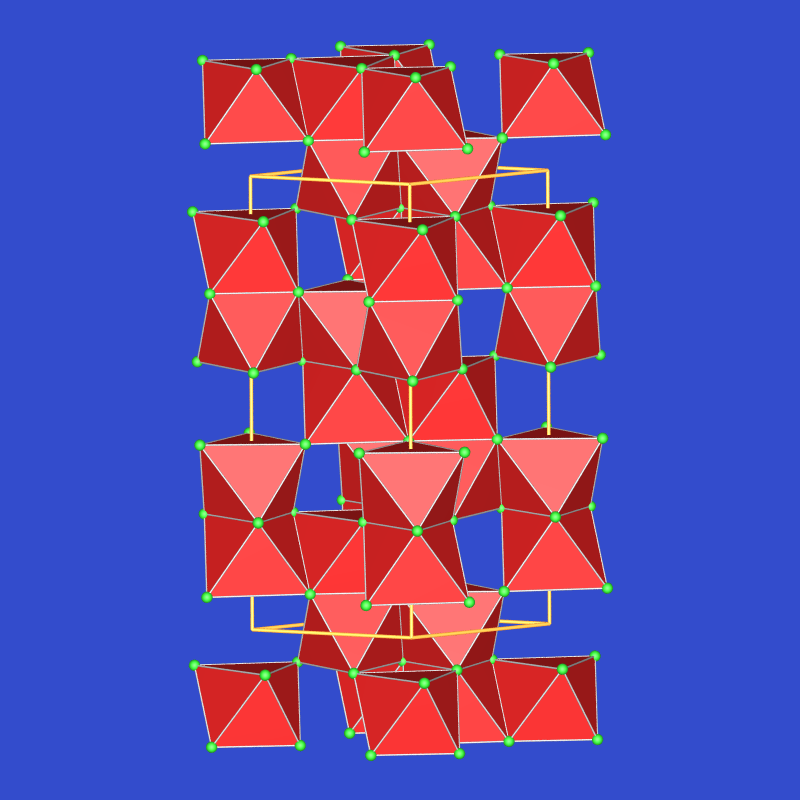

The comprehensive scope of this guide encompasses various aspects of korund-struktur, including its types, applications across different sectors, supplier vetting processes, and cost considerations. By delving into the intricacies of korund's trigonally structured crystalline form, buyers can better appreciate its hardness and suitability for applications such as abrasives, ceramics, and gemstones.

Moreover, this guide empowers B2B buyers by providing actionable insights into identifying reputable suppliers, negotiating favorable terms, and understanding market trends. With a focus on practical solutions, this resource seeks to enhance buyer confidence in sourcing korund-based products that meet their specific business needs. As you explore the guide, you will gain the tools necessary to navigate the complexities of the global korund market effectively.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Corundum | Naturally occurring, includes rubies and sapphires | Jewelry, abrasives, industrial applications | Pros: Unique colors and properties; high value. Cons: Variability in quality; higher cost. |

| Synthetic Corundum | Lab-created, uniform in quality | Industrial abrasives, gemstones | Pros: Consistent quality; lower cost. Cons: Less unique aesthetic appeal. |

| Fused Corundum | Produced by melting bauxite and alumina | Refractory materials, abrasives | Pros: High durability; versatile applications. Cons: Requires specific conditions for production. |

| Abrasive Corundum | Granulated form, often mixed with other materials | Grinding wheels, cutting tools | Pros: Effective for hard materials; diverse uses. Cons: Potentially less effective on softer materials. |

| Colored Corundum | Includes treated varieties for enhanced color | Specialty jewelry, decorative items | Pros: Attractive aesthetics; market demand. Cons: Treatment may affect resale value. |

Natural corundum is renowned for its beauty, particularly in the form of rubies and sapphires. These gemstones are valued for their unique colors and clarity, making them highly sought after in the jewelry market. For B2B buyers, the quality of natural corundum can vary significantly, which necessitates careful sourcing from reputable suppliers to ensure authenticity and quality. When considering purchasing natural corundum, buyers should assess the gemstone's origin, treatment history, and certification to maximize value.

Synthetic corundum is engineered to replicate the properties of natural corundum but offers greater uniformity in quality. This type of corundum is widely used in industrial applications, including abrasives and gemstones, due to its cost-effectiveness. B2B buyers favor synthetic corundum for its consistent performance and lower price point, making it an attractive option for bulk purchases. However, its aesthetic appeal may not match that of natural stones, which could impact marketability in certain sectors.

Fused corundum is created by melting bauxite and alumina at high temperatures, resulting in a highly durable product suitable for various industrial applications. Its robustness makes it ideal for refractory materials and abrasives. B2B buyers should consider fused corundum for its versatility and strength, particularly in demanding environments. However, the production process requires specialized equipment and conditions, which can influence supply chain logistics and costs.

Abrasive corundum is often granulated and used in grinding wheels and cutting tools, making it essential for industries requiring precision machining and surface finishing. Its effectiveness on hard materials makes it a staple in manufacturing and construction sectors. Buyers should evaluate the granule size and purity of abrasive corundum when sourcing to ensure optimal performance. While it excels in grinding harder substances, it may not be as effective on softer materials, which could limit its application scope.

Colored corundum includes treated varieties that enhance the natural color of the stones, making them appealing for specialty jewelry and decorative applications. The market demand for these stones can be significant, but buyers must consider the treatment processes involved, as they can affect resale value and authenticity. When purchasing colored corundum, B2B buyers should ensure that they obtain proper certification and documentation to maintain the integrity of their offerings in the market.

| Industry/Sector | Specific Application of korund-struktur | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Abrasives for Metal and Woodworking | Enhanced precision and surface finish in machining | Quality certification, grit size specifications |

| Electronics | Insulating substrates in electronic devices | Improved thermal and electrical insulation properties | Compliance with international standards |

| Automotive | Engine components and wear-resistant coatings | Increased durability and reduced maintenance costs | Material compatibility and performance testing |

| Construction | Corundum-based refractory materials | High-temperature resistance for industrial furnaces | Sourcing from reliable suppliers with consistent quality |

| Jewelry and Gemstones | Synthetic rubies and sapphires | Cost-effective alternatives to natural gemstones | Certification of authenticity and quality assurance |

In the manufacturing sector, korund-struktur is predominantly used in abrasives designed for metal and woodworking applications. Due to its high hardness, korund is effective in grinding, cutting, and polishing hard materials, ensuring precision and a superior surface finish. For international B2B buyers, particularly those from Europe and South America, sourcing high-quality abrasives involves verifying grit size specifications and obtaining quality certifications that guarantee performance. This ensures that the abrasives meet the stringent requirements of the manufacturing processes.

Korund-struktur serves as an essential component in the production of insulating substrates for electronic devices. Its excellent thermal and electrical insulation properties make it ideal for applications requiring high reliability and durability. Buyers from Africa and the Middle East should focus on suppliers that comply with international standards, as this ensures that the materials can withstand rigorous operational conditions. Additionally, understanding the specific application requirements is crucial for selecting the right type of korund-based insulation.

In the automotive sector, korund-struktur is utilized in the production of engine components and wear-resistant coatings. The material's durability significantly reduces maintenance costs and enhances the lifespan of automotive parts. For B2B buyers, particularly in regions like Germany and Saudi Arabia, sourcing korund-based materials involves assessing material compatibility with existing systems and conducting performance testing to ensure optimal results under operational stress.

Korund-based refractory materials are vital in the construction industry, particularly for high-temperature applications such as industrial furnaces. These materials provide exceptional resistance to thermal shock and chemical attack, ensuring the longevity of construction projects. Buyers from regions with emerging markets, like Africa and South America, should prioritize sourcing from suppliers known for consistent quality and reliability, as this impacts the overall project success and operational efficiency.

In the jewelry industry, korund-struktur is instrumental in creating synthetic rubies and sapphires, offering a cost-effective alternative to natural gemstones. This application allows jewelers to maintain high-quality standards while reducing production costs. B2B buyers should ensure that suppliers provide certification of authenticity and quality assurance to meet consumer expectations. Understanding market trends and consumer preferences can further enhance sourcing strategies for these synthetic gemstones.

A stock image related to korund-struktur.

The Problem: B2B buyers often encounter inconsistencies in the quality of korund products, which can lead to significant operational challenges. For example, a manufacturer sourcing korund for abrasives may find that variations in hardness and purity affect the performance of their final products. This unpredictability can lead to increased costs, production delays, and ultimately, customer dissatisfaction.

The Solution: To mitigate these quality issues, buyers should prioritize sourcing from reputable suppliers who provide detailed certifications and consistent quality assurance processes. Establishing a direct line of communication with suppliers can also facilitate transparency regarding their sourcing and processing methods. It is advisable to conduct regular quality audits and to request samples for testing before committing to large orders. By implementing stringent quality control measures and building strong supplier relationships, B2B buyers can ensure they receive high-quality korund consistently.

The Problem: Many B2B buyers struggle with understanding the technical specifications of korund products, which can hinder their ability to select the appropriate type for their applications. For instance, a buyer in the metalworking industry may be uncertain about the correct grade of korund to use for specific grinding tasks, leading to inefficiencies and increased wear on machinery.

The Solution: To overcome this challenge, buyers should invest time in educating themselves about the different grades and types of korund available in the market. Engaging with technical experts or consultants who specialize in material applications can provide valuable insights. Additionally, buyers should leverage resources such as product data sheets and case studies from suppliers that highlight the performance characteristics of various korund grades in real-world applications. By aligning their understanding of korund specifications with their operational needs, buyers can make more informed purchasing decisions that enhance efficiency and productivity.

The Problem: Cost fluctuations in the market for korund can pose a significant challenge for B2B buyers, especially when budgeting for long-term projects. Buyers may face unexpected price increases or find it difficult to forecast costs accurately, impacting their overall financial planning and project viability.

The Solution: To manage costs effectively, buyers should adopt a proactive procurement strategy that includes long-term contracts with suppliers to lock in prices. This approach can provide stability in budgeting and help mitigate the impact of market volatility. Additionally, establishing relationships with multiple suppliers can create competitive tension, leading to better pricing and terms. Buyers should also stay informed about market trends and potential supply chain disruptions that could affect pricing. Utilizing cost-analysis tools and engaging in strategic sourcing can further enhance cost management efforts, ensuring that buyers can navigate the complexities of korund procurement without compromising their financial goals.

When selecting materials for korund-struktur applications, it is essential to consider specific properties that directly impact product performance. Materials commonly used in conjunction with korund include alumina, zirconia, silicon carbide, and titanium dioxide. Each of these materials has unique characteristics that can influence their suitability for various applications.

Alumina (Al₂O₃) is a widely used material in korund-struktur due to its excellent hardness and thermal stability. It can withstand high temperatures (up to 1,600°C) and has good corrosion resistance against various chemicals.

Pros: Alumina is durable and cost-effective, making it suitable for a range of applications, including cutting tools and wear-resistant components. Its manufacturing processes are well-established, resulting in consistent quality.

Cons: While alumina is robust, it can be brittle, which may lead to failure under impact or shock loading. Additionally, its performance may be limited in environments with severe thermal cycling.

Impact on Application: Alumina is compatible with a variety of media, including oils, gases, and mild acids, making it suitable for chemical processing industries.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with ASTM and DIN standards, particularly for high-temperature applications.

A stock image related to korund-struktur.

Zirconia (ZrO₂) is known for its exceptional toughness and resistance to thermal shock. It is particularly valuable in applications requiring high wear resistance and mechanical strength.

Pros: Zirconia can operate effectively in extreme conditions, maintaining its integrity at high temperatures (up to 1,200°C). It also exhibits low thermal conductivity, which can be beneficial in thermal barrier applications.

Cons: The cost of zirconia is generally higher than alumina, which may be a limiting factor for some projects. Additionally, its complex manufacturing process can lead to longer lead times.

Impact on Application: Zirconia is suitable for applications in the aerospace and automotive sectors, where high-performance materials are critical.

Considerations for International Buyers: Buyers should be aware of the specific regulations regarding zirconia products in their regions, especially in Europe, where stringent quality standards apply.

Silicon carbide (SiC) is a highly durable material known for its hardness and thermal conductivity. It is often used in abrasive applications and high-performance ceramics.

Pros: Silicon carbide can withstand high temperatures (up to 1,600°C) and has excellent resistance to oxidation and corrosion. Its abrasive properties make it suitable for cutting and grinding applications.

Cons: The brittleness of silicon carbide can be a disadvantage in applications where impact resistance is required. Additionally, the manufacturing process can be complex and costly.

Impact on Application: SiC is particularly effective in applications involving harsh chemicals and high temperatures, making it ideal for the semiconductor and energy industries.

Considerations for International Buyers: Buyers should verify compliance with international standards, such as JIS and ASTM, especially for applications in high-tech industries.

Titanium dioxide (TiO₂) is known for its excellent chemical stability and is often used as a pigment. While not as hard as the other materials discussed, it has unique properties that can be advantageous in specific applications.

Pros: TiO₂ is lightweight and has strong UV resistance, making it suitable for outdoor applications. Its non-toxic nature is also a significant advantage in consumer products.

Cons: The hardness of titanium dioxide is lower than that of alumina or zirconia, which may limit its use in high-wear applications. Additionally, its cost can be higher than that of traditional pigments.

Impact on Application: TiO₂ is often used in coatings and paints, providing UV protection and durability in outdoor environments.

Considerations for International Buyers: Buyers should ensure that TiO₂ products meet local environmental regulations, particularly in Europe, where there are strict guidelines on chemical safety.

| Material | Typical Use Case for korund-struktur | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | Cutting tools, wear-resistant parts | Excellent hardness and cost-effectiveness | Brittle under impact | Medium |

| Zirconia | Aerospace components, automotive parts | Exceptional toughness and thermal stability | Higher cost and complex manufacturing | High |

| Silicon Carbide | Abrasives, high-performance ceramics | High thermal resistance and hardness | Brittle and costly to manufacture | Medium to High |

| Titanium Dioxide | Coatings, pigments | Lightweight and UV resistant | Lower hardness than alternatives | Medium |

This guide provides a comprehensive overview of the strategic material selection for korund-struktur, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

The manufacturing of korund-struktur, primarily composed of aluminum oxide (Al₂O₃), involves several critical stages. Each phase requires precision and adherence to stringent quality standards to ensure that the final product meets the expectations of international B2B buyers.

Material Preparation:

The first step involves sourcing high-quality raw materials. For korund, this includes bauxite or other aluminum-rich minerals. The materials undergo purification to remove impurities that may affect the final product's properties. This stage is crucial for ensuring that the korund produced has the desired hardness and durability.

Forming:

The purified aluminum oxide is then subjected to various forming techniques. The most common methods include:

- Sintering: This involves heating the powder at high temperatures to create a solid mass without melting it. Sintering is essential for achieving the desired density and strength.

- Pressing: In this method, the powdered material is compressed into molds to form specific shapes. This is often followed by a secondary sintering process to enhance the structural integrity.

Assembly:

If the korund is part of a larger component, assembly may involve combining it with other materials. This could include attaching korund-based components to metal or ceramic substrates, depending on the application. Techniques such as adhesive bonding or mechanical fastening are typically employed.

Finishing:

The final stage of manufacturing involves surface finishing to achieve the desired texture and appearance. Common finishing processes include grinding, polishing, and coating. These steps not only enhance the aesthetic appeal but also improve performance characteristics, such as wear resistance.

Quality assurance (QA) is a critical component of the manufacturing process for korund-struktur. It ensures that the product meets both international standards and specific industry requirements.

For B2B buyers, understanding the applicable quality standards is essential. The following international standards are particularly relevant:

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure product integrity. Key checkpoints include:

Incoming Quality Control (IQC):

This involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that only high-quality materials enter the production process is vital for the final product's performance.

In-Process Quality Control (IPQC):

During the manufacturing process, regular checks are conducted to monitor various parameters, such as temperature, pressure, and material consistency. This proactive approach allows manufacturers to identify and rectify issues before they affect the final product.

Final Quality Control (FQC):

Once the korund components are finished, a final inspection is performed. This includes dimensional checks, surface quality assessments, and performance testing to ensure compliance with specifications.

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier's quality control practices is crucial. Here are some actionable steps:

Conduct Audits:

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and identify areas for improvement.

Request Quality Reports:

Suppliers should provide detailed quality reports, including test results and compliance certificates. Reviewing these documents can help buyers ensure that the products meet required specifications.

Engage Third-Party Inspectors:

Utilizing third-party inspection services adds an extra layer of assurance. Independent inspectors can verify that the manufacturing process adheres to agreed-upon standards and that the final products are of the expected quality.

Several testing methods are employed to evaluate the quality of korund-struktur products:

Hardness Testing:

Given korund's position on the Mohs hardness scale, hardness tests such as Vickers or Knoop can provide critical information about the material's durability.

Microstructure Analysis:

Techniques like scanning electron microscopy (SEM) can be used to assess the microstructure of korund components. This analysis helps identify any defects or inconsistencies in the material.

Understanding the manufacturing processes and quality assurance practices for korund-struktur is essential for international B2B buyers. By focusing on material preparation, forming techniques, and stringent quality control measures, buyers can ensure they procure high-quality products that meet their specific needs. Additionally, verifying suppliers through audits, quality reports, and third-party inspections will help maintain high standards in the supply chain, ultimately leading to successful business outcomes.

In this sourcing guide, we provide a practical checklist to assist international B2B buyers in procuring korund-struktur effectively. This guide is particularly relevant for businesses operating in Africa, South America, the Middle East, and Europe, where understanding the technical specifications and sourcing processes is critical for successful procurement.

Clearly outline the specifications required for korund-struktur. This includes determining the grade, purity, and physical characteristics necessary for your applications. Understanding these requirements upfront helps streamline the sourcing process and ensures that you receive materials that meet your operational needs.

Stay informed about current market trends and pricing structures for korund. Conduct market analysis to understand price fluctuations and demand in different regions, which can significantly impact your procurement costs. Leverage industry reports and supplier insights to gauge fair pricing and avoid overpaying.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of delivering quality korund and assess their capabilities to meet your specific requirements.

Ensure that your potential suppliers hold the necessary certifications and adhere to international quality standards. Compliance with ISO and other relevant regulations is critical to guarantee the quality and safety of the korund products. This step not only protects your business from potential legal issues but also assures product reliability.

Before making a bulk purchase, request samples of the korund to conduct your own testing. This step allows you to verify the quality and suitability of the material for your specific applications. Be sure to evaluate the samples against your defined technical specifications to ensure compatibility.

Once you have selected a supplier, engage in negotiations to establish favorable terms and conditions. This includes discussing pricing, payment terms, delivery schedules, and warranty provisions. Clear negotiations help avoid misunderstandings and ensure that both parties are aligned on expectations.

Finally, develop a logistics plan to manage the transportation and delivery of korund. Consider factors such as shipping methods, import regulations, and potential customs challenges. A well-structured logistics plan ensures timely delivery and helps mitigate disruptions in your supply chain.

By following these steps, B2B buyers can effectively navigate the procurement process for korund-struktur, ensuring they secure high-quality materials that meet their business needs.

When considering korund-struktur sourcing, understanding the cost components is essential for making informed purchasing decisions. The major cost elements include:

Materials: The primary material cost for korund-struktur is the raw aluminum oxide (Al₂O₃). Prices can fluctuate based on global supply and demand, mining activities, and geopolitical factors. Buyers should keep abreast of market trends to anticipate price changes.

Labor: This encompasses the workforce required for manufacturing processes. Labor costs can vary significantly based on the region; for instance, labor in Europe may be higher compared to Africa or South America. Understanding local wage standards can help buyers estimate overall costs accurately.

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory management. A higher overhead can indicate a facility with advanced technology and better quality control, which may justify higher product prices.

Tooling: Specialized tooling may be necessary for producing specific korund-struktur products. These costs can be substantial, especially for custom designs. Buyers should factor in these expenses when evaluating total costs.

Quality Control (QC): Ensuring product quality can incur additional costs. Comprehensive QC processes are crucial for minimizing defects and ensuring compliance with international standards, particularly for buyers in Europe and the Middle East, where quality certifications are often mandatory.

Logistics: Transportation costs can significantly impact total sourcing expenses. Factors such as distance from suppliers, shipping methods, and customs duties should be carefully evaluated to avoid unexpected costs.

Margin: Supplier margins can vary widely based on market positioning, service level, and perceived value. Understanding a supplier's pricing strategy can provide insights into potential negotiation avenues.

Several factors can influence the pricing of korund-struktur products:

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract lower per-unit prices due to economies of scale. Buyers should assess their needs against suppliers' MOQs to optimize costs.

Specifications and Customization: Custom products often come at a premium. Buyers should clarify specifications early to avoid costly changes later in the production process.

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO standards) can lead to increased costs but may also enhance product performance and longevity. Buyers must balance upfront costs with long-term benefits.

Supplier Factors: The reliability, reputation, and location of suppliers can affect pricing. Suppliers with a proven track record may charge more but offer better service and fewer risks.

Incoterms: Understanding the Incoterms agreed upon in contracts is crucial as they define who bears the costs and risks at various stages of transportation. This can significantly impact total landed costs.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can implement several strategies to optimize costs:

Negotiation: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a strong relationship can yield better deals over time.

Cost-Efficiency Analysis: Regularly review the total cost of ownership (TCO) rather than just initial purchase prices. TCO considers maintenance, operational costs, and potential downtime, providing a clearer picture of long-term value.

Understanding Pricing Nuances: Familiarize yourself with local market conditions and pricing strategies in the supplier's country. This knowledge can empower buyers to negotiate effectively and avoid being overcharged.

Regional Considerations: Buyers from Europe may have different compliance and quality expectations compared to those in Africa or South America. Tailoring sourcing strategies to regional requirements can enhance success.

Prices for korund-struktur materials and products can fluctuate due to various factors, including market conditions, supplier changes, and geopolitical events. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always verify current prices with suppliers before making purchasing decisions.

When evaluating solutions for industrial applications, particularly in markets across Africa, South America, the Middle East, and Europe, it's essential to consider viable alternatives to established technologies like the korund-struktur. This section provides a comparative analysis of korund-struktur against other methods, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Korund-Struktur | Alternative 1: Diamond-Based Solutions | Alternative 2: Silicon Carbide (SiC) |

|---|---|---|---|

| Performance | High hardness (Mohs 9) | Superior hardness (Mohs 10) | High thermal conductivity |

| Cost | Moderate cost | High cost due to rarity | Lower cost than diamond |

| Ease of Implementation | Easy to integrate into existing processes | Requires specialized equipment | Relatively easy to implement |

| Maintenance | Low maintenance | High maintenance due to wear | Moderate maintenance |

| Best Use Case | Ideal for grinding and polishing | Best for cutting tools in precision work | Excellent for high-temperature applications |

Diamond-based solutions, while offering the highest hardness, come with a significant financial investment due to the material's rarity and production costs. Their performance in cutting and grinding applications is unmatched, making them ideal for precision work. However, the high cost and maintenance requirements can deter B2B buyers, especially in cost-sensitive markets.

Silicon Carbide (SiC) is gaining traction as a versatile alternative, particularly in applications requiring high thermal conductivity and resistance to oxidation. While it offers a lower cost than diamond, its performance in hardness and durability is less than that of korund and diamond. SiC is easier to implement in existing systems compared to diamond solutions, making it an appealing option for many industries, especially in electronics and automotive sectors.

When selecting the right solution, B2B buyers should carefully assess their specific needs and constraints. Korund-struktur offers a balanced approach with high performance and low maintenance, making it suitable for a range of industrial applications. However, if budget allows and precision is paramount, diamond-based solutions may be the best option. Conversely, for applications needing efficient thermal management and cost-effectiveness, Silicon Carbide could be the ideal alternative. Analyzing these factors will empower buyers to make informed decisions that align with their operational goals and financial capabilities.

When evaluating korund-structure for industrial applications, understanding its essential technical properties is crucial for B2B buyers. Here are some of the most significant specifications:

Material grade refers to the purity and composition of korund (Al₂O₃), which can significantly impact its performance in applications such as abrasives and ceramics. Higher purity grades exhibit superior hardness and resistance to wear, making them ideal for demanding industrial processes. Buyers should verify the grade to ensure it meets their operational standards.

Korund ranks 9 on the Mohs hardness scale, just below diamond. This exceptional hardness allows it to be used effectively in cutting tools and grinding applications. For manufacturers and processors, this property is vital as it indicates the material's durability and longevity, reducing the need for frequent replacements.

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before failing. Korund's high tensile strength makes it suitable for high-stress applications, such as in the production of grinding wheels or refractory materials. Understanding tensile strength is essential for buyers to ensure that the material will perform reliably under operational conditions.

Korund exhibits excellent thermal stability, allowing it to maintain its properties at high temperatures. This characteristic is especially important in industries that involve high-temperature processes, such as metallurgy or ceramics. B2B buyers should consider thermal stability when selecting korund for applications where temperature fluctuations are a concern.

Korund is chemically inert, meaning it does not react with acids or bases under normal conditions. This property makes it highly suitable for use in corrosive environments. Buyers must assess the chemical resistance of korund to ensure it will not degrade when exposed to specific substances in their applications.

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. For korund products, precise tolerances are crucial in applications requiring exact specifications, such as in precision grinding or manufacturing. Buyers should specify tolerance levels to ensure that the materials meet their production requirements.

Understanding trade terminology is essential for international B2B buyers. Here are some common terms that are particularly relevant in korund transactions:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of korund, OEMs may source high-grade korund materials for use in their products. Buyers should consider OEM partnerships for reliable sourcing of quality materials.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for buyers to manage inventory and cash flow effectively. When dealing with korund suppliers, knowing the MOQ can help in planning purchases according to production needs.

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. For korund purchases, submitting an RFQ can help buyers compare offers from multiple suppliers, ensuring they secure the best deal.

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms is vital for B2B buyers to understand their obligations regarding shipping costs, insurance, and risk during transit.

Lead time refers to the time it takes for a supplier to fulfill an order after it has been placed. For korund products, lead times can vary based on material availability and production schedules. Buyers should inquire about lead times to plan their procurement and production schedules effectively.

Certification indicates that a product meets certain standards or regulations. In the korund industry, certifications may relate to quality, safety, or environmental compliance. Buyers should look for certified products to ensure they are sourcing reliable and compliant materials.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing korund-structure materials for their operations.

The korund-struktur sector is experiencing significant growth, driven by increasing demand in industries such as abrasives, ceramics, and electronics. Key market dynamics include the rise of automation and digitalization, which are streamlining sourcing processes and enhancing supply chain transparency. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these trends is crucial.

Emerging technologies, such as Artificial Intelligence (AI) and Internet of Things (IoT), are transforming how manufacturers source and utilize korund-based materials. These technologies facilitate better inventory management and predictive analytics, allowing businesses to respond swiftly to market demands. Moreover, the shift towards online procurement platforms is simplifying the purchasing process, enabling buyers from diverse regions to access global suppliers more efficiently.

Another significant trend is the increasing focus on product customization. As industries evolve, there is a growing need for tailored solutions that meet specific application requirements. This trend is particularly relevant in sectors like automotive and aerospace, where precision materials are critical. B2B buyers should prioritize partnerships with suppliers that can offer flexible manufacturing capabilities and a broad range of korund products.

Sustainability has become a paramount concern for businesses worldwide, impacting sourcing decisions across all sectors, including korund-struktur. The environmental impact of mining and processing korund raises questions about ethical sourcing practices. International B2B buyers must prioritize suppliers that demonstrate a commitment to sustainable practices, including responsible extraction methods and waste management.

The importance of ethical supply chains cannot be overstated. Companies are increasingly held accountable for their sourcing decisions, and consumers are more inclined to support brands that prioritize sustainability. As a result, certifications such as ISO 14001 for environmental management systems and other 'green' labels are becoming essential for suppliers in the korund sector. Buyers should seek out suppliers who can provide proof of these certifications to ensure compliance with global sustainability standards.

Furthermore, the demand for eco-friendly alternatives is growing. B2B buyers should explore korund products that incorporate recycled materials or sustainable processing methods. This shift not only meets market demand for green products but also positions companies as leaders in corporate social responsibility.

The korund mineral, primarily composed of aluminum oxide (Al2O3), has a rich history that dates back thousands of years. Historically, it was used in ancient civilizations for decorative purposes and as a gemstone. However, its industrial significance has surged in the past century, primarily due to its hardness and thermal stability, making it an ideal material for abrasives and refractory applications.

In the B2B context, the evolution of korund-struktur has been marked by technological advancements that have expanded its applications across various industries. From its initial use in traditional grinding wheels to modern applications in cutting-edge electronics and ceramics, korund has adapted to meet the needs of evolving markets. Understanding this historical context allows international buyers to appreciate the material's versatility and the potential for future innovations within the sector.

How do I choose the right korund-struktur supplier for my business needs?

Selecting the right supplier for korund-struktur involves thorough research and evaluation. Start by identifying suppliers with a proven track record in quality and reliability. Check their certifications and compliance with international standards. Request samples to assess the quality of their korund products. Additionally, consider their ability to meet your specific requirements, such as size, grade, and customization options. Engaging with suppliers who have experience in your region (Africa, South America, the Middle East, or Europe) can also facilitate smoother communication and logistics.

What are the key characteristics of high-quality korund-struktur?

High-quality korund-struktur should exhibit exceptional hardness, typically rated 9 on the Mohs scale, making it suitable for various industrial applications. Look for products with minimal impurities and consistent grain sizes, which enhance performance in abrasive applications. The crystal structure should be intact, as any flaws can affect the material's durability and effectiveness. Moreover, consider the supplier's quality assurance processes to ensure that their products consistently meet industry standards.

What are the typical minimum order quantities (MOQs) for korund-struktur?

Minimum order quantities for korund-struktur can vary significantly among suppliers, typically ranging from 100 kg to several tons. Factors influencing MOQs include the type of korund (e.g., synthetic vs. natural), customization requirements, and supplier policies. For international buyers, it’s advisable to negotiate MOQs based on your purchasing capacity and project needs. Smaller businesses may also seek suppliers willing to accommodate lower quantities, especially during initial orders.

How can I ensure the quality of korund-struktur during international shipping?

To guarantee the quality of korund-struktur during shipping, collaborate closely with your supplier to implement robust packaging and handling procedures. Use durable containers that can withstand transportation stresses, and ensure that the material is protected from moisture and contamination. Consider employing third-party quality assurance inspections before shipment to confirm that the product meets your specifications. Additionally, selecting reliable logistics partners with experience in handling industrial materials can minimize risks during transit.

What customization options are available for korund-struktur products?

Many suppliers offer customization options for korund-struktur to meet specific industrial requirements. Customization can include variations in grain size, purity levels, and packaging formats. Suppliers may also provide tailored formulations for specialized applications, such as abrasives or cutting tools. When discussing customization, be clear about your application needs and any performance criteria that the korund must meet. This dialogue will help ensure that the final product aligns with your operational goals.

What are the common applications of korund-struktur in various industries?

Korund-struktur is widely used across several industries, primarily in abrasives, cutting tools, and ceramics. Its hardness makes it ideal for grinding and polishing applications in metalworking, automotive, and construction sectors. Additionally, korund is utilized in the production of high-performance refractories and as a filler in various composite materials. Understanding the specific applications relevant to your industry can guide you in selecting the right type of korund for your operational needs.

How do I handle disputes or quality issues with my korund-struktur supplier?

In the event of disputes or quality issues with your korund-struktur supplier, prompt and clear communication is key. Start by documenting the issue with detailed evidence, including photographs and product specifications. Reach out to your supplier to discuss the problem and seek resolution, whether through replacement, refunds, or corrective measures. If direct negotiations fail, consider involving a third-party mediator or arbitration, especially if a contractual agreement exists. Maintaining a professional relationship with your supplier can facilitate smoother negotiations and resolutions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of korund-structure presents significant opportunities for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the unique properties of korund, including its hardness and crystalline structure, enables buyers to make informed decisions that align with their specific needs. By prioritizing quality suppliers and establishing long-term partnerships, businesses can optimize their production processes and reduce costs.

The value of strategic sourcing lies not only in cost savings but also in enhancing the overall quality of materials. Buyers should leverage data-driven insights to evaluate potential suppliers, ensuring they meet stringent quality standards and can provide reliable supply chains. As global markets continue to evolve, the ability to adapt sourcing strategies will be crucial in maintaining a competitive edge.

Looking forward, B2B buyers are encouraged to explore innovative sourcing strategies that incorporate sustainability and technological advancements. By embracing these trends, companies can not only meet their operational goals but also contribute positively to their communities and the environment. Engage with suppliers today to unlock the full potential of korund-structure in your operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina