In the quest for high-quality lija carburo de silicio, international B2B buyers often face the challenge of navigating a complex global market. Sourcing reliable suppliers while ensuring product quality and competitive pricing can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe, including countries like Colombia and Germany. This guide is designed to simplify that process, offering a comprehensive overview of lija carburo de silicio, its various types, applications, and the critical factors that influence purchasing decisions.

Throughout this guide, we will delve into the different forms of lija carburo de silicio available in the market, explore its applications across industries, and provide insights on effective supplier vetting techniques. Additionally, we will discuss cost considerations and pricing strategies to help you make informed decisions that align with your business objectives.

By empowering B2B buyers with essential knowledge and practical tools, this guide aims to enhance your procurement strategy, ensuring that you can confidently source high-quality lija carburo de silicio that meets your specific needs. Whether you're a seasoned buyer or new to the market, understanding these dynamics will enable you to navigate the complexities of international sourcing effectively.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Silicon Carbide | High purity, uniformity, and finer grain structure | Precision grinding, polishing, and blasting | Pros: Excellent finish; Cons: Higher cost |

| Green Silicon Carbide | More abrasive than black, with high thermal resistance | Metalworking, ceramics, and glass industries | Pros: Versatile; Cons: Limited availability |

| Silicon Carbide Grit | Coarse particles, ideal for heavy-duty applications | Sanding, surface preparation, and cutting | Pros: Durable; Cons: May leave rough finishes |

| Silicon Carbide Powder | Fine particles used for intricate applications | Abrasive pastes, coatings, and composites | Pros: High adaptability; Cons: Requires careful handling |

| Silicon Carbide Discs | Pre-cut discs for easy application | Woodworking, metal finishing, and automotive | Pros: Time-saving; Cons: Limited to disc formats |

Black Silicon Carbide is known for its high purity and uniform grain structure, making it an ideal choice for precision grinding and polishing applications. Its finer grain allows for a smoother finish, which is crucial for industries that require high-quality surface finishes, such as aerospace and automotive. Buyers should consider its higher cost compared to other types, but the superior results often justify the investment.

Green Silicon Carbide is significantly more abrasive than its black counterpart and boasts excellent thermal resistance. This makes it suitable for a variety of applications, including metalworking and ceramics. While it is highly versatile, its limited availability can pose challenges for international buyers. Companies should evaluate their supply chain to ensure consistent access to this material.

Silicon Carbide Grit is characterized by its coarse particle size, making it perfect for heavy-duty applications like sanding and surface preparation. It is particularly effective for removing material quickly, making it a favorite in construction and manufacturing sectors. However, buyers should be aware that it may leave a rougher finish, which might not be suitable for all applications.

Silicon Carbide Powder consists of fine particles that can be used in various intricate applications, including abrasive pastes and coatings. Its high adaptability allows it to be tailored for specific uses, making it a valuable asset in industries such as electronics and optics. However, careful handling is required due to its fine nature, which can lead to dust formation.

Silicon Carbide Discs are pre-cut for easy application, saving time in processes like woodworking and metal finishing. Their convenience makes them a popular choice in automotive and manufacturing settings where efficiency is key. While they offer significant time savings, buyers should note that their use is limited to disc formats, which may not suit all project requirements.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of lija carburo de silicio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision grinding of turbine components | Enhanced durability and efficiency of components | Certification standards, supplier reliability, and material purity |

| Automotive | Manufacturing of brake pads and clutches | Improved friction performance and longevity | Compliance with automotive standards, testing certifications, and cost-effectiveness |

| Electronics | Semiconductor wafer fabrication | Higher yield rates and reduced defects | Quality control measures, sourcing of high-purity materials, and technological compatibility |

| Construction | Abrasive tools for stone and concrete cutting | Increased cutting speed and reduced wear | Tool design specifications, compatibility with existing machinery, and bulk sourcing options |

| Renewable Energy | Solar panel manufacturing | Enhanced energy conversion efficiency | Supplier certifications, material sourcing transparency, and cost competitiveness |

In the aerospace industry, lija carburo de silicio is extensively used for precision grinding of turbine components. Its hardness and thermal stability allow for the effective shaping and finishing of critical parts, which are essential for ensuring optimal performance and safety in aircraft engines. By utilizing this material, manufacturers can achieve enhanced durability and efficiency, ultimately leading to lower maintenance costs and improved operational reliability. International buyers should consider certification standards and the supplier's reliability when sourcing this material.

In the automotive sector, lija carburo de silicio is crucial for the production of brake pads and clutches. Its unique properties contribute to improved friction performance and longevity, which are vital for vehicle safety and efficiency. By integrating this material into their products, automotive manufacturers can enhance the performance of their braking systems, leading to a competitive edge in the market. Buyers must ensure compliance with automotive standards and consider testing certifications when sourcing.

The electronics industry leverages lija carburo de silicio in semiconductor wafer fabrication, where its superior hardness and thermal conductivity are essential. This application helps in achieving higher yield rates and reducing defects during the manufacturing process. Given the increasing demand for high-performance electronic devices, sourcing high-purity materials is critical for maintaining quality control. International buyers should focus on the technological compatibility of suppliers and their ability to meet stringent quality standards.

In construction, lija carburo de silicio is widely used in the production of abrasive tools for cutting stone and concrete. Its abrasive qualities significantly increase cutting speed and reduce wear on tools, leading to more efficient project completion. For buyers in this sector, understanding tool design specifications and ensuring compatibility with existing machinery are important considerations when sourcing this material.

In the renewable energy sector, particularly in solar panel manufacturing, lija carburo de silicio is used to enhance energy conversion efficiency. Its application in the production process contributes to higher performance and reliability of solar panels, which is crucial for meeting the growing demand for renewable energy solutions. Buyers should prioritize supplier certifications and material sourcing transparency to ensure cost competitiveness and quality in their procurement processes.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: B2B buyers often encounter challenges in sourcing high-quality 'lija carburo de silicio' that meets specific application requirements. The market is flooded with suppliers, and distinguishing between premium-grade and subpar products can be daunting. Buyers may worry about the longevity and performance of the materials, especially when they require them for precision applications in industries like automotive, aerospace, or electronics. The fear of investing in inferior products that could compromise their processes or lead to costly rework is a significant concern.

The Solution: To overcome these challenges, B2B buyers should establish a robust sourcing strategy that includes thorough supplier evaluations. Begin by requesting certifications and quality assurance documentation to verify that the 'lija carburo de silicio' meets industry standards, such as ISO 9001. Additionally, consider engaging with suppliers who specialize in your specific industry application, as they will have a better understanding of your needs. Leverage online marketplaces and trade shows to connect with reputable manufacturers, and don't hesitate to ask for samples before committing to a large order. This proactive approach ensures that you are investing in high-quality materials that will enhance your operational efficiency and product reliability.

The Problem: Another common pain point for B2B buyers is the complexity surrounding the technical specifications of 'lija carburo de silicio.' With various grades, grain sizes, and bonding agents available, it can be overwhelming to determine which type aligns with their specific needs. Misunderstanding these specifications can lead to poor performance in applications such as grinding, polishing, or cutting, ultimately affecting product quality and increasing costs.

The Solution: To navigate this complexity, B2B buyers should invest time in educating themselves about the different grades and specifications of 'lija carburo de silicio.' Collaborate with your technical team to define the specific requirements for your application, including desired hardness, particle size, and bonding type. Many manufacturers offer technical datasheets that provide detailed information on performance characteristics. Utilize these resources to compare products effectively. Additionally, consider reaching out to suppliers for technical support; many are willing to provide guidance on selecting the right product for your application. This collaborative approach not only reduces the risk of errors but also enhances product performance.

The Problem: Supply chain disruptions are a persistent issue that B2B buyers face, particularly in the context of global sourcing for 'lija carburo de silicio.' Factors such as geopolitical tensions, transportation delays, or raw material shortages can lead to unexpected lead times and inventory shortages. These disruptions can hinder production schedules and negatively impact customer satisfaction, leading to potential loss of business.

The Solution: To mitigate these risks, B2B buyers should adopt a multi-sourcing strategy. By diversifying your supplier base across different regions, you can reduce dependence on a single source and improve supply chain resilience. Additionally, maintaining an open line of communication with suppliers is crucial; regular check-ins can help anticipate potential disruptions and allow for timely adjustments in orders. Implementing inventory management systems that utilize real-time data can also aid in forecasting demand and adjusting procurement strategies accordingly. By taking these proactive measures, buyers can ensure a more stable supply of 'lija carburo de silicio,' ultimately protecting their operations and maintaining customer satisfaction.

When selecting materials for lija carburo de silicio (silicon carbide sanding paper), international B2B buyers must consider various factors, including material properties, application suitability, and compliance with regional standards. Below is an analysis of three common materials used in the production of lija carburo de silicio, focusing on their key properties, advantages, disadvantages, and specific considerations for international markets.

Key Properties:

Silicon carbide is known for its exceptional hardness and thermal stability, withstanding temperatures up to 1,600°C. It also exhibits excellent corrosion resistance, making it suitable for various abrasive applications.

Pros & Cons:

The durability of SiC is a significant advantage, providing a long lifespan in abrasive applications. However, it can be more expensive than other materials, which may affect cost-sensitive projects. The manufacturing complexity is moderate, requiring specialized equipment.

Impact on Application:

SiC is highly effective for sanding hard materials, including metals and ceramics. Its compatibility with aggressive media makes it a preferred choice in industries like automotive and aerospace.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM for material properties. In Europe, adherence to DIN standards is crucial for market acceptance.

Key Properties:

Aluminum oxide is another common abrasive material, noted for its toughness and ability to resist wear. It operates effectively at temperatures up to 1,200°C and offers good corrosion resistance.

Pros & Cons:

While aluminum oxide is generally less expensive than silicon carbide, it may not perform as well on harder surfaces. Its manufacturing process is relatively straightforward, which can lead to lower production costs.

Impact on Application:

This material is ideal for sanding softer metals and wood, making it versatile across various industries, including construction and woodworking.

Considerations for International Buyers:

For buyers in the Middle East and Europe, it's essential to check for compliance with JIS and DIN standards, which can impact the acceptance of aluminum oxide products in these markets.

Key Properties:

Zirconia alumina combines the properties of zirconium and aluminum oxide, providing enhanced durability and heat resistance. It can withstand temperatures up to 1,500°C and offers excellent fracture toughness.

Pros & Cons:

The primary advantage of zirconia alumina is its longevity, making it suitable for heavy-duty applications. However, it is typically more expensive than aluminum oxide, which may be a consideration for budget-conscious buyers.

Impact on Application:

This material is particularly effective for grinding and sanding tough materials, such as stainless steel and high-strength alloys, making it ideal for the metalworking industry.

Considerations for International Buyers:

Buyers in Germany and other European countries should ensure that zirconia alumina products meet the stringent quality and safety standards set by local regulations.

| Material | Typical Use Case for lija carburo de silicio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Sanding hard materials like metals and ceramics | Exceptional hardness and durability | Higher cost compared to alternatives | High |

| Aluminum Oxide (Al2O3) | Sanding softer metals and wood | Cost-effective and versatile | Less effective on harder surfaces | Medium |

| Zirconia Alumina | Grinding and sanding tough materials like stainless steel | Enhanced durability and heat resistance | Higher cost than aluminum oxide | High |

In conclusion, selecting the right material for lija carburo de silicio requires a thorough understanding of the specific applications, material properties, and regional compliance standards. By carefully considering these factors, international B2B buyers can make informed decisions that enhance product performance and market competitiveness.

The manufacturing of lija carburo de silicio (silicon carbide abrasive) involves several critical stages that ensure the final product meets high-performance standards. Understanding these stages is essential for international B2B buyers looking to source reliable and high-quality abrasives.

The first stage in the manufacturing process is material preparation. Silicon carbide is produced by heating silica and carbon in a furnace at high temperatures (around 2,500°C). This process results in the formation of silicon carbide crystals. The raw materials must be of high purity to minimize impurities in the final product. Suppliers often conduct quality checks on raw materials to ensure they comply with industry standards before proceeding to the next stage.

Once the silicon carbide is synthesized, the next stage is forming. The material is crushed and classified into different sizes, depending on the intended application. Advanced techniques such as pressing and sintering are employed to create abrasive sheets or discs. During this stage, it's vital to maintain precise control over particle size distribution, as it directly affects the performance of the abrasive. B2B buyers should inquire about the forming methods used by suppliers to ensure they align with their specific needs.

In the assembly stage, the shaped lija carburo de silicio is combined with backing materials, which could be paper, cloth, or film. The choice of backing material affects the durability and flexibility of the abrasive product. Adhesives are applied to ensure strong bonding between the abrasive and backing. Buyers should evaluate the types of adhesives used, as this can impact the product's performance and longevity.

Finishing processes, such as grinding and polishing, are crucial to achieving the desired surface texture and performance characteristics of the abrasive. This stage often includes additional quality control measures to check for surface defects and ensure uniformity. B2B buyers should inquire about the finishing techniques employed and any certifications that assure the quality of the final product.

Quality assurance (QA) is integral to the manufacturing of lija carburo de silicio. Various international and industry-specific standards guide these processes to ensure product reliability and safety.

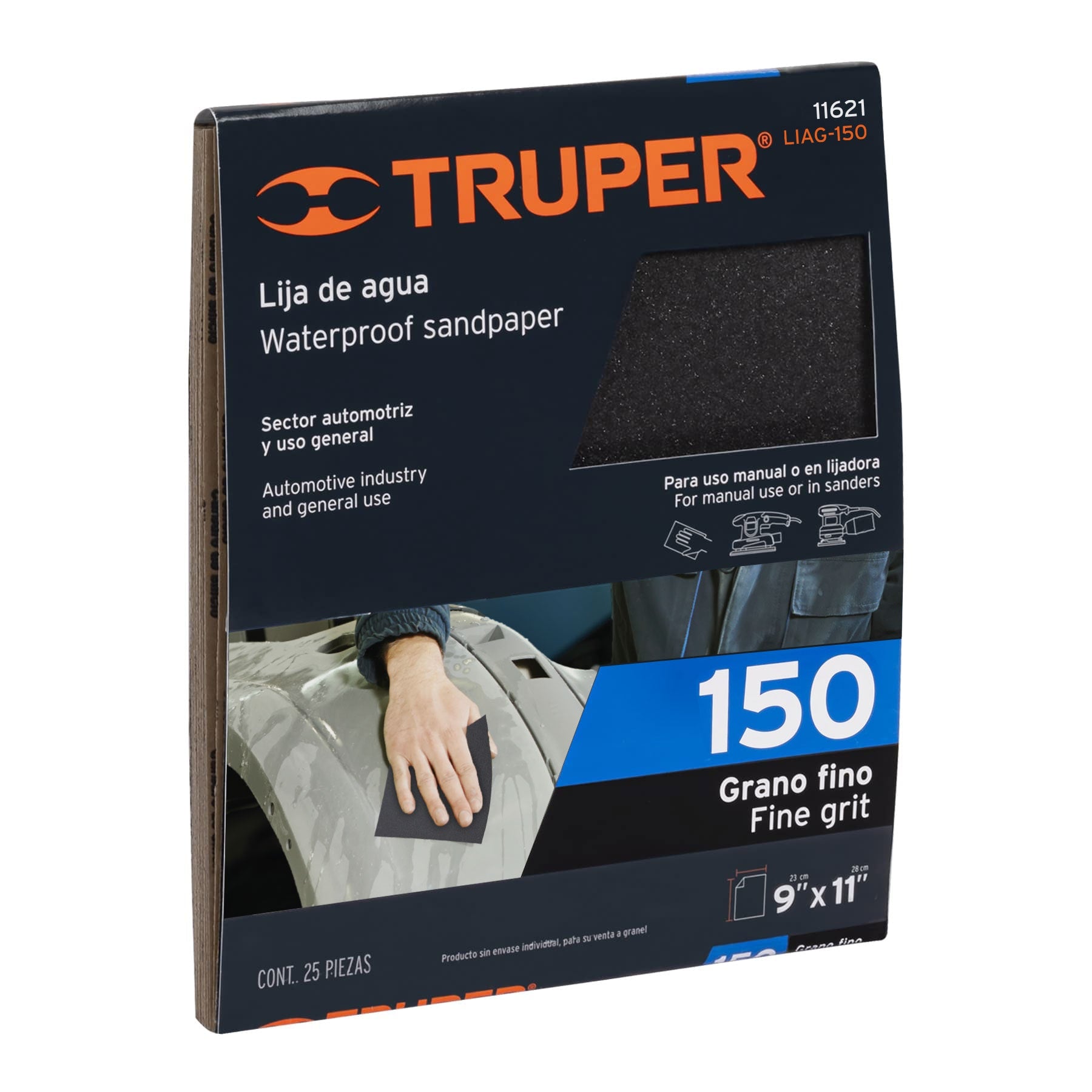

A stock image related to lija carburo de silicio.

One of the most recognized quality management standards is ISO 9001, which focuses on various aspects of quality management systems. Manufacturers of lija carburo de silicio should ideally be certified to this standard, which indicates a commitment to quality and continuous improvement. Other relevant certifications may include CE marking for compliance with European safety standards and API standards for specific applications in the oil and gas industry.

Quality control in the manufacturing of lija carburo de silicio typically involves several checkpoints:

Incoming Quality Control (IQC): This step involves testing raw materials before they enter the production process. Suppliers should provide certificates of analysis (CoA) for raw materials to verify compliance with specifications.

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring ensures that processes are in control. Techniques such as statistical process control (SPC) can be employed to track variations.

Final Quality Control (FQC): Once the product is completed, final inspections are performed to ensure it meets all specifications and standards. This may include visual inspections, dimensional checks, and performance tests.

B2B buyers looking to ensure the quality of lija carburo de silicio from suppliers should consider several verification methods:

Buyers should request regular quality assurance reports from suppliers, including summaries of IQC, IPQC, and FQC activities. Conducting supplier audits can also provide insights into the manufacturing process and quality management practices. An audit allows buyers to assess compliance with international standards and identify areas for improvement.

Engaging third-party inspection services adds an extra layer of assurance. Independent inspectors can evaluate the manufacturing process, check compliance with specifications, and conduct product testing. This is particularly valuable for international buyers who may face challenges assessing suppliers in different regions.

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, must navigate various nuances when sourcing lija carburo de silicio.

Different regions may have varying standards and regulations regarding product safety and quality. For example, European buyers may prioritize CE certification, while buyers in the Middle East might focus on compliance with local standards. Understanding these regional requirements is crucial for successful sourcing.

Cultural differences can impact communication and expectations regarding quality assurance. B2B buyers should be aware of these differences and establish clear communication channels with suppliers. Regular updates and feedback loops can help mitigate misunderstandings and ensure alignment on quality expectations.

The manufacturing processes and quality assurance measures for lija carburo de silicio are critical for ensuring product reliability and performance. By understanding these processes and implementing thorough verification methods, international B2B buyers can confidently source high-quality abrasives that meet their specific needs. Being proactive in quality assurance will not only enhance product satisfaction but also foster long-term supplier relationships.

A stock image related to lija carburo de silicio.

When sourcing 'lija carburo de silicio' (silicon carbide paper), it's essential to follow a structured approach to ensure quality and reliability. This guide provides a practical checklist to help international B2B buyers navigate the procurement process effectively, particularly for those in Africa, South America, the Middle East, and Europe.

Clearly outlining your requirements is the first step in sourcing silicon carbide paper. Specify the grit size, dimensions, and intended application (e.g., automotive, woodworking, metalworking). This clarity will help you communicate effectively with suppliers and ensure that you receive the right product for your needs.

Understanding the market landscape is critical. Research potential suppliers and identify those that specialize in silicon carbide products. Look for companies with a strong reputation and positive reviews from other B2B buyers.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, product catalogs, and references from buyers in similar industries or regions. This due diligence helps minimize risks associated with sourcing.

Certifications can serve as indicators of quality and compliance with industry standards. Check if the supplier holds relevant certifications, such as ISO 9001 or other specific industry certifications.

Before finalizing an order, always request samples of the silicon carbide paper. Testing samples allows you to evaluate the quality and suitability for your specific applications.

Once you've identified a suitable supplier, engage in negotiations to establish favorable terms. Discuss pricing, minimum order quantities, payment terms, and delivery schedules.

After negotiations, finalize your order and confirm the logistics of delivery. Ensure all terms are documented and agreed upon to avoid misunderstandings.

By following this step-by-step checklist, B2B buyers can streamline the sourcing process for 'lija carburo de silicio' and ensure they partner with reliable suppliers who meet their quality and operational needs.

When sourcing lija carburo de silicio (silicon carbide), it's essential to understand the various cost components that contribute to the overall pricing structure. The main cost elements include:

Materials: The cost of raw materials significantly impacts the pricing of silicon carbide. Prices can fluctuate based on global supply and demand, so buyers should keep an eye on market trends.

Labor: Labor costs vary by region and can influence manufacturing costs. In regions with higher labor costs, such as Europe, the final product may be priced higher compared to regions with lower labor costs.

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help mitigate these costs.

Tooling: Specialized tooling for silicon carbide production can require a significant upfront investment. Buyers should inquire about tooling costs, especially if customization is needed.

Quality Control (QC): Implementing rigorous quality control measures ensures the product meets specific standards. These costs should be factored into the overall pricing.

Logistics: Shipping and handling costs can vary significantly based on the destination and shipping method. Buyers should consider these costs, particularly for international orders.

Margin: Suppliers typically add a profit margin to their costs. Understanding the typical margin in the industry can help buyers gauge fair pricing.

Several factors influence the pricing of lija carburo de silicio:

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to better pricing due to economies of scale. Buyers should negotiate MOQs to optimize their costs.

Specifications and Customization: Customized products may incur higher costs due to additional processing and material requirements. Clearly defining specifications can help avoid unexpected costs.

Materials: The quality of materials used can greatly affect pricing. Higher purity silicon carbide will generally cost more, but it may offer better performance in applications.

Quality Certifications: Products that meet international quality standards may be priced higher. Buyers should evaluate whether these certifications are necessary for their applications.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven quality and service.

Incoterms: The chosen Incoterms (International Commercial Terms) dictate who is responsible for shipping costs and risks. Understanding these terms can help buyers manage costs effectively.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should consider the following tips for effective negotiation and cost management:

Negotiate Terms: Always negotiate prices and terms with suppliers. Establishing a long-term relationship can also result in better pricing over time.

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, including maintenance, operational costs, and potential downtime.

Understand Pricing Nuances: Be aware of pricing variations based on region, supplier, and product specifications. Conduct thorough market research to benchmark prices.

Leverage Volume: If possible, consolidate orders to meet higher MOQs, which can lead to significant discounts.

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times, potentially offsetting higher product prices.

Prices for lija carburo de silicio can vary widely based on market conditions, supplier negotiations, and specific requirements. It is advisable for buyers to conduct thorough due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

When considering the procurement of materials or technologies in B2B contexts, understanding the available alternatives to a specific solution is crucial. For buyers exploring options, comparing lija carburo de silicio with other viable solutions can help inform a strategic purchasing decision. Below is a detailed analysis of lija carburo de silicio against two alternatives: Alumina and Diamond Abrasives.

| Comparison Aspect | Lija Carburo De Silicio | Alumina | Diamond Abrasives |

|---|---|---|---|

| Performance | High hardness and durability, excellent for cutting and grinding | Good hardness, less effective than carbide | Superior cutting efficiency and durability |

| Cost | Moderate | Low to moderate | High |

| Ease of Implementation | Relatively straightforward to integrate | Easy to source and use | Requires specialized equipment for use |

| Maintenance | Low maintenance needed | Low maintenance | Requires regular checks and maintenance |

| Best Use Case | Ideal for hard materials like metals and ceramics | Suitable for softer materials like plastics | Best for precision cutting in high-tech applications |

Alumina is a widely used abrasive material known for its versatility and cost-effectiveness. It performs well for a range of applications, particularly in industries dealing with softer materials. The primary advantage of alumina is its lower cost, making it an attractive option for budget-conscious buyers. However, its performance does not match that of lija carburo de silicio when it comes to harder materials. For applications requiring high durability and cutting efficiency, alumina may fall short.

Diamond abrasives are renowned for their exceptional cutting ability and longevity, making them the preferred choice for high-precision tasks. Their performance is unmatched, particularly in hard materials, providing a superior finish and reduced processing times. However, the high cost of diamond abrasives can be a significant barrier for many businesses, particularly small to medium-sized enterprises. Additionally, the need for specialized equipment to use diamond abrasives can complicate their integration into existing processes.

When selecting the right solution, B2B buyers must consider their specific application needs, budget constraints, and the materials they typically work with. If the focus is on cost-efficiency and versatility, alumina may be the best choice. For projects requiring top-tier performance and precision, despite the higher costs, diamond abrasives could be justified. Lija carburo de silicio serves as a robust middle-ground option, offering high performance for hard materials at a moderate price, making it suitable for diverse industrial applications. Buyers should assess their operational requirements and long-term goals to make an informed decision that aligns with their business strategy.

When considering the procurement of lija carburo de silicio (silicon carbide sandpaper), B2B buyers must understand its technical properties to ensure they choose the right product for their applications. Below are some critical specifications:

Material grade refers to the quality and purity of the silicon carbide used in the manufacturing process. Higher grades offer better durability and performance, particularly in abrasive applications. Understanding the material grade is crucial for buyers looking for long-lasting products that can withstand heavy usage, reducing the frequency of replacements.

Grit size indicates the coarseness or fineness of the sandpaper. Measured in numbers, a lower grit number corresponds to coarser paper, while a higher number indicates finer paper. Choosing the right grit size is essential for achieving the desired finish on materials. Buyers should consider the specific application—whether sanding wood, metal, or other materials—to select an appropriate grit size that will optimize performance.

The backing material provides support to the abrasive grains and affects the flexibility and durability of the sandpaper. Common backing materials include paper, cloth, and film. Buyers must evaluate the backing material based on the intended use; for example, cloth-backed sandpaper is typically more durable and suitable for heavy-duty applications, while paper-backed varieties are often more economical for lighter tasks.

Tolerance refers to the allowable deviation in the dimensions of the sandpaper. This specification is particularly important in precision applications where uniformity is critical. Understanding the tolerance can help buyers ensure that they receive consistent products that meet their manufacturing standards, ultimately affecting the quality of the final product.

The coating type determines how the abrasive particles are applied to the backing material. Common types include open-coat and closed-coat. Open-coat sandpapers are less densely packed with abrasive material, which reduces clogging during use. Buyers should assess their needs based on the materials being worked on and the desired finish.

Familiarity with industry jargon can significantly enhance communication and negotiation with suppliers. Here are some essential terms:

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether a supplier operates as an OEM can clarify the source of the products and their compatibility with existing equipment.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Understanding MOQ can help buyers negotiate better terms, especially if they require smaller batches or are testing new products.

An RFQ is a formal document sent to suppliers requesting a price quote for specific products. B2B buyers should utilize RFQs to compare pricing and terms from different suppliers, facilitating informed purchasing decisions.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and delivery obligations, ensuring smoother international transactions.

Lead time is the time taken from placing an order to receiving the product. Understanding lead times is essential for planning and inventory management. Buyers should communicate with suppliers to ascertain lead times to avoid disruptions in their production schedules.

By comprehending these technical properties and trade terms, international B2B buyers from regions like Africa, South America, the Middle East, and Europe can make more informed decisions when purchasing lija carburo de silicio.

The lija carburo de silicio (silicon carbide sandpaper) sector is experiencing significant transformations driven by global industrial demands and technological advancements. One of the primary market drivers is the growing need for high-performance abrasives across various industries, including automotive, aerospace, and manufacturing. The increasing adoption of electric vehicles (EVs) is also propelling the demand for silicon carbide due to its superior thermal conductivity and efficiency compared to traditional materials.

Emerging trends in B2B sourcing highlight the shift toward digital platforms for procurement. Buyers from regions like Africa and South America are increasingly leveraging online marketplaces to streamline their sourcing processes, allowing for better price comparisons and supplier evaluations. Additionally, the rise of data analytics in supply chain management is enabling international buyers to make more informed decisions, assess risks effectively, and optimize their procurement strategies.

Market dynamics are further influenced by geopolitical factors and trade agreements, particularly in Europe and the Middle East. Buyers must remain vigilant about tariffs and import regulations, as these can significantly impact pricing and availability. As sustainability becomes a priority, international buyers are also seeking suppliers who adhere to environmentally friendly practices, making it essential for businesses in this sector to adapt and innovate in response to changing market conditions.

In today's B2B landscape, sustainability and ethical sourcing are no longer optional but essential components of a responsible supply chain strategy. The production of lija carburo de silicio presents environmental challenges, including energy-intensive manufacturing processes and the sourcing of raw materials. As such, international buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing sustainable practices.

Companies are now seeking certifications that validate their environmental efforts, such as ISO 14001 for effective environmental management systems and other green certifications that highlight the use of recyclable or biodegradable materials in production. Buyers from Europe, for instance, are particularly stringent about compliance with these standards, as they align with the EU's broader sustainability goals.

Moreover, ethical sourcing practices are becoming paramount, with buyers demanding transparency in the supply chain. This includes understanding the source of materials and ensuring fair labor practices in production facilities. By fostering strong relationships with ethically responsible suppliers, B2B buyers can enhance their brand reputation and attract environmentally conscious consumers.

The evolution of the lija carburo de silicio sector can be traced back to the early 20th century, when silicon carbide was first synthesized as a synthetic abrasive. Initially used in industrial applications, its properties soon made it a preferred choice for various grinding and polishing tasks. Over the decades, advancements in manufacturing processes have significantly improved the quality and efficiency of silicon carbide products.

In recent years, the focus has shifted toward enhancing the performance and sustainability of silicon carbide products. Innovations in material science have led to the development of more effective and eco-friendly abrasives. As industries evolve and the demand for high-performance materials grows, the lija carburo de silicio sector continues to adapt, responding to the needs of international B2B buyers seeking both quality and sustainability in their sourcing decisions.

How do I choose the right type of lija carburo de silicio for my project?

Selecting the appropriate type of lija carburo de silicio (silicon carbide sandpaper) depends on the specific application and desired finish. For heavy-duty tasks, opt for coarse grits (40-60), while fine grits (120-220) are ideal for finishing touches. Consider the material being worked on; for example, harder materials like metals may require a different grit than softer woods. Additionally, assess whether you need wet or dry sanding options, as some products are specifically designed for one or the other, impacting performance.

What is the best grit size of lija carburo de silicio for woodworking?

For woodworking, a range of grit sizes can be effective depending on the stage of the project. Coarser grits (60-80) are suitable for initial shaping or removing material, while medium grits (100-150) work well for smoothing surfaces. For final finishing, finer grits (180-220) provide a smooth finish, preparing the surface for varnish or paint. Always test a small area first to ensure the grit chosen achieves the desired result without damaging the wood.

What are the key factors to consider when vetting suppliers of lija carburo de silicio?

When vetting suppliers, consider their reputation, quality certifications, and experience in the industry. Look for suppliers who provide detailed product specifications and samples to evaluate quality. Additionally, assess their production capabilities, lead times, and compliance with international standards. Customer reviews and testimonials can also provide insight into reliability and service levels. Establishing communication to discuss your specific needs can help gauge their responsiveness and willingness to customize.

What are the minimum order quantities (MOQ) for lija carburo de silicio?

Minimum order quantities can vary significantly by supplier and product type. Typically, MOQs range from 100 to 1,000 sheets or rolls, depending on the manufacturer. It's advisable to inquire directly with suppliers to understand their specific MOQs, as some may offer flexibility for first-time buyers or bulk orders. Additionally, consider negotiating for lower MOQs if you have a specific requirement or if you plan to establish a long-term partnership.

What payment terms are common for international purchases of lija carburo de silicio?

Common payment terms for international transactions include upfront payments, letters of credit, or payment upon delivery. Many suppliers may require a deposit (usually 30% to 50%) upon order confirmation, with the balance due before shipping. It’s essential to clarify payment terms in advance to avoid misunderstandings. Using secure payment methods and obtaining pro forma invoices can help protect both parties. Always ensure that payment terms are documented in the purchase agreement.

How do I ensure quality assurance for lija carburo de silicio products?

To ensure quality assurance, request certifications from suppliers, such as ISO 9001, which indicates adherence to international quality standards. Additionally, consider implementing a quality control process where you inspect samples before placing bulk orders. If feasible, visit the supplier's facility to assess their manufacturing processes. Establishing clear specifications for the product will help in evaluating quality consistently, and consider third-party inspections for larger orders.

What logistics considerations should I keep in mind when importing lija carburo de silicio?

When importing, consider shipping methods (air vs. sea), lead times, and customs regulations in your country. Ensure that your supplier provides appropriate documentation, such as packing lists and invoices, to facilitate customs clearance. Evaluate shipping costs and transit times to determine the most cost-effective and timely delivery options. Additionally, be aware of potential tariffs and duties that may apply to your imports, and factor these into your overall cost analysis.

Are there customization options available for lija carburo de silicio?

Many suppliers offer customization options for lija carburo de silicio, including tailored sizes, grits, and backing materials. Customization can be particularly beneficial for specific applications or industries. When discussing options with suppliers, clearly outline your requirements, including dimensions, grit size, and any specific performance characteristics needed. Some suppliers may require minimum order quantities for customized products, so it's wise to inquire about these details early in the negotiation process.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the evolving landscape of international trade, the strategic sourcing of lija carburo de silicio presents a unique opportunity for B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe. By focusing on quality, supplier reliability, and cost-effectiveness, businesses can optimize their procurement processes and enhance their competitive edge.

Investing in a strategic sourcing approach allows companies to build strong relationships with suppliers, ensuring consistent access to high-quality silicon carbide products. This not only reduces lead times but also mitigates risks associated with supply chain disruptions. Furthermore, leveraging regional suppliers can provide insights into local market conditions and trends, facilitating better decision-making.

As we look to the future, international B2B buyers are encouraged to explore innovative sourcing strategies that align with sustainability goals and technological advancements. Emphasizing collaboration with suppliers who prioritize ethical practices and environmental considerations will be crucial in navigating the complexities of global sourcing.

In conclusion, the strategic sourcing of lija carburo de silicio is not merely a transactional process; it is a pathway to building resilient supply chains that can adapt to changing market demands. Engage with suppliers today to unlock new growth opportunities and secure your business's future in this dynamic marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina