In today's rapidly evolving global market, understanding the precio del silicio is essential for B2B buyers looking to stay competitive. Sourcing silicon at the right price can significantly impact the production costs and profit margins of businesses across various sectors, including electronics, renewable energy, and construction. This guide serves as a comprehensive resource, providing insights into the different types of silicon, its diverse applications, and essential strategies for supplier vetting and negotiation.

As international buyers from regions like Africa, South America, the Middle East, and Europe navigate this complex landscape, they face unique challenges—ranging from fluctuating prices to varying quality standards. This guide not only outlines the key factors influencing silicon pricing but also empowers buyers with actionable strategies to make informed purchasing decisions. Whether you are in Kenya, Saudi Arabia, or beyond, understanding the nuances of silicon sourcing can lead to better supplier relationships and enhanced product quality.

By exploring the intricacies of the silicon market, including trends, potential suppliers, and cost considerations, this guide aims to equip you with the knowledge necessary to optimize your procurement process. Ultimately, it seeks to foster a deeper understanding of how to effectively leverage silicon in your business operations, ensuring you remain at the forefront of your industry.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polycrystalline Silicon | Made from multiple silicon crystals; cost-effective | Solar panels, electronics | Pros: Lower cost, suitable for large-scale production. Cons: Less efficient than monocrystalline. |

| Monocrystalline Silicon | Made from a single crystal structure; higher efficiency | High-efficiency solar cells, semiconductors | Pros: Higher energy efficiency, longer lifespan. Cons: More expensive, requires more energy to produce. |

| Amorphous Silicon | Non-crystalline form; flexible and lightweight | Thin-film solar cells, flexible electronics | Pros: Lightweight, low production costs. Cons: Lower efficiency, shorter lifespan than crystalline forms. |

| Silicon Carbide (SiC) | Compound of silicon and carbon; high thermal conductivity | Power electronics, high-temperature applications | Pros: High durability, efficient at high temperatures. Cons: Higher cost, specialized manufacturing processes. |

| Silicon Wafer | Thin slices of silicon; essential for semiconductor manufacturing | Microelectronics, photovoltaic cells | Pros: Essential for advanced tech applications, versatile. Cons: Requires careful handling and processing. |

Polycrystalline silicon is characterized by its formation from multiple silicon crystals, making it a cost-effective choice for various applications. It is predominantly used in solar panels and electronics, where its lower production costs can be a significant advantage for B2B buyers looking to maximize margins. However, while it is suitable for large-scale production, it is less efficient than its monocrystalline counterpart, which may impact long-term performance in energy applications.

Monocrystalline silicon is distinguished by its single crystal structure, offering higher energy efficiency and performance in applications such as high-efficiency solar cells and semiconductors. B2B buyers often prefer this type for projects where long-term investment in energy savings is critical, despite its higher upfront costs. The efficiency and longevity of monocrystalline silicon can justify the investment, especially for businesses focused on sustainable energy solutions.

Amorphous silicon is unique due to its non-crystalline structure, allowing for flexibility and lightweight designs. It is primarily used in thin-film solar cells and flexible electronic devices, making it a valuable option for B2B buyers in emerging tech sectors. While its production costs are lower, the trade-off includes reduced efficiency and a shorter lifespan compared to crystalline forms, which buyers need to consider based on application requirements.

Silicon carbide combines silicon with carbon, resulting in a material known for its high thermal conductivity and durability. It is ideal for applications in power electronics and high-temperature environments, appealing to B2B buyers in sectors requiring reliable performance under extreme conditions. Although SiC can be more expensive and requires specialized manufacturing processes, its efficiency and reliability can lead to cost savings over time, particularly in high-performance applications.

Silicon wafers are thin slices of silicon that serve as the foundation for semiconductor manufacturing and photovoltaic cells. They are essential for microelectronics, making them a crucial purchase for B2B buyers in tech industries. While wafers are versatile and critical for advanced technology applications, they require careful handling and processing, which can add complexity to the supply chain. Buyers should consider their manufacturing capabilities and quality control processes when sourcing silicon wafers.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of precio del silicio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics & Semiconductors | Manufacturing of solar cells and photovoltaic panels | High efficiency in energy conversion, reduced energy costs | Quality of silicon purity, sourcing from reputable suppliers |

| Automotive | Production of silicon-based sensors and chips | Enhanced vehicle safety and performance features | Compliance with international standards, reliability of supply |

| Construction & Building | Use in concrete additives for improved durability | Increased structural integrity and longevity of materials | Understanding regional regulations, cost-effectiveness of sourcing |

| Telecommunications | Development of silicon photonics for data transmission | Faster data transfer rates, reduced latency | Innovation capabilities of suppliers, scalability of production |

| Renewable Energy | Integration in energy storage systems like batteries | Enhanced energy efficiency, sustainability credentials | Lifecycle and recycling policies, availability of raw materials |

In the electronics and semiconductor industry, precio del silicio plays a crucial role in the manufacturing of solar cells and photovoltaic panels. This application leverages the high efficiency of silicon in converting sunlight into electricity, thereby significantly reducing energy costs for businesses. For international B2B buyers, particularly from regions like Africa and South America, sourcing high-purity silicon is essential to ensure optimal performance and longevity of solar products. Buyers should prioritize suppliers with a proven track record of quality and reliability to avoid supply chain disruptions.

In the automotive sector, precio del silicio is integral to the production of silicon-based sensors and chips that enhance vehicle safety and performance. These components are essential for advanced driver-assistance systems (ADAS) and electric vehicles (EVs), which are increasingly in demand in Europe and the Middle East. Buyers should consider sourcing silicon from manufacturers who meet international quality standards and can provide consistent supply, ensuring that the components perform reliably under various conditions.

In construction, precio del silicio is utilized in concrete additives that improve the material's durability and strength. This application is vital for projects requiring enhanced structural integrity, particularly in regions prone to environmental stressors. International buyers should be aware of local regulations regarding construction materials and should seek suppliers who offer cost-effective solutions without compromising on quality, ensuring compliance with safety standards.

Silicon photonics, which utilizes precio del silicio, is a game-changer in telecommunications, facilitating faster data transmission rates and reduced latency. This technology is crucial as demand for high-speed internet and communication services surges globally, especially in Europe and the Middle East. Buyers should evaluate the innovation capabilities of their suppliers and their ability to scale production to meet growing market demands, ensuring that they stay competitive.

In the renewable energy sector, precio del silicio is essential for the integration of silicon into energy storage systems, such as batteries. This application enhances energy efficiency and supports sustainability initiatives, which are increasingly important for businesses worldwide. Buyers should consider the lifecycle and recycling policies of their silicon suppliers, as these factors contribute to the overall sustainability and environmental impact of their energy solutions, aligning with global trends towards greener technologies.

A stock image related to precio del silicio.

Related Video: 'Complete garbage': GOP uses gimmick to make Trump's awful spending bill seem like it's not so bad

The Problem:

B2B buyers often struggle with the unpredictable nature of silicon prices, which can fluctuate dramatically due to market demands, geopolitical factors, and supply chain disruptions. This volatility makes it challenging for companies to forecast their budget and pricing strategies effectively. For businesses relying on silicon for manufacturing semiconductors or solar panels, these price changes can significantly impact profit margins and project viability.

The Solution:

To mitigate the risks associated with fluctuating silicon prices, international buyers should consider establishing long-term contracts with suppliers. These agreements can lock in prices over an extended period, providing financial stability and predictability. Additionally, buyers should diversify their supplier base across different regions, such as Africa and South America, to take advantage of varying market conditions and reduce dependency on a single source. Implementing a robust market analysis tool can also help buyers keep track of price trends and make informed purchasing decisions based on real-time data.

The Problem:

Another significant pain point for B2B buyers is the inconsistency in the quality of silicon received from different suppliers. Variations in purity levels can affect the performance of end products, leading to increased rejection rates and warranty claims. This issue is particularly pronounced when sourcing from emerging markets where quality control measures may not be as stringent.

The Solution:

To address quality variability, buyers should implement a thorough supplier evaluation process that includes certifications and quality assurance protocols. Requesting samples for testing before committing to large orders can ensure that the silicon meets the required specifications. Collaborating with suppliers who are ISO certified or have a proven track record in quality management can also enhance reliability. Furthermore, investing in in-house quality testing capabilities can help buyers maintain consistent standards throughout their supply chain.

The Problem:

B2B buyers frequently encounter a lack of transparency in the sourcing process of silicon. This opacity can lead to challenges in understanding the origin of the material, the ethical implications of its procurement, and the overall sustainability of the supply chain. For companies focused on corporate social responsibility (CSR), this can pose significant reputational risks.

The Solution:

To foster transparency in silicon sourcing, buyers should prioritize partnerships with suppliers who provide traceability in their supply chains. Utilizing blockchain technology can enhance visibility and allow buyers to track the origin and journey of silicon from its source to their facilities. Additionally, engaging with suppliers who adhere to ethical sourcing practices and sustainability certifications can align purchasing decisions with corporate values. Conducting regular audits of suppliers to ensure compliance with sustainability and ethical standards can further reinforce a commitment to responsible sourcing.

When selecting materials for applications involving precio del silicio, it is essential to consider various options that can affect performance, cost, and compliance with international standards. Below is an analysis of four common materials used in conjunction with silicon, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Silicon Carbide (SiC) is known for its exceptional hardness and thermal conductivity, making it suitable for high-temperature applications. It can withstand temperatures exceeding 1,600°C and has excellent resistance to thermal shock and corrosion. This material is often used in semiconductor devices and high-power applications.

Pros and Cons: The primary advantage of SiC is its ability to operate at high temperatures and voltages, which enhances the efficiency of electronic devices. However, its manufacturing process is complex and can be costly, making it less accessible for smaller companies or projects with tight budgets.

Impact on Application: SiC is particularly effective in applications involving high power and high-frequency environments, such as electric vehicles and industrial equipment. Its compatibility with various media, including corrosive substances, makes it a versatile choice.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and JIS when sourcing SiC components. Understanding local regulations regarding semiconductor materials is also crucial.

Aluminum Silicon Alloy is a popular choice due to its lightweight and excellent corrosion resistance. This alloy typically consists of about 10-12% silicon, which improves fluidity and reduces shrinkage during casting.

Pros and Cons: The lightweight nature of aluminum-silicon alloys makes them ideal for automotive and aerospace applications. They are also cost-effective compared to pure aluminum. However, they may not perform as well under high-temperature conditions compared to SiC.

Impact on Application: This alloy is commonly used in die-casting applications, particularly in the automotive industry for engine components. Its corrosion resistance is beneficial for parts exposed to harsh environments.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of specific compliance standards for aluminum alloys, such as EN and ASTM specifications. Understanding the local market's preference for lightweight materials can also guide purchasing decisions.

Glass-Filled Nylon is a composite material that combines nylon with glass fibers to enhance strength and stiffness. This material is well-regarded for its durability and resistance to wear and tear.

Pros and Cons: The primary advantage of glass-filled nylon is its high strength-to-weight ratio, making it suitable for applications requiring robust components without excessive weight. However, the material can be more expensive than standard nylon and may require specialized processing techniques.

Impact on Application: This material is often used in automotive and industrial applications where mechanical strength is critical. Its compatibility with various chemical media makes it suitable for diverse environments.

Considerations for International Buyers: Buyers from Europe should consider compliance with ISO standards when sourcing glass-filled nylon. Additionally, understanding the local manufacturing capabilities can aid in selecting suppliers who can meet specific processing requirements.

Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It is often used in applications requiring durable yet lightweight materials.

Pros and Cons: The key advantage of polycarbonate is its ability to withstand high impact without breaking, making it ideal for safety applications. However, it can be more susceptible to scratching and UV degradation compared to other materials.

Impact on Application: Polycarbonate is widely used in safety glasses, automotive parts, and electronic housings. Its compatibility with various media makes it a versatile option for many applications.

Considerations for International Buyers: Buyers from South America should be aware of local regulations regarding the use of plastics and ensure compliance with environmental standards. Understanding the market demand for lightweight and durable materials can also influence purchasing decisions.

| Material | Typical Use Case for precio del silicio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | High-power semiconductor devices | High thermal conductivity and voltage tolerance | Complex manufacturing process | High |

| Aluminum Silicon Alloy | Automotive engine components | Lightweight and corrosion-resistant | Lower performance at high temperatures | Medium |

| Glass-Filled Nylon | Industrial and automotive applications | High strength-to-weight ratio | More expensive than standard nylon | Medium |

| Polycarbonate | Safety glasses and electronic housings | High impact resistance | Susceptible to scratching and UV damage | Low |

This guide provides a comprehensive overview of material options for international B2B buyers considering precio del silicio. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

The manufacturing process for silica products, particularly in the context of 'precio del silicio', involves several critical stages. These stages ensure that the final product meets the required specifications and quality standards for various applications, including electronics, construction, and glass manufacturing.

Material Preparation: The first step involves sourcing high-purity silica sand. This raw material is then subjected to cleaning processes to remove impurities. Techniques such as washing, attrition scrubbing, and magnetic separation are commonly employed to enhance purity levels.

Forming: Once the silica is prepared, it undergoes forming processes. Depending on the end product, methods such as casting, molding, or extrusion may be utilized. In the case of silica glass, the melting process at high temperatures (over 1700°C) is critical to achieve the desired viscosity and workability.

Assembly: For products that require assembly, such as silicon wafers used in electronics, precise techniques are applied. This may include layering, bonding, or integrating with other materials to create composites. The assembly stage is crucial for ensuring that the product meets functional requirements.

Finishing: The final stage involves surface treatments and finishing processes, which may include polishing, coating, or annealing. These processes not only enhance the aesthetic qualities of the product but also improve its durability and resistance to environmental factors.

Innovative techniques play a significant role in ensuring the efficiency and quality of silica manufacturing. Some of these techniques include:

High-Temperature Processing: For applications requiring high-purity silica, advanced furnace technologies that operate at extreme temperatures are essential. This ensures that impurities are completely eliminated.

Chemical Vapor Deposition (CVD): This method is particularly important in the semiconductor industry, where high-purity silicon is required for integrated circuits. CVD allows for precise control over the material properties.

Hydrothermal Synthesis: Used for producing silica gels and zeolites, this technique involves the reaction of silica sources in an aqueous solution under high pressure and temperature, resulting in unique material properties.

Quality assurance is a fundamental aspect of the manufacturing process for silica products. International standards and industry-specific certifications guide the QA processes.

International Standards: Compliance with ISO 9001 is critical for silica manufacturers. This standard focuses on maintaining an effective quality management system and ensuring continuous improvement. Manufacturers must document processes, monitor performance, and implement corrective actions when needed.

Industry-Specific Certifications: Depending on the application of silica products, other certifications such as CE (Conformité Européenne) for products sold in Europe, or API (American Petroleum Institute) standards for materials used in oil and gas applications, may also be required.

Quality control (QC) is integrated into various stages of the manufacturing process. The following checkpoints are essential for maintaining product quality:

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival. Verification of material specifications, such as particle size and purity, is conducted to ensure they meet predefined standards.

In-Process Quality Control (IPQC): During manufacturing, regular sampling and testing are performed to monitor the production process. This includes checking the temperature and pressure in furnaces, as well as monitoring chemical compositions during synthesis.

Final Quality Control (FQC): The finished products undergo rigorous testing to verify that they meet all specifications. Common tests include mechanical strength, thermal resistance, and chemical composition analysis.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it is crucial to ensure that suppliers adhere to quality standards. Here are some strategies:

Conduct Supplier Audits: Regular audits of the manufacturing facilities can help verify compliance with quality standards. These audits should assess the entire production process, from raw material sourcing to final product testing.

Request Quality Reports: Suppliers should provide detailed quality assurance reports that outline testing methods, results, and compliance with relevant standards. This documentation serves as evidence of their commitment to quality.

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. These services often include detailed reporting and certification, which can be crucial for buyers.

When engaging with suppliers from different regions, international buyers must be aware of several nuances regarding quality control:

Regional Standards Variability: Quality standards can vary significantly between regions. Buyers should ensure that suppliers are compliant with both local and international standards applicable to their products.

Cultural Differences in Quality Assurance: Different cultures may have varying approaches to quality assurance. Understanding these differences can aid in establishing effective communication and collaboration with suppliers.

Supply Chain Transparency: Buyers should seek suppliers who provide transparency throughout the supply chain. This includes traceability of raw materials and clarity on the manufacturing processes employed, which can enhance trust and reliability.

By understanding the manufacturing processes and quality assurance measures for silica products, B2B buyers can make informed decisions that align with their quality expectations and business needs.

To successfully procure silicon (precio del silicio) for your B2B needs, especially in the diverse markets of Africa, South America, the Middle East, and Europe, follow this comprehensive sourcing checklist. Each step is designed to guide you through the process of selecting the right supplier and ensuring a smooth transaction.

Before starting your sourcing journey, it's essential to clearly outline your technical requirements for silicon. This includes the purity level, form (e.g., wafers, granules), and any specific certifications that may be required for your industry.

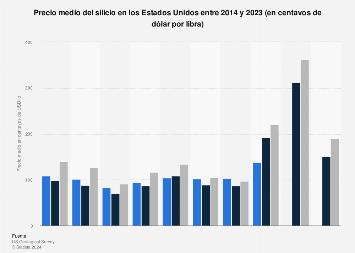

Conduct thorough research to understand the current market prices for silicon in your target regions. This involves analyzing historical price trends and understanding factors that may influence prices, such as supply chain disruptions or seasonal demands.

Before committing, vet potential suppliers meticulously. Request comprehensive company profiles, case studies, and references from other buyers in similar industries or regions.

Ensure that your chosen suppliers possess the necessary certifications that comply with international standards, such as ISO or industry-specific certifications.

Before finalizing your order, always request samples of silicon products. This allows you to verify the quality and specifications against your requirements.

Engage in negotiations to establish favorable terms, including pricing, payment terms, delivery schedules, and after-sales support.

Finally, develop a logistics plan for the delivery of your silicon materials. Consider factors such as shipping methods, customs clearance, and local regulations in your purchasing region.

By following this practical sourcing guide, you can navigate the complexities of procuring silicon effectively, ensuring that you select the best suppliers for your business needs while minimizing risks.

When sourcing precio del silicio, understanding the cost structure is crucial for international B2B buyers. The primary components of the cost include:

Materials: The raw silicon used in manufacturing is the most significant cost factor. Prices can fluctuate based on market demand, purity levels, and availability of silicon from suppliers. Buyers should consider sourcing from multiple suppliers to mitigate risks associated with price volatility.

Labor: Labor costs vary significantly by region. For instance, manufacturing facilities in Africa may have lower labor costs compared to Europe. Understanding the local labor market can provide insight into potential savings.

Manufacturing Overhead: This includes costs associated with utilities, factory maintenance, and administrative expenses. Manufacturers may pass these costs onto buyers, so understanding a supplier's operational efficiency can be beneficial.

Tooling: Costs related to the tools and machinery used in production also contribute to the overall price. This can include initial investment costs as well as maintenance and depreciation over time.

Quality Control (QC): Ensuring the silicon meets specified standards can incur additional costs. Buyers should inquire about the QC processes in place to ensure the materials provided meet their requirements.

Logistics: Shipping and handling costs can significantly affect the final price. Factors such as distance, shipping method, and customs duties should be considered, especially for international transactions.

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help buyers negotiate better terms.

Several factors influence the pricing of silicon, and recognizing these can help buyers make informed decisions:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing. Buyers should assess their requirements carefully and consider bulk purchasing to leverage better rates.

Specifications and Customization: Customized silicon products may come at a premium. Buyers should clearly define their specifications to avoid unexpected costs.

Material Quality and Certifications: Higher quality silicon or certifications (e.g., ISO standards) can increase costs. Buyers should weigh the importance of these factors against their project needs.

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers may charge more due to their experience and quality assurance processes.

Incoterms: Understanding Incoterms is essential for international buyers as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the final cost.

International B2B buyers can adopt several strategies to enhance their sourcing efficiency:

Negotiate Terms: Engage in discussions with suppliers about pricing, payment terms, and delivery schedules. Flexibility on both sides can lead to better deals.

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider long-term costs such as maintenance, logistics, and potential wastage.

Research Market Trends: Stay informed about market trends affecting silicon prices. Being aware of geopolitical issues or changes in demand can provide leverage during negotiations.

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Trust and reliability can often yield favorable terms in future transactions.

Consider Local Suppliers: For buyers in regions like Africa or South America, local sourcing can reduce logistics costs and lead times. Evaluate local suppliers for competitive pricing without compromising quality.

Sourcing precio del silicio involves understanding a complex interplay of costs and pricing influencers. By being informed and strategic in negotiations, international B2B buyers from Africa, South America, the Middle East, and Europe can optimize their purchasing decisions. Remember, prices can fluctuate, so always request indicative quotes and remain flexible in your sourcing strategies.

A stock image related to precio del silicio.

In the competitive landscape of international B2B transactions, understanding alternative solutions to 'precio del silicio' can be vital for making informed purchasing decisions. This analysis will focus on comparing 'precio del silicio' against two viable alternatives: advanced silicon carbide (SiC) technology and gallium nitride (GaN) technology. Each alternative offers unique advantages and disadvantages that can influence a buyer's choice based on their specific requirements.

| Comparison Aspect | Precio Del Silicio | Advanced Silicon Carbide (SiC) | Gallium Nitride (GaN) |

|---|---|---|---|

| Performance | High efficiency in solar applications | Superior thermal conductivity and efficiency | Excellent high-frequency performance |

| Cost | Moderate cost | Higher initial investment | Higher than silicon but decreasing |

| Ease of Implementation | Relatively easy | More complex due to material properties | Requires specific manufacturing processes |

| Maintenance | Low maintenance | Low maintenance, but sensitive to overloading | Low maintenance, robust under high temperatures |

| Best Use Case | Solar panels and electronics | High-voltage and high-temperature applications | RF applications and power converters |

Advanced silicon carbide (SiC) technology is increasingly being adopted for high-voltage applications due to its superior thermal conductivity and efficiency. While the initial investment is higher compared to 'precio del silicio', the long-term savings from energy efficiency and reduced cooling requirements often justify the cost. However, SiC devices can be more complex to implement, requiring specialized knowledge and equipment. They are ideal for applications in electric vehicles and renewable energy systems, where performance under extreme conditions is crucial.

Gallium nitride (GaN) technology excels in high-frequency applications, making it particularly suitable for RF amplifiers and power converters. Although GaN components come with a higher price tag than traditional silicon, the costs have been steadily decreasing as the technology matures. GaN devices can be challenging to manufacture due to their specific requirements, but they offer remarkable performance in terms of efficiency and thermal management. This makes GaN a strong candidate for applications in telecommunications and advanced computing systems.

When considering alternatives to 'precio del silicio', B2B buyers should evaluate their specific needs against the strengths and weaknesses of each option. If the application demands high thermal efficiency and robustness under extreme conditions, SiC may be the best choice despite the higher costs. Conversely, for applications requiring high-frequency performance, GaN technology could provide the necessary advantages. Ultimately, the decision should be guided by a thorough analysis of performance requirements, budget constraints, and the complexity of implementation. By understanding these alternatives, buyers can make informed decisions that align with their operational goals.

Understanding the technical properties of silicon is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential specifications to consider:

Material grade refers to the quality and purity of silicon. It is typically categorized into different grades based on the percentage of silicon present. For instance, electronic-grade silicon (EGS) is about 99.9999% pure, making it ideal for semiconductor applications. Buyers must ensure they procure the correct grade to meet their specific application requirements, as it directly affects the performance and reliability of the final product.

Tolerance defines the permissible limit of variation in dimensions or properties of silicon products. For instance, in semiconductor manufacturing, tight tolerances are essential to ensure consistent electrical characteristics. Understanding tolerance levels helps buyers evaluate supplier capabilities and ensure that components will fit properly within their assemblies, reducing the risk of defects.

Silicon's electrical conductivity is a critical property that influences its application in electronics. The conductivity can vary based on the doping process (adding impurities to silicon). Buyers should be aware of the specific conductivity requirements for their applications, as this will impact the efficiency of devices like solar cells and transistors.

Thermal conductivity indicates how well silicon can conduct heat. This property is vital in applications where heat dissipation is critical, such as in power electronics. B2B buyers should assess the thermal conductivity specifications to ensure the silicon components can handle the thermal loads in their applications, thereby enhancing reliability and performance.

Mechanical properties, such as tensile strength and hardness, are important for silicon used in structural applications. High tensile strength ensures that the material can withstand mechanical stresses without failure. Buyers should consider these properties when selecting silicon for applications that involve significant physical loads.

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several key terms relevant to B2B buyers in the silicon market:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of silicon, OEMs often require specific grades and tolerances to meet their product standards. Understanding OEM requirements helps buyers ensure compatibility with existing systems.

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and pricing strategies. Buyers should negotiate MOQs that align with their operational needs without incurring excessive costs.

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. This process is vital for B2B buyers to compare suppliers, negotiate better prices, and clarify product specifications. Crafting a detailed RFQ can help in securing favorable terms.

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B transactions, as they dictate how costs and risks are shared during the shipping process.

Lead time refers to the time taken from placing an order to the delivery of the product. In the silicon market, lead times can vary based on production capabilities and supply chain factors. Buyers should consider lead times when planning their procurement strategies to avoid disruptions in production.

Certification refers to the process through which products are verified to meet specific standards or regulations. Certifications such as ISO or RoHS are important for ensuring product quality and compliance. Buyers should seek suppliers who possess relevant certifications to mitigate risks associated with substandard products.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions and foster successful partnerships in the silicon market.

The precio del silicio sector is witnessing transformative changes driven by technological advancements and shifting global demand. As the backbone of solar panels, semiconductors, and various electronic devices, the demand for silicon is surging. In regions like Africa and South America, the push for renewable energy solutions is accelerating the need for high-purity silicon, particularly for photovoltaic applications. Meanwhile, the Middle East is increasingly focusing on diversifying its economy away from oil, with investments in solar energy prompting a rise in silicon imports.

Moreover, the rise of Industry 4.0 is reshaping supply chains, making them more efficient and transparent. Digital procurement platforms and AI-driven analytics are becoming critical tools for international buyers, enabling them to make informed sourcing decisions. B2B buyers from Europe, particularly in the automotive and electronics sectors, are increasingly looking for suppliers that can provide not just quality silicon but also sustainable sourcing practices. This trend highlights the importance of building relationships with suppliers who can ensure compliance with international standards.

The environmental impact of silicon production cannot be overlooked. Traditional mining and processing methods can lead to significant ecological degradation. Consequently, the importance of ethical supply chains in the precio del silicio sector has gained momentum. Companies are now seeking suppliers who adhere to sustainable practices, such as utilizing renewable energy in production and minimizing water usage.

For international B2B buyers, understanding the certifications related to sustainability is crucial. Certifications like ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) provide assurance that suppliers are committed to minimizing their environmental footprint. Furthermore, the shift towards 'green' materials is becoming a significant differentiator in procurement decisions. Buyers are encouraged to engage with suppliers who can provide transparent supply chain information and demonstrate their commitment to sustainability.

The precio del silicio sector has evolved significantly over the past few decades. Initially dominated by traditional mining practices, the industry has shifted towards more innovative and efficient production methods. The advent of new technologies has enabled the extraction of silicon from lower-grade sources, improving yield and reducing costs.

Additionally, the global focus on renewable energy has spurred investments in silicon production, particularly in regions rich in solar potential. As countries strive to meet their climate goals, the demand for high-purity silicon for solar panels is expected to rise, leading to further innovations in sourcing and production practices. This evolution presents unique opportunities for B2B buyers to align their procurement strategies with market trends and sustainability goals.

By staying informed about market dynamics, embracing ethical sourcing, and understanding the historical context of the precio del silicio sector, international B2B buyers can navigate this complex landscape effectively.

How do I solve the challenges of sourcing high-quality silico products internationally?

To effectively source high-quality silico products, begin by conducting thorough market research to identify reputable suppliers in the regions you are targeting, such as Africa, South America, the Middle East, and Europe. Utilize B2B platforms, trade shows, and industry reports to gather information on potential suppliers. Request samples to assess quality, and consider third-party quality assurance services to verify product specifications. Building relationships with suppliers through clear communication and negotiating terms that ensure quality can significantly mitigate sourcing challenges.

What is the best method for vetting suppliers of silico in international markets?

Vetting suppliers involves a multi-step process. Start by checking their business credentials, such as registration and compliance with local regulations. Look for reviews or testimonials from other B2B buyers, and request references from existing clients. Conduct site visits if possible, or utilize video conferencing to assess their operations. Additionally, evaluating their financial stability through credit checks can help ensure they can meet your order requirements consistently.

What are the minimum order quantities (MOQ) for silico products, and how can they affect my purchasing strategy?

Minimum order quantities for silico products can vary widely based on the supplier and the product type. Understanding MOQs is crucial as they impact your purchasing strategy and cash flow. If the MOQ is high and you have limited storage or cash, consider negotiating lower quantities or working with multiple suppliers. It’s also essential to analyze demand forecasts to avoid overstocking or stockouts, which can disrupt your supply chain.

What payment terms should I negotiate when purchasing silico internationally?

When negotiating payment terms, consider options that protect your investment while ensuring supplier confidence. Common terms include letters of credit, advance payments, or payment upon delivery. Discussing payment milestones based on shipment stages can also mitigate risks. Ensure that you understand currency exchange rates and potential fees associated with international transactions, as these can impact overall costs.

How can I ensure the quality of silico products during shipping and delivery?

To ensure quality during shipping, collaborate closely with your supplier on packaging and handling procedures. Use robust packaging materials to protect the products from damage. Consider employing a logistics partner with experience in handling silico products, as they can provide insights on best practices. Additionally, implementing a quality assurance process upon receipt can help verify that the products meet your specifications before they enter your inventory.

What are the common logistical challenges when importing silico products, and how can I address them?

Common logistical challenges include customs clearance delays, unexpected tariffs, and transportation disruptions. To address these, work with experienced freight forwarders who can navigate customs regulations and provide insights into the best shipping routes. Establishing a buffer time in your supply chain can help accommodate potential delays. Additionally, staying informed about trade agreements and tariffs in the regions you are dealing with can help you plan more effectively.

What customization options should I consider when sourcing silico products?

When sourcing silico products, inquire about customization options that may enhance product performance or meet specific application needs. Discuss variations in purity levels, particle sizes, or chemical compositions that could be tailored for your use case. Understanding the supplier's ability to accommodate your customization requests can provide a competitive edge in your market. Ensure that any customizations are documented and agreed upon to avoid misunderstandings during production.

How do I handle disputes with international suppliers over silico product quality?

Handling disputes effectively begins with clear communication and documentation. Always maintain records of contracts, product specifications, and correspondence. If a dispute arises, approach the supplier with your concerns backed by evidence. Negotiation or mediation may resolve the issue amicably. If necessary, consider legal avenues, but understand the implications of international law and jurisdiction. Establishing a clear dispute resolution process in your contracts can help prevent future conflicts.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

As international B2B buyers navigate the complexities of the silicon market, strategic sourcing emerges as a vital approach to securing competitive pricing and ensuring supply chain resilience. By understanding the fluctuating dynamics of silicon prices, businesses can better forecast their procurement needs, optimize inventory management, and negotiate favorable contracts with suppliers. Key takeaways include the importance of leveraging regional suppliers, diversifying sources to mitigate risks, and staying informed about global market trends that influence pricing.

How Can International Buyers Prepare for Future Silicon Price Changes?

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe should remain proactive in their sourcing strategies. Engaging in robust market analysis and fostering strong relationships with suppliers can yield significant advantages. Furthermore, embracing technology and data analytics will empower buyers to make informed decisions, enhancing their competitive edge in the marketplace.

In conclusion, as the demand for silicon continues to grow across various industries, now is the time for international B2B buyers to refine their strategic sourcing practices. By taking action today, companies can position themselves for success in an evolving market landscape.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina