In today’s interconnected world, understanding "qu'est ce que le sic" (what is SIC) is crucial for international B2B buyers looking to navigate complex sourcing landscapes effectively. The challenge often lies in identifying reliable suppliers who can meet specific business needs, especially in regions like Africa, South America, the Middle East, and Europe. This guide aims to demystify the intricacies of SIC, providing comprehensive insights into various types, applications, and the vital process of supplier vetting.

Buyers will benefit from a detailed examination of sourcing strategies, cost considerations, and industry standards, enabling them to make informed purchasing decisions. By focusing on quality and compliance, this guide empowers businesses to minimize risks and enhance their operational efficiency. Furthermore, we delve into the nuances of negotiating contracts and establishing long-term partnerships with suppliers, tailored to meet the unique demands of diverse markets.

As you explore this guide, you will uncover actionable strategies that equip you with the knowledge needed to thrive in the global market. Whether you are seeking innovative solutions or looking to optimize existing processes, understanding "qu'est ce que le sic" will be your key to unlocking new opportunities and driving business success across borders.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SIC-1: Traditional SIC | Established standards, widely recognized, regulatory compliance | Manufacturing, Energy, Construction | Pros: High credibility, regulatory support. Cons: Can be rigid and slow to adapt. |

| SIC-2: Emerging SIC | Innovative approaches, technology-driven, adaptable | Tech Startups, Digital Services | Pros: Flexibility, fast-paced evolution. Cons: Less regulatory guidance, potential instability. |

| SIC-3: Hybrid SIC | Combination of traditional and emerging features | Healthcare, Finance | Pros: Balanced approach, diverse applications. Cons: Complexity in implementation, potential for confusion. |

| SIC-4: Sector-Specific SIC | Tailored to niche markets, specialized standards | Agribusiness, Renewable Energy | Pros: Highly relevant, targeted solutions. Cons: Limited applicability outside niche. |

| SIC-5: Global SIC | Internationally recognized standards, cross-border relevance | International Trade, Logistics | Pros: Facilitates global trade, ensures compliance. Cons: May not address local nuances effectively. |

Traditional SICs are based on established frameworks that have been recognized for decades. They are often essential for industries like manufacturing and construction, where regulatory compliance is crucial. Buyers should consider the credibility of these systems, as they provide a solid foundation for operational standards. However, the rigidity of these standards may hinder innovation, making it essential for companies to weigh the benefits of stability against the need for adaptability.

Emerging SICs represent a shift towards innovative and technology-driven approaches. These systems are particularly suited for tech startups and digital services, where rapid evolution is necessary. Buyers are drawn to the flexibility and responsiveness of emerging SICs, but they must also recognize the potential for instability due to the lack of established regulatory guidance. Companies should assess their risk tolerance when considering these new frameworks.

Hybrid SICs blend the elements of both traditional and emerging systems, offering a balanced approach that can cater to various sectors like healthcare and finance. This versatility allows businesses to leverage the strengths of both types while mitigating some of their respective weaknesses. However, the complexity of implementing hybrid SICs can pose challenges, and organizations must ensure that their teams are adequately trained to navigate these multifaceted systems.

Sector-specific SICs are designed to meet the unique needs of particular industries, such as agribusiness or renewable energy. These standards provide highly relevant solutions tailored to the challenges faced within these niches. Buyers benefit from targeted applications, but they should be cautious of the limited applicability of these standards outside their specific sectors. This can lead to missed opportunities for growth and diversification.

Global SICs are recognized internationally, making them essential for businesses engaged in international trade and logistics. These standards ensure compliance with cross-border regulations, facilitating smoother operations in diverse markets. While global SICs enhance trade opportunities, buyers must be aware that they may not always address local nuances, which can lead to challenges in implementation. Companies should evaluate their global strategies to ensure alignment with these international standards.

| Industry/Sector | Specific Application of qu'est ce que le sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Solar energy systems utilizing SIC technology | Increased efficiency and lower costs | Supplier reliability, compliance with local regulations, and technical support |

| Automotive | Electric vehicle (EV) components | Enhanced performance and energy efficiency | Quality certifications, material sourcing, and global supply chain logistics |

| Telecommunications | High-frequency components | Improved signal integrity and bandwidth | Compatibility with existing systems, pricing, and after-sales service |

| Aerospace and Defense | Lightweight structural components | Reduced weight leading to fuel savings | Material certifications, sourcing from trusted suppliers, and international trade regulations |

| Electronics Manufacturing | Semiconductor fabrication | Higher yield rates and lower defect rates | Cleanroom standards, technology transfer, and R&D collaboration |

In the renewable energy sector, particularly in solar energy systems, 'qu'est ce que le sic' is employed to enhance the efficiency of photovoltaic cells. The use of silicon carbide (SIC) allows for better thermal conductivity and power handling, which translates to lower operational costs and improved energy output. For international buyers in regions like Africa and South America, sourcing SIC-based components requires a focus on supplier reliability and adherence to local environmental regulations to ensure sustainable practices.

In the automotive sector, especially with the rise of electric vehicles (EVs), 'qu'est ce que le sic' is critical for manufacturing components such as inverters and power electronics. SIC materials offer higher efficiency and thermal stability, which are essential for maximizing battery performance and longevity. Buyers must consider quality certifications and material sourcing to ensure compatibility with their existing EV platforms, particularly in European markets where regulatory standards are stringent.

The telecommunications industry utilizes 'qu'est ce que le sic' in high-frequency components to improve signal integrity and increase bandwidth. These applications are vital for modern communication systems, including 5G networks. For B2B buyers, key considerations include ensuring the components' compatibility with existing network infrastructure and evaluating pricing against performance benchmarks, especially in rapidly evolving markets in the Middle East and Europe.

In aerospace and defense, 'qu'est ce que le sic' is used for lightweight structural components, which significantly reduces overall aircraft weight, leading to fuel savings and enhanced performance. The stringent requirements for material certifications and sourcing from trusted suppliers are critical for compliance with international trade regulations. Buyers must engage with manufacturers that can provide the necessary documentation and support for these highly regulated industries.

In electronics manufacturing, 'qu'est ce que le sic' is pivotal in semiconductor fabrication, where it helps achieve higher yield rates and lower defect rates. This is crucial for maintaining competitive edge in a market that demands quality and efficiency. International buyers should prioritize suppliers who meet cleanroom standards and can facilitate technology transfer, ensuring that they remain at the forefront of innovation while navigating complex global supply chains.

The Problem: Many B2B buyers from international markets, particularly in regions like Africa and South America, find it challenging to grasp the concept of 'qu'est ce que le sic' (what is SIC). This confusion is compounded by language barriers, cultural differences, and varying interpretations of what SIC entails in different business contexts. Buyers may struggle with how SIC applies to their specific industries or markets, leading to uncertainty in decision-making and potential misalignment in supplier relationships.

The Solution: To overcome this challenge, B2B buyers should seek educational resources tailored to their specific industry and region. Engaging with local experts or consultants who understand both the concept of SIC and the regional nuances can provide clarity. Additionally, attending workshops or webinars focused on SIC can enhance understanding. Buyers should also utilize glossaries or simplified guides that break down technical terms into relatable language. By fostering a deeper understanding of SIC, buyers can confidently navigate supplier discussions and make informed purchasing decisions.

The Problem: International B2B buyers often encounter communication issues when discussing SIC with potential suppliers. This problem is especially prevalent in regions like the Middle East and Europe, where industry jargon can vary. Misunderstandings regarding specifications, compliance requirements, or the relevance of SIC can lead to inadequate product offerings or misaligned expectations, ultimately affecting project timelines and budgets.

The Solution: To improve communication with suppliers, buyers should establish clear and concise documentation outlining their expectations and the specific SIC-related requirements. Creating a standardized questionnaire that includes key SIC concepts relevant to the buyer's industry can help suppliers respond accurately. Additionally, conducting preliminary meetings to clarify terms and expectations can enhance mutual understanding. Leveraging technology, such as collaborative platforms for real-time feedback, can also streamline communication. By fostering an open dialogue and ensuring clarity on SIC, buyers can mitigate misunderstandings and build stronger supplier relationships.

The Problem: B2B buyers often face compliance challenges related to SIC, especially when dealing with international suppliers. Different countries, such as those in Europe or Africa, may have varying regulations governing SIC, leading to confusion about compliance standards. This situation can result in delays, fines, or even legal repercussions if buyers inadvertently procure goods that do not meet local regulations.

The Solution: To navigate compliance issues effectively, buyers should prioritize researching and understanding the regulatory landscape in both their home country and the supplier’s country. Engaging with legal experts or compliance officers who specialize in international trade can provide invaluable insights into the relevant SIC regulations. Moreover, buyers should request compliance documentation from suppliers upfront, such as certifications or proof of adherence to local SIC standards. Regularly updating compliance knowledge through industry associations or trade groups can also help buyers stay informed about changes in regulations. By proactively addressing compliance concerns, buyers can safeguard their operations and ensure smooth transactions with suppliers.

When selecting materials for applications related to "qu'est ce que le sic," it is crucial to understand the properties, advantages, and limitations of common materials. This knowledge assists international B2B buyers in making informed decisions that align with their operational needs, particularly in regions like Africa, South America, the Middle East, and Europe.

Key Properties:

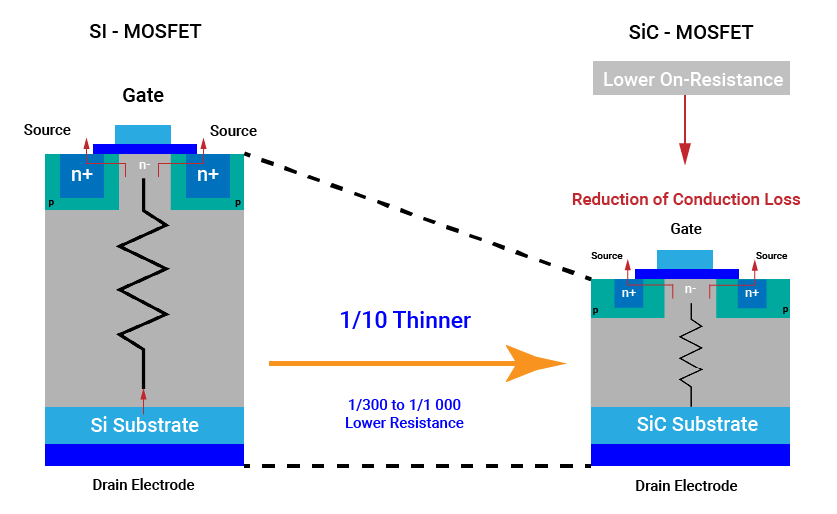

Silicon carbide is known for its high thermal conductivity, exceptional hardness, and resistance to thermal shock. It can operate at temperatures exceeding 1,600°C, making it suitable for high-temperature applications.

Pros & Cons:

The main advantage of SiC is its durability and ability to withstand harsh environments, including high temperatures and corrosive media. However, the manufacturing complexity and higher cost compared to traditional materials can be a drawback.

Impact on Application:

SiC is particularly effective in applications involving abrasive materials or high thermal loads, such as semiconductor devices and high-performance power electronics.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe and the Middle East, the demand for SiC is growing due to its energy efficiency, aligning with sustainability goals.

Key Properties:

Aluminum oxide exhibits excellent wear resistance, high melting point (over 2,000°C), and good electrical insulation properties. It is also chemically inert, making it suitable for various applications.

Pros & Cons:

Alumina is relatively inexpensive and widely available, making it a popular choice for many applications. However, its brittleness can limit its use in high-impact environments.

Impact on Application:

Alumina is commonly used in applications requiring electrical insulation and wear resistance, such as insulators and cutting tools.

Considerations for International Buyers:

Buyers should verify the material's compliance with local regulations and standards. In Africa and South America, where cost-effectiveness is crucial, alumina's lower price point can be a significant advantage.

Key Properties:

Zirconia is known for its high fracture toughness, thermal stability, and resistance to corrosion. It can operate effectively at temperatures up to 1,200°C.

Pros & Cons:

Zirconia's primary advantage is its exceptional mechanical properties and resistance to wear. However, it is more expensive than other ceramics, which can be a limiting factor for some applications.

Impact on Application:

Zirconia is ideal for applications in corrosive environments, such as chemical processing and biomedical implants.

Considerations for International Buyers:

When sourcing zirconia, buyers must consider its certification and compliance with international quality standards, especially in Europe where stringent regulations exist.

Key Properties:

Polytetrafluoroethylene (PTFE) is known for its excellent chemical resistance, low friction properties, and ability to operate in a wide temperature range (-200°C to 260°C).

Pros & Cons:

PTFE is highly versatile and suitable for a variety of applications. However, its mechanical strength is lower than that of ceramics and metals, which may limit its use in high-stress environments.

Impact on Application:

PTFE is commonly used in applications that require chemical resistance, such as seals, gaskets, and linings in the chemical industry.

Considerations for International Buyers:

Buyers should ensure that the polymeric materials meet local and international standards, particularly in the Middle East where chemical processing industries are prevalent.

| Material | Typical Use Case for qu'est ce que le sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | High-performance electronics | High thermal conductivity | High manufacturing complexity | High |

| Aluminum Oxide | Electrical insulators, cutting tools | Cost-effective and widely available | Brittle, limited impact resistance | Low |

| Zirconium Oxide | Chemical processing, biomedical implants | Exceptional mechanical properties | Higher cost compared to other ceramics | High |

| Polymeric Materials | Seals, gaskets in chemical industries | Excellent chemical resistance | Lower mechanical strength | Medium |

This guide provides essential insights into the strategic selection of materials for applications related to "qu'est ce que le sic," helping international B2B buyers navigate their purchasing decisions effectively.

A stock image related to qu'est ce que le sic.

The manufacturing of qu'est ce que le SIC involves several critical stages that ensure the final product meets quality and performance standards. Here’s a breakdown of the typical manufacturing processes:

The first stage involves selecting and preparing raw materials. This can include sourcing high-quality materials that adhere to international standards. For B2B buyers, it’s essential to verify that the materials meet specific criteria, such as sustainability and compliance with local regulations. Buyers should inquire about the supplier's material certification process and the traceability of raw materials used in production.

In the forming stage, various techniques are employed to shape the materials into the desired form. Common methods include:

B2B buyers should consider the implications of each technique on production time and cost. Understanding the forming process can help buyers negotiate better pricing and lead times based on the complexity of the required shapes.

Assembly involves the integration of various components to create the final product. This stage can include manual labor or automated assembly lines, depending on the complexity and volume of the production. Key quality assurance measures should be in place, such as:

B2B buyers should ask suppliers about their assembly processes and how they ensure that each unit meets quality standards.

Finishing processes enhance the product's appearance and functionality. Techniques may include:

For international buyers, understanding the finishing processes can help assess the suitability of products for specific environments, especially in industries like construction and automotive.

Quality assurance (QA) is vital in ensuring that products meet specified standards and customer expectations. Here are the key elements of QA relevant to B2B buyers:

Several international standards are crucial for assessing product quality. Key standards include:

B2B buyers should verify that their suppliers hold these certifications, as they indicate a commitment to quality and compliance.

Quality control (QC) involves systematic monitoring of the manufacturing process to ensure product integrity. Key QC checkpoints include:

Understanding these checkpoints allows buyers to gauge how proactive a supplier is in maintaining quality.

Various testing methods are employed to verify product quality, including:

B2B buyers should ask suppliers about the testing methods used and request documentation of test results to ensure quality compliance.

Conducting supplier audits is a critical step for B2B buyers to verify the effectiveness of a supplier’s quality control system. Key steps include:

Third-party inspections offer an unbiased evaluation of a supplier’s quality control processes. Buyers can engage independent inspection agencies to conduct assessments at various stages of production. This practice not only enhances transparency but also builds trust between buyers and suppliers.

B2B buyers from different regions may face unique challenges related to quality control. For instance:

By being proactive in understanding these nuances, international B2B buyers can foster better relationships with suppliers and ensure consistent product quality.

To effectively navigate the procurement of "qu'est ce que le sic," a comprehensive checklist is essential for international B2B buyers. This guide outlines key steps to ensure a successful sourcing experience, focusing on critical aspects such as supplier evaluation, quality assurance, and compliance.

Clearly outline the technical specifications of the product or service you are sourcing. This step is crucial as it sets the foundation for your procurement process. Identify the essential features, performance criteria, and any regulatory standards that must be met. Document these specifications to communicate effectively with potential suppliers.

Before reaching out to suppliers, perform thorough market research to understand the landscape. Investigate potential suppliers, their market reputation, and the range of products available. This research will help you identify competitive pricing and innovative solutions.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don't just rely on their website; a robust evaluation will help mitigate risks.

Ensure that potential suppliers possess the necessary certifications and compliance with local and international standards. This step is vital for maintaining product quality and safety.

Once you have shortlisted suppliers, request samples or prototypes of the products. This step allows you to assess the quality and suitability of the offerings before making a large-scale commitment.

Engage in negotiations with your chosen suppliers to establish clear terms and conditions. This includes pricing, payment terms, delivery schedules, and warranties. A well-defined agreement protects both parties and ensures a smooth transaction.

Effective communication is vital throughout the sourcing process. Develop a communication plan that outlines how you will interact with suppliers, including regular check-ins and updates on production timelines.

By following this structured checklist, B2B buyers can enhance their sourcing strategy for "qu'est ce que le sic," ensuring they make informed decisions that align with their business needs.

Understanding the cost structure of qu'est ce que le sic sourcing is critical for international B2B buyers. The primary cost components include:

Materials: The raw materials used significantly influence the overall cost. Prices can vary based on quality, sourcing location, and market demand. Buyers should assess local versus international suppliers to find the best balance of quality and cost.

Labor: Labor costs can differ greatly depending on the region. For instance, sourcing from countries with lower labor costs, such as those in parts of Africa and South America, can offer significant savings. However, it is essential to consider the skill level and experience of the workforce, as these factors directly affect product quality.

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can lower overhead, so inquire about the supplier's operational efficiency.

Tooling: This refers to the costs involved in creating molds, dies, and other tools needed for production. Tooling costs can be substantial for custom products, so it’s wise to consider the initial investment versus long-term benefits.

Quality Control (QC): Ensuring product quality is essential, especially in international transactions. QC processes add to the cost but are vital for maintaining standards and avoiding costly returns or reputation damage.

Logistics: Shipping and handling costs can significantly affect pricing, particularly for international shipments. Factors such as distance, weight, and shipping method all play a role. It's advisable to explore various logistics options to find the most cost-effective solution.

Margin: Supplier profit margins can vary widely. Understanding the typical margins in your industry can help in negotiations, ensuring you are not overpaying.

Several factors can influence the pricing of qu'est ce que le sic sourcing:

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Larger orders often lead to lower per-unit costs, so consider consolidating orders or partnering with other companies to meet MOQs.

Specifications and Customization: Custom products typically incur higher costs due to the additional labor and materials required. Clearly defining your specifications upfront can help avoid unexpected price increases later in the process.

Materials: The choice of materials directly impacts cost. High-quality or specialized materials may be necessary for certain applications, but they can also lead to higher prices. Always weigh the benefits against the costs.

Quality and Certifications: Products that require specific certifications or compliance with international standards often cost more. Ensure that you understand what certifications are necessary for your market.

Supplier Factors: The supplier’s reputation, location, and operational capabilities can all affect pricing. Building a strong relationship with reliable suppliers can lead to better pricing and terms.

Incoterms: The choice of Incoterms (International Commercial Terms) can influence the final price. Different terms dictate who is responsible for shipping, insurance, and tariffs, and understanding these can help you avoid hidden costs.

To navigate the complexities of sourcing qu'est ce que le sic effectively, consider the following tips:

Negotiation: Always approach negotiations with clear objectives. Understand the supplier's cost structure to identify areas where you can negotiate for better terms without compromising quality.

Cost-Efficiency: Look for suppliers that demonstrate cost-efficient practices. This could include advanced manufacturing technologies or lean processes that reduce waste.

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, not just the initial purchase price. Consider maintenance, operational costs, and potential savings from quality improvements.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and duties that can impact pricing when sourcing from different regions, particularly from Africa, South America, the Middle East, and Europe.

Disclaimer for Indicative Prices: Always seek quotes based on your specific requirements. Prices can vary significantly based on the factors discussed, so consider quotes as indicative rather than fixed.

By understanding these elements, international B2B buyers can make informed decisions, ensuring they achieve the best value in their sourcing endeavors.

A stock image related to qu'est ce que le sic.

When evaluating "qu'est ce que le sic," it's essential to consider viable alternatives that can achieve similar objectives. This analysis helps B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Qu'Est Ce Que Le Sic | Alternative 1: Technology A | Alternative 2: Technology B |

|---|---|---|---|

| Performance | High efficiency in data processing and analysis | Moderate efficiency, suitable for smaller datasets | High efficiency, but requires extensive training data |

| Cost | Mid-range investment with scalable options | Lower initial cost, but hidden costs in scaling | Higher upfront cost but lower long-term operational costs |

| Ease of Implementation | Requires specialized knowledge | User-friendly interface, easier for non-tech users | Moderate complexity; requires training |

| Maintenance | Regular updates needed, but manageable | Minimal maintenance, mostly automated | High maintenance due to system complexity |

| Best Use Case | Ideal for large enterprises needing robust analytics | Best for SMEs with limited budgets | Suited for large-scale operations needing advanced analytics |

Alternative Technology A offers a user-friendly interface that is particularly advantageous for small to medium-sized enterprises (SMEs). Its lower initial cost makes it attractive for businesses with tight budgets. However, it may not handle larger datasets efficiently, which could limit its scalability as the company grows. Additionally, while it requires minimal maintenance, the automation may not cater to specific needs, leading to potential gaps in performance.

Alternative Technology B is designed for large-scale operations that require sophisticated analytics. Its high efficiency makes it a strong competitor for enterprises that demand advanced capabilities. However, this technology comes with a higher upfront investment, which might be a barrier for smaller companies. Furthermore, the complexity of the system requires extensive training for employees, which can delay implementation and increase initial costs. Despite these drawbacks, its lower long-term operational costs make it appealing for businesses ready to invest in growth.

Selecting the right solution among these options involves assessing specific business needs and operational capacities. Buyers should consider their current and future data processing requirements, budget constraints, and the technical expertise available within their teams. Companies in emerging markets may prioritize cost and ease of implementation, while established firms might focus on performance and scalability. Engaging with vendors for trial periods or demos can also provide insights into which solution aligns best with organizational goals. Ultimately, the choice should reflect a balance between immediate requirements and long-term strategic objectives.

Understanding the essential technical properties of 'qu'est ce que le sic' is crucial for international B2B buyers looking to make informed purchasing decisions. Here are some of the critical specifications to consider:

Material Grade

- The material grade indicates the quality and suitability of 'sic' (silicon carbide) for specific applications. Higher grades typically offer superior performance, including increased hardness and thermal resistance. For B2B buyers, selecting the right material grade is essential to ensure product longevity and reliability.

Tolerance Levels

- Tolerance levels refer to the allowable variation in dimensions during manufacturing. In the context of 'qu'est ce que le sic', precise tolerances are critical for applications requiring exact fits, such as in semiconductor devices. A tighter tolerance often signifies higher manufacturing quality, which can reduce the likelihood of product failure.

Thermal Conductivity

- This property measures how well 'sic' can conduct heat. High thermal conductivity is vital in applications like power electronics, where efficient heat dissipation is necessary to maintain performance and prevent overheating. B2B buyers should assess thermal conductivity ratings to ensure their components can operate effectively under high temperatures.

Mechanical Strength

- Mechanical strength defines the material's ability to withstand stress without deformation. For 'qu'est ce que le sic', high mechanical strength is crucial in high-pressure environments, making it suitable for industrial applications. Buyers should verify strength specifications to ensure they meet operational demands.

Chemical Resistance

- Silicon carbide exhibits strong resistance to chemical corrosion, making it suitable for various harsh environments. This property is particularly relevant for buyers in sectors such as chemicals and pharmaceuticals. Understanding the chemical resistance can prevent costly failures and maintenance issues.

Electrical Resistivity

- Electrical resistivity is a measure of how strongly a material opposes the flow of electric current. In the case of 'qu'est ce que le sic', low resistivity is often desired for applications in electronics. B2B buyers must consider resistivity levels to ensure compatibility with their electrical systems.

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

- An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 'qu'est ce que le sic', knowing your OEM can help buyers ensure quality and compatibility in their supply chain.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and avoid overstocking or stockouts.

RFQ (Request for Quotation)

- An RFQ is a document sent to suppliers to request pricing and other details for specific products. For B2B buyers, issuing an RFQ can streamline the procurement process and facilitate better pricing negotiations.

Incoterms (International Commercial Terms)

- Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. They clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms can prevent misunderstandings and financial disputes.

Lead Time

- Lead time refers to the time taken from placing an order to receiving the product. For buyers, understanding lead times helps in planning and managing production schedules effectively.

Warranty Period

- The warranty period is the time frame in which a product is guaranteed against defects. Knowing the warranty terms for 'qu'est ce que le sic' products can provide buyers with peace of mind and protect their investment.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing 'qu'est ce que le sic' more effectively, ensuring better purchasing decisions and enhancing their supply chain management.

The 'qu'est ce que le sic' sector is currently witnessing significant transformation driven by global market dynamics. A key factor is the increasing demand for technology integration, which has shifted sourcing strategies towards more digital solutions. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are prioritizing platforms that facilitate seamless transactions and enhance supply chain visibility. Technologies such as Artificial Intelligence (AI) and Blockchain are emerging as critical tools for improving transparency and efficiency in sourcing processes.

Moreover, the rise of remote work and digital collaboration tools has influenced buyer-supplier relationships. Companies are now more inclined to partner with suppliers who can offer flexible, scalable solutions that adapt to fluctuating market conditions. This trend is particularly relevant for businesses in Africa and South America, where market volatility can impact supply chain stability.

Sustainability is also becoming a pivotal consideration in sourcing decisions. B2B buyers are increasingly seeking suppliers who align with their environmental values, emphasizing the importance of sustainable practices and eco-friendly products. This trend is not only a response to consumer demand but also a proactive strategy to mitigate risks associated with regulatory changes related to environmental standards.

Sustainability and ethical sourcing are increasingly shaping the decision-making processes of B2B buyers in the 'qu'est ce que le sic' sector. The environmental impact of sourcing practices has gained prominence, with businesses recognizing the need to reduce their carbon footprint. Buyers are now evaluating suppliers based on their commitment to sustainable materials, production processes, and waste management.

The importance of ethical supply chains cannot be overstated. Companies that prioritize ethical sourcing not only enhance their brand reputation but also foster customer loyalty. Certifications such as Fair Trade, FSC (Forest Stewardship Council), and ISO 14001 are becoming critical benchmarks for B2B buyers when assessing potential suppliers. These certifications serve as assurances that suppliers are committed to responsible practices, which is particularly appealing to buyers from Europe and the Middle East, where consumer awareness regarding ethical sourcing is high.

Investing in 'green' materials and technologies is also gaining traction. Buyers are looking for innovative solutions that minimize environmental impact while still delivering high-quality products. Suppliers that can demonstrate a clear commitment to sustainability are likely to gain a competitive edge in the market.

The 'qu'est ce que le sic' sector has evolved significantly over the years, shaped by technological advancements and changing market demands. Initially focused on traditional sourcing methods, the sector has embraced digital transformation, leading to the adoption of e-commerce platforms and supply chain management software. This evolution has enabled greater efficiency and accessibility for international B2B buyers.

As the market has matured, the focus has shifted towards sustainability and ethical sourcing, reflecting broader societal changes and consumer expectations. This shift has led to an increased emphasis on transparency, traceability, and responsible sourcing practices within the sector, aligning with global initiatives aimed at promoting sustainable development.

In summary, understanding these dynamics is crucial for B2B buyers looking to navigate the complexities of the 'qu'est ce que le sic' sector effectively. By staying informed about market trends and prioritizing sustainability, businesses can make strategic sourcing decisions that enhance their competitiveness and align with their corporate values.

How do I evaluate suppliers for 'qu'est ce que le sic'?

To effectively evaluate suppliers, consider their industry experience, reputation, and financial stability. Request references from previous clients and analyze their production capabilities, quality assurance processes, and certifications. Additionally, assess their responsiveness and willingness to customize products to meet your specific needs. Conducting site visits or audits can further enhance your understanding of their operations, ensuring they align with your business requirements.

What are the typical minimum order quantities (MOQ) for 'qu'est ce que le sic'?

MOQs can vary significantly based on the supplier and the specific product. Typically, suppliers will set an MOQ to cover production costs and ensure profitability. For 'qu'est ce que le sic', you might encounter MOQs ranging from a few hundred to several thousand units. Always clarify MOQs upfront to avoid misunderstandings and negotiate terms that suit your business's scale and budget.

What payment terms should I expect when sourcing 'qu'est ce que le sic'?

Payment terms can vary widely among suppliers, influenced by factors like order size and the supplier's policies. Common terms include a deposit (often 30% to 50%) upfront, with the balance due upon delivery or before shipping. It’s essential to negotiate terms that align with your cash flow needs and establish a clear timeline for payments to avoid potential disputes.

How can I ensure quality assurance when sourcing 'qu'est ce que le sic'?

To ensure quality assurance, request detailed specifications and samples before placing a full order. Implement a robust quality control process, including inspections during production and final audits before shipment. Consider working with third-party inspection services to provide an unbiased assessment of the products, ensuring they meet your standards and comply with any relevant regulations.

What are the logistics considerations when importing 'qu'est ce que le sic'?

Logistics considerations include choosing the right shipping method (air, sea, or land), understanding customs regulations, and coordinating with freight forwarders for efficient transport. Evaluate potential shipping times and costs, and consider the reliability of the supplier's shipping practices. Additionally, familiarize yourself with import duties and taxes applicable to your region to accurately calculate total landed costs.

How do I handle customs clearance for 'qu'est ce que le sic'?

Customs clearance involves submitting the necessary documentation to your country's customs authority, including invoices, packing lists, and certificates of origin. Ensure all paperwork is accurate and complete to avoid delays. It may be beneficial to hire a customs broker who can navigate the complexities of international trade regulations, ensuring compliance and facilitating a smooth clearance process.

What customization options are available for 'qu'est ce que le sic'?

Many suppliers offer customization options, such as alterations in design, size, and packaging to meet specific market needs. Discuss your requirements early in the negotiation process to determine what modifications are feasible and at what additional cost. Understanding the supplier's capabilities in customization will help you tailor the product effectively for your target market.

How can I build long-term relationships with suppliers of 'qu'est ce que le sic'?

Building long-term relationships with suppliers involves consistent communication, transparency, and mutual respect. Regularly provide feedback on product performance and maintain open dialogue about any issues or improvements needed. Consider establishing partnership agreements that outline expectations and commitments, fostering a collaborative environment that benefits both parties over time.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In today's interconnected global marketplace, strategic sourcing emerges as a pivotal process for B2B buyers aiming to optimize their supply chains. For international buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of strategic sourcing can lead to significant cost savings, enhanced supplier relationships, and improved product quality. Key takeaways include the importance of thorough market research, the evaluation of supplier capabilities, and the negotiation of favorable terms that align with your business goals.

As the landscape of global trade continues to evolve, leveraging technology and data analytics will further empower buyers to make informed decisions. Embracing these innovative tools can streamline sourcing processes and enhance transparency, particularly in regions with diverse regulatory environments, such as France and Egypt.

Looking ahead, B2B buyers are encouraged to adopt a proactive approach to strategic sourcing. This involves not only adapting to market changes but also anticipating future trends that could impact supply chains. By doing so, businesses can position themselves for sustained growth and competitive advantage in the years to come. Engage with local suppliers, invest in strategic partnerships, and prioritize sustainability to ensure your sourcing strategies are resilient and future-ready.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina