In today's competitive landscape, international B2B buyers face the pressing challenge of sourcing high-quality sand blasting corundum abrasives efficiently. With a growing demand for these essential materials across various industries—ranging from manufacturing to construction—understanding the nuances of this market has never been more critical. This comprehensive guide aims to equip buyers from Africa, South America, the Middle East, and Europe, including regions like the UAE and Argentina, with the necessary insights to make informed purchasing decisions.

Throughout this guide, we will explore the different types of corundum abrasives available, their specific applications, and the crucial factors to consider when vetting suppliers. Additionally, we will provide an overview of cost structures and market trends, empowering buyers to navigate the complexities of global sourcing effectively. By leveraging this information, businesses can enhance their operational efficiencies, reduce costs, and ensure compliance with environmental standards.

Ultimately, this guide serves as a valuable resource for international buyers looking to optimize their procurement strategies and achieve sustainable success in the sand blasting industry. Whether you are a seasoned purchaser or new to the market, the insights provided here will enable you to make decisions that align with your business objectives and environmental considerations.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brown Fused Alumina | High hardness, angular shape, and consistent grit size | Metal fabrication, surface preparation | Pros: Excellent cutting ability, durable. Cons: Higher cost than some alternatives. |

| White Fused Alumina | High purity, lower iron content, finer grit sizes | Precision applications, automotive parts | Pros: Produces a clean finish, less contamination. Cons: More expensive than brown fused. |

| Corundum Grit | Naturally occurring, less uniform size distribution | General-purpose blasting, maintenance | Pros: Cost-effective, readily available. Cons: Inconsistent performance due to size variation. |

| Garnet Abrasives | Natural mineral, non-toxic, and environmentally friendly | Waterjet cutting, paint stripping | Pros: Minimal dust production, reusable. Cons: Can be less effective on harder surfaces. |

| Silicon Carbide | Very hard, sharp edges, and finer particle sizes | Glass etching, electronic component cleaning | Pros: Highly effective on hard materials, versatile. Cons: Fragile, can break down quickly under heavy use. |

Brown Fused Alumina is known for its high hardness and angular shape, which makes it ideal for cutting and grinding applications. Its consistent grit size ensures uniform performance across various jobs, making it a preferred choice in metal fabrication and surface preparation industries. When purchasing, buyers should consider the durability and cutting efficiency against the higher cost compared to other abrasives.

White Fused Alumina boasts a high purity level and lower iron content, making it suitable for precision applications such as automotive parts and electronics. Its finer grit sizes help achieve a clean finish with minimal contamination. However, the cost is a key consideration for buyers, as it tends to be more expensive than brown fused alumina, which may impact budget decisions.

Corundum Grit is a natural abrasive that offers a cost-effective solution for general-purpose blasting and maintenance tasks. Its less uniform size distribution can lead to inconsistent performance, which may not be ideal for precision tasks. Buyers should weigh the affordability against the potential variability in results, especially for critical applications.

Garnet Abrasives are derived from natural minerals and are recognized for their non-toxic properties, making them suitable for environmentally conscious applications like waterjet cutting and paint stripping. They produce minimal dust, enhancing workplace safety, and can be reused, providing cost savings. However, buyers should note that garnet may be less effective on harder surfaces compared to more aggressive abrasives.

Silicon Carbide is renowned for its extreme hardness and sharp edges, making it effective for glass etching and cleaning electronic components. Its ability to perform well on hard materials adds to its versatility. However, buyers should be aware of its fragility; under heavy use, silicon carbide can break down quickly, necessitating consideration of the application intensity and frequency in purchasing decisions.

Related Video: Grit Blasting process Vs Sand Blasting process, Types of Grit Blasting abrasive materials

| Industry/Sector | Specific Application of sand blasting corundum abrasives | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Surface preparation for metal components | Enhances adhesion of coatings and paints | Consistency in grain size and purity of abrasives |

| Automotive | Cleaning and finishing of engine parts | Increases efficiency and lifespan of components | Availability of specific grades for different metals |

| Construction | Restoration of concrete surfaces | Improves aesthetics and extends surface durability | Environmental regulations on waste disposal |

| Aerospace | Deburring and surface finishing of aircraft components | Reduces weight and improves performance | Compliance with industry standards and certifications |

| Shipbuilding | Hull cleaning and preparation for painting | Enhances protection against corrosion | Sourcing from suppliers with reliable delivery times |

In the manufacturing sector, sand blasting corundum abrasives are essential for surface preparation of metal components. This process removes rust, scale, and other impurities, ensuring a clean surface for subsequent coatings or paint applications. The enhanced adhesion that results from this preparation significantly increases the durability of the final product. For international buyers, particularly in regions like Africa and South America, sourcing high-quality abrasives that meet specific standards is crucial to ensure consistent results across various manufacturing processes.

In the automotive industry, sand blasting corundum abrasives are utilized for cleaning and finishing engine parts. This application is critical as it not only improves the aesthetic appeal of components but also enhances their efficiency and longevity. By removing contaminants and preparing surfaces for coatings, these abrasives help manufacturers deliver high-performance vehicles. Buyers in the Middle East and Europe must consider the specific grades of abrasives that cater to different metals and alloys used in automotive manufacturing.

The construction industry employs sand blasting corundum abrasives for the restoration of concrete surfaces. This process effectively removes old paint, graffiti, and other blemishes, thereby improving the aesthetics and extending the durability of structures. For businesses in Europe and the Middle East, it’s essential to understand the environmental regulations surrounding waste disposal and the types of abrasives permitted for use to ensure compliance while achieving the desired results.

In the aerospace sector, sand blasting corundum abrasives are crucial for deburring and surface finishing of aircraft components. This application is vital as it contributes to weight reduction and enhances performance, which are critical factors in aviation. International buyers need to focus on sourcing abrasives that comply with stringent industry standards and certifications to ensure safety and reliability in aerospace applications.

In shipbuilding, sand blasting corundum abrasives are used for hull cleaning and preparation prior to painting. This process is essential for enhancing the protection of vessels against corrosion, thereby prolonging their service life. Businesses in regions like the UAE and South America should prioritize sourcing from suppliers that offer reliable delivery times, as delays can significantly impact project timelines and overall operational efficiency.

The Problem:

International B2B buyers often face the challenge of inconsistent quality in sand blasting corundum abrasives, which can lead to subpar surface finishes and increased operational costs. For businesses in regions like Africa and South America, sourcing abrasives from local suppliers can result in varying grades of materials. This inconsistency can affect the performance of blasting equipment and compromise the quality of the finished products, leading to customer dissatisfaction and potential loss of contracts.

The Solution:

To mitigate this issue, buyers should establish relationships with reputable suppliers who can provide certifications for their corundum abrasives. Look for suppliers that offer detailed specifications, including mineral content and particle size distribution. Additionally, consider implementing a testing protocol upon receipt of abrasives to verify their quality against the provided specifications. Utilizing third-party testing services can also ensure that the materials meet industry standards. By consistently sourcing from certified suppliers and conducting regular quality checks, businesses can maintain high standards in their blasting operations and reduce the risk of quality-related issues.

The Problem:

As global awareness of environmental issues increases, B2B buyers are under pressure to ensure that their sourcing and usage of sand blasting corundum abrasives comply with stringent environmental regulations. Companies operating in Europe and the Middle East, for example, may face legal repercussions if they use abrasives that contain harmful contaminants or fail to manage waste properly. This can lead to unexpected fines and damage to a company's reputation.

The Solution:

To address these compliance challenges, buyers should prioritize suppliers who adhere to sustainable mining practices and offer environmentally friendly corundum abrasives. Request documentation that outlines the supplier's mining and processing methods, including any certifications related to environmental management systems (such as ISO 14001). Moreover, investing in effective waste management solutions, such as recycling used abrasives, can help companies minimize their environmental footprint. By aligning sourcing practices with regulatory requirements and promoting sustainability, businesses can not only avoid penalties but also enhance their brand image as environmentally responsible entities.

The Problem:

Many B2B buyers experience high consumption rates of sand blasting corundum abrasives, leading to increased operational costs and inefficiencies. This challenge is particularly pronounced in industries such as automotive and metal fabrication, where the abrasives must be frequently replenished to maintain production levels. Buyers may find themselves in a cycle of ordering frequently, which strains budgets and disrupts workflow.

The Solution:

To combat high abrasive consumption, buyers should analyze their blasting processes to identify areas for efficiency improvements. This may include optimizing the pressure settings of blasting equipment, adjusting the distance from the nozzle to the workpiece, and ensuring that operators are well-trained in best practices. Additionally, consider investing in advanced abrasive recycling systems that can reclaim and reuse spent abrasives, significantly reducing overall consumption. Collaborating with suppliers to identify high-performance abrasive formulations designed for longevity can also be beneficial. By focusing on process optimization and material efficiency, companies can reduce abrasive usage, lower costs, and improve overall productivity.

When selecting sand blasting corundum abrasives, understanding the properties, advantages, and limitations of various materials is crucial for optimizing performance and ensuring compliance with industry standards. Below are analyses of four common materials used in sand blasting abrasives, tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

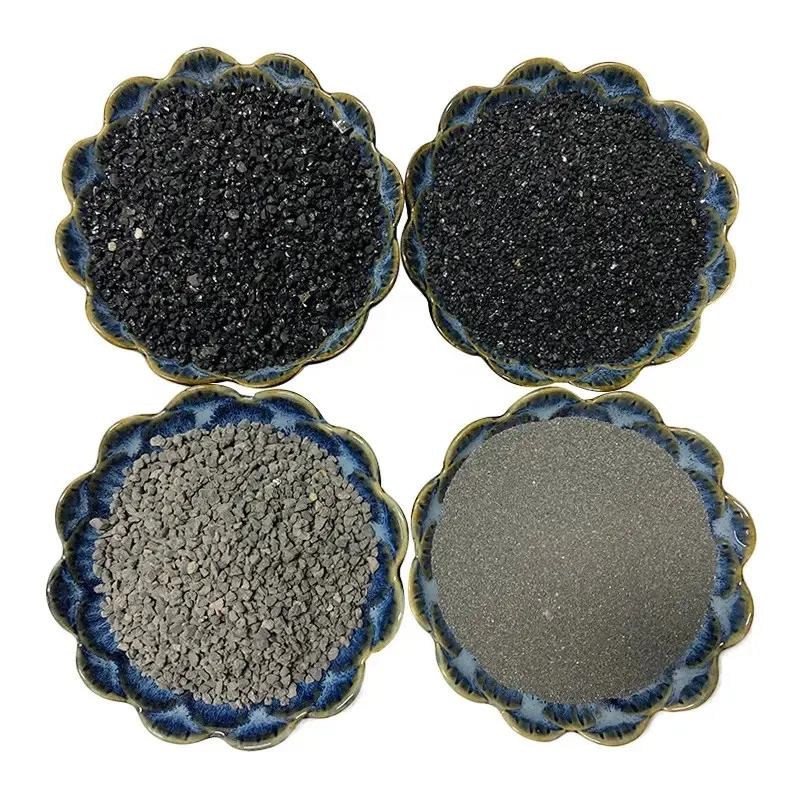

A stock image related to sand blasting corundum abrasives.

Aluminum oxide, often referred to as corundum, is a widely used abrasive material in sand blasting applications. It exhibits excellent hardness and durability, making it suitable for high-pressure blasting environments. Its temperature resistance is notable, withstanding temperatures up to 2000°C without degrading.

Pros:

- High durability and long lifespan.

- Effective for a variety of surfaces, including metals and plastics.

- Available in various grit sizes for different applications.

Cons:

- Higher cost compared to other abrasives like silica sand.

- Can produce hazardous dust if not managed properly.

Impact on Application: Aluminum oxide is compatible with most blasting equipment and is ideal for applications requiring a fine finish, such as automotive and aerospace industries.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is essential, especially in Europe and the Middle East. Buyers should also consider local regulations regarding dust exposure.

Garnet is another popular abrasive material known for its angular shape and high density. It is less abrasive than aluminum oxide but offers a good balance of performance and cost.

Pros:

- Non-toxic and environmentally friendly.

- Produces less dust, making it safer for operators.

- Versatile for both wet and dry blasting applications.

Cons:

- Lower hardness compared to aluminum oxide, which may not be suitable for heavy-duty applications.

- Can be more expensive than silica sand.

Impact on Application: Garnet is particularly effective for removing coatings and preparing surfaces for painting, making it popular in the shipbuilding and construction sectors.

Considerations for International Buyers: Ensure compliance with environmental regulations, especially in regions like South America where sustainability is increasingly prioritized.

Silicon carbide is a synthetic abrasive known for its sharpness and durability. It is often used in applications requiring a high level of precision.

Pros:

- Extremely hard and fast-cutting.

- Suitable for a wide range of materials, including glass and ceramics.

- Good thermal conductivity.

Cons:

- Higher cost compared to natural abrasives.

- Can be brittle, leading to breakage during use.

Impact on Application: Silicon carbide is ideal for applications requiring fine finishes and is commonly used in the electronics and automotive industries.

Considerations for International Buyers: Compliance with JIS and ASTM standards is critical, especially in Asian markets. Buyers should also be aware of the import regulations in their respective countries.

Glass beads are a unique abrasive material that provides a different finish compared to traditional abrasives. They are often used for peening and polishing applications.

Pros:

- Produce a smooth, polished surface.

- Non-toxic and environmentally friendly.

- Reusable, reducing overall costs.

Cons:

- Less effective for heavy material removal.

- May require more frequent replacement than harder abrasives.

Impact on Application: Glass beads are ideal for applications where surface finish is critical, such as in the aerospace and automotive industries.

Considerations for International Buyers: Buyers should ensure that glass beads meet local safety standards and are suitable for their specific applications.

| Material | Typical Use Case for Sand Blasting Corundum Abrasives | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Automotive and aerospace applications | High durability and long lifespan | Higher cost compared to silica sand | High |

| Garnet | Coating removal and surface preparation | Non-toxic and environmentally friendly | Lower hardness for heavy-duty applications | Medium |

| Silicon Carbide | Precision applications in electronics and automotive | Extremely hard and fast-cutting | Higher cost and brittleness | High |

| Glass Beads | Polishing and peening applications | Produces a smooth, polished surface | Less effective for heavy material removal | Medium |

A stock image related to sand blasting corundum abrasives.

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions when sourcing sand blasting corundum abrasives tailored to their specific needs and regional compliance requirements.

The manufacturing of sand blasting corundum abrasives involves several critical stages that ensure the final product meets the high standards required by various industries. Here’s a breakdown of the main stages:

The first step in manufacturing corundum abrasives is sourcing high-quality raw corundum. This mineral, primarily composed of aluminum oxide, is obtained from bauxite or through synthetic processes. Once sourced, the raw material undergoes crushing and grinding to achieve the desired particle size. This stage is crucial as the size of the abrasives directly affects their performance in sand blasting applications.

After preparation, the corundum is formed into specific shapes and sizes. Techniques like granulation and sieving are employed to ensure uniformity. Granulation involves agglomerating finer particles into larger granules, which are then classified using sieves to meet specific standards. This process helps in creating abrasives that are effective in various blasting applications, from surface cleaning to coating removal.

In the assembly phase, the processed corundum is blended with other materials if necessary, depending on the desired properties of the final product. Following this, the finishing process involves additional treatments such as drying and packaging. The abrasives may undergo surface treatments to enhance their durability and performance. This stage ensures that the product meets the specific requirements of different industries, including automotive, aerospace, and construction.

Quality assurance is paramount in the manufacturing of sand blasting abrasives. Adhering to international standards not only guarantees product quality but also builds trust with B2B buyers.

Manufacturers must comply with international quality standards such as ISO 9001, which focuses on quality management systems. Other relevant certifications may include CE marking for products sold in the European market, and API standards for specific industrial applications. These certifications signify that the products have undergone rigorous testing and meet industry-specific requirements.

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

Common testing methods for corundum abrasives include:

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier QC practices is crucial for ensuring product quality. Here are actionable steps:

Buyers should request detailed QC reports that outline the testing methods used and the results obtained. Supplier audits can provide insights into the manufacturing processes and quality management systems in place. It’s beneficial to look for suppliers that are transparent about their QC processes and willing to share documentation.

Engaging third-party inspection services can provide an unbiased assessment of the supplier's quality control practices. These inspections can be conducted at various stages of the manufacturing process, ensuring compliance with international standards and verifying the integrity of the final product.

When sourcing corundum abrasives from international suppliers, buyers should be aware of specific nuances that may affect product quality and compliance:

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing sand blasting corundum abrasives, ensuring they receive high-quality products that meet their operational needs.

When sourcing sand blasting corundum abrasives, it’s essential to follow a structured approach to ensure you select the right materials and suppliers for your needs. This checklist will guide you through the critical steps in the procurement process, enabling you to make informed decisions that align with your business objectives.

Clearly outline the specific requirements for the corundum abrasives you intend to purchase. Consider factors such as grit size, purity levels, and intended applications (e.g., surface preparation, cleaning, or finishing).

Identify potential suppliers from regions known for producing high-quality corundum abrasives, such as Europe and South America. Utilize online platforms, trade fairs, and industry publications to gather a comprehensive list of suppliers.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

Check that the suppliers hold relevant certifications and adhere to international quality standards, such as ISO 9001 or other industry-specific certifications.

Before making a bulk purchase, ask for samples of the corundum abrasives. Conduct tests to evaluate performance, consistency, and suitability for your applications.

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that all agreements are documented clearly.

Consider forming a long-term relationship with your chosen supplier. This can lead to better pricing, priority support, and improved service levels over time.

By following these steps, B2B buyers can effectively navigate the sourcing process for sand blasting corundum abrasives, ensuring they select the best suppliers for their operational needs.

When sourcing sand blasting corundum abrasives, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The primary raw material for corundum abrasives is aluminum oxide. The price of this material can fluctuate based on global supply and demand dynamics, mining regulations, and environmental concerns surrounding sand mining. Buyers should stay informed about market trends that could affect material costs.

Labor: Labor costs can vary significantly depending on the region and the complexity of the production process. In regions such as Africa and South America, labor might be less expensive, while in Europe and the Middle East, higher labor costs may affect overall pricing.

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which is beneficial for pricing flexibility.

Tooling: The cost of specialized machinery and tools required for the production of abrasives can be substantial. Suppliers with advanced technology may offer higher quality products but at a premium price.

Quality Control (QC): Ensuring the quality of abrasives is paramount, especially for international buyers who may require specific certifications. The costs associated with QC processes should be factored into the overall pricing.

Logistics: Transportation costs can vary greatly depending on the distance from the supplier and the method of shipping. International buyers must consider Incoterms to understand who bears the logistics costs.

Margin: Suppliers will add a profit margin to their costs, which can vary based on market competition, brand reputation, and customer relationships.

Several factors can influence the pricing of sand blasting corundum abrasives:

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing.

Specifications and Customization: Customized products may incur additional costs. Buyers should clearly communicate their specifications to avoid unexpected charges.

Quality and Certifications: Higher quality abrasives often come with certifications that may justify a higher price. International buyers, especially in regulated industries, should prioritize suppliers that can meet these standards.

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may offer better service and quality assurance, which can be worth the additional cost.

Incoterms: Understanding the chosen Incoterms is essential as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the total landed cost.

When negotiating prices for corundum abrasives, international buyers should consider the following strategies:

Research Market Prices: Understanding the current market rates for corundum abrasives will empower buyers to negotiate effectively. Utilize industry reports and supplier quotes for comparisons.

Build Relationships: Developing strong relationships with suppliers can lead to better pricing and terms. Trust and communication can foster long-term partnerships that benefit both parties.

Consider Total Cost of Ownership (TCO): Instead of focusing solely on the initial price, evaluate the TCO, including maintenance, replacement, and operational costs. A higher-quality abrasive may yield better performance and lower overall costs.

Leverage Multiple Quotes: Obtaining quotes from various suppliers allows buyers to compare prices and negotiate better terms. This competitive approach can lead to more favorable pricing.

Be Open to Adjustments: Flexibility in terms of order size and delivery timelines can sometimes result in better pricing. Discussing potential adjustments with suppliers can lead to mutual benefits.

It is crucial to note that the prices for sand blasting corundum abrasives can vary significantly based on the factors discussed above. Prices are subject to change due to market fluctuations, supplier negotiations, and regional economic conditions. Therefore, buyers are encouraged to conduct thorough due diligence and seek updated quotes before making purchasing decisions.

When considering the use of sand blasting corundum abrasives, it is essential for international B2B buyers to explore alternative solutions that can achieve similar results. This comparison not only highlights the unique advantages of corundum abrasives but also provides insight into other viable options available in the market.

| Comparison Aspect | Sand Blasting Corundum Abrasives | Steel Grit | Baking Soda |

|---|---|---|---|

| Performance | High durability, effective on hard surfaces | Good for surface preparation, less aggressive | Gentle cleaning, ideal for soft surfaces |

| Cost | Moderate initial investment | Lower cost per unit | Higher cost per unit |

| Ease of Implementation | Requires specialized equipment | Easy to implement with standard blasters | Requires specific equipment adjustments |

| Maintenance | Low maintenance, long-lasting | Moderate maintenance due to wear | High maintenance, frequent replenishment needed |

| Best Use Case | Industrial applications, metal preparation | Construction and shipbuilding | Food industry, delicate parts |

Steel grit is a common alternative to corundum abrasives, particularly in heavy-duty applications. Its main advantage lies in its cost-effectiveness and ease of use. Steel grit is less aggressive, making it suitable for surface preparation without damaging the substrate. However, it may not perform as well on harder surfaces and can lead to faster wear on equipment. Additionally, it produces more dust and requires proper ventilation during use.

Baking soda is a softer alternative that is particularly effective for delicate cleaning tasks, such as removing paint from sensitive surfaces or cleaning food processing equipment. Its gentle nature minimizes the risk of damage, making it ideal for industries where surface integrity is crucial. However, baking soda is typically more expensive and requires more frequent replenishment, leading to higher operational costs. Moreover, it necessitates specialized equipment adjustments, which can complicate implementation.

When selecting between sand blasting corundum abrasives and alternatives like steel grit or baking soda, B2B buyers should consider their specific application requirements, budget constraints, and maintenance capabilities. Corundum abrasives excel in durability and effectiveness for industrial applications, while steel grit offers a more economical solution for larger projects. Baking soda, although costly, shines in environments requiring careful handling. By assessing these factors, buyers can make informed decisions that align with their operational needs and ensure optimal performance.

When evaluating sand blasting corundum abrasives, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

Material Grade

- Material grade indicates the purity and quality of corundum used in abrasives. Higher grades (e.g., A or AA) contain fewer impurities and are more effective for precision applications. For B2B buyers, selecting the appropriate material grade ensures optimal performance, which can reduce costs associated with frequent replacements.

Particle Size Distribution

- The particle size distribution refers to the range of particle sizes in the abrasive material. This property is vital for achieving the desired surface finish and cleaning efficiency. Buyers should consider the application requirements, as finer particles can produce smoother finishes, while coarser particles are better for aggressive cleaning.

Hardness

- Corundum is known for its hardness, typically rated 9 on the Mohs scale. This property determines the abrasive's ability to withstand wear and tear during blasting processes. For international buyers, investing in harder abrasives can lead to longer service life and lower operational costs.

Bulk Density

- Bulk density measures the mass of the abrasive per unit volume. A higher bulk density often indicates better packing efficiency, leading to reduced dust generation and increased effectiveness in blasting operations. Understanding bulk density helps buyers optimize their abrasive usage and improve productivity.

Moisture Content

- Moisture content indicates the amount of water present in the abrasive material. Excess moisture can lead to clumping and reduced blasting efficiency. Buyers must ensure that the moisture content is within acceptable limits to maintain operational effectiveness.

Familiarity with industry terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some key terms to know:

OEM (Original Equipment Manufacturer)

- OEM refers to companies that manufacture products that are sold under another company's brand name. In the sand blasting industry, understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ can assist in budgeting and inventory planning. It's important to negotiate MOQs to ensure they align with operational needs.

RFQ (Request for Quotation)

- An RFQ is a document sent by buyers to suppliers to request pricing and terms for specific products. This process allows buyers to compare options from different suppliers, ensuring they get the best value for their investment.

Incoterms (International Commercial Terms)

- Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for buyers to understand shipping costs, risk allocation, and delivery responsibilities.

Blasting Media

- This term refers to the materials used in the sand blasting process. Understanding the different types of blasting media, including corundum abrasives, helps buyers choose the most effective material for their specific applications.

Surface Profile

- Surface profile describes the texture of a surface after blasting. This property is critical for applications such as coating adhesion. Buyers should specify the desired surface profile to ensure compatibility with subsequent processes.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing sand blasting corundum abrasives, ultimately leading to enhanced operational efficiency and cost-effectiveness.

The global sand blasting corundum abrasives market is witnessing significant growth, driven by the increasing demand for surface preparation and finishing in various industries such as automotive, aerospace, and construction. Key factors influencing this market include rapid industrialization and the rising need for efficient cleaning and coating processes. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging technologies are reshaping sourcing trends within this sector. Automation and advanced manufacturing techniques are enhancing the efficiency of abrasive production, thereby reducing costs and lead times. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers and a broader range of products. Buyers are increasingly leveraging data analytics to assess supplier performance and optimize their procurement strategies, ensuring they can respond swiftly to market changes.

Sustainability is another critical trend shaping the market. As environmental regulations tighten globally, businesses are being pushed to adopt more sustainable practices. This shift is particularly relevant for buyers in environmentally-conscious regions like Europe, where compliance with stringent regulations is mandatory. The integration of eco-friendly materials and processes in the production of sand blasting corundum abrasives is becoming a key factor in supplier selection.

The environmental impact of sand mining and abrasive production is a pressing concern. Unsustainable practices can lead to habitat destruction, water scarcity, and increased carbon footprints. For international B2B buyers, particularly in regions like the Middle East and Africa, ensuring that suppliers adhere to sustainable practices is not just a compliance issue but also a competitive advantage.

Ethical sourcing is increasingly becoming a priority for buyers. Companies are now seeking suppliers who demonstrate transparency in their supply chains and commit to fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade standards can serve as indicators of a supplier's commitment to sustainability. Buyers should prioritize partnerships with manufacturers that can provide evidence of their sustainable practices, thus enhancing their brand reputation and meeting consumer demand for responsible sourcing.

In addition to ethical considerations, the adoption of 'green' materials in the production of sand blasting corundum abrasives is gaining traction. Innovations in recycling and the use of alternative materials not only reduce environmental impact but can also lead to cost savings in the long run. B2B buyers are encouraged to evaluate suppliers based on their ability to offer sustainable options, which can enhance their market position.

The use of abrasives for surface treatment can be traced back to ancient times when natural materials were employed for polishing and finishing surfaces. However, the modern sand blasting technique was developed in the late 19th century, revolutionizing how materials are prepared for finishing. The introduction of corundum abrasives provided a more durable and efficient option compared to traditional materials.

Over the decades, advancements in technology have refined abrasive production and application processes. The focus has shifted towards efficiency, sustainability, and the development of specialized abrasives tailored for specific industries. Today, B2B buyers benefit from a rich history of innovation that has led to a diverse range of products, catering to the nuanced demands of various sectors. Understanding this evolution allows buyers to appreciate the value and capabilities of contemporary corundum abrasives in their procurement strategies.

How do I choose the right corundum abrasive for my sand blasting needs?

Choosing the right corundum abrasive involves considering several factors, including the type of substrate you are working with, the desired finish, and the specific application (e.g., cleaning, shaping, or finishing). For metal surfaces, a coarser grade may be needed, while for delicate materials, a finer grade is more appropriate. Additionally, evaluate the hardness and angularity of the abrasive, as these properties influence the effectiveness and efficiency of the blasting process. Always consult with suppliers for tailored recommendations based on your project requirements.

What is the best grade of corundum abrasive for specific applications?

The best grade of corundum abrasive depends on the application. For heavy-duty applications like rust removal, a coarse grade (e.g., 24 to 60 grit) is ideal. For general cleaning or surface preparation, medium grades (e.g., 80 to 120 grit) are suitable. Fine grades (e.g., 150 grit and above) are recommended for achieving a smooth finish on sensitive surfaces. Always ensure that the selected grade aligns with both the material being blasted and the desired outcome.

How can I verify the quality of corundum abrasives from suppliers?

To verify the quality of corundum abrasives, request product certifications and test reports that confirm compliance with industry standards. Conduct a physical inspection of samples, checking for consistency in particle size and lack of impurities. Additionally, consider suppliers who provide transparent information regarding their sourcing and manufacturing processes. Building a relationship with reputable suppliers who have positive customer reviews can also help ensure you receive high-quality products.

What are the typical minimum order quantities (MOQs) for corundum abrasives?

Minimum order quantities (MOQs) for corundum abrasives can vary significantly based on the supplier and the specific product. Generally, MOQs range from 500 kg to several tons. For international buyers, it’s advisable to discuss MOQs directly with suppliers, as they may offer flexibility based on your purchasing frequency or provide mixed-load options to meet your requirements.

What payment terms should I negotiate with corundum abrasive suppliers?

When negotiating payment terms with suppliers, consider options like net 30 or net 60 days to allow for adequate cash flow. You may also explore partial payments upfront with the balance upon delivery or after inspection. For international transactions, discussing payment methods such as letters of credit or escrow services can provide additional security. Ensure that all terms are clearly documented to avoid any misunderstandings.

How can I ensure timely delivery of my corundum abrasives order?

To ensure timely delivery, work closely with suppliers to establish clear timelines and shipping methods. Discuss logistics options that best suit your region, considering factors such as customs clearance and local transport. Tracking systems can provide real-time updates on your order status. Establishing a reliable communication channel with your supplier will help address any potential delays promptly.

What are the environmental considerations when sourcing corundum abrasives?

When sourcing corundum abrasives, consider the environmental impact of extraction and production processes. Look for suppliers who prioritize sustainable practices, such as responsible mining operations and waste management. Additionally, inquire about the use of recycled materials in their products, which can reduce environmental degradation. Compliance with international environmental standards is also a key factor to ensure your sourcing practices align with sustainability goals.

How do I handle quality assurance (QA) for corundum abrasives?

Implementing a robust quality assurance (QA) process involves defining specifications and testing procedures for incoming materials. Conduct regular inspections and tests to evaluate the abrasives’ performance in your specific applications. Collaborate with suppliers to establish a clear quality control protocol, including documentation of batch testing and certification of compliance with industry standards. Regular communication with your supplier can help address any quality concerns swiftly.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of sand blasting corundum abrasives is crucial for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The increasing global demand for these abrasives underscores the necessity for buyers to engage with reliable suppliers who prioritize sustainability and ethical sourcing practices. Understanding the environmental implications of sand mining is imperative, as it not only affects sourcing costs but also corporate social responsibility initiatives.

As the industry evolves, staying informed about technological advancements and innovative applications in sand blasting will enable buyers to optimize their operations. Embracing these changes can lead to enhanced efficiency and cost-effectiveness, ultimately driving better business outcomes.

International B2B buyers are encouraged to leverage strategic partnerships with suppliers who demonstrate a commitment to sustainable practices and quality assurance. By prioritizing these relationships, buyers can secure a reliable supply chain and align with global standards. As you move forward, consider the long-term impacts of your sourcing decisions and remain proactive in adapting to market dynamics. Together, we can foster a responsible and prosperous future in the sand blasting industry.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina