Navigating the global market for sandblasting medium near me presents a unique set of challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The quest for the right abrasive materials can often feel overwhelming, with varying quality standards, sourcing options, and compliance regulations to consider. This guide aims to simplify the process by providing a comprehensive overview of the different types of sandblasting mediums available, their specific applications, and key factors to evaluate when selecting suppliers.

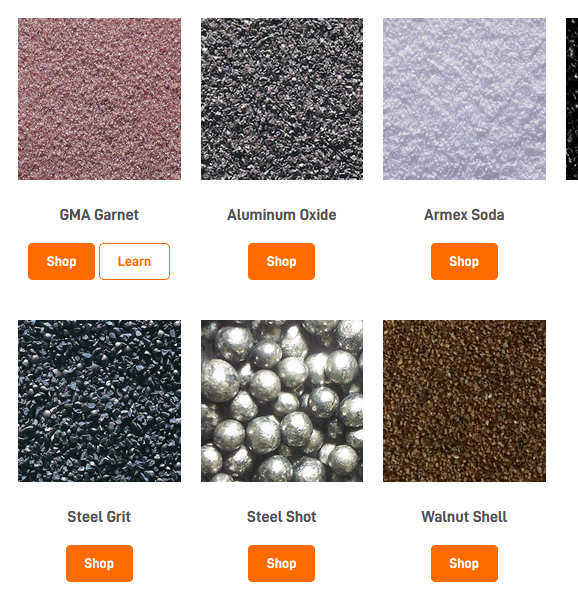

Understanding the nuances of sandblasting mediums, such as silica sand, garnet, and glass beads, is crucial for businesses looking to optimize their surface preparation and finishing processes. Beyond just product selection, this guide will delve into the importance of vetting suppliers, assessing cost factors, and ensuring compliance with local regulations, which can significantly impact operational efficiency and profitability.

By leveraging the insights presented in this guide, international B2B buyers will be empowered to make informed purchasing decisions. Whether you are based in bustling cities like Cairo or Nairobi, or industrial hubs in South America and Europe, this resource will help streamline your procurement strategies and enhance your competitive edge in the market. Understanding how to effectively source sandblasting mediums not only facilitates smoother operations but also fosters long-term partnerships with reliable suppliers.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silica Sand | Fine texture, high hardness, and natural availability | Metal preparation, glass etching, and casting | Pros: Economical; Cons: Health hazards due to silica dust. |

| Aluminum Oxide | Synthetic, angular grains, and high durability | Surface preparation, polishing, and coating | Pros: Long-lasting; Cons: Higher cost compared to silica. |

| Garnet | Non-toxic, angular grains with excellent cutting ability | Abrasive blasting and waterjet cutting | Pros: Environmentally friendly; Cons: More expensive than silica. |

| Glass Beads | Round shape, smooth finish, and low impact | Surface finishing, peening, and cleaning | Pros: Produces a fine finish; Cons: Not suitable for heavy abrasion. |

| Steel Shot | Spherical shape, high density, and reusable | Shot peening and surface hardening | Pros: Durable and cost-effective; Cons: Can leave a rough surface finish. |

Silica sand is one of the most commonly used sandblasting mediums due to its natural availability and cost-effectiveness. It features a fine texture and high hardness, making it suitable for various applications, including metal preparation and glass etching. However, buyers should consider the health implications associated with silica dust, which can pose respiratory risks. When sourcing silica sand, it is crucial to ensure compliance with local regulations regarding safety and environmental impact.

Aluminum oxide stands out for its synthetic production and angular grain structure, which enhances its durability and effectiveness in surface preparation and polishing applications. It is particularly favored in industries requiring high-performance results, like automotive and aerospace. While it is more expensive than silica sand, its longevity and efficiency often justify the investment. B2B buyers should evaluate their specific needs and budget when considering aluminum oxide as a sandblasting medium.

Garnet is an increasingly popular sandblasting medium, known for its non-toxic nature and excellent cutting ability. Its angular grains allow for efficient abrasive blasting and waterjet cutting, making it suitable for a wide range of industrial applications. While garnet tends to be more expensive than silica sand, its environmental friendliness and performance can make it a worthwhile investment. Buyers should assess their project requirements and environmental considerations when choosing garnet.

Glass beads are characterized by their round shape and smooth finish, making them ideal for surface finishing and cleaning applications. They are particularly effective in achieving a fine finish without causing significant substrate damage. However, glass beads are not suitable for heavy abrasion tasks. B2B buyers should consider the specific requirements of their projects, including the desired finish and material compatibility, when opting for glass beads as their sandblasting medium.

Steel shot is a robust sandblasting medium known for its spherical shape and high density, which allows for effective shot peening and surface hardening. It is reusable, making it a cost-effective choice for many industrial applications. However, steel shot may leave a rough surface finish, which could be undesirable in certain contexts. Buyers should carefully evaluate their application needs and surface finish requirements when considering steel shot as a sandblasting option.

Related Video: Sandblasting Information for Beginners and experts

| Industry/Sector | Specific Application of sandblasting medium near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Surface preparation for metal components | Ensures strong adhesion of coatings, enhancing durability | Quality and consistency of the medium; local availability |

| Construction | Cleaning and restoring concrete surfaces | Improves aesthetics and longevity of structures | Abrasiveness and environmental compliance; supplier reliability |

| Automotive | Paint stripping and surface finishing | Reduces labor costs and improves finish quality | Compatibility with various substrates; waste disposal options |

| Oil & Gas | Cleaning of pipes and equipment | Enhances operational efficiency and safety | Material specifications; sourcing for remote locations |

| Aerospace | Precision surface cleaning of aircraft components | Increases performance and safety of aircraft | Certification of materials; adherence to industry standards |

In the manufacturing sector, sandblasting mediums are crucial for surface preparation of metal components. This process involves removing rust, old paint, and other contaminants to ensure proper adhesion of coatings. For international buyers, especially from regions like Africa and South America, sourcing high-quality sandblasting media that meets local environmental regulations is essential. The chosen medium must consistently deliver the required finish to enhance the durability of the final product.

In the construction industry, sandblasting is utilized for cleaning and restoring concrete surfaces, which is vital for both aesthetic and structural integrity. This process removes dirt, grime, and old coatings, revealing a clean surface ready for treatment. Buyers in the Middle East and Europe should consider the specific abrasiveness of the sandblasting medium to avoid damaging the concrete substrate. Additionally, ensuring compliance with local environmental standards is a critical factor when sourcing these materials.

Automotive applications of sandblasting mediums include paint stripping and surface finishing. This method effectively removes old paint layers, allowing for a smooth base for new coatings. For B2B buyers, particularly in Europe and Africa, it's crucial to select a sandblasting medium that is compatible with various substrates to prevent damage. Furthermore, considering waste disposal options for used media can significantly impact operational efficiency and compliance with environmental regulations.

A stock image related to sandblasting medium near me.

In the oil and gas industry, sandblasting is employed to clean pipes and equipment, ensuring they operate efficiently and safely. This application helps remove rust, scale, and other deposits that can hinder performance. International buyers must focus on the specifications of the sandblasting medium to ensure it meets the rigorous demands of oil and gas operations. Additionally, sourcing materials that can be delivered to remote locations is vital for maintaining continuous operations.

Aerospace applications require precision surface cleaning of aircraft components to ensure safety and performance. Sandblasting mediums are used to prepare surfaces for coatings that protect against corrosion and wear. Buyers in this sector, especially from Europe and the Middle East, need to ensure that the materials sourced are certified and adhere to stringent industry standards. Quality control in the sourcing process is essential to maintain safety and performance in aerospace operations.

Related Video: Internal & External Sandblasting Process

The Problem:

B2B buyers often struggle to find high-quality sandblasting media within their local areas. This challenge is particularly prevalent in regions such as Africa and South America, where suppliers may be limited or the quality of available products varies significantly. Without reliable sources, buyers face the risk of selecting inferior media that could lead to poor surface finishes or even damage to the equipment. This not only affects the quality of their projects but can also result in increased costs and time delays.

The Solution:

To effectively source quality sandblasting medium, buyers should first conduct thorough research on local suppliers. Utilize online platforms that aggregate reviews and ratings of different suppliers. Websites like Google My Business and local industrial directories can provide insights into the reputation of suppliers in your area. Additionally, consider reaching out to industry peers for recommendations and insights on reliable sources. When contacting suppliers, request samples to evaluate the quality of the sandblasting media before making a bulk purchase. This proactive approach ensures that you select a medium that meets your project's specific requirements and maintains the integrity of your equipment.

The Problem:

Another common pain point for B2B buyers is the inconsistency in pricing for sandblasting media. Many suppliers may not provide transparent pricing structures, leading to confusion and potential budget overruns. This is especially true in regions with fluctuating market conditions, such as the Middle East, where geopolitical factors can influence supply and demand. Buyers may find themselves facing unexpected costs, which can complicate project planning and financial forecasting.

The Solution:

To mitigate pricing discrepancies, it is essential to establish clear communication with suppliers regarding pricing structures. Request detailed quotes that outline all costs, including shipping, taxes, and potential surcharges. Additionally, consider negotiating contracts that lock in pricing for a specified period, protecting your budget from sudden increases. Engage in competitive bidding by reaching out to multiple suppliers to compare prices and terms. Implementing a cost-tracking system can also help monitor expenses related to sandblasting media over time, allowing for better financial planning and decision-making.

The Problem:

B2B buyers often encounter challenges due to a lack of technical support when selecting and using sandblasting media. This issue can be particularly pronounced in Europe, where regulations around safety and environmental impact are stringent. Buyers may not fully understand the specifications of different media types or how to choose the right one for specific applications, leading to suboptimal results and potential compliance issues.

The Solution:

To address the need for technical support, buyers should prioritize suppliers that offer comprehensive guidance and expertise. Look for vendors that provide detailed product specifications, application guidelines, and safety data sheets. It may also be beneficial to attend training sessions or workshops hosted by suppliers or industry associations to gain a deeper understanding of sandblasting techniques and media selection. Additionally, consider leveraging online resources, such as webinars and instructional videos, which can provide valuable insights into the proper use of various sandblasting media. This knowledge will empower buyers to make informed decisions, ensuring compliance with industry standards and optimizing the performance of their sandblasting operations.

When selecting a sandblasting medium, international B2B buyers should consider various materials based on their specific applications, performance requirements, and regional compliance standards. Here, we analyze four common materials used in sandblasting, focusing on their properties, advantages, disadvantages, and implications for buyers in Africa, South America, the Middle East, and Europe.

Silica sand is one of the most widely used materials for sandblasting due to its availability and effectiveness. It has a high melting point and excellent hardness, making it suitable for various applications, including metal finishing and surface preparation.

Garnet is a natural mineral that has gained popularity as an alternative to silica sand. It is known for its sharp edges and high density, making it effective for heavy-duty applications.

Aluminum oxide is a synthetic abrasive that is often used for precision blasting applications. Its durability makes it ideal for heavy-duty tasks.

Steel shot is a spherical abrasive used primarily for cleaning and finishing metal surfaces. Its unique shape allows for efficient blasting with minimal dust generation.

| Material | Typical Use Case for sandblasting medium near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silica Sand | General surface preparation and metal finishing | Cost-effective and widely available | Health risks due to silica dust | Low |

| Garnet | Heavy-duty applications and eco-friendly blasting | Environmentally friendly and reusable | Higher initial cost | Medium |

| Aluminum Oxide | Precision blasting for tough surfaces | Long-lasting and effective | Higher cost and equipment requirements | High |

| Steel Shot | Cleaning and finishing metal surfaces | Reusable and less dust generation | Higher initial investment | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into choosing the right sandblasting medium, ensuring that they make informed decisions that align with their operational needs and compliance requirements.

The manufacturing process for sandblasting mediums typically involves several key stages that ensure the final product meets the required specifications for quality and performance. Here’s a breakdown of these stages:

The first step in the manufacturing of sandblasting media is the selection and preparation of raw materials. Common materials include silica sand, aluminum oxide, garnet, and glass beads. The chosen material must be sourced from reliable suppliers who adhere to environmental regulations, as the quality of the raw material directly influences the performance of the sandblasting medium.

Once the raw materials are prepared, they undergo forming processes to create the desired shapes and sizes. This step can include various techniques depending on the material:

In the context of sandblasting media, the assembly stage is less about physical assembly and more about blending different materials to achieve specific characteristics. For example, a manufacturer might combine different abrasives to enhance the performance of the medium for specific applications.

The final stage of the manufacturing process involves finishing operations that refine the product. This includes:

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for international B2B buyers who require consistency and reliability in their products. Here are the key components of QA in sandblasting medium production:

To ensure the quality of sandblasting media, manufacturers often adhere to various international standards. The most relevant include:

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

Testing methods are vital for verifying the quality and performance of sandblasting media. Common testing techniques include:

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps:

Regular audits can help assess the supplier's manufacturing processes and quality assurance practices. Buyers should look for:

Buyers should request detailed quality reports that include:

Hiring third-party inspectors can provide an unbiased assessment of the supplier’s operations and products. This is particularly valuable for buyers who may not have the expertise to evaluate quality independently.

For buyers in diverse regions, understanding the nuances of QC is crucial:

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when sourcing sandblasting media, ensuring that they receive products that meet their specific needs and standards.

In the competitive landscape of international B2B procurement, sourcing the right sandblasting medium is crucial for maintaining operational efficiency and product quality. This guide offers a practical checklist designed to assist buyers from Africa, South America, the Middle East, and Europe in finding the best suppliers of sandblasting media.

Before initiating the sourcing process, clearly define your technical specifications. Consider the type of sandblasting medium you require, such as silica sand, aluminum oxide, or glass beads, and the intended application—whether it's for surface preparation or cleaning. This clarity will help you communicate effectively with suppliers and ensure that you receive suitable products.

Conduct thorough research to identify potential suppliers both locally and internationally. Utilize online directories, industry associations, and trade shows to create a list of reputable companies. Pay attention to suppliers that specialize in your specific sandblasting media type, as they are more likely to meet your quality and performance needs.

Ensure that the suppliers you are considering comply with local and international regulations regarding safety and environmental standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Suppliers with these certifications are more likely to provide reliable products and services.

Before making a bulk purchase, request samples of the sandblasting medium to evaluate its performance. Testing samples allows you to assess factors such as grit size, hardness, and contamination levels. This step is essential to ensure that the product meets your operational standards and won't cause damage to your equipment.

Investigate the reputation of potential suppliers by checking online reviews and requesting references from other clients. Engaging with businesses that have previously worked with the supplier can provide insights into their reliability, quality of service, and customer support. A solid reputation often correlates with better product consistency and service quality.

Once you have shortlisted potential suppliers, engage in negotiations to secure the best terms and pricing. Discuss minimum order quantities, delivery timelines, payment terms, and any potential discounts for bulk orders. Effective negotiation can lead to cost savings and a more favorable partnership.

After selecting a supplier, focus on building a long-term relationship. Regular communication can help address issues proactively and allow for adjustments based on your evolving needs. A strong partnership can lead to better pricing, priority service, and access to new products or innovations in sandblasting media.

By following these steps, B2B buyers can streamline the sourcing process for sandblasting media and ensure they select the most suitable suppliers to meet their operational requirements.

When sourcing sandblasting medium, international B2B buyers must consider a variety of cost components that contribute to the overall pricing structure. These components typically include:

Materials: The primary cost driver, which varies based on the type of sandblasting medium (e.g., silica sand, garnet, glass beads). Higher-quality materials often lead to higher prices but can result in better performance and reduced wear on equipment.

Labor: Costs associated with the workforce involved in manufacturing, processing, and handling the sandblasting medium. Labor costs can fluctuate based on local wage standards and the complexity of the production process.

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses related to the production facility. Understanding these costs can help buyers gauge the supplier's pricing strategy.

Tooling: Specialized equipment and tools necessary for producing specific types of sandblasting mediums can add to the upfront costs. Buyers should inquire about the tooling used and its impact on pricing.

Quality Control (QC): Ensuring the consistency and quality of the sandblasting medium often incurs additional costs. Suppliers may implement stringent QC measures that affect pricing, particularly for high-grade materials.

Logistics: Transportation and handling costs are significant, especially for international shipments. Factors like distance, shipping method, and customs duties can substantially impact the total cost.

Margin: Suppliers will typically add a profit margin on top of their production costs. Understanding the typical margins in the industry can help buyers negotiate better deals.

Several factors can influence the pricing of sandblasting medium beyond the basic cost components:

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to volume discounts, making it essential for buyers to assess their needs and negotiate MOQs with suppliers.

Specifications and Customization: Custom blends or specific grades of sandblasting medium may incur additional costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

Quality and Certifications: Mediums that meet specific industry standards or certifications may come at a premium. Buyers should verify the certifications relevant to their applications.

Supplier Factors: Supplier reputation, reliability, and the ability to deliver on time can also impact pricing. Engaging with reputable suppliers can often lead to better pricing and service.

Incoterms: Understanding the shipping terms (Incoterms) is crucial for international buyers. Different terms affect who bears the cost and risk at various stages of the shipping process, influencing the final price.

International B2B buyers can employ various strategies to secure cost-effective pricing on sandblasting medium:

Negotiate Based on Volume: Leverage bulk purchasing to negotiate lower prices. Suppliers are often more willing to offer discounts for larger orders.

Assess Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but the total cost of ownership, including logistics, storage, and waste disposal. This holistic view can justify higher upfront costs for better quality materials.

Stay Informed on Pricing Trends: Regularly monitor market trends and competitor pricing to stay informed. This knowledge empowers buyers during negotiations.

Build Long-Term Relationships: Establishing a partnership with suppliers can lead to better pricing and terms over time. Suppliers may be more inclined to offer favorable prices to loyal customers.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several additional considerations are vital:

Currency Fluctuations: Be aware of exchange rate volatility, which can significantly affect pricing. Consider locking in prices or negotiating terms that mitigate this risk.

Local Regulations: Different countries have varying regulations concerning the import and use of certain materials. Ensure compliance to avoid unexpected costs.

Supplier Reliability: Conduct thorough due diligence on potential suppliers to assess their reliability and ability to meet delivery timelines.

Customs and Duties: Factor in potential customs duties and tariffs when calculating the total cost of sourcing sandblasting medium.

A stock image related to sandblasting medium near me.

Prices for sandblasting medium can vary widely based on market conditions, material type, and supplier factors. It is essential for buyers to conduct their own research and request quotes from multiple suppliers to obtain accurate and competitive pricing tailored to their specific needs.

When evaluating the options for surface preparation and cleaning in industrial applications, it's essential to consider various alternatives to traditional sandblasting mediums. This analysis will provide insights into different methods that can achieve similar goals, allowing international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed decisions.

| Comparison Aspect | Sandblasting Medium Near Me | Dry Ice Blasting | Water Jet Cutting | Soda Blasting |

|---|---|---|---|---|

| Performance | High efficiency for tough surfaces | Effective for delicate surfaces; non-abrasive | Extremely precise; can cut through thick materials | Good for removing paint and contaminants |

| Cost | Moderate initial investment | Higher operational costs | High initial equipment cost | Low to moderate costs |

| Ease of Implementation | Requires trained personnel | Specialized training needed | Highly skilled operators needed | Easy to use with proper training |

| Maintenance | Moderate; regular equipment checks needed | Low; minimal wear on components | High; requires maintenance of cutting heads | Low; simple equipment maintenance |

| Best Use Case | Heavy-duty cleaning and surface preparation | Cleaning sensitive equipment | Cutting and shaping materials | Paint stripping and cleaning |

Dry ice blasting utilizes compressed air to propel dry ice pellets against a surface. This method is highly effective for cleaning delicate equipment without causing damage, making it ideal for industries such as food processing and pharmaceuticals. However, the operational costs can be higher than sandblasting due to the need for specialized equipment and dry ice supply.

Water jet cutting employs high-pressure water jets, often mixed with abrasives, to cut through materials with precision. It is particularly advantageous for industries requiring exact cuts, such as metal fabrication. While it is effective for diverse materials and provides a clean cut, the initial investment in equipment can be substantial, and skilled operators are necessary for optimal results.

Soda blasting uses sodium bicarbonate as the blasting medium, making it an eco-friendly option for removing paint, grease, and contaminants. It is less abrasive than sandblasting, which makes it suitable for softer materials. The cost is relatively low, and the equipment is easier to maintain. However, it may not be as effective for heavy-duty applications compared to traditional sandblasting.

When selecting a surface preparation method, B2B buyers should consider their specific application requirements, including the materials involved, the desired finish, and the environmental impact. Each alternative presents unique benefits and drawbacks. Buyers in industries such as manufacturing, automotive, and construction should weigh the performance needs against cost and ease of implementation. Ultimately, a thorough evaluation of operational needs and available resources will guide buyers to the most suitable solution for their operations.

When selecting a sandblasting medium, international B2B buyers must consider specific technical properties that affect performance and suitability for various applications. Here are several critical specifications:

Material Grade

The grade of the blasting medium, such as aluminum oxide, silica sand, or glass beads, defines its hardness and suitability for different surfaces. Higher-grade materials are more effective for heavy-duty applications, while lower grades may be suitable for lighter tasks. Understanding material grade helps buyers ensure they select a medium that meets their project requirements without causing damage to the substrate.

Particle Size Distribution

Particle size significantly impacts the efficiency and finish quality of sandblasting. A uniform particle size can lead to consistent results, whereas a mixed size can cause uneven surfaces. Buyers should request detailed specifications regarding the particle size distribution to optimize the blasting process and achieve desired outcomes.

Moisture Content

Excess moisture can lead to clumping and ineffective blasting. Buyers must ensure that the sandblasting medium has low moisture content to maintain optimal performance. This property is particularly crucial in humid climates, where moisture can affect the quality of the blasting process.

Hardness

The hardness of the medium, often measured on the Mohs scale, dictates its abrasiveness and suitability for different applications. Harder materials are typically used for tougher surfaces, while softer options might be used for delicate tasks. Understanding the hardness of the medium allows buyers to select the right product for their specific needs.

Toxicity and Environmental Impact

It is essential to consider the environmental and health implications of the blasting medium. Materials that produce harmful dust or contain toxic components should be avoided. Buyers should look for eco-friendly alternatives that comply with local regulations and ensure worker safety.

Familiarity with trade terminology is crucial for effective communication and negotiation in the sandblasting medium market. Here are several common terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications can help buyers ensure compatibility with existing equipment, leading to smoother operations.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory costs and aligns purchasing decisions with project needs. It is particularly relevant for international buyers who may face shipping and storage challenges.

RFQ (Request for Quotation)

An RFQ is a document issued when an organization wants to receive price quotes from suppliers. Buyers should provide detailed specifications in their RFQs to ensure accurate pricing and avoid misunderstandings. This term is vital for managing procurement processes efficiently.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping costs, risk, and insurance. Familiarity with Incoterms helps buyers understand their obligations and negotiate better terms with suppliers.

Batch Testing

This refers to the process of evaluating a sample of the sandblasting medium from a production batch to ensure it meets specified quality standards. Buyers should inquire about batch testing practices to confirm the consistency and reliability of the products they are sourcing.

Understanding these properties and terms equips international B2B buyers with the knowledge necessary to make informed decisions, ensuring that they select the right sandblasting medium for their specific applications while navigating the complexities of global trade.

The sandblasting medium market is experiencing significant shifts driven by technological advancements and changing buyer preferences. Notably, the rise of eco-friendly materials and the adoption of automation in the procurement process are reshaping sourcing strategies for international B2B buyers. In regions like Africa, South America, the Middle East, and Europe, businesses are increasingly prioritizing quality and sustainability in their purchasing decisions. For instance, buyers from Egypt and Kenya are actively seeking suppliers that offer high-performance abrasive materials while ensuring compliance with environmental regulations.

Emerging trends include the integration of digital platforms for sourcing, which streamline the procurement process and enhance transparency. B2B buyers are leveraging e-commerce solutions to compare products, read reviews, and connect with manufacturers directly, thus reducing reliance on traditional distributors. Furthermore, the demand for specialized sandblasting mediums—such as aluminum oxide and glass beads—is on the rise, driven by industries like automotive and aerospace that require precision and quality in surface preparation.

Sustainability has become a critical factor in the decision-making process for B2B buyers in the sandblasting medium sector. The environmental impact of traditional abrasive materials, such as silica sand, has raised concerns over health risks and ecological damage. As a result, ethical sourcing practices are gaining traction, with buyers seeking materials that not only perform well but also minimize environmental harm.

The importance of certifications cannot be overstated. Buyers are increasingly looking for 'green' certifications that validate the sustainability of their suppliers. For instance, materials such as recycled glass or biodegradable alternatives are becoming more popular as they align with global sustainability goals. Moreover, buyers are encouraged to engage with suppliers who implement ethical labor practices throughout their supply chains, ensuring that their sourcing decisions contribute positively to communities and the environment.

The sandblasting medium sector has evolved significantly from its early days when silica sand was the primary choice for abrasive blasting. As awareness of health risks associated with silica dust increased, industries began to explore alternative materials that offered similar performance with reduced health hazards. This evolution has led to the development of a diverse array of products, including garnet, aluminum oxide, and even organic materials.

In recent years, technological innovations have further transformed the sector. The introduction of automated blasting systems and advanced materials has enhanced efficiency and effectiveness in various applications, from industrial cleaning to surface preparation. Today, international B2B buyers are not only focused on the performance of sandblasting mediums but also on their sourcing practices, sustainability credentials, and overall impact on health and the environment. This shift reflects a broader trend in global commerce where responsible sourcing is becoming integral to business operations.

How do I choose the right sandblasting medium for my project?

Selecting the appropriate sandblasting medium depends on various factors, including the material being blasted, the desired finish, and the equipment used. Common media types include aluminum oxide, glass beads, and silica sand, each offering unique benefits. For instance, aluminum oxide is ideal for aggressive blasting on hard surfaces, while glass beads provide a smoother finish. It's essential to consult with suppliers who can provide technical specifications and recommendations based on your specific requirements.

What are the key factors to consider when sourcing sandblasting media suppliers?

When sourcing suppliers for sandblasting media, consider their reputation, product quality, and compliance with international safety standards. Look for suppliers with a track record of serving clients in your region, as they will understand local regulations and logistics. Additionally, assess their ability to provide customized solutions and their responsiveness to inquiries, as these factors significantly impact your purchasing experience.

What is the minimum order quantity (MOQ) for sandblasting media?

Minimum order quantities (MOQ) for sandblasting media can vary widely among suppliers, typically ranging from 500 kg to several tons. When negotiating with suppliers, clarify their MOQ policies and see if they offer flexibility for smaller orders, especially if you are testing different media types. Understanding the MOQ is crucial for managing your inventory and cash flow effectively.

How can I ensure the quality of sandblasting media?

To ensure the quality of sandblasting media, request product certifications and test reports from suppliers. Look for media that meets international standards, such as ISO or ASTM specifications. Additionally, consider conducting your own tests on samples before placing a bulk order. Establishing a quality assurance process helps mitigate risks associated with subpar materials, which can affect your project outcomes.

What payment terms should I negotiate with sandblasting media suppliers?

Negotiating favorable payment terms is vital for managing your cash flow. Common payment options include upfront payments, letters of credit, or payment upon delivery. Consider negotiating for extended payment terms if you have a long-standing relationship with the supplier. Ensure clarity on payment methods accepted, as international transactions may involve additional fees or currency conversion issues.

How do logistics impact the sourcing of sandblasting media?

Logistics play a crucial role in the timely delivery of sandblasting media. Consider factors such as shipping methods, transit times, and customs clearance when selecting suppliers. Engage suppliers who have experience with international shipping, as they can provide insights into potential delays and ensure compliance with import regulations. Proper logistics planning can save costs and prevent project delays.

Can I customize the sandblasting medium for specific applications?

Many suppliers offer customization options for sandblasting media based on your project needs. This can include adjustments in granule size, composition, or treatment processes to achieve specific performance characteristics. Discuss your application requirements with potential suppliers to explore tailored solutions that enhance efficiency and effectiveness in your blasting processes.

What are the environmental considerations when using sandblasting media?

When sourcing sandblasting media, be aware of environmental impacts, including dust generation and waste disposal. Opt for eco-friendly media options, such as crushed glass or biodegradable materials, which minimize health risks and environmental harm. Additionally, ensure that your suppliers adhere to environmental regulations and provide safe handling instructions to protect workers and the surrounding environment.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing for sandblasting mediums is essential for international B2B buyers looking to optimize their procurement processes. By understanding local suppliers and global trends, businesses from Africa, South America, the Middle East, and Europe can enhance their supply chain resilience. Key takeaways include prioritizing quality and sustainability in sourcing, leveraging technology for better supplier visibility, and fostering partnerships that can adapt to market fluctuations.

What are the future trends in sourcing sandblasting mediums? As industries evolve, the demand for eco-friendly materials and innovative solutions will increase. Buyers should stay ahead by engaging with suppliers who prioritize sustainable practices and can offer advanced products tailored to their specific needs.

To navigate this dynamic landscape successfully, international buyers are encouraged to conduct thorough market research and establish strong relationships with reliable suppliers. By doing so, they can not only secure the best prices but also ensure a consistent quality of sandblasting mediums. The future is bright for those who strategically source their materials; take the next step in your procurement journey today.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina