In today’s competitive landscape, sourcing high-quality silicon carbide (SiC) 3D printing solutions poses a significant challenge for international B2B buyers. As industries increasingly leverage advanced manufacturing technologies, understanding the intricacies of SiC 3D printing becomes crucial for optimizing production processes and enhancing product performance. This guide serves as a comprehensive resource, covering various aspects of SiC 3D printing, including types of materials, applications across different sectors, supplier vetting processes, and cost considerations.

For businesses in Africa, South America, the Middle East, and Europe, making informed purchasing decisions is essential to stay ahead in the global market. This guide empowers buyers by providing actionable insights into selecting the right suppliers, understanding market trends, and evaluating the total cost of ownership associated with SiC 3D printing technologies. By navigating through this resource, you will gain valuable knowledge that can streamline your sourcing strategy, mitigate risks, and enhance operational efficiency.

Moreover, as SiC 3D printing continues to evolve, this guide will keep you abreast of emerging technologies and best practices, ensuring that your organization remains competitive and innovative. Whether you are seeking to enhance your product line or improve manufacturing processes, understanding the nuances of SiC 3D printing will be instrumental in achieving your business goals.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Binder Jetting | Uses a liquid binder to bond powder materials layer by layer | Metal components, sand casting | Pros: Cost-effective for large parts; Cons: Limited material choices. |

| Fused Deposition Modeling (FDM) | Extrudes thermoplastic filament to create parts layer by layer | Prototyping, low-volume production | Pros: Wide material availability; Cons: Lower precision than other methods. |

| Stereolithography (SLA) | Utilizes a UV light source to cure liquid resin into hardened plastic | High-detail prototypes, dental applications | Pros: Exceptional surface finish; Cons: Longer production times. |

| Selective Laser Sintering (SLS) | Uses a laser to sinter powdered material into solid parts | Aerospace, automotive, and medical parts | Pros: Strong, functional parts; Cons: Higher equipment and material costs. |

| Digital Light Processing (DLP) | Similar to SLA but uses a digital light projector for faster curing | Jewelry, dental, and intricate designs | Pros: Faster production than SLA; Cons: Limited to resin-based materials. |

Binder Jetting is characterized by its ability to produce parts from a variety of materials, including metals and ceramics, by selectively depositing a liquid binder onto a bed of powder. This method is particularly suitable for creating complex geometries and large parts without the need for support structures. For B2B buyers, the cost-effectiveness of Binder Jetting for mass production runs is a significant advantage, although the limited range of materials compared to other methods may restrict its applications.

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, primarily due to its versatility and accessibility. It works by extruding thermoplastic filaments, which are melted and deposited layer by layer. This method is well-suited for prototyping and low-volume production runs, making it a popular choice among startups and small manufacturers. While FDM offers a broad range of materials, buyers should consider its lower precision compared to other advanced methods when high accuracy is required.

Stereolithography (SLA) is known for its ability to produce high-resolution parts with excellent surface finishes using a UV light source to cure liquid resin. This technology is particularly advantageous for industries requiring detailed prototypes, such as dental and jewelry applications. Although SLA offers unparalleled detail, B2B buyers should be aware of its longer production times and the need for post-processing, which may affect turnaround times and costs.

Selective Laser Sintering (SLS) employs a laser to fuse powdered material into solid structures, making it an ideal choice for producing strong, functional parts. This method is widely used in industries like aerospace and automotive, where durability and performance are critical. While SLS can produce complex geometries without support structures, buyers must consider the higher initial investment in equipment and materials, which may impact budgeting for smaller operations.

Digital Light Processing (DLP) is similar to SLA but utilizes a digital light projector to cure resin, significantly speeding up the production process. This method is particularly effective for creating intricate designs in industries such as jewelry and dental applications. The faster production capabilities of DLP make it appealing for businesses needing quick turnaround times. However, its limitation to resin-based materials may not suit all B2B applications, so buyers should evaluate their material needs carefully.

Related Video: Types of 3D Printers - 11 Different Types of 3D Printers - Introduction to 3D Printing

| Industry/Sector | Specific Application of sic 3d printing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of lightweight components | Reduced weight leading to fuel savings and increased efficiency | Certification standards, material properties, and delivery timelines |

| Automotive | Production of custom tooling and fixtures | Enhanced production efficiency and reduced lead times | Compatibility with existing manufacturing processes and equipment |

| Healthcare | Creation of patient-specific implants and prosthetics | Improved patient outcomes and reduced surgery time | Regulatory compliance, material biocompatibility, and customization capabilities |

| Electronics | Prototyping of complex circuit boards | Faster time-to-market for new products | Precision requirements, scalability, and material compatibility |

| Energy | Production of heat-resistant components for turbines | Increased operational efficiency and reduced downtime | Material durability, performance under extreme conditions, and sourcing of specialized materials |

In the aerospace industry, sic 3D printing is pivotal for creating lightweight components such as brackets and housings. These parts are essential for reducing the overall weight of aircraft, leading to significant fuel savings and enhanced operational efficiency. International B2B buyers must consider certification standards that govern aerospace components, ensuring that the materials used can withstand the rigors of flight. Additionally, timely delivery is crucial to align with production schedules.

For the automotive sector, sic 3D printing facilitates the production of custom tooling and fixtures that streamline assembly processes. This technology allows manufacturers to produce components that perfectly fit their assembly lines, thus enhancing production efficiency and significantly reducing lead times. Buyers in this sector should focus on the compatibility of 3D-printed tools with existing manufacturing processes and the ability to scale production as needed.

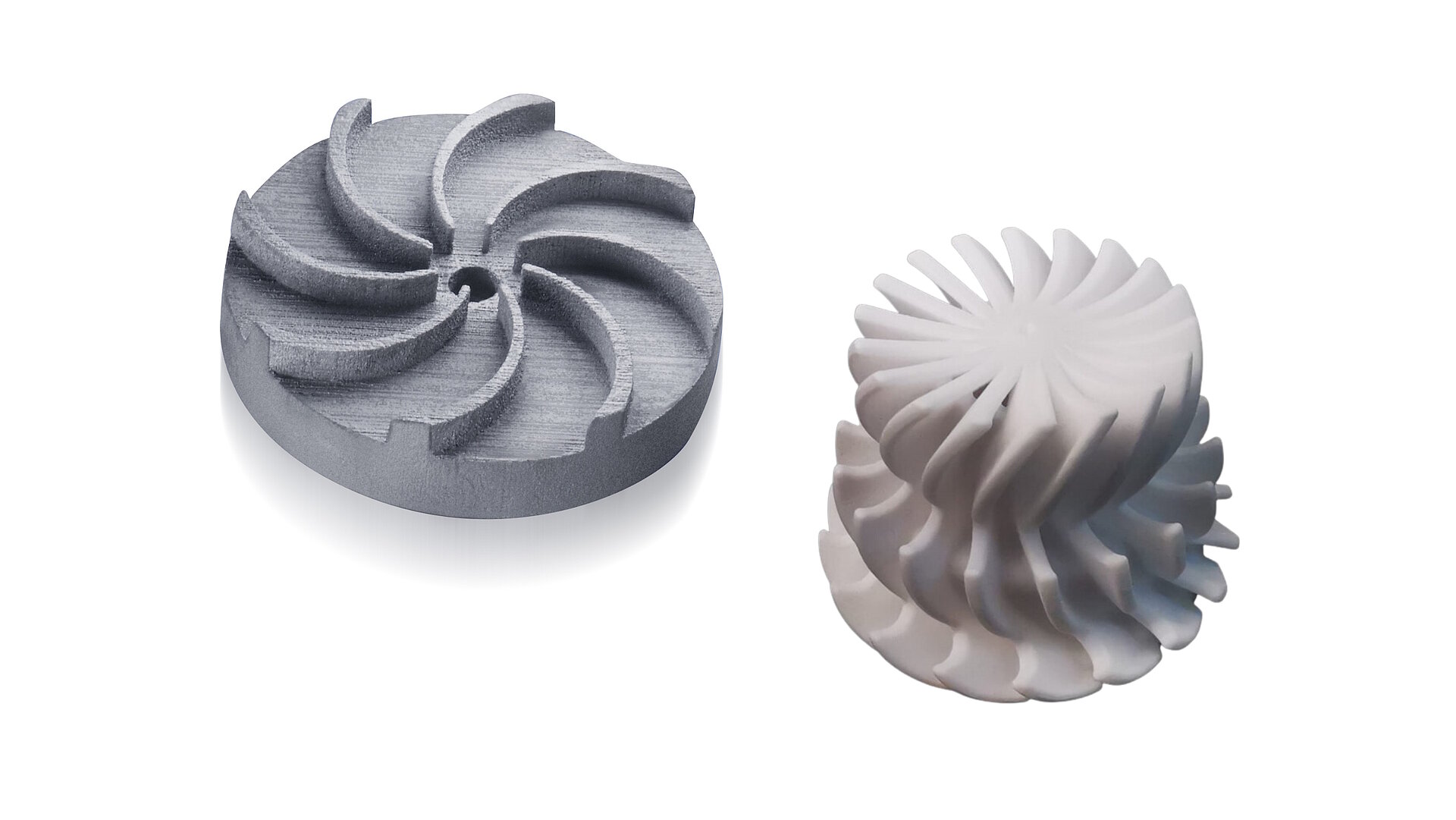

A stock image related to sic 3d printing.

In healthcare, sic 3D printing is revolutionizing the creation of patient-specific implants and prosthetics. This customization leads to improved patient outcomes, as devices can be tailored to fit individual anatomical requirements. Moreover, the use of sic materials can reduce surgery time, enhancing recovery rates. B2B buyers must prioritize regulatory compliance and material biocompatibility when sourcing these products, as well as the customization capabilities offered by suppliers.

The electronics industry leverages sic 3D printing for rapid prototyping of complex circuit boards. This approach allows companies to accelerate their time-to-market for new products, providing a competitive edge in a fast-paced environment. Buyers should evaluate the precision requirements of their projects and ensure that suppliers can meet scalability demands while maintaining material compatibility for electronic components.

In the energy sector, sic 3D printing is instrumental in producing heat-resistant components for turbines and other machinery. These components are designed to withstand extreme conditions, thereby increasing operational efficiency and reducing downtime. Buyers must assess the durability of materials used in production and their performance under high-stress scenarios, as well as the sourcing of specialized materials that meet these demanding requirements.

Related Video: Stereolithography (SLA) 3D Printing Explained: Guide to Resin 3D Printers

The Problem:

B2B buyers often struggle with selecting the right materials for their SIC (Silicon Carbide) 3D printing projects. The complexity arises from the diverse range of materials available, each offering distinct mechanical properties, thermal stability, and compatibility with various printing technologies. Buyers may find themselves overwhelmed, especially when trying to match the material characteristics with their specific application requirements—be it for aerospace components, automotive parts, or electronics. This uncertainty can lead to significant project delays, increased costs, and ultimately, product failures.

The Solution:

To navigate the material selection process effectively, buyers should adopt a systematic approach. Begin by conducting thorough research on the specific requirements of your application, including the operating environment and performance criteria. Engage with SIC 3D printing suppliers who can provide technical datasheets and performance analyses of their materials. Consider utilizing prototype testing to assess how different materials perform under operational conditions. Additionally, forming partnerships with research institutions or industry experts can provide invaluable insights into emerging materials and technologies, ensuring that you make informed decisions that align with your production goals.

The Problem:

One of the most pressing challenges B2B buyers face in SIC 3D printing is achieving the desired accuracy and precision in their designs. In industries like aerospace and medical devices, where tolerances are critical, even minor discrepancies can lead to costly failures and safety hazards. Buyers often encounter issues related to layer adhesion, dimensional inaccuracies, and surface finish, which can compromise the integrity of the final product and necessitate costly rework.

The Solution:

To enhance design accuracy in SIC 3D printing, it is essential to invest in high-quality printers equipped with advanced calibration capabilities. Regularly calibrate the 3D printer to maintain its accuracy and precision, and utilize software that allows for precise modeling and simulation before printing. Furthermore, consider implementing a comprehensive quality assurance process that includes dimensional verification and non-destructive testing (NDT) methods for critical components. Collaborating closely with your design and engineering teams to iterate and refine designs based on empirical feedback from printed prototypes can also lead to significant improvements in final product accuracy.

The Problem:

As companies look to incorporate SIC 3D printing into their existing manufacturing workflows, they often encounter integration challenges. Many organizations have established processes and equipment that may not be compatible with new 3D printing technologies. This can lead to disruptions in production, inefficiencies, and increased operational costs, as employees must adapt to new systems and processes without adequate training or resources.

The Solution:

To facilitate a smoother integration of SIC 3D printing into your existing manufacturing processes, begin with a comprehensive assessment of your current workflows. Identify areas where 3D printing can enhance efficiency or reduce costs, such as tooling, prototyping, or low-volume production. Invest in training programs for your staff to familiarize them with the new technology and processes, ensuring they understand the benefits and limitations of SIC 3D printing. Additionally, consider phased implementation, where you start with less critical applications before fully scaling the technology across your operations. Engaging with consultants or industry experts can also provide guidance on best practices and integration strategies tailored to your specific manufacturing environment.

When selecting materials for silicon carbide (SiC) 3D printing, international B2B buyers must consider various factors that influence product performance, manufacturing complexity, and cost. Below are analyses of four common materials used in SiC 3D printing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Silicon Carbide (SiC) Powder

- Key Properties: SiC powder is known for its high thermal conductivity, excellent hardness, and superior chemical resistance. It can withstand extreme temperatures (up to 1600°C) and has a high melting point, making it suitable for high-performance applications.

- Pros & Cons: The durability of SiC powder ensures long-lasting products, but it can be expensive to source. The manufacturing complexity is moderate, requiring specialized equipment for 3D printing. End products are highly suitable for aerospace and automotive applications.

- Impact on Application: SiC is compatible with aggressive media, making it ideal for applications in corrosive environments.

- Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, which govern the quality and safety of materials.

2. Alumina (Al2O3)

- Key Properties: Alumina is a ceramic material that offers excellent wear resistance and high-temperature stability. It can operate effectively at temperatures exceeding 1500°C and has good electrical insulation properties.

- Pros & Cons: While alumina is relatively cost-effective compared to SiC, its brittleness can be a limitation in applications requiring high mechanical strength. The manufacturing process can be complex, requiring precise control to avoid defects.

- Impact on Application: Alumina is well-suited for applications in electronics and wear-resistant components due to its insulating properties.

- Considerations for International Buyers: Compliance with JIS standards is crucial, especially for buyers in Japan and surrounding regions.

3. Zirconia (ZrO2)

- Key Properties: Zirconia is known for its exceptional toughness and thermal stability. It can withstand high temperatures (up to 1200°C) and exhibits good resistance to thermal shock.

- Pros & Cons: The primary advantage of zirconia is its durability and resistance to wear, making it suitable for demanding applications. However, it is more expensive than alumina and requires careful handling during the printing process.

- Impact on Application: Zirconia is ideal for applications in dental and biomedical fields due to its biocompatibility.

- Considerations for International Buyers: Buyers should be aware of the certifications required for medical-grade materials, particularly in Europe and the Middle East.

4. Polyether Ether Ketone (PEEK)

- Key Properties: PEEK is a high-performance thermoplastic known for its excellent mechanical properties and chemical resistance. It can withstand temperatures up to 250°C and is highly resistant to harsh chemicals.

- Pros & Cons: PEEK offers a good balance of strength and flexibility, making it suitable for a variety of applications. However, its high cost and the complexity of the 3D printing process can be barriers for some manufacturers.

- Impact on Application: PEEK is commonly used in aerospace, automotive, and medical applications where high performance is critical.

- Considerations for International Buyers: Compliance with industry-specific standards (like ISO for medical applications) is vital for buyers in Europe and the Middle East.

| Material | Typical Use Case for SiC 3D printing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) Powder | Aerospace, automotive components | High thermal conductivity and durability | High sourcing cost | High |

| Alumina (Al2O3) | Electronics, wear-resistant parts | Cost-effective and good wear resistance | Brittleness can limit applications | Medium |

| Zirconia (ZrO2) | Dental, biomedical applications | Exceptional toughness and thermal stability | Higher cost and handling complexity | High |

| Polyether Ether Ketone (PEEK) | Aerospace, automotive, medical | Excellent mechanical properties | High cost and complex printing process | High |

This guide provides a solid foundation for international B2B buyers to make informed decisions about material selection for SiC 3D printing, ensuring that they consider both performance and compliance with regional standards.

The manufacturing process for SiC (Silicon Carbide) 3D printing involves several critical stages that ensure high quality and precision in the final product. For international B2B buyers, understanding these processes and the associated quality assurance measures is essential in making informed purchasing decisions.

The initial stage in SiC 3D printing involves the careful preparation of raw materials. The SiC powder must be of high purity and suitable grain size to ensure optimal performance during the printing process. Techniques such as milling and sieving are commonly used to achieve the desired particle distribution. Additionally, additives may be incorporated to enhance the flowability and sintering characteristics of the powder.

Once the material is prepared, the next step is the forming process, which primarily involves additive manufacturing techniques. The most prevalent method for SiC 3D printing is Binder Jetting, where a liquid binder is selectively deposited onto the powder bed. This creates a green part that is then subjected to a sintering process to achieve the final density and strength. Other techniques, such as Selective Laser Sintering (SLS) and Direct Ink Writing (DIW), may also be employed depending on the specific requirements of the application.

In cases where multiple components are required, assembly becomes crucial. This may involve joining printed parts using methods such as adhesive bonding or mechanical fastening. For complex assemblies, it’s vital to ensure that the interfaces meet specific tolerances and surface finish requirements to maintain the integrity of the final product.

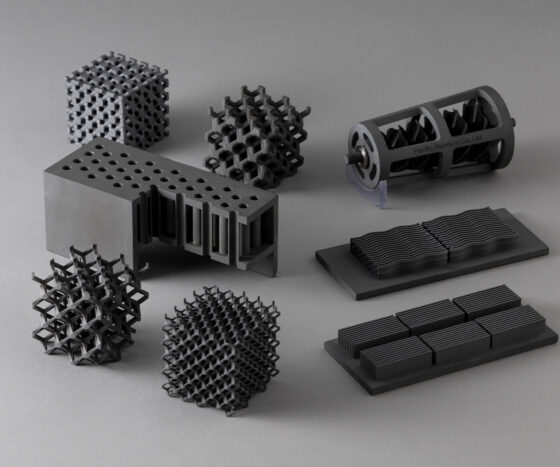

A stock image related to sic 3d printing.

After assembly, finishing processes are employed to enhance the surface quality and dimensional accuracy of the SiC components. Common techniques include grinding, polishing, and coating. These finishing steps not only improve aesthetics but also ensure that the components meet the functional requirements of their intended applications, such as wear resistance and thermal stability.

Quality assurance in SiC 3D printing is paramount, especially for B2B buyers who operate in regulated industries. Compliance with international standards such as ISO 9001 is crucial, as it ensures that suppliers maintain consistent quality management systems. Additionally, industry-specific certifications such as CE marking for the European market or API certification for oil and gas applications can further validate a supplier's commitment to quality.

Quality control during the manufacturing process involves several checkpoints to ensure that the products meet the required specifications:

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Buyers should ensure that suppliers conduct rigorous testing for material purity and consistency.

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is essential. This includes regular checks on the forming and sintering processes to identify any deviations from established parameters.

Final Quality Control (FQC): After the components are finished, a final inspection is conducted to verify that the products meet all specifications. This often includes dimensional checks, surface finish assessments, and functional testing.

B2B buyers can take several proactive steps to verify the quality control measures of their suppliers:

Conduct Audits: Regular audits of suppliers’ facilities can provide insights into their quality management practices. This allows buyers to assess compliance with international standards and industry-specific requirements.

Request Quality Reports: Suppliers should provide detailed quality reports that outline their testing methodologies, inspection results, and any corrective actions taken. This transparency helps buyers understand the reliability of the manufacturing processes.

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier's quality control processes. These inspections can cover various aspects, including material quality, manufacturing practices, and final product assessments.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate a complex landscape of regulations and certifications. Understanding the local compliance requirements is essential. For instance, European buyers may prioritize CE marking, while buyers in the Middle East might focus on Gulf Standards Organization (GSO) certifications.

Different regions may have varying expectations regarding quality assurance. Buyers should engage in open communication with suppliers about these expectations and ensure that they are incorporated into the manufacturing process. This may involve adapting quality control practices to align with local standards while still adhering to international benchmarks.

In summary, the manufacturing processes and quality assurance measures for SiC 3D printing are multifaceted and critical to achieving high-quality outcomes. By understanding the stages of manufacturing and implementing rigorous quality control practices, B2B buyers can ensure that they partner with reliable suppliers who meet their specific needs. This knowledge not only enhances product quality but also fosters long-term business relationships across diverse markets.

To effectively source SIC 3D printing solutions, international B2B buyers must follow a structured approach. This guide will assist you in navigating the procurement process, ensuring you select the right technology and supplier for your needs.

Establishing clear technical specifications is crucial for successful sourcing. Consider factors such as the materials required, desired print resolution, and production volume. This clarity not only helps in communicating your needs to suppliers but also ensures you receive accurate quotes and capabilities that match your project requirements.

Thorough market research is essential to understand the landscape of SIC 3D printing. Investigate potential suppliers and their offerings, pricing structures, and market reputation. Utilize industry reports, online forums, and trade shows to gather insights.

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience in SIC 3D printing to ensure they can meet your technical and logistical requirements.

Obtaining samples or prototypes allows you to evaluate the quality of the SIC 3D printing outputs. This hands-on experience is invaluable in assessing whether the supplier can meet your specifications and quality standards.

Once you have identified a suitable supplier, enter into negotiations regarding pricing, delivery timelines, and payment terms. Clear agreements will help prevent misunderstandings and ensure that both parties are aligned.

Effective communication is vital throughout the sourcing process. Set up regular check-ins and updates to ensure that any issues are promptly addressed and that the project stays on track.

Consider the after-sales support offered by your supplier. This includes maintenance, troubleshooting, and additional training if needed. Robust support can significantly enhance the value of your investment in SIC 3D printing technology.

By following these steps, international B2B buyers can navigate the complexities of sourcing SIC 3D printing solutions effectively. This structured approach will enhance your procurement strategy and ensure you achieve optimal results from your investment.

When sourcing SIC (Silicon Carbide) 3D printing services, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Several factors influence pricing in SIC 3D printing:

B2B buyers can adopt several strategies to ensure cost-efficiency when sourcing SIC 3D printing:

It is important to note that prices for SIC 3D printing can vary significantly based on numerous factors, including market conditions, material availability, and supplier pricing strategies. Always seek specific quotes tailored to your project's unique requirements.

In the rapidly evolving landscape of manufacturing technologies, it is crucial for B2B buyers to evaluate various solutions to meet their production needs effectively. Sic 3D printing offers unique advantages, but understanding how it stacks up against other technologies can empower buyers to make informed decisions. This analysis compares Sic 3D printing with two viable alternatives: Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM).

| Comparison Aspect | Sic 3D Printing | Selective Laser Sintering (SLS) | Fused Deposition Modeling (FDM) |

|---|---|---|---|

| Performance | High precision and durability | Excellent for complex geometries | Good for basic shapes |

| Cost | Higher initial investment | Moderate cost, material intensive | Lower cost for setup and materials |

| Ease of Implementation | Requires specialized training | Moderate complexity, needs calibration | User-friendly, minimal training required |

| Maintenance | Low maintenance | Moderate maintenance needs | Low maintenance |

| Best Use Case | Aerospace, automotive parts | Prototyping, intricate designs | Basic prototyping, educational use |

SLS technology employs a laser to fuse powdered materials, allowing for the creation of highly complex geometries that are not achievable with traditional methods. Its performance excels in producing detailed prototypes and functional parts, making it ideal for industries like aerospace and automotive. However, the cost can be a significant factor, as SLS machines and materials can be expensive. Additionally, the process requires a certain level of technical expertise, which may necessitate additional training for staff.

FDM is one of the most commonly used 3D printing technologies, ideal for beginners due to its straightforward setup and operation. It works by extruding thermoplastic filament to create parts layer by layer. While it is less costly and easier to implement than Sic 3D printing and SLS, FDM typically results in lower precision and is best suited for basic prototypes and educational purposes. This makes it less appropriate for industries requiring high-performance components, such as aerospace or medical devices.

When selecting the right manufacturing technology, B2B buyers should consider their specific needs, including the complexity of the parts, budget constraints, and the level of expertise available within their teams. For high-performance applications requiring durability and precision, Sic 3D printing may be the best fit despite its higher cost. Conversely, for businesses focused on rapid prototyping with simpler designs, FDM could be the more practical choice. SLS presents a middle ground, offering a blend of performance and complexity that suits specialized applications.

In summary, understanding the strengths and limitations of Sic 3D printing in relation to alternatives like SLS and FDM is essential for making an informed decision that aligns with business objectives and production requirements.

When considering SIC (Silicon Carbide) 3D printing, understanding its technical properties is crucial for B2B buyers. Here are some of the essential specifications to keep in mind:

Material grade refers to the quality and type of silicon carbide used in 3D printing. Higher grades typically offer superior mechanical strength, thermal stability, and resistance to wear and corrosion. For international buyers, selecting the right material grade is essential for ensuring that the final product meets industry standards and application requirements.

Tolerance levels indicate the allowable deviation from specified dimensions. In SIC 3D printing, tight tolerances are vital for parts that require precise fitting and functionality, such as in aerospace or medical applications. Buyers should confirm that the manufacturer can achieve the required tolerances to avoid costly reworks or failures in application.

Thermal conductivity is the ability of the material to conduct heat. SIC is known for its high thermal conductivity, making it ideal for applications where heat dissipation is critical. Buyers in industries like electronics or automotive should prioritize this property to ensure efficient thermal management in their products.

Mechanical strength encompasses various factors, including tensile strength and hardness. SIC materials are renowned for their exceptional hardness and resistance to deformation under stress. For B2B buyers, understanding the mechanical properties is crucial for applications requiring durability and longevity.

The surface finish of 3D printed SIC parts affects both aesthetics and functionality. A smoother surface finish can enhance the part's performance in terms of friction and wear resistance. Buyers should discuss surface treatment options with suppliers to achieve the desired finish for specific applications.

Understanding industry jargon can significantly streamline communication between buyers and suppliers. Here are some common terms used in the SIC 3D printing sector:

OEM refers to companies that manufacture products that are sold under another company's brand name. For B2B buyers, partnering with an OEM can provide access to high-quality SIC components without the need for in-house manufacturing.

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is vital for buyers to manage inventory costs and production planning. This term is particularly important for international buyers who may be looking to optimize their supply chain.

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. It is essential for establishing clear expectations and comparing offers from multiple suppliers, thus ensuring competitive pricing.

Incoterms are internationally recognized terms used in shipping and freight that define the responsibilities of buyers and sellers. Understanding these terms can help B2B buyers navigate logistics and mitigate risks in international trade.

Lead time refers to the time taken from placing an order to receiving the product. For buyers, knowing the lead time is crucial for planning production schedules and inventory management, especially in industries where timing is critical.

Customization in SIC 3D printing allows buyers to specify unique design features tailored to their application. This flexibility can lead to enhanced performance and efficiency in the final products, making it an important consideration for B2B buyers looking for competitive advantages.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when engaging with SIC 3D printing suppliers, ensuring successful procurement and product development.

The SIC 3D printing sector is experiencing transformative growth driven by technological advancements and increasing demand across various industries. Key factors propelling this market include the rising need for rapid prototyping, custom manufacturing, and the ability to create complex geometries that traditional manufacturing cannot achieve. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly leveraging SIC 3D printing for its cost-effectiveness and flexibility, enabling them to respond swiftly to market demands.

Emerging trends in sourcing include the integration of artificial intelligence and machine learning to optimize production processes and enhance quality control. Additionally, the rise of localized production models is gaining traction, allowing companies to reduce logistics costs and lead times. This shift is particularly relevant for buyers in regions like Vietnam and Germany, where supply chain resilience has become a priority post-pandemic. Moreover, the adoption of hybrid manufacturing techniques that combine additive and subtractive methods is creating new opportunities for innovation in product design and material utilization.

Sustainability is becoming a critical consideration in the SIC 3D printing sector. As businesses aim to reduce their environmental footprint, sourcing materials that are eco-friendly and recyclable is paramount. B2B buyers should prioritize suppliers who offer 'green' certifications, such as ISO 14001, which indicates adherence to environmental management standards. The use of bio-based materials and recycled feedstocks in 3D printing processes is gaining popularity, further aligning with global sustainability goals.

Ethical sourcing is equally important, particularly for international buyers who are increasingly scrutinizing supply chains for social responsibility. Companies must ensure that their suppliers adhere to ethical labor practices and contribute positively to local communities. This not only mitigates reputational risks but also enhances brand loyalty among environmentally and socially conscious consumers. Buyers should engage with suppliers who transparently share their sourcing practices and sustainability initiatives, fostering a collaborative approach to ethical supply chain management.

The evolution of SIC 3D printing can be traced back to its inception in the 1980s, where it began as a niche technology primarily used for prototyping. Over the years, advancements in material science and printing technologies have broadened its applications, allowing for the production of end-use parts in sectors such as aerospace, healthcare, and automotive. The introduction of SIC materials, known for their high-temperature resistance and mechanical strength, has further expanded the capabilities of 3D printing, making it a viable solution for complex industrial applications.

As industries continue to embrace digital transformation, the role of SIC 3D printing is expected to grow, driven by the need for innovation and efficiency in manufacturing processes. International B2B buyers should remain informed about these advancements to capitalize on the benefits that SIC 3D printing can offer in enhancing their competitive advantage.

How do I choose the right SIC 3D printing supplier for my business needs?

Choosing the right SIC 3D printing supplier involves evaluating their experience, technology, and service offerings. Start by assessing their portfolio and client testimonials to gauge their expertise in your specific industry. Additionally, inquire about their production capabilities, including materials used and the range of applications they can handle. It's also essential to discuss their customization options and whether they can accommodate your unique specifications. Finally, request sample prints to evaluate their quality before making a commitment.

What customization options are available with SIC 3D printing?

SIC 3D printing offers extensive customization options, allowing businesses to tailor products to their specific needs. Customization can include variations in design, size, and material properties. Many suppliers also provide rapid prototyping services, enabling you to test and refine designs before full-scale production. It’s crucial to communicate your requirements clearly and discuss potential design constraints with the supplier to ensure that your expectations align with their capabilities.

What are the minimum order quantities (MOQ) for SIC 3D printing services?

Minimum order quantities for SIC 3D printing services can vary significantly among suppliers. Some may offer low MOQs for prototyping or small-scale production, while others might require larger orders to optimize production efficiency and cost-effectiveness. When approaching suppliers, clarify your needs and inquire about any flexibility in their MOQ policies, especially if you're entering a new market or testing a new product line.

How do I ensure quality assurance (QA) in SIC 3D printing?

To ensure quality assurance in SIC 3D printing, it’s vital to establish clear QA protocols with your supplier. Request detailed information about their quality control processes, including material inspections, printing accuracy, and post-processing measures. Consider implementing a third-party inspection service for large orders or critical applications. Additionally, ask for certifications or compliance with industry standards, which can provide added assurance of product quality.

What payment terms should I expect when sourcing SIC 3D printing services?

Payment terms for SIC 3D printing services can vary based on the supplier's policies and the scope of your project. Common terms include upfront deposits, milestone payments, or payment upon delivery. It’s advisable to negotiate terms that balance risk for both parties, especially for larger orders. Be sure to clarify all terms in writing, including any potential penalties for late payments or changes in order specifications.

How can I manage logistics and shipping for SIC 3D printed products?

Managing logistics and shipping for SIC 3D printed products involves coordinating with your supplier to determine the best shipping options. Discuss lead times, shipping methods, and costs upfront to avoid surprises. Consider using a logistics partner familiar with international shipping regulations to streamline the process, particularly if you're importing to regions like Africa or South America. Tracking shipments and ensuring proper documentation can also mitigate potential delays at customs.

What should I know about international trade regulations for SIC 3D printing?

Understanding international trade regulations is crucial when sourcing SIC 3D printing services. Each country may have specific import/export requirements, tariffs, and compliance standards that can impact your project. Research the regulations applicable to both your country and your supplier's country. Engaging a customs broker can help navigate these complexities and ensure compliance with all necessary documentation, reducing the risk of delays and additional costs.

How do I evaluate the sustainability practices of SIC 3D printing suppliers?

To evaluate the sustainability practices of SIC 3D printing suppliers, inquire about their materials and processes. Look for suppliers using eco-friendly materials and energy-efficient technologies. Request information on waste management practices and whether they have certifications related to environmental standards. Additionally, consider engaging with suppliers who have initiatives focused on reducing their carbon footprint, as this can enhance your brand's sustainability credentials in the market.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

As we conclude our exploration of SIC 3D printing, it is vital for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to recognize the transformative potential of strategic sourcing in this sector. Leveraging advanced 3D printing technologies allows businesses to streamline production processes, reduce lead times, and enhance customization capabilities. By strategically sourcing materials and technology, buyers can significantly lower costs while maintaining high-quality standards, ultimately leading to improved competitive advantage in their respective markets.

The future of SIC 3D printing is promising, with ongoing advancements poised to redefine manufacturing landscapes. International buyers are encouraged to stay informed about emerging trends, such as sustainable materials and innovative printing techniques, that can further enhance operational efficiencies. As collaboration between suppliers and manufacturers becomes increasingly crucial, establishing strong partnerships will be essential in navigating this evolving market.

To capitalize on these opportunities, B2B buyers should actively engage in research, attend industry conferences, and network with key players in the SIC 3D printing space. Embracing a proactive approach to sourcing will not only drive innovation but also position businesses for sustainable growth in a competitive global environment. Now is the time to invest in SIC 3D printing solutions that align with your strategic goals and unlock new avenues for success.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina