In today’s interconnected economy, understanding the complexities of sourcing sic 6h is essential for businesses aiming to maintain a competitive edge. As a critical component widely used across diverse industries—from manufacturing to advanced engineering—sic 6h demands a nuanced approach to procurement that balances quality, cost-efficiency, and supply chain reliability. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, navigating this market presents unique challenges and opportunities shaped by regional dynamics, regulatory frameworks, and evolving technological standards.

This guide offers a comprehensive roadmap to mastering the global sic 6h landscape. It covers essential topics including the various types and grades of sic 6h available, the key raw materials involved, and the latest manufacturing and quality control processes that ensure product integrity. Buyers will gain actionable insights into identifying reputable suppliers, understanding cost structures, and evaluating market trends to make well-informed sourcing decisions.

Designed with international buyers in mind—whether you are operating in Vietnam’s emerging industrial sectors or Poland’s advanced manufacturing hubs—this guide equips you to optimize your procurement strategies. By delving into detailed FAQs and market analyses, you will be empowered to mitigate risks, enhance supplier negotiations, and secure the best value for your investment. Ultimately, this resource is your strategic partner in unlocking the full potential of sic 6h within the global supply chain.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SIC 6H Standard | Core design with balanced performance and durability | Industrial manufacturing, machinery components | Pros: Reliable, cost-effective; Cons: Limited customization options |

| SIC 6H High-Temperature | Enhanced thermal resistance and stability | Aerospace, automotive exhaust systems | Pros: Excellent heat tolerance; Cons: Higher cost, specialized handling |

| SIC 6H Composite | Combined with other materials for improved toughness | Electronics, high-stress mechanical parts | Pros: Superior strength and flexibility; Cons: Complex sourcing, integration challenges |

| SIC 6H Coated | Surface-treated for corrosion and wear resistance | Chemical processing, marine equipment | Pros: Extended lifespan, reduced maintenance; Cons: Additional upfront cost, coating degradation risks |

| SIC 6H Nano-Enhanced | Incorporates nanomaterials for improved electrical and mechanical properties | Advanced electronics, sensors, cutting tools | Pros: Cutting-edge performance; Cons: Premium pricing, limited supplier availability |

SIC 6H Standard

The SIC 6H Standard type is the foundational variant, prized for its balance between performance and cost-efficiency. It offers reliable durability suitable for general industrial applications, including manufacturing and machinery parts. For B2B buyers, this type is ideal when seeking dependable materials without specialized requirements. Key purchasing considerations include volume discounts and supplier reliability to ensure consistent quality.

SIC 6H High-Temperature

Designed to withstand extreme heat, this variation is essential in sectors such as aerospace and automotive, where components face intense thermal stress. Its enhanced thermal stability makes it a preferred choice for exhaust systems and heat shields. Buyers should assess supplier expertise in handling high-temperature materials and factor in the higher acquisition costs against long-term performance benefits.

SIC 6H Composite

This type integrates SIC 6H with other materials to enhance toughness and flexibility, making it suitable for electronics and mechanical parts exposed to high stress. B2B buyers benefit from improved product lifespan and resilience but must navigate complexities in sourcing composite materials and ensuring compatibility with existing production lines. Collaboration with suppliers on technical specifications is critical.

SIC 6H Coated

With specialized surface treatments, the coated SIC 6H variant offers superior resistance to corrosion and wear, ideal for chemical processing plants and marine applications. Buyers should evaluate the trade-offs between upfront coating costs and reduced maintenance expenses. Additionally, understanding the coating’s longevity and environmental resistance is vital to maximize ROI.

SIC 6H Nano-Enhanced

Incorporating nanomaterials, this advanced variation delivers heightened electrical conductivity and mechanical strength, serving high-tech industries like sensors and cutting tools. For international buyers, especially in emerging markets, sourcing may require partnerships with niche suppliers. While the premium pricing reflects innovation, the performance gains can justify investment in competitive product lines.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of sic 6h | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | High-performance semiconductor substrates | Enables efficient, high-temperature, and high-voltage operation | Consistent crystal quality, purity, and supplier certifications for reliability |

| Automotive | Electric vehicle (EV) power modules | Enhances durability and thermal management in EV powertrains | Compliance with automotive industry standards and supply chain traceability |

| Renewable Energy | Photovoltaic (solar) power devices | Improves conversion efficiency and device lifespan | Availability of large-area wafers and cost-effective sourcing options |

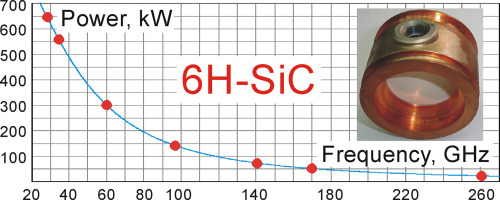

| Aerospace & Defense | High-frequency, high-power microwave devices | Provides robustness under extreme environmental conditions | Proven material performance, supplier capability to meet stringent specs |

| Industrial Automation | High-speed power switching devices | Increases operational efficiency and reduces energy losses | Long-term supply agreements and technical support for integration |

Power Electronics:

In power electronics, SiC 6H serves as a critical substrate for semiconductor devices that operate under high voltages and temperatures. Its wide bandgap and thermal conductivity enable power modules to handle higher power densities with improved efficiency. Buyers from regions such as Africa and South America should prioritize suppliers offering consistent crystal quality and purity, as these factors directly impact device reliability and performance. Certifications and traceability are essential to ensure compliance with international standards.

Automotive Industry:

The rise of electric vehicles (EVs) has increased demand for SiC 6H in power modules, where thermal management and durability are paramount. SiC 6H substrates help in reducing energy losses and improving the lifespan of power electronics within EV powertrains. International buyers, especially from Europe and the Middle East, need to ensure that suppliers meet automotive-grade quality standards and offer robust supply chain transparency to support just-in-time manufacturing models.

Renewable Energy:

SiC 6H substrates are increasingly used in photovoltaic power devices to boost conversion efficiency and extend device life under harsh environmental conditions. For buyers in emerging markets like Vietnam and South America, sourcing large-area, defect-free wafers at competitive prices is critical to scaling solar projects efficiently. Evaluating supplier capacity to deliver consistent wafer sizes and quality can significantly influence project success.

Aerospace & Defense:

In aerospace and defense, SiC 6H is utilized for high-frequency, high-power microwave devices that must withstand extreme temperatures and mechanical stresses. Buyers from Europe and the Middle East should focus on suppliers with proven track records of delivering materials that meet stringent military and aerospace specifications. Ensuring material certification and supplier capability to provide technical documentation is vital for qualification processes.

Industrial Automation:

High-speed power switching devices in industrial automation benefit from SiC 6H’s ability to reduce switching losses and improve operational efficiency. For B2B buyers in Africa and Europe, securing long-term supply agreements and technical support from manufacturers can facilitate seamless integration into automated systems. Attention to supplier reliability and after-sales support is crucial to maintaining continuous production uptime.

Related Video: Sci6 Q3 - Characteristics and Uses of Simple Machines

Key Properties:

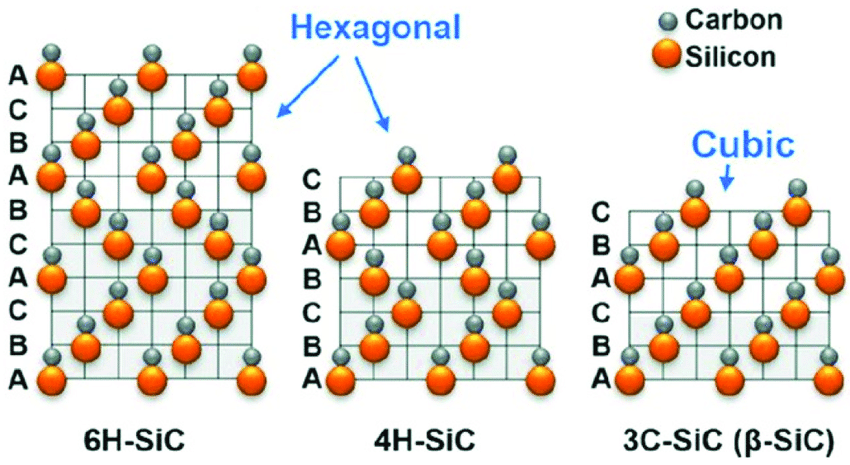

The 6H polytype of silicon carbide is characterized by a hexagonal crystal structure offering high thermal conductivity (approximately 4.9 W/cm·K) and excellent mechanical strength. It can withstand temperatures up to 1600°C and exhibits outstanding chemical inertness, making it highly resistant to corrosion and oxidation. Its wide bandgap (~3.0 eV) supports high-voltage and high-frequency electronic applications.

Pros & Cons:

- Pros: Exceptional thermal stability and electrical properties suitable for high-power devices; excellent wear and corrosion resistance; low thermal expansion coefficient reducing thermal stress.

- Cons: Higher manufacturing complexity due to crystal growth challenges; relatively high raw material cost; brittle nature complicates machining and handling.

Impact on Application:

SiC 6H is ideal for harsh environments involving high temperatures and corrosive media, such as chemical reactors, power electronics, and aerospace components. Its resistance to acidic and alkaline substances makes it suitable for media like sulfuric acid or molten salts.

International B2B Considerations:

Buyers from regions such as Europe and the Middle East should verify compliance with ASTM CVD standards and IEC semiconductor specifications. In Africa and South America, sourcing from suppliers who can provide traceability and certification aligned with ISO 9001 and RoHS directives is critical. Vietnam and Poland buyers often prefer materials compliant with JIS and DIN standards due to local manufacturing alignments.

Key Properties:

PC-SiC consists of multiple small SiC crystals bonded together, offering good thermal conductivity (~3.5 W/cm·K) and high hardness. It can tolerate temperatures up to 1400°C and provides excellent resistance to wear and chemical attack.

Pros & Cons:

- Pros: More cost-effective than single-crystal SiC; easier to manufacture in bulk; good mechanical strength and thermal shock resistance.

- Cons: Lower electrical performance compared to single-crystal 6H SiC; grain boundaries can reduce overall material uniformity; less suitable for high-frequency electronics.

Impact on Application:

PC-SiC is widely used in mechanical seals, kiln furniture, and abrasive components where thermal and chemical resistance is needed but electrical properties are secondary. It performs well in environments with abrasive slurries and corrosive gases.

International B2B Considerations:

Buyers in South America and Africa benefit from PC-SiC’s cost efficiency and robustness for industrial applications. Compliance with ASTM C799 and ISO 9001 is often requested. European and Middle Eastern buyers should ensure suppliers meet EN standards for ceramic materials, especially when used in food or pharmaceutical processing.

Key Properties:

This composite combines SiC 6H’s hardness and thermal stability with h-BN’s lubricating properties and electrical insulation. It offers thermal conductivity around 2-3 W/cm·K and can operate up to 1200°C. The composite is chemically inert and exhibits excellent resistance to thermal shock.

Pros & Cons:

- Pros: Enhanced machinability and reduced friction; good electrical insulation; improved thermal shock resistance.

- Cons: Slightly lower thermal conductivity than pure SiC 6H; higher production complexity; cost can be elevated due to composite processing.

Impact on Application:

Ideal for applications requiring both wear resistance and electrical insulation, such as semiconductor processing equipment, high-temperature electrical insulators, and precision mechanical parts exposed to corrosive media.

International B2B Considerations:

Buyers from Europe and the Middle East should verify compliance with IEC 60664 and ASTM D5470 for electrical insulation and thermal conductivity. In Africa and South America, emphasis on supplier quality management systems (e.g., ISO/TS 16949) ensures consistent composite performance. Vietnam and Poland manufacturers may prefer materials meeting JIS C 6471 for electrical ceramics.

Key Properties:

SSiC is produced by sintering SiC powder with additives, resulting in a dense, strong ceramic with thermal conductivity around 3.7 W/cm·K and temperature resistance up to 1600°C. It offers excellent corrosion resistance and mechanical strength.

Pros & Cons:

- Pros: High density and strength; good thermal shock resistance; relatively easier to shape and machine compared to single-crystal SiC.

- Cons: Additives used in sintering can slightly reduce purity and electrical properties; cost varies depending on sintering method; potential variability in grain size affecting uniformity.

Impact on Application:

Commonly used in pump components, valve parts, and heat exchangers exposed to aggressive chemicals and high temperatures. Suitable for slurry handling and abrasive environments.

International B2B Considerations:

For buyers in Africa and South America, SSiC offers a balance of performance and cost, with ASTM C799 and ISO 14001 environmental compliance often requested. European and Middle Eastern buyers should ensure materials meet DIN EN 623 standards for ceramic mechanical components. Vietnam and Poland markets value suppliers providing full material traceability and compliance with local industrial safety regulations.

| Material | Typical Use Case for sic 6h | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (6H Polytype) | High-power electronics, chemical reactors | Superior thermal stability and electrical properties | High manufacturing complexity and brittleness | High |

| Polycrystalline Silicon Carbide | Mechanical seals, kiln furniture, abrasive components | Cost-effective with good wear and chemical resistance | Lower electrical performance and uniformity | Medium |

| h-BN Composite with SiC 6H | Electrical insulators, semiconductor equipment | Combines wear resistance with electrical insulation | Reduced thermal conductivity and higher cost | High |

| Sintered Silicon Carbide (SSiC) | Pump parts, valves, heat exchangers | High density and strength with good machinability | Additive impurities can affect purity | Medium |

The production of Sic 6H, a specialized material known for its superior mechanical and thermal properties, involves a meticulously controlled multi-stage manufacturing process. Understanding these stages helps B2B buyers assess supplier capabilities and ensure product consistency.

1. Material Preparation

Raw materials, typically high-purity silicon carbide powders combined with sintering aids, undergo stringent selection and preprocessing. This includes powder refinement, homogenization, and drying to ensure uniform particle size and composition. Advanced suppliers often utilize ball milling or jet milling to achieve optimal powder characteristics, crucial for the final product’s performance.

2. Forming

The prepared powders are shaped into the desired geometry through methods such as cold isostatic pressing (CIP) or uniaxial pressing. For complex shapes, hot pressing or injection molding techniques might be applied. These forming processes influence the density and microstructure of Sic 6H, impacting mechanical strength and thermal conductivity.

3. Sintering and Heat Treatment

Sintering is a pivotal stage where the pressed parts are subjected to high temperatures (often exceeding 2000°C) in controlled atmospheres to bond particles and densify the material. Techniques like pressureless sintering or hot isostatic pressing (HIP) enhance the microstructure uniformity and reduce porosity. Post-sintering heat treatments may be employed to tailor thermal expansion coefficients or relieve internal stresses.

4. Machining and Assembly

Due to Sic 6H’s hardness, machining requires precision tools such as diamond-coated cutters and advanced CNC equipment. Suppliers skilled in grinding, lapping, and laser cutting can achieve tight tolerances and complex finishes. If Sic 6H components are part of assemblies, integration with metals or ceramics demands expertise in bonding or mechanical fastening techniques compatible with the material’s properties.

5. Surface Finishing

Finishing processes improve surface quality and functional performance. Techniques include chemical etching, polishing, and coating applications to enhance wear resistance or electrical insulation. Final inspection ensures the surface integrity meets application-specific requirements.

Robust quality assurance (QA) is essential when sourcing Sic 6H, especially for international buyers who require consistent product performance across diverse applications.

International and Industry Standards

- ISO 9001: The foundational quality management system standard ensuring supplier consistency, process control, and continual improvement.

- CE Marking: Relevant for Sic 6H components used in machinery or electrical equipment within the European Economic Area, guaranteeing compliance with EU safety and environmental directives.

- API (American Petroleum Institute) Standards: Applicable if Sic 6H parts serve in oil, gas, or chemical processing, emphasizing material integrity under harsh conditions.

- ASTM and DIN Standards: Often referenced for material testing and certification, providing benchmarks for mechanical and thermal properties.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw material certificates, chemical composition, and particle size distribution upon receipt.

- In-Process Quality Control (IPQC): Monitoring critical parameters during forming, sintering, and machining, including dimensional checks, density measurements, and microstructural inspections using microscopy.

- Final Quality Control (FQC): Comprehensive testing of finished products, including mechanical strength, thermal conductivity, and surface finish assessments.

Ensuring Sic 6H meets stringent application demands requires a suite of advanced testing techniques:

For B2B buyers from Africa, South America, the Middle East, and Europe, ensuring supplier QC reliability is critical due to geographic and regulatory differences. Consider the following strategies:

International buyers must be aware of regional variations in quality expectations and regulatory frameworks:

A deep understanding of Sic 6H’s manufacturing nuances and quality assurance frameworks enables international B2B buyers to make informed sourcing decisions. Prioritizing suppliers with transparent processes, robust certifications, and proven testing regimes reduces risk and fosters long-term partnerships. Leveraging audits, independent inspections, and sample validations further strengthens quality assurance, ensuring Sic 6H components meet the demanding requirements of global industrial applications.

Understanding the cost structure and pricing dynamics of sourcing sic 6h products is essential for international B2B buyers aiming to optimize their procurement strategy. The pricing landscape is shaped by multiple interrelated components and influenced by various market and supplier-specific factors. This analysis highlights key cost elements and pricing influencers, alongside actionable tips for buyers from regions such as Africa, South America, the Middle East, and Europe (including countries like Vietnam and Poland).

Materials

The raw materials used in sic 6h production are often high-grade and specialized, impacting the base cost significantly. Fluctuations in raw material prices, driven by global supply-demand and geopolitical factors, can cause price variability.

Labor

Labor costs vary widely by country and region. For instance, manufacturers in Eastern Europe (e.g., Poland) may offer competitive labor rates compared to Western Europe, while Asian suppliers (Vietnam) might provide even lower labor costs but with different quality standards.

Manufacturing Overhead

This includes utilities, plant maintenance, and indirect labor costs. Efficient factories with modern automation tend to have lower overhead, influencing pricing favorably.

Tooling and Setup

Initial tooling and setup expenses can be substantial, especially for customized sic 6h components. These costs are typically amortized over production volume, affecting unit price.

Quality Control (QC)

Rigorous QC processes, certifications (e.g., ISO, RoHS), and testing add to costs but are critical for ensuring product reliability, particularly for buyers in regulated markets.

Logistics and Shipping

Freight costs, customs duties, insurance, and warehousing fees vary by origin and destination. Buyers from Africa or South America should anticipate higher logistics costs due to longer transit routes and less frequent shipping options.

Supplier Margin

Margins depend on supplier positioning, market competition, and order size. Premium suppliers with strong reputations may charge higher margins but offer better reliability and support.

Order Volume and Minimum Order Quantity (MOQ)

Larger orders typically reduce per-unit costs through economies of scale. However, buyers with smaller procurement needs must negotiate to avoid excessive MOQ penalties.

Product Specifications and Customization

Tailored specifications or enhanced performance features increase complexity and cost. Standardized sic 6h products usually come at lower prices.

Material Grades and Quality Certifications

Higher-grade materials and compliance with international standards elevate costs but also reduce risk and improve lifecycle performance.

Supplier Location and Capabilities

Suppliers in regions with advanced manufacturing infrastructure may offer better quality control but at higher prices. Conversely, emerging markets may provide cost advantages with trade-offs in lead times or quality consistency.

Incoterms and Payment Terms

The choice of Incoterms (e.g., FOB, CIF, DDP) influences who bears logistics risk and cost, affecting overall pricing. Favorable payment terms can also improve cash flow and cost predictability.

Negotiate Beyond Price:

Engage suppliers on lead times, payment terms, and after-sales service to enhance value, not just reduce price.

Analyze Total Cost of Ownership (TCO):

Consider not only purchase price but also logistics, customs, quality risks, and warranty support. A low upfront cost may lead to higher long-term expenses.

Leverage Regional Strengths:

For buyers in Africa and South America, partnering with suppliers closer to Europe or the Middle East can reduce transit times and costs. Similarly, European buyers can benefit from regional sourcing hubs for faster turnaround.

Understand Pricing Nuances:

Be aware that prices quoted ex-works differ substantially from delivered prices. Clarify Incoterms and ensure all hidden costs (duties, taxes, handling fees) are accounted for.

Request Detailed Cost Breakdowns:

Transparent supplier quotations enable better negotiation and identification of cost-saving opportunities, such as material substitutions or process optimizations.

Plan for Volume Flexibility:

If possible, consolidate orders to meet MOQ thresholds or negotiate staggered deliveries to balance cash flow and inventory risks.

Prices for sic 6h products vary widely based on the factors discussed and current market conditions. The figures referenced in this analysis are indicative and should be validated with direct supplier quotations and updated market research before finalizing procurement decisions.

By carefully dissecting cost components and understanding the multiple price influencers, international buyers can strategically navigate sic 6h sourcing, achieving cost efficiency without compromising on quality or supply reliability.

Understanding the critical technical properties and trade terminology related to sic 6h is vital for international B2B buyers aiming to make informed purchasing decisions. This knowledge ensures clarity in specifications, quality expectations, and negotiation terms, ultimately reducing risks in cross-border transactions.

Material Grade

The material grade defines the purity and composition standards of sic 6h. Higher grades indicate better performance in terms of durability, thermal stability, and resistance to wear. For buyers, specifying the correct grade ensures the product meets industry or application-specific requirements, minimizing failures in end-use.

Dimensional Tolerance

This refers to the allowable deviation from specified dimensions (e.g., thickness, diameter). Tight tolerances are crucial in precision applications where fitting and compatibility matter. Buyers should confirm tolerance levels to avoid costly rejections or rework, especially when components must integrate with other parts.

Thermal Conductivity

Sic 6h’s ability to conduct heat efficiently impacts its suitability for high-temperature environments. Buyers from industries like electronics or aerospace should prioritize this property to ensure operational reliability under thermal stress.

Mechanical Strength

Defined by tensile strength and hardness, this property indicates how well sic 6h can withstand mechanical forces without deformation or failure. Understanding mechanical strength helps buyers select materials that ensure longevity and safety in demanding applications.

Illustrative Image (Source: Google Search)

Surface Finish

The surface condition (e.g., roughness, coating) affects both functional performance and aesthetics. For example, smoother finishes may be required for sealing surfaces or optical applications. Buyers should specify surface finish requirements to align with end-use functionality.

Chemical Stability and Resistance

Sic 6h’s resistance to chemical corrosion or oxidation is essential for applications in harsh environments. International buyers need to assess chemical compatibility, especially when sourcing for sectors like chemical processing or marine industries.

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end products. For buyers, sourcing directly from OEMs often means better quality assurance and customization options, reducing supply chain complexities.

MOQ (Minimum Order Quantity)

MOQ specifies the smallest amount of sic 6h that a supplier is willing to sell. Understanding MOQ helps buyers plan inventory and cash flow, particularly in markets where small batch purchases are not feasible or cost-effective.

Illustrative Image (Source: Google Search)

RFQ (Request for Quotation)

RFQ is a formal invitation sent by buyers to suppliers asking for pricing and terms on specified quantities and specifications. Crafting a detailed RFQ ensures clear communication, enabling suppliers to provide accurate quotes and reducing negotiation time.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Familiarity with common Incoterms (e.g., FOB, CIF, DDP) empowers buyers to negotiate favorable delivery terms and manage logistics risks effectively.

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times helps buyers synchronize supply with production schedules and avoid costly downtime.

Certification and Compliance

Certifications such as ISO, RoHS, or REACH indicate adherence to quality, safety, and environmental standards. Buyers should verify these certifications to ensure compliance with regional regulations and avoid import restrictions.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms is essential. It enables clearer communication with suppliers, supports better quality control, and fosters smoother international transactions involving sic 6h products.

The sic 6h sector has experienced significant transformation driven by globalization, technological innovation, and evolving buyer expectations. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these market dynamics is critical to maintaining competitive advantage and optimizing sourcing strategies.

Illustrative Image (Source: Google Search)

Global Drivers:

- Digitalization and Automation: The integration of advanced technologies such as IoT, AI, and blockchain in sic 6h operations is improving transparency, efficiency, and traceability across supply chains. Buyers benefit from enhanced real-time data, enabling smarter procurement decisions and risk management.

- Regional Supply Chain Diversification: Geopolitical uncertainties and trade disruptions have accelerated the diversification of sourcing bases. Buyers in emerging economies like Vietnam and Poland increasingly seek suppliers in multiple regions to mitigate risks and ensure continuity.

- Demand for Customization and Flexibility: End-users are demanding more tailored sic 6h solutions, pushing suppliers to adopt modular designs and flexible manufacturing processes. This trend requires buyers to engage with partners capable of agile production and rapid innovation.

- Price Volatility and Raw Material Constraints: Fluctuations in raw material costs, influenced by global economic shifts and environmental regulations, impact pricing structures. Buyers must develop robust cost-analysis frameworks and foster strong supplier relationships to navigate volatility.

Emerging B2B Sourcing Trends:

- Collaborative Platforms: Digital marketplaces and B2B platforms are becoming pivotal for cross-border sourcing, particularly for buyers in Africa and South America. These platforms facilitate supplier discovery, streamline negotiations, and support compliance checks.

- Nearshoring and Regional Hubs: European buyers, including those in Poland, are increasingly exploring nearshoring options to reduce lead times and carbon footprint. Similarly, Middle Eastern buyers leverage regional hubs to optimize logistics and customs processes.

- Data-Driven Procurement: Advanced analytics tools enable buyers to predict demand patterns, assess supplier performance, and optimize inventory management, fostering more strategic sourcing decisions.

By aligning sourcing strategies with these market trends, international buyers can enhance supply chain resilience, reduce costs, and capitalize on innovation within the sic 6h sector.

Sustainability has become a non-negotiable priority in the sic 6h sector, driven by regulatory pressures, stakeholder expectations, and the urgent need to mitigate environmental impact. For B2B buyers across Africa, South America, the Middle East, and Europe, embedding sustainability into procurement practices is essential for long-term success and brand reputation.

Environmental Impact Considerations:

- The sic 6h sector often involves resource-intensive processes that contribute to carbon emissions, waste generation, and water consumption. Buyers must assess the full lifecycle impact of sourced products and components, from raw material extraction to end-of-life disposal.

- Embracing circular economy principles—such as product reuse, recycling, and materials recovery—can significantly reduce environmental footprints and lower costs.

Ethical Supply Chains:

- Transparency and traceability are critical to ensuring ethical sourcing, including fair labor practices and compliance with international labor standards. Buyers should demand supplier audits, certifications, and real-time monitoring to verify compliance.

- Collaborative initiatives, such as supplier capacity-building programs and multi-stakeholder partnerships, help uplift social standards and foster sustainable development in supplier regions.

Green Certifications and Materials:

- Certifications like ISO 14001 (Environmental Management), FSC (Forest Stewardship Council), and Cradle to Cradle provide assurance of sustainable practices and materials. Buyers should prioritize suppliers holding these or equivalent certifications to mitigate risks and meet regulatory requirements.

- The adoption of bio-based, recycled, or low-impact materials in sic 6h products is gaining traction. Buyers can differentiate their offerings and meet end-customer demand by sourcing from suppliers committed to green innovation.

By integrating sustainability criteria into supplier selection and contract negotiations, B2B buyers not only comply with emerging regulations but also drive competitive differentiation and contribute to global environmental goals.

The sic 6h sector has evolved from traditional, labor-intensive operations to a highly specialized and technology-driven industry. Historically, the sector’s growth was fueled by increasing industrialization and global trade expansion in the late 20th century. Early supply chains were often regional and fragmented, with limited transparency and efficiency.

Over the past two decades, globalization and digital transformation have reshaped the sector into a complex, interconnected ecosystem characterized by advanced manufacturing techniques, integrated supply networks, and sophisticated logistics. The rise of emerging markets such as Vietnam and Poland as key production hubs reflects shifting economic balances and the strategic importance of cost-effective, quality-driven sourcing.

Sustainability concerns and regulatory frameworks have further accelerated the sector’s maturation, compelling stakeholders to adopt responsible sourcing and circular economy models. For today’s international B2B buyers, understanding this evolution is key to navigating current market complexities and identifying future growth opportunities in the sic 6h sector.

How can I effectively vet suppliers of sic 6h to ensure reliability and product quality?

To vet suppliers, start by verifying their business licenses and certifications relevant to sic 6h manufacturing. Request detailed product specifications, sample products, and client references to assess quality consistency. Use third-party inspection services to audit supplier facilities and production processes. Platforms with verified supplier ratings and trade assurance can add security. For buyers in Africa, South America, the Middle East, and Europe, prioritize suppliers experienced in international compliance standards like ISO and CE to minimize risks and ensure smooth customs clearance.

Is customization of sic 6h products available, and how should I approach it with suppliers?

Many suppliers offer customization options such as size, material composition, or packaging tailored to your market needs. Clearly communicate your technical requirements and intended application to the supplier upfront. Discuss minimum order quantities (MOQ) and additional costs associated with customization. Request prototypes or samples before full production to avoid costly errors. For international buyers, ensure your supplier understands any regional regulatory requirements to guarantee compliance and market acceptance.

What are typical MOQ and lead times for sic 6h orders, and how can I negotiate favorable terms?

MOQ varies widely depending on the supplier’s scale and product complexity, often ranging from hundreds to thousands of units. Lead times typically span 4 to 8 weeks but can extend based on customization and shipping logistics. To negotiate better terms, consolidate orders or agree to longer-term contracts, which may encourage suppliers to lower MOQs or expedite production. International buyers should factor in additional time for customs clearance and potential delays at ports, especially when shipping to Africa or South America.

Which payment methods are safest and most common for international B2B transactions involving sic 6h?

Secure payment methods include Letters of Credit (LC), Escrow services, and Verified Payment Platforms such as PayPal for smaller transactions. LC is preferred for large orders, offering protection to both parties by releasing funds only after shipment confirmation. Avoid upfront full payments without guarantees. For buyers in emerging markets, negotiate partial deposits combined with balance payments upon delivery or inspection to reduce financial risk.

What quality assurance certifications should I look for when purchasing sic 6h internationally?

Key certifications include ISO 9001 (quality management), CE marking (European conformity), and any industry-specific standards relevant to sic 6h’s application. Additionally, suppliers should provide material safety data sheets (MSDS) and third-party lab test reports verifying product composition and performance. For buyers in Africa and the Middle East, confirm certifications recognized by local regulatory bodies to ensure smooth import and market entry.

How should I manage logistics and shipping challenges when importing sic 6h from overseas suppliers?

Engage with freight forwarders experienced in handling chemical or specialized materials to navigate customs regulations, especially in regions like Africa and South America where clearance can be complex. Choose Incoterms carefully (e.g., FOB, CIF) to clarify cost and risk responsibilities. Consider multimodal transport options to optimize cost and delivery speed. Always prepare for potential delays due to geopolitical issues or port congestion, and build buffer time into your supply chain planning.

What are best practices for handling disputes or quality issues with sic 6h suppliers?

Establish clear contractual terms covering quality standards, inspection procedures, and dispute resolution mechanisms before order confirmation. In case of issues, conduct an independent third-party inspection and document all findings. Attempt amicable resolution via supplier negotiation or mediation. If unresolved, escalate through arbitration clauses or legal channels stipulated in the contract, preferably under internationally recognized frameworks such as ICC arbitration. Maintaining detailed communication records is crucial.

How can international buyers optimize cost-efficiency when sourcing sic 6h in bulk?

Leverage volume discounts by consolidating orders and negotiating long-term supply agreements. Consider suppliers located closer to your distribution hubs to reduce freight costs. Analyze total landed cost, including tariffs, taxes, and logistics, rather than focusing solely on unit price. Utilize bulk shipping methods like sea freight for large orders to minimize expenses. Additionally, collaborate with suppliers to optimize packaging and palletization to reduce shipping volume and handling fees.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing in the context of sic 6h offers international B2B buyers a critical pathway to optimize supply chains, reduce costs, and enhance supplier collaboration. For buyers across Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Poland—leveraging data-driven insights and fostering strong regional partnerships can unlock competitive advantages. Prioritizing supplier diversity, risk mitigation, and sustainable practices is essential to navigate the complexities of today’s global trade environment.

Key takeaways for B2B buyers include:

Looking ahead, strategic sourcing in sic 6h will increasingly rely on agility and innovation. Buyers are encouraged to proactively engage with suppliers, invest in digital transformation, and remain adaptable to shifting market dynamics. By doing so, businesses will not only secure better value but also position themselves for long-term growth in a competitive global landscape. Now is the time for international B2B buyers to deepen strategic sourcing capabilities and turn supply chain challenges into opportunities.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina