Guide to Sic Armor

In today’s interconnected global economy, the demand for high-performance security solutions like SIC armor has never been more critical. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable, durable, and cost-effective protective materials, understanding the nuances of the SIC armor market becomes essential. Whether for military, law enforcement, or private security applications, sourcing the right type of armor directly impacts operational safety, compliance, and overall investment value.

This comprehensive guide aims to equip you with actionable insights into every facet of SIC armor procurement. We will explore the different types and materials used in manufacturing, highlight key quality control standards, and identify reputable global suppliers. Additionally, it will shed light on cost considerations, market trends, and regulatory factors affecting international trade.

By navigating these critical aspects, you will be empowered to make informed sourcing decisions that align with your operational needs and budget constraints. Whether you are sourcing from emerging markets or established suppliers, this guide provides the strategic knowledge necessary to optimize your supply chain, mitigate risks, and secure the best value in the global SIC armor market. Ultimately, it’s about transforming complexity into clarity—enabling you to confidently meet the security demands of your stakeholders worldwide.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid Wedge Gate Valve | Single-piece construction, wedge-shaped disc | Water supply, oil & gas, chemical processing | Durable and reliable; cost-effective but limited in flow control precision |

| Rising Stem Gate Valve | Stem moves vertically with disc, often with handwheel | Municipal water, fire protection systems | Easy to operate and maintain; higher installation costs and larger footprint |

| Parallel Slide Gate Valve | Two parallel discs, minimal sealing surface | Slurries, corrosive fluids, mining | Good for abrasive media; complex design may increase maintenance costs |

| Knife Gate Valve | Thin, sharp-edged disc for cutting through media | Pulp & paper, wastewater, mining | Excellent for viscous or fibrous media; potential for leakage if not properly maintained |

| Resilient Seat Gate Valve | Elastomeric seats for tight sealing | Food processing, potable water, pharmaceuticals | Provides tight shutoff, low torque operation; limited temperature and chemical resistance |

The Solid Wedge Gate Valve features a single, robust piece of metal forming the wedge-shaped disc that moves within the valve body. Its simplicity makes it highly durable and suitable for applications requiring minimal maintenance, such as water supply and oil pipelines. For B2B buyers, especially those sourcing in regions like Kenya or Poland, the key advantages are cost-effectiveness and reliability. However, this type may not provide the precise flow control needed for certain processes and can be prone to sticking if thermal expansion occurs. When purchasing, consider the operating environment and maintenance capabilities.

The Rising Stem Gate Valve has a stem that moves vertically as the disc opens or closes, often equipped with a handwheel for manual operation. It is favored in municipal and fire protection systems due to ease of operation and visual confirmation of valve position. For international buyers, the main considerations include its straightforward design, which simplifies maintenance, but it often requires more space and higher initial costs. Its robustness makes it suitable for high-pressure applications, making it a reliable choice for critical infrastructure projects.

The Parallel Slide Gate Valve employs two parallel discs that slide against each other, providing a tight seal even with abrasive or corrosive media. Its design is ideal for mining and slurry applications, where durability against wear is paramount. B2B buyers should evaluate its complex construction, which can lead to increased maintenance and higher upfront costs, against its excellent sealing capabilities. Suitable for industries with challenging media, this valve offers longevity but requires skilled installation and regular inspection.

The Knife Gate Valve features a thin, sharp-edged disc designed to cut through viscous, fibrous, or slurry media. It is widely used in pulp & paper, wastewater, and mining industries. For buyers, its ability to handle challenging media makes it valuable, especially in regions with heavy industrial activity. However, it can experience leakage if not properly maintained, and its lifespan may be shorter in highly abrasive environments. Proper selection and maintenance are critical for maximizing its operational lifespan.

The Resilient Seat Gate Valve incorporates elastomeric seats that provide a tight seal, making it ideal for potable water, food processing, and pharmaceutical applications. It offers low torque operation, which reduces actuator costs and simplifies automation. B2B buyers should consider its limited temperature and chemical resistance, which may restrict use in more aggressive environments. Its quick shutoff capability and ease of operation make it a popular choice for applications requiring frequent operation and high sealing integrity.

This overview provides a comprehensive understanding of key SIC armor variations, enabling international buyers to make informed procurement decisions aligned with their specific operational needs and regional considerations.

| Industry/Sector | Specific Application of sic armor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pipeline protection against corrosion and mechanical wear | Enhances pipeline longevity, reduces maintenance costs, and prevents leaks | Material certification, compatibility with operational media, supply chain reliability |

| Mining & Mineral Processing | Wear-resistant linings for crushers and chutes | Extends equipment lifespan, minimizes downtime, and lowers replacement costs | Customization options, thermal stability, supplier track record |

| Aerospace & Defense | Thermal protection and lightweight armor components | Improves safety, reduces weight for fuel efficiency, and ensures durability | Certification standards (e.g., aerospace-grade), weight-to-strength ratio |

| Automotive & Heavy Machinery | High-performance brake systems and cladding | Increased safety, durability under extreme conditions, and reduced maintenance | Material purity, compliance with industry standards, sourcing logistics |

| Electronics & Semiconductor Manufacturing | Protective barriers against thermal and mechanical stress | Ensures device integrity, reduces failure rates, and supports miniaturization | Purity levels, process compatibility, supplier certifications |

Sic armor is extensively used in the oil and gas industry for pipeline protection, especially in corrosive environments typical of Africa, South America, and the Middle East. It provides high resistance to mechanical wear and corrosion, ensuring pipeline integrity over long periods. For international buyers, sourcing high-quality, API-certified sic armor ensures compliance with safety standards and reduces operational risks. Additionally, buyers should verify supplier reliability and material compatibility with specific fluids or gases transported, especially in remote or harsh environments.

In mining operations, sic armor is applied to wear-resistant linings in crushers, chutes, and conveyors. Its exceptional hardness and durability withstand abrasive mineral ores, significantly reducing equipment downtime and maintenance costs. For buyers in regions like Poland or South America, selecting suppliers with proven track records and customization capabilities is vital. Thermal stability and ease of installation are also critical factors, particularly for large-scale operations requiring rapid deployment and minimal disruption.

Sic armor finds critical applications in aerospace and defense sectors for thermal protection and lightweight armor components. Its high strength-to-weight ratio is essential for aircraft, satellites, and military vehicles operating under extreme thermal and mechanical stresses. European and Middle Eastern defense contractors, in particular, prioritize certified materials that meet stringent aerospace standards. Buyers should focus on suppliers offering aerospace-grade certifications, consistent quality, and options for customization to meet specific project needs.

In the automotive and heavy machinery sectors, sic armor is used for high-performance brake systems and protective cladding in equipment exposed to extreme conditions. Its resistance to thermal stress and mechanical wear enhances safety and reduces the frequency of repairs. European and African manufacturers should prioritize sourcing from suppliers with proven industry certifications and reliable logistics networks to ensure timely delivery of high-purity, certified materials suitable for critical applications.

Sic armor is increasingly employed in electronics and semiconductor manufacturing for protective barriers against thermal and mechanical stress. Its robustness supports miniaturization and enhances device reliability, especially in high-temperature environments. For buyers in regions like South America and Europe, sourcing high-purity sic materials with certifications aligned to industry standards is essential. Compatibility with manufacturing processes and supplier transparency are key considerations to ensure seamless integration into sensitive production lines.

Selecting the appropriate materials for sic (silicon carbide) armor involves understanding the properties, advantages, and limitations of common materials used in conjunction with sic to optimize performance, cost, and compliance across different markets. Below is an analysis of four prevalent materials: Silicon Carbide (SiC) itself, Aluminum Oxide (Al₂O₃), Boron Carbide (B₄C), and Zirconia (ZrO₂). Each material offers unique benefits and challenges, which are crucial for international B2B buyers to consider.

Key Properties:

Silicon carbide is renowned for its exceptional hardness, high thermal stability, and excellent corrosion resistance. It withstands high temperatures up to 1600°C and maintains structural integrity under extreme pressure, making it ideal for ballistic and industrial armor applications.

Pros & Cons:

The primary advantage of SiC is its superior durability and lightweight nature compared to traditional ceramics. Manufacturing, however, can be complex and costly due to the need for high-temperature sintering and advanced fabrication techniques. End-products are highly resistant to wear and corrosion, suitable for environments with aggressive media.

Impact on Application:

SiC's chemical inertness ensures compatibility with various media, including acidic and alkaline environments. Its thermal properties enable use in high-temperature settings, such as industrial protection shields.

International Buyer Considerations:

For buyers in Africa, South America, the Middle East, and Europe, compliance with standards like ASTM C1167 or DIN 16908 is critical. SiC's high performance aligns with stringent safety and durability standards, but sourcing quality-grade material may involve navigating regional supply chains. Cost considerations are significant, especially for large-scale deployments in developing regions.

Key Properties:

Aluminum oxide, or alumina, is a widely used ceramic known for its good hardness, electrical insulation, and corrosion resistance. It can withstand temperatures up to approximately 2000°C, depending on purity and grade.

Pros & Cons:

Alumina is generally less expensive than B₄C and ZrO₂, with well-established manufacturing processes. It offers good mechanical strength and is relatively easy to produce in various shapes and sizes. However, it is more brittle than SiC and B₄C, which can limit its durability under high-impact conditions.

Impact on Application:

Its chemical inertness makes alumina suitable for media where chemical resistance is necessary, such as in chemical processing environments. Its lower toughness may require design considerations to prevent fracture under dynamic loads.

International Buyer Considerations:

In markets like Kenya or Poland, compliance with European standards (EN 12413) or ASTM standards ensures quality. Alumina's affordability makes it attractive in cost-sensitive projects, but buyers must consider potential supply chain variability and ensure sourcing from reputable manufacturers to meet safety standards.

Key Properties:

Boron carbide is one of the hardest materials after diamond and cubic boron nitride, with excellent ballistic resistance and low density. It maintains stability at high temperatures and exhibits outstanding neutron absorption properties, making it suitable for specialized applications.

Pros & Cons:

Its high hardness and low weight provide superior ballistic protection, ideal for lightweight armor systems. Manufacturing is complex and expensive, often requiring specialized sintering processes. B₄C is also susceptible to oxidation at elevated temperatures if not properly coated or protected.

Impact on Application:

Boron carbide performs exceptionally well in environments requiring high-impact resistance and low weight, such as military or aerospace armor. Its chemical stability is good, but oxidation resistance may necessitate additional coatings in certain environments.

International Buyer Considerations:

For buyers in regions with strict export controls, like the Middle East or Europe, sourcing B₄C requires navigating regulatory frameworks. Its high cost may be justified by performance needs, but budget constraints in developing regions could limit adoption. Standards like ASTM C1334 or DIN 16908 are relevant for quality assurance.

Key Properties:

Zirconia offers high fracture toughness, good wear resistance, and excellent thermal stability. It can withstand temperatures up to 2700°C and exhibits transformation toughening, which enhances its resistance to crack propagation.

Pros & Cons:

While zirconia provides superior toughness compared to other ceramics, it is more expensive and may require precise processing to prevent phase transformation issues. It is also sensitive to low-temperature degradation in humid environments, which can affect long-term durability.

Impact on Application:

Zirconia's toughness makes it suitable for applications where impact resistance is critical, such as specialized armor panels. Its chemical inertness supports use in corrosive media, but cost and processing complexity can be limiting factors.

International Buyer Considerations:

European and Middle Eastern markets often favor zirconia for high-end applications due to its performance. Buyers should verify compliance with ISO standards and ensure supplier transparency regarding manufacturing processes. Cost considerations are significant, especially for large-scale or budget-sensitive projects.

| Material | Typical Use Case for sic armor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Ballistic and industrial armor, high-temperature shields | High hardness, thermal stability, corrosion resistance | Complex manufacturing, higher cost | High |

| Aluminum Oxide (Al₂O₃) | Chemical processing, basic ballistic applications | Cost-effective, good chemical resistance | Brittle, less impact resistant | Low |

| Boron Carbide (B₄C) | Lightweight ballistic armor, aerospace applications | Superior ballistic resistance, low weight | Expensive, oxidation susceptibility | High |

| Zirconia (ZrO₂) | Impact-resistant armor, high-performance applications | Excellent toughness, thermal stability | Costly, sensitive to environmental degradation | High |

This comprehensive analysis provides international B2B buyers with critical insights into material selection, emphasizing performance, cost, and regional compliance considerations essential for successful procurement and deployment of sic armor solutions across diverse markets.

The production of Silicon Carbide (SiC) armor involves a complex sequence of high-precision manufacturing stages designed to ensure optimal performance, durability, and safety. For international B2B buyers, understanding these processes helps in assessing supplier capabilities and product reliability.

The process begins with sourcing high-purity Silicon Carbide powders, typically exceeding 99% purity levels to meet industry standards. These powders are subjected to rigorous quality checks for contaminants and particle size distribution, as these factors influence the final product's strength and consistency. Suppliers often source raw materials from established chemical producers with verified certifications (e.g., ISO 9001, ISO 14001).

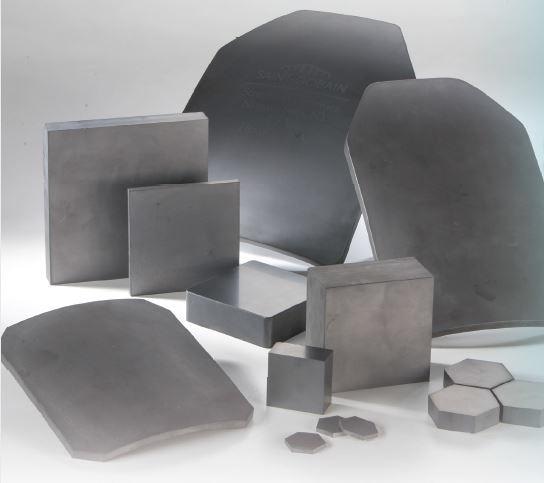

Illustrative Image (Source: Google Search)

Key considerations for buyers:

- Verify supplier certifications for raw material sourcing.

- Request detailed material data sheets and test reports.

The prepared SiC powders are compacted into desired shapes through advanced forming techniques such as isostatic pressing or die pressing. These methods ensure uniform density and minimal porosity, critical for ballistic performance. Sometimes, binder agents are added to facilitate molding, which are later eliminated through thermal treatment.

Key techniques include:

- Hot Pressing: Applies heat and pressure simultaneously, producing dense and uniform armor plates.

- Reaction Bonding: Involves chemical reactions during sintering that enhance material properties.

Buyer insights:

- Confirm the forming method used and its suitability for the intended application.

- Ensure the process adheres to international standards for consistency.

Post-forming, the shaped SiC parts undergo sintering at high temperatures (typically above 2000°C) in controlled atmospheres (argon, nitrogen). This step densifies the material, reduces porosity, and enhances mechanical strength. Some manufacturers incorporate hot isostatic pressing (HIP) for further densification, especially for high-performance armor.

Critical factors:

- Precise temperature control and atmosphere regulation to prevent defects.

- Use of advanced furnaces with real-time monitoring.

Implication for buyers:

- Ask for detailed sintering cycle reports and thermal process documentation.

Following sintering, the armor plates are machined to tight tolerances using CNC equipment. Edges and surfaces are finished to specifications, often involving grinding and polishing to meet ballistic standards. In some cases, multiple layers or composite structures are assembled for enhanced protection, involving bonding or welding techniques compatible with SiC materials.

Assembly considerations:

- Use of industry-approved adhesives or mechanical fasteners.

- Compatibility of bonding agents with SiC to avoid compromising integrity.

The final step includes surface treatments such as coatings or sealants to improve resistance against environmental factors like corrosion or abrasion. Advanced coatings may include ceramic-based or polymer layers designed for ballistic performance and longevity.

Buyers should:

- Confirm coating specifications align with operational environments.

- Request detailed application procedures and certification of coatings.

Ensuring the quality of SiC armor is paramount, particularly when dealing with international suppliers. A comprehensive QC framework combines adherence to international standards with industry-specific certifications and rigorous testing regimes.

Actionable tip:

- Always verify the presence of relevant certifications and ask for valid certificates from accredited bodies.

Incoming Quality Control (IQC):

- Raw material testing for purity, particle size, and contaminant levels.

- Supplier audits to verify raw material provenance and certification compliance.

In-Process Quality Control (IPQC):

- Monitoring during forming and sintering, including temperature, pressure, and atmosphere controls.

- Dimensional checks via coordinate measuring machines (CMMs).

- Non-destructive testing (NDT) such as ultrasonic or X-ray inspections to detect internal flaws.

Final Quality Control (FQC):

- Ballistic testing according to standards like NIJ (National Institute of Justice) or STANAG (NATO).

- Mechanical testing for hardness, fracture toughness, and wear resistance.

- Surface integrity assessments, including coating adhesion and corrosion resistance.

Common Testing Methods:

- Vickers or Rockwell Hardness Tests: To assess material hardness.

- Ultrasonic Testing (UT): For internal flaw detection.

- X-ray Computed Tomography (CT): For detailed internal inspection.

- Ballistic Testing: Using controlled projectiles to verify performance.

International buyers should leverage third-party inspection agencies such as SGS, Bureau Veritas, or Intertek to validate supplier QC claims. These agencies conduct audits, verify test reports, and perform independent testing if necessary.

Recommended steps for buyers:

- Engage third-party inspectors before shipment.

- Request comprehensive inspection reports, including test results and compliance certificates.

- Conduct periodic audits of manufacturing facilities to ensure ongoing adherence to quality standards.

Understanding Local Standards and Regulations:

Buyers from Africa (e.g., Kenya), South America (e.g., Brazil), the Middle East (e.g., UAE), and Europe (e.g., Poland) must align their QC expectations with local regulations. For instance, the European CE marking mandates compliance with EU directives, while in Africa and South America, regulatory bodies may have varying certification requirements.

Supplier Transparency and Documentation:

- Request detailed documentation covering every manufacturing stage.

- Verify traceability of raw materials and process controls.

- Ensure suppliers provide test certificates compliant with international standards.

Logistics and Inspection Readiness:

- Coordinate pre-shipment inspections at the manufacturing site.

- Consider the logistics of testing samples in-country versus importing samples for external testing.

- Establish clear communication channels to address QC issues promptly.

By understanding and scrutinizing manufacturing processes and quality assurance protocols, international B2B buyers from diverse regions can mitigate risks, ensure product reliability, and foster successful, compliant procurement of SiC armor.

Understanding the comprehensive cost components involved in sourcing SIC armor is essential for international B2B buyers. The primary cost elements include:

Several factors influence the final pricing structure for SIC armor:

While prices vary widely based on specifications and order size, typical unit costs for standard SIC armor can range from $200 to $600 per piece for bulk orders. Custom or high-certification armor might command $800 or more per unit. Buyers from regions like Africa or South America should be aware of added logistics and import duties, which can increase costs by 10-30%. European buyers may benefit from proximity to manufacturing hubs, potentially reducing lead times and shipping expenses.

Disclaimer: These price ranges are indicative and subject to market fluctuations, supplier negotiations, and specific product requirements. It is advisable to request detailed quotations and conduct supplier audits to ensure optimal pricing and quality assurance.

By thoroughly analyzing these cost components and influencing factors, international B2B buyers can make informed sourcing decisions, optimize their procurement budgets, and establish mutually beneficial supplier relationships in the SIC armor market.

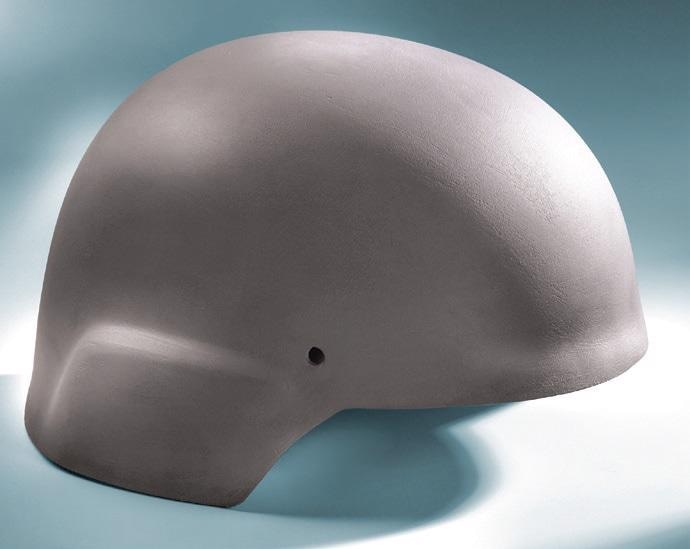

Illustrative Image (Source: Google Search)

1. Material Grade

The material grade of SIC (Silicon Carbide) armor determines its hardness, toughness, and overall durability. Higher-grade SIC materials typically feature enhanced resistance to wear, impact, and thermal stress, making them suitable for high-security applications. For international buyers, understanding material grades helps evaluate the product's suitability for specific operational environments and security standards.

2. Thickness and Density

Thickness directly impacts the armor’s protective capability, with thicker panels offering greater resistance against ballistic threats. Density influences the weight and structural integrity of the armor. Buyers should consider the balance between weight (for ease of handling and installation) and protective performance, especially in applications like military vehicles or industrial shielding.

3. Tolerance Levels

Tolerance refers to the permissible variation in dimensions during manufacturing, usually expressed in millimeters or as a percentage. Tight tolerances ensure precise fitting and optimal performance of armor panels. For importers, understanding tolerance standards helps prevent installation issues and ensures compatibility with existing systems.

4. Thermal Conductivity and Resistance

Since SIC armor often operates in high-temperature environments, its thermal properties are crucial. High thermal conductivity can dissipate heat effectively, reducing thermal stress, while thermal resistance ensures the material maintains its integrity under extreme heat. This property is vital for applications in harsh climates or industrial settings.

5. Impact Resistance and Hardness

Impact resistance measures how well the armor withstands sudden blows or ballistic impacts without cracking or deforming. Hardness, often measured on the Mohs scale, indicates the material’s ability to resist scratching and penetration. High impact resistance and hardness are essential for ensuring long-term durability and protection.

6. Surface Finish and Coatings

A smooth, defect-free surface minimizes stress concentrations that could lead to failure. Protective coatings, such as anti-corrosion layers, enhance durability against environmental factors like moisture and chemicals. These features extend the lifespan of SIC armor in various operational conditions.

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce components or armor panels directly for integration into final products. Understanding OEM relationships helps buyers identify reliable sources and ensure quality consistency, especially when sourcing from international suppliers.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. Knowledge of MOQ helps buyers plan procurement volumes and manage inventory costs effectively, particularly when dealing with custom or specialized SIC armor.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead-time details from multiple suppliers. Issuing RFQs allows buyers to compare offers accurately, ensuring competitive pricing and better terms for large or recurring purchases.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and delivery. Familiarity with Incoterms (e.g., FOB, CIF) is crucial for calculating total costs, managing logistics, and avoiding misunderstandings in cross-border transactions.

5. Certification & Compliance Standards

References to industry standards such as ISO, ASTM, or NATO specifications. Ensuring products meet recognized standards guarantees quality, safety, and interoperability—critical for international procurement decisions.

6. Lead Time

The duration from order placement to product delivery. Understanding lead times helps buyers schedule procurement to meet project timelines and avoid delays, especially when sourcing from regions with longer shipping durations.

Conclusion:

For international B2B buyers, mastering these technical properties and trade terms is vital for making informed procurement decisions. Recognizing material specifications ensures compatibility and performance, while understanding trade jargon streamlines negotiations and logistics. By aligning technical expectations with industry standards, buyers can optimize supply chain efficiency and secure high-quality SIC armor suited to their operational needs.

The global sic armor market is experiencing dynamic shifts driven by technological advancements, geopolitical considerations, and evolving security needs. As a critical component in personal and vehicle protection, sic armor is increasingly sought after in regions facing heightened security threats, including parts of Africa, South America, the Middle East, and Europe.

Emerging B2B sourcing trends highlight a move toward diversified supply chains, with buyers seeking reliable manufacturers capable of delivering high-quality, customizable solutions at competitive prices. Countries like Poland and other European nations are investing in advanced manufacturing capabilities, leveraging innovation to produce lighter, more flexible, and more effective armor materials. Meanwhile, African and South American buyers are increasingly engaging with international suppliers to access cutting-edge materials, often balancing cost-efficiency with quality requirements.

Market dynamics are also influenced by geopolitical tensions and trade policies. For instance, import tariffs, sanctions, or trade agreements can impact sourcing options and costs. As a result, buyers are adopting strategic sourcing approaches, including establishing local partnerships or nearshoring production to mitigate risks.

Furthermore, the integration of digital tools such as supply chain management platforms, blockchain for traceability, and AI-driven quality control is revolutionizing procurement processes. These innovations enable B2B buyers from diverse regions to ensure transparency, reduce lead times, and optimize inventory management.

Overall, the market is poised for continued growth, driven by increasing demand for advanced protection solutions in both civilian and military sectors. Buyers should stay attuned to regional manufacturing developments, technological innovations, and geopolitical shifts to optimize sourcing strategies effectively.

Sustainability has become a pivotal consideration in the sic armor supply chain, driven by global environmental concerns and increasing pressure from clients for ethically sourced products. The environmental impact of manufacturing armor—particularly regarding raw material extraction, energy consumption, and waste management—necessitates adopting greener practices.

For international B2B buyers, prioritizing suppliers with robust sustainability credentials can mitigate reputational risks and align procurement with corporate social responsibility (CSR) goals. Certifications such as ISO 14001 (Environmental Management) or specific eco-labels for raw materials signal a commitment to environmental stewardship.

Ethical sourcing also encompasses ensuring that raw materials, like ceramics or composite fibers used in sic armor, are obtained responsibly. This involves verifying that suppliers adhere to fair labor practices, avoid conflict minerals, and maintain transparent supply chains. Increasingly, suppliers are adopting traceability systems—often blockchain-based—to provide verifiable proof of ethical sourcing.

Moreover, the development and utilization of 'green' materials—such as biodegradable composites or recycled content—are gaining traction. These innovations reduce environmental footprints and appeal to buyers seeking sustainable solutions. Incorporating sustainability into procurement not only meets regulatory requirements but also enhances brand value and customer trust across markets like Kenya, Poland, and South America.

The sic armor sector has evolved significantly over the past few decades, transitioning from traditional ceramic and composite solutions to highly sophisticated, lightweight, and versatile materials. Early armor designs prioritized maximum protection, often at the expense of weight and mobility. With technological innovations, modern sic armor now incorporates nanomaterials, advanced ceramics, and composite fibers, offering enhanced protection with reduced weight.

This evolution has been driven by military needs, law enforcement demands, and civilian security applications. The integration of digital manufacturing techniques and R&D investments has accelerated the development of tailored solutions suitable for diverse operational environments. For B2B buyers, understanding this evolution helps in sourcing products that are not only effective but also future-proofed against emerging threats and regulatory standards.

By staying informed about these advancements, international buyers can better evaluate supplier capabilities and select armor solutions aligned with current and future security landscapes, ensuring resilience and value in their procurement strategies.

To vet sic armor suppliers effectively, start with comprehensive due diligence. Request detailed company credentials, including business licenses, manufacturing certifications (ISO, CE, etc.), and third-party quality assurance reports. Check references from other international buyers, especially from your region, to assess their reputation and delivery track record. Conduct or commission factory audits if feasible, or hire local inspection agencies to verify production capabilities and quality controls. Additionally, review sample products for compliance with safety standards relevant to your market. Establish clear communication channels to gauge responsiveness and transparency before committing to large orders.

When seeking customization, clarify your specific requirements early—such as size, weight, ballistic ratings, or additional features like coatings or branding. Confirm the supplier’s ability to accommodate these specifications without compromising safety standards. Discuss lead times for custom orders and request detailed prototypes or samples for approval before mass production. Ensure contractual agreements specify quality benchmarks and acceptance criteria for customized items. Be aware that customization may increase costs and lead times; therefore, plan your procurement schedule accordingly. Establish ongoing communication to manage revisions and ensure alignment with your end-use requirements.

MOQs for sic armor vary depending on the supplier and product complexity, but they generally range from 500 to 5,000 units for bulk orders. Lead times can span from 4 to 12 weeks, influenced by manufacturing capacity, customization needs, and logistics. Common payment terms include 30% upfront payment with the balance due upon shipment or delivery, but some suppliers may offer letter of credit (LC) terms for larger orders. Negotiating flexible terms is advisable, especially for initial orders. Always confirm these details in advance and factor them into your procurement planning to ensure timely delivery and financial efficiency.

Ensure suppliers provide certifications demonstrating compliance with international safety and quality standards relevant to your target markets, such as CE, NIJ, ISO, or local standards. Request Quality Assurance (QA) reports, test results, and material certificates (e.g., ballistic testing, impact resistance). Verify that testing was conducted by accredited laboratories and that certificates are valid and up-to-date. For export to specific regions, confirm if additional certifications or documentation are required (e.g., customs declarations, export licenses). Maintaining rigorous documentation helps mitigate risks of non-compliance, product recalls, or legal issues in your market.

Coordinate closely with suppliers to determine the most efficient shipping options—air freight for faster delivery or sea freight for cost efficiency on large orders. Clarify Incoterms (e.g., FOB, CIF, DDP) upfront to understand responsibilities and costs associated with shipping, customs clearance, and insurance. Engage with experienced freight forwarders familiar with your destination country’s import regulations, taxes, and duties. Ensure proper packaging to prevent damage during transit and request tracking updates throughout the journey. Additionally, verify if the supplier can assist with customs documentation to streamline clearance and reduce delays.

Establish clear contractual terms covering quality standards, inspection rights, and dispute resolution mechanisms before finalizing the deal. In case of disputes, initiate open communication to understand the root cause—whether it’s quality, delivery, or documentation. Use third-party inspection reports or testing results as objective evidence. If negotiations stall, consider mediation or arbitration under internationally recognized frameworks (e.g., ICC arbitration). Maintain detailed records of correspondence, inspection reports, and shipment documents to support your case. Building a relationship based on transparency and mutual respect can often facilitate quicker resolution and ongoing cooperation.

Illustrative Image (Source: Google Search)

Key cost drivers include raw material quality, manufacturing complexity, customization requirements, order volume, and logistical expenses. Higher ballistic ratings or specialized features typically increase unit costs. Bulk orders usually benefit from economies of scale, reducing per-unit costs. Shipping costs vary with distance, mode, and fuel prices; tariffs and import duties also impact total expenditure. Establishing long-term relationships with reliable suppliers can lead to better pricing and favorable payment terms. Conduct market research to compare multiple suppliers and negotiate bulk discounts or value-added services, ensuring cost-effectiveness without compromising quality.

Foster trust through transparent communication, consistent quality, and timely payments. Invest in understanding your supplier’s capabilities and constraints, and share your long-term vision and forecasted volumes to encourage collaboration. Regularly visit suppliers or engage local representatives to strengthen relationships and gain insights into their operations. Implement quality management systems like periodic audits and continuous improvement programs. Use technology platforms for order tracking, documentation, and communication. Long-term partnerships often result in better pricing, priority service, and co-development of tailored solutions, which are crucial for sustaining competitiveness in the international security market.

Effective strategic sourcing of sic armor is vital for international B2B buyers seeking reliable, cost-effective, and high-quality solutions. Key considerations include evaluating supplier certifications, ensuring supply chain transparency, and fostering long-term partnerships that prioritize innovation and compliance. By adopting a strategic approach, buyers can mitigate risks, optimize procurement costs, and ensure product integrity—critical factors in defense, security, and industrial applications.

As global markets evolve, staying ahead of technological advancements and geopolitical shifts will be essential. Emerging regions such as Africa, South America, the Middle East, and Europe are increasingly becoming key players in the sic armor supply chain. Leveraging local expertise and fostering regional collaborations can unlock new sourcing opportunities and enhance supply resilience.

Looking forward, international B2B buyers should prioritize building diverse, agile sourcing networks that adapt to market dynamics. Proactively engaging with trusted suppliers and staying informed on regulatory changes will position buyers for sustained success. Embrace strategic sourcing as a competitive advantage to secure high-quality sic armor solutions that meet both current and future security needs.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina