Navigating the complexities of sourcing high-quality sic balls can be a daunting challenge for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. As these buyers seek to enhance their operational efficiency and product offerings, understanding the various types of sic balls available, their applications across industries, and the nuances of supplier vetting becomes crucial. This guide serves as a comprehensive resource, addressing critical elements such as material specifications, performance metrics, and cost considerations, ensuring that buyers are well-equipped to make informed purchasing decisions.

In today's global marketplace, the demand for sic balls continues to grow, driven by their applications in sectors ranging from manufacturing to energy. However, navigating this landscape requires a strategic approach. This guide empowers B2B buyers by outlining best practices for supplier evaluation, highlighting key industry trends, and providing insights into pricing strategies. By leveraging the knowledge presented here, buyers can confidently engage with suppliers, negotiate better terms, and ultimately enhance their supply chain resilience. Whether you are a seasoned buyer or new to the market, this guide aims to demystify the procurement process, ensuring that you can source the right sic balls effectively and efficiently.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SIC Ball | Generally spherical, made from silicon carbide | Industrial machinery, automotive | Pros: High durability, cost-effective. Cons: Limited to specific applications. |

| High-Temperature SIC Ball | Enhanced thermal resistance, specialized coatings | Aerospace, energy sectors | Pros: Excellent performance in extreme conditions. Cons: Higher initial cost. |

| Custom SIC Ball | Tailored dimensions and materials | Specialized manufacturing processes | Pros: Optimized for specific needs. Cons: Longer lead times and potentially higher costs. |

| Coated SIC Ball | Additional protective coatings for enhanced performance | Chemical processing, food industry | Pros: Increased resistance to corrosion. Cons: May require more maintenance. |

| Miniature SIC Ball | Smaller size for precision applications | Electronics, medical devices | Pros: Ideal for compact spaces. Cons: Can be more expensive due to precision engineering. |

Standard SIC balls are typically characterized by their spherical shape and composition of silicon carbide, which provides a high level of durability and resistance to wear. These balls are commonly used in various industrial applications, including machinery and automotive components, where reliability and cost-effectiveness are essential. When considering a purchase, B2B buyers should evaluate the specific requirements of their applications, ensuring that the standard SIC ball meets the necessary performance standards without incurring excessive costs.

High-temperature SIC balls are designed to withstand extreme thermal environments, making them ideal for applications in the aerospace and energy sectors. These balls often feature specialized coatings that enhance their thermal resistance and overall performance. B2B buyers must weigh the benefits of increased durability and performance against the higher initial investment. Understanding the specific thermal requirements of your application is crucial for making an informed purchasing decision.

Custom SIC balls are tailored to meet specific dimensions and material requirements, making them suitable for specialized manufacturing processes. The ability to optimize these balls for unique applications can lead to improved operational efficiency and performance. However, B2B buyers should be aware of the potential for longer lead times and higher costs associated with custom orders. Assessing the urgency and budget constraints of your project will help determine if custom SIC balls are the right choice.

Coated SIC balls are enhanced with protective coatings that increase their resistance to corrosion and wear, making them suitable for use in chemical processing and the food industry. The coatings help prolong the lifespan of the balls, reducing the frequency of replacements. Buyers should consider the maintenance requirements of coated SIC balls and how they align with their operational capabilities. While these balls may involve a higher upfront cost, the long-term savings from reduced maintenance can justify the investment.

Miniature SIC balls are specifically designed for precision applications, such as those found in electronics and medical devices. Their smaller size allows them to fit into compact spaces, making them invaluable in high-tech industries. However, the manufacturing process for miniature balls can be more costly due to the precision engineering required. B2B buyers should evaluate the trade-off between size and cost, ensuring that the miniature SIC balls provide the necessary performance without compromising on quality.

Related Video: Sicilian Defense ALL Variations Explained in 15 Minutes

| Industry/Sector | Specific Application of sic ball | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Ball bearings in aircraft engines | Enhanced durability and performance under extreme conditions | Compliance with aerospace standards and certifications |

| Automotive | Components in electric vehicle drivetrains | Improved efficiency and reduced weight | Material quality and supply chain reliability |

| Manufacturing | Precision grinding media | Increased production efficiency and product quality | Consistency in size and hardness specifications |

| Energy | Ball valves in oil and gas pipelines | Reliable sealing and flow control | Resistance to corrosion and high temperatures |

| Electronics | Components in semiconductor manufacturing | Higher precision and reduced defect rates | Purity of materials and compatibility with existing systems |

In the aerospace sector, sic balls are primarily used as ball bearings in aircraft engines. Their exceptional hardness and thermal stability allow them to perform efficiently under extreme temperatures and pressures. This application is crucial for improving the durability and performance of engines, which are subject to rigorous operational demands. For international buyers, especially in regions like Europe and the Middle East, it is vital to ensure that the sic balls comply with aerospace standards such as AS9100 or ISO 9001 to avoid costly disruptions in production.

Sic balls are increasingly being utilized in electric vehicle (EV) drivetrains, where they serve as lightweight components that enhance efficiency. Their reduced weight contributes to the overall performance of EVs by improving energy consumption. B2B buyers in Africa and South America should focus on sourcing sic balls that meet specific automotive standards and certifications, as well as ensuring the materials used are compatible with the latest advancements in electric vehicle technology.

In manufacturing, sic balls are often employed as precision grinding media, which enhances the efficiency of the grinding process. Their superior hardness leads to increased production rates and improved quality of finished products. For buyers in this sector, particularly from Europe, it is essential to prioritize consistency in size and hardness specifications to maintain operational efficiency and product quality. This ensures that the grinding media performs optimally, reducing downtime and waste.

Sic balls are critical components in ball valves used within oil and gas pipelines. They provide reliable sealing and flow control, which is essential for maintaining operational integrity in high-pressure systems. Buyers in the Middle East, where energy production is a key industry, should consider the corrosion resistance and high-temperature tolerance of sic balls to ensure longevity and reliability in their applications. This is particularly important in harsh environments where equipment failure can lead to significant financial losses.

In the electronics industry, sic balls are used in semiconductor manufacturing, where they contribute to higher precision and reduced defect rates in electronic components. The purity of the materials used in these sic balls is crucial, as impurities can lead to performance issues. B2B buyers from Africa and South America should ensure that their suppliers can provide detailed material specifications and certifications to guarantee compatibility with existing manufacturing systems, thereby enhancing yield and performance in their production processes.

Related Video: How Ball Mills Work (Engineering and Mining)

The Problem:

International B2B buyers often face challenges in sourcing high-quality sic balls that meet their specific requirements. This can be particularly problematic for companies in sectors such as manufacturing, construction, and ceramics, where the performance of sic balls directly impacts product quality. In regions like Africa and South America, where there may be fewer suppliers, buyers might struggle with limited options, leading to concerns about the reliability of the products they are obtaining.

The Solution:

To effectively source high-quality sic balls, buyers should consider establishing relationships with established manufacturers that specialize in this material. Conduct thorough research to identify suppliers with a strong reputation and positive customer reviews. It's beneficial to request samples and certifications that verify the material's quality and compliance with industry standards. Additionally, utilizing online platforms and trade shows specific to the ceramics and manufacturing industries can help connect buyers with reputable suppliers from Europe and the Middle East, ensuring access to a broader range of products.

The Problem:

Another common pain point for B2B buyers is the inconsistent performance of sic balls across different applications. This inconsistency can lead to operational inefficiencies, increased costs, and product failures. Companies may find that the sic balls they purchase do not perform as expected under varying conditions, which can be particularly frustrating for businesses in high-demand industries such as automotive and aerospace.

The Solution:

To mitigate performance issues, buyers should engage in detailed discussions with suppliers to understand the specific properties of the sic balls they intend to purchase. It’s crucial to specify the intended application, environmental conditions, and performance metrics required. Buyers should also consider implementing a testing phase where sic balls are evaluated in real-world conditions before full-scale deployment. This proactive approach enables buyers to identify the most suitable product and reduces the risk of performance-related setbacks.

The Problem:

International B2B buyers often find themselves lacking technical support and guidance when it comes to the selection and application of sic balls. This lack of assistance can lead to improper usage, which can compromise the integrity of their operations. For instance, buyers in the Middle East may encounter unique environmental challenges that require tailored solutions, yet they may not have access to the necessary expertise.

The Solution:

To address this challenge, buyers should prioritize suppliers who offer robust technical support and consultation services. Engaging with manufacturers that provide comprehensive product documentation, including usage guidelines and compatibility information, is essential. Additionally, buyers can benefit from participating in training sessions or workshops offered by suppliers to better understand the application of sic balls in their specific contexts. Establishing a clear line of communication with the supplier's technical team can also facilitate troubleshooting and ensure that buyers are making informed decisions, ultimately leading to improved operational efficiency.

When selecting materials for silicon carbide (SiC) balls, international B2B buyers must consider various factors, including performance characteristics, cost implications, and application suitability. Below, we analyze four common materials used in the production of SiC balls, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Key Properties: Silicon carbide is renowned for its exceptional hardness, thermal conductivity, and resistance to wear and corrosion. It can withstand high temperatures (up to 1600°C) and is suitable for applications involving aggressive media.

Pros & Cons: SiC balls offer outstanding durability and longevity, making them ideal for high-stress environments. However, they can be more expensive than alternatives and may require specialized manufacturing techniques that increase production complexity.

Impact on Application: SiC is highly compatible with abrasive and corrosive media, making it suitable for industries like aerospace, automotive, and chemical processing.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM C 833 for ceramic materials and consider the availability of suppliers who can meet these standards.

Key Properties: Alumina (Al2O3) is another common material used in SiC balls. It offers good hardness and excellent thermal stability, with a melting point around 2050°C.

Pros & Cons: Alumina is generally more cost-effective than SiC and easier to manufacture. However, it does not have the same level of wear resistance or thermal conductivity, which may limit its use in high-performance applications.

Impact on Application: Alumina balls are suitable for applications requiring moderate wear resistance and thermal stability, making them ideal for standard industrial processes.

Considerations for International Buyers: Buyers should verify that alumina products meet relevant standards such as ISO 12677 for chemical analysis and ASTM C 618 for industrial applications.

Key Properties: Zirconia (ZrO2) is known for its toughness and resistance to thermal shock, with a melting point of approximately 2700°C.

Pros & Cons: Zirconia balls provide excellent mechanical strength and are less brittle than other ceramic materials. However, they can be more expensive and may not perform as well in high-temperature applications compared to SiC.

Impact on Application: Zirconia is often used in applications requiring high strength and toughness, such as in the medical and dental industries.

Considerations for International Buyers: Buyers should check for compliance with medical device regulations if applicable, as well as standards like ASTM F 1566 for zirconia ceramics.

Key Properties: Stainless steel, particularly grades like 316 and 440C, is often used for its corrosion resistance and mechanical strength.

Pros & Cons: Stainless steel balls are relatively inexpensive and easy to manufacture. However, they may not provide the same level of wear resistance as ceramic materials and can be susceptible to corrosion in harsh environments.

Impact on Application: Stainless steel is suitable for applications in food processing, pharmaceuticals, and general industrial use where corrosion resistance is critical.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A276 for stainless steel bars and shapes, especially in food and pharmaceutical applications.

| Material | Typical Use Case for sic ball | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Aerospace, automotive, chemical | Exceptional hardness and durability | Higher cost and manufacturing complexity | High |

| Alumina | Standard industrial processes | Cost-effective and easy to manufacture | Moderate wear resistance | Medium |

| Zirconia | Medical and dental applications | High strength and toughness | More expensive, limited high-temp performance | High |

| Stainless Steel | Food processing, pharmaceuticals | Corrosion resistance and affordability | Lower wear resistance than ceramics | Low |

This strategic material selection guide provides insights into the various materials available for SiC balls, helping international B2B buyers make informed decisions based on their specific application requirements and regional standards.

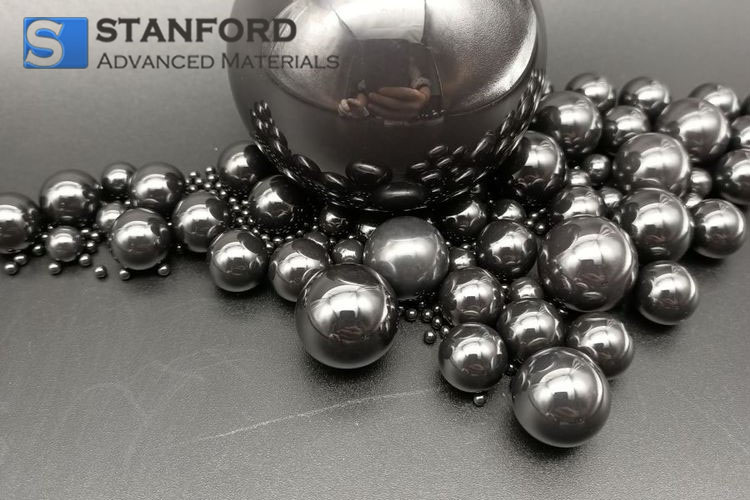

A stock image related to sic ball.

The manufacturing of Silicon Carbide (SiC) balls involves several critical stages, each of which plays a significant role in ensuring the final product meets the rigorous demands of various applications, particularly in industries like aerospace, automotive, and energy.

Material Preparation

The first step in the manufacturing process is material preparation, where high-purity silicon carbide powder is sourced. This powder is often produced through a chemical vapor deposition process, ensuring a fine particle size and high surface area. The powder is then mixed with a binding agent to enhance the cohesiveness of the final product.

Forming

In the forming stage, the prepared material is shaped into the desired form using techniques such as pressing or injection molding. Pressing involves compacting the powder into a mold under high pressure, while injection molding allows for more complex shapes to be formed. Both methods require precise control over parameters like temperature and pressure to ensure uniform density.

Assembly

For applications requiring multiple components, the assembly stage involves combining the SiC balls with other materials or components. This can include embedding the balls in various matrices or integrating them into larger mechanical systems. Precision is key during assembly to ensure proper fit and function.

Finishing

The finishing stage includes various processes aimed at refining the surface of the SiC balls. Techniques such as grinding, polishing, and coating are employed to achieve the required surface finish and dimensional accuracy. This stage is crucial as it influences the performance characteristics of the balls, such as wear resistance and friction properties.

Quality assurance (QA) is paramount in the manufacturing of SiC balls, ensuring that products meet international standards and customer specifications. The QA process typically follows several key steps:

International and Industry-Specific Standards

Compliance with international quality standards such as ISO 9001 is essential for manufacturers. This standard outlines a framework for effective quality management systems, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications, such as CE marking for safety in the European market and API standards for the oil and gas sector, may also apply.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, featuring several checkpoints:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for purity and quality before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor parameters like density and dimensional accuracy, ensuring adherence to specifications.

- Final Quality Control (FQC): After finishing, the final products undergo rigorous testing to verify they meet all quality standards before shipment.

Common Testing Methods

Various testing methods are employed to evaluate the performance of SiC balls. These may include:

- Mechanical Testing: Assessing hardness, tensile strength, and wear resistance to ensure durability.

- Dimensional Inspection: Using precision measuring tools to confirm that products meet specified dimensions.

- Surface Analysis: Techniques like scanning electron microscopy (SEM) can be used to evaluate surface properties and detect any defects.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is critical. Here are several actionable steps buyers can take:

Supplier Audits

Conducting on-site audits is one of the most effective ways to assess a supplier's quality assurance practices. During an audit, buyers can evaluate the manufacturing processes, inspect QC checkpoints, and review documentation related to compliance with international standards.

Requesting Quality Reports

Buyers should request detailed quality reports from suppliers, which should outline the results of various testing methods, compliance with standards, and any corrective actions taken in case of non-conformance. This documentation provides insight into the supplier's commitment to quality.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier's quality control measures. These inspections can be particularly valuable for buyers unfamiliar with the local manufacturing landscape or those looking to mitigate risks in their supply chain.

Understanding QC and Certification Nuances

Different regions may have varying requirements for quality certifications. Buyers should familiarize themselves with the specific QC norms applicable in their target markets. For example, while CE marking is crucial for European buyers, API certification may be more relevant for those in the oil and gas sector. Understanding these nuances can help buyers make informed decisions and select suppliers that align with their quality expectations.

International buyers face unique challenges when sourcing SiC balls, influenced by regional factors:

Regulatory Differences: Each region has its own regulatory framework that may affect quality standards and certifications. Buyers must ensure that their suppliers comply with the relevant regulations to avoid delays in importation or penalties.

Cultural and Communication Barriers: Differences in business practices and communication styles can lead to misunderstandings. Establishing clear lines of communication and setting expectations upfront can mitigate these issues.

Supply Chain Risks: Buyers should consider the stability of the supply chain, especially in regions prone to political or economic instability. Building relationships with multiple suppliers can provide a buffer against disruptions.

By understanding the manufacturing processes and quality assurance practices associated with SiC balls, B2B buyers can make informed decisions and build partnerships that enhance their operational efficiency and product quality.

To ensure a successful procurement process for ‘sic ball’, international B2B buyers must follow a structured approach. This checklist serves as a practical guide, detailing essential steps to source high-quality products effectively.

Establishing clear technical specifications is critical for sourcing the right ‘sic ball’ for your business needs. Consider factors such as size, material composition, and performance characteristics. These specifications should align with your operational requirements to ensure the product meets industry standards and your specific applications.

Understanding the market landscape will help you identify potential suppliers and price points. Utilize online resources, industry reports, and trade shows to gather information on leading manufacturers and emerging players in the ‘sic ball’ sector. This step enables you to compare offerings and make informed decisions based on market trends.

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, product catalogs, and case studies that showcase their expertise. Additionally, reach out to existing clients for references, particularly those in similar industries or geographical regions, to gain insights into the supplier's reliability and service quality.

Once you’ve shortlisted suppliers, request samples of the ‘sic ball’ to assess quality and performance. Testing samples in real-world applications will allow you to verify if they meet your specifications and performance expectations. This step is crucial to avoid potential operational disruptions caused by substandard products.

Effective negotiation can lead to better pricing and favorable terms. Discuss payment options, delivery timelines, and warranty agreements. Ensure that all terms are documented to protect your interests and to avoid misunderstandings later in the procurement process.

Understanding the logistics involved in your order is vital, especially when dealing with international suppliers. Assess the supplier’s ability to meet shipping timelines and their experience with customs and import regulations specific to your region. This will help mitigate delays and ensure a smooth delivery process.

Clear communication is key to a successful supplier relationship. Set up regular check-ins and updates to discuss order status, product changes, or potential issues. A proactive communication strategy helps build trust and ensures that both parties are aligned throughout the procurement process.

A stock image related to sic ball.

By following this checklist, B2B buyers can navigate the complexities of sourcing ‘sic ball’ effectively, ensuring they select the best suppliers to meet their operational needs.

When sourcing sic balls, understanding the cost structure is essential for B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. The primary cost components include:

Materials: The quality and type of materials used in manufacturing sic balls significantly impact costs. Silicon carbide is a premium material, and variations in purity and grain size can lead to price fluctuations.

Labor: Labor costs vary by region and can be influenced by the skill level required for production. Countries with lower labor costs may offer competitive pricing, but quality must be assessed.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can reduce overhead, making sourcing from high-tech facilities more attractive.

Tooling: Initial investment in molds and machinery is necessary for production. Custom tooling for unique specifications can increase costs significantly.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to costs. Certifications such as ISO can enhance product credibility but may also reflect in the pricing.

Logistics: Shipping costs, including freight, customs duties, and warehousing, are critical, especially for international transactions. The geographical location of the supplier can greatly influence these costs.

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market conditions and competition.

Several factors can influence the final pricing of sic balls, which international buyers should consider:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Understanding the MOQ of suppliers can help buyers negotiate better deals.

Specifications and Customization: Custom designs or specific quality requirements can increase costs. Buyers should clarify specifications upfront to avoid unexpected pricing.

Material Quality and Certifications: Higher quality materials and relevant certifications usually lead to higher prices but provide assurance of product performance.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge a premium for their proven track record.

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics costs and responsibilities. Buyers should be aware of which party bears costs and risks during transit.

To optimize sourcing costs, B2B buyers should employ strategic negotiation tactics:

Research and Benchmarking: Understand market rates and competitor pricing to leverage during negotiations. This knowledge can help in advocating for better terms.

Build Relationships: Establishing rapport with suppliers can facilitate more favorable terms and flexibility in pricing.

Emphasize Total Cost of Ownership (TCO): Rather than focusing solely on purchase price, consider the TCO, which includes maintenance, logistics, and potential downtime costs.

Flexible Payment Terms: Negotiate payment terms that align with cash flow needs, which can help in managing overall costs effectively.

Explore Alternative Suppliers: Having multiple suppliers as options not only provides leverage in negotiations but also mitigates risks associated with reliance on a single source.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding pricing nuances is crucial. Currency fluctuations, tariffs, and import regulations can all impact the final cost of procurement. Moreover, cultural differences in negotiation styles and business practices can affect how deals are structured and finalized.

It is important to note that the prices discussed are indicative and can vary significantly based on the factors mentioned above. Buyers should conduct due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

When evaluating solutions for specific business needs, it's crucial to consider alternatives to the Sic Ball. This evaluation allows international B2B buyers to make informed decisions, particularly in regions such as Africa, South America, the Middle East, and Europe. Below, we compare Sic Ball with two viable alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Sic Ball | Alternative 1: Steel Ball | Alternative 2: Plastic Ball |

|---|---|---|---|

| Performance | High durability and resistance to wear | Excellent load-bearing capacity | Lightweight but less durable |

| Cost | Moderate investment | Lower initial cost | Lowest initial cost |

| Ease of Implementation | Requires specific machinery for installation | Simple installation process | Very easy to implement |

| Maintenance | Low maintenance required | Moderate maintenance needed due to rust | Minimal maintenance needed |

| Best Use Case | Ideal for high-stress environments | Suitable for general applications | Best for lightweight tasks and lower stress scenarios |

Steel balls are a common alternative to Sic Balls, especially in applications requiring high load-bearing capacities. Their primary advantage lies in their strength and ability to withstand significant pressure, making them ideal for heavy machinery and industrial applications. However, they are more susceptible to rust and corrosion, necessitating regular maintenance to ensure longevity. For businesses that prioritize performance and can accommodate a moderate maintenance schedule, steel balls may be a viable option.

Plastic balls offer a lightweight solution that is very easy to implement, making them a popular choice for applications where weight is a critical factor. Their cost is significantly lower than both Sic and steel balls, making them attractive for businesses operating on tight budgets. However, plastic balls typically do not possess the same durability and load-bearing capacity as the other options. They are best suited for low-stress environments or applications where the weight advantage outweighs the need for strength.

Selecting the right solution for your business hinges on understanding your specific requirements. If your operations involve high-stress environments and durability is paramount, Sic Ball may be the best choice despite its moderate cost and maintenance needs. Conversely, if budget constraints are a priority, and your applications are less demanding, steel or plastic balls could serve your needs effectively. By assessing the performance, cost, ease of implementation, and maintenance of each option, B2B buyers can make informed decisions that align with their operational goals and financial considerations.

When sourcing Sic balls, understanding their technical properties is critical for ensuring compatibility with your applications. Below are some key specifications that international B2B buyers should consider:

Material Grade

- Sic balls are primarily made from silicon carbide, known for its exceptional hardness and thermal stability. The grade of silicon carbide affects its wear resistance and thermal conductivity. Buyers should verify that the material grade meets their operational requirements, as higher grades typically offer better performance in high-stress environments.

Tolerance Levels

- Tolerance refers to the permissible limit of variation in a physical dimension. For Sic balls, tight tolerances (e.g., ±0.01 mm) are often essential in applications requiring precision, such as aerospace or semiconductor manufacturing. Understanding the required tolerance will help buyers select the right product that minimizes the risk of mechanical failure.

Density

- The density of Sic balls is a critical property affecting their mechanical strength and thermal properties. High-density Sic balls provide better performance in high-temperature applications and contribute to overall durability. Buyers should assess the density specifications to ensure optimal performance in their specific applications.

Hardness Rating

- Measured on the Mohs scale, the hardness of Sic balls is a crucial factor in determining their wear resistance. Sic typically rates between 9 and 9.5, making it one of the hardest materials available. Buyers should prioritize hardness ratings to ensure longevity in abrasive environments.

Thermal Conductivity

- Sic balls possess high thermal conductivity, making them ideal for applications where heat dissipation is necessary. Understanding the thermal conductivity values can help buyers evaluate how well the balls will perform in thermal management applications, such as in electric vehicles or high-performance machinery.

In addition to technical specifications, familiarizing yourself with common trade terminology can streamline the purchasing process:

OEM (Original Equipment Manufacturer)

- This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the Sic balls being sourced.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is essential for budgeting and planning inventory levels. Suppliers may set MOQ based on production costs and logistics.

RFQ (Request for Quotation)

- An RFQ is a formal process where buyers request pricing and terms from suppliers for specified products. By issuing an RFQ for Sic balls, buyers can compare offers and negotiate better terms, ensuring they receive competitive pricing.

Incoterms (International Commercial Terms)

- These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs and risks associated with transporting Sic balls.

Lead Time

- This refers to the time taken from placing an order to the delivery of goods. Knowing the lead time for Sic balls is essential for project planning and inventory management, especially for international buyers who may face longer shipping durations.

Certification Standards

- Certifications like ISO or ASTM denote compliance with quality and safety standards. Buyers should check for certification to ensure that the Sic balls meet industry requirements, which can enhance product reliability and performance.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when procuring Sic balls, ultimately leading to more successful and efficient sourcing strategies.

The sic ball market is experiencing significant growth driven by advancements in technology and increasing demand across various industries. Major drivers include the rise in automation in manufacturing processes, where sic balls are critical components due to their durability and resistance to high temperatures. Additionally, the ongoing shift towards lightweight materials in automotive and aerospace applications is propelling the adoption of sic balls.

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should pay attention to emerging trends such as digital sourcing platforms that enhance supply chain transparency and efficiency. These platforms facilitate direct communication with suppliers, enabling buyers to negotiate better prices and terms. Another trend is the increasing use of artificial intelligence in inventory management, which optimizes stock levels and reduces waste.

Understanding regional market dynamics is also crucial. For instance, in Europe and the Middle East, stringent regulations regarding materials and environmental impact are shaping sourcing decisions. Buyers must align with local compliance standards while considering global sourcing options that offer cost advantages.

Sustainability is becoming a cornerstone in the sourcing of sic balls, as environmental concerns gain prominence globally. The production of sic balls can have a substantial environmental impact, particularly in energy consumption and waste generation. Therefore, international B2B buyers are increasingly prioritizing suppliers who implement sustainable practices in their operations.

Ethical sourcing is equally significant, as buyers are now scrutinizing their supply chains for social responsibility. This includes ensuring fair labor practices and minimizing the ecological footprint. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming prerequisites for suppliers in this sector.

Moreover, the use of "green" materials—such as recycled silicon carbide—can enhance a company's brand reputation and appeal to environmentally conscious customers. By integrating sustainability into their sourcing strategies, B2B buyers can not only comply with regulations but also differentiate themselves in a competitive market.

The sic ball sector has evolved significantly since its inception, originating in the mid-20th century when silicon carbide was first recognized for its unique properties. Initially used in abrasives and cutting tools, the material's exceptional hardness and thermal resistance paved the way for its application in high-performance bearings and automotive components.

Over the decades, technological advancements have refined the manufacturing processes of sic balls, enhancing their performance characteristics and expanding their applications across industries such as aerospace, electronics, and renewable energy. This evolution has enabled suppliers to cater to a global market, responding to diverse needs from regions such as Africa and South America, where industrial growth is rapidly accelerating.

In summary, international B2B buyers should navigate the current dynamics of the sic ball market with a keen eye on sustainability, technological advancements, and regional trends to make informed sourcing decisions that align with their business objectives.

How do I ensure the quality of sic balls when sourcing internationally?

To ensure the quality of sic balls, request certifications from suppliers that comply with international standards, such as ISO or ASTM. Conduct thorough supplier vetting, including checking references and reviewing previous client feedback. Whenever possible, arrange for third-party inspections before shipment to verify product specifications. Additionally, consider requesting samples to evaluate the product quality firsthand before committing to larger orders.

What are the best practices for negotiating payment terms for sic balls?

Negotiating payment terms is crucial for cash flow management. Aim for terms that align with your business cycle, such as net 30 or net 60 days. Consider offering a deposit upfront to secure the order while negotiating a balance upon delivery or satisfactory inspection. Always document the agreed terms in a formal contract to avoid misunderstandings. Additionally, explore payment methods that offer protection, such as letters of credit or escrow services.

What is the minimum order quantity (MOQ) for sic balls?

Minimum order quantities for sic balls can vary significantly by supplier and region. Typically, MOQs range from 100 to 1,000 units, depending on the manufacturer's production capabilities. When sourcing, clarify the MOQ upfront and assess if it aligns with your demand forecasts. If the MOQ is higher than needed, negotiate with the supplier for a smaller trial order or explore other suppliers who may offer lower MOQs.

How can I customize sic balls to meet my specific needs?

Customization options for sic balls may include size, material composition, and branding. When discussing customization, provide detailed specifications and any relevant technical drawings to the supplier. Inquire about their capabilities for producing custom designs and the associated costs or minimum order requirements. It’s also beneficial to establish clear timelines for prototypes and final production runs to ensure timely delivery.

What are the key logistics considerations when importing sic balls?

Logistics considerations include understanding shipping methods, freight costs, and customs regulations in your region. Opt for reliable shipping partners who can provide tracking and timely updates. Be aware of potential tariffs and duties that may apply upon importation, which can affect overall costs. Planning for warehousing and inventory management upon arrival is also essential to avoid delays in distribution.

How do I vet suppliers for sic balls in international markets?

When vetting suppliers, utilize online platforms like Alibaba or ThomasNet to review company profiles and ratings. Look for suppliers with a proven track record in the sic ball industry, verified by third-party audits. Request trade references and visit their manufacturing facilities if feasible. Additionally, consider using trade assurance services that protect your investment in case of non-compliance or quality issues.

What should I include in a contract when purchasing sic balls?

A comprehensive contract should detail product specifications, pricing, payment terms, delivery schedules, and quality assurance measures. Include clauses for dispute resolution and any warranties or guarantees on the products. It’s also wise to specify penalties for late delivery or non-compliance to ensure accountability. Consulting with a legal expert familiar with international trade can further safeguard your interests.

What are the common challenges faced when sourcing sic balls internationally?

Common challenges include language barriers, cultural differences, and varying standards of quality and compliance. Additionally, navigating customs and import regulations can be complex, leading to potential delays. Currency fluctuations may also impact pricing. To mitigate these challenges, maintain clear communication with suppliers, work with local agents when necessary, and consider using a logistics partner experienced in international trade to streamline the process.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing for sic balls presents significant opportunities for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Emphasizing a thorough understanding of supplier capabilities, market trends, and regional regulations will enhance procurement processes. Buyers should leverage local partnerships to navigate the complexities of international trade, ensuring compliance with trade agreements and regional standards.

The value of strategic sourcing cannot be overstated. It not only optimizes cost-efficiency but also strengthens supply chain resilience. By engaging in proactive supplier relationship management, buyers can foster innovation and secure competitive advantages. Moreover, incorporating sustainability considerations into sourcing strategies aligns with global trends, resonating well with increasingly eco-conscious consumers.

Looking ahead, the demand for sic balls is expected to grow as industries expand and diversify. International B2B buyers are encouraged to stay informed about technological advancements and shifts in market dynamics. By adopting a forward-thinking approach and remaining adaptable, businesses can position themselves to capitalize on emerging opportunities. Engage with suppliers today to unlock the potential of strategic sourcing in your operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina