In today’s rapidly evolving marketplace, sourcing high-quality SIC LED products poses significant challenges for international B2B buyers. As the demand for energy-efficient lighting solutions grows across diverse sectors, understanding the nuances of SIC LED technology becomes crucial. This guide provides a comprehensive overview of SIC LED types, their various applications, and strategies for supplier vetting, ensuring that businesses make informed purchasing decisions.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and the UAE—this guide addresses the complexities of sourcing SIC LED products. It empowers decision-makers by offering insights into cost considerations, regulatory compliance, and market trends.

By navigating the global market effectively, buyers can optimize their procurement processes, enhance operational efficiency, and align their investments with sustainability goals. Whether you’re looking to upgrade your existing lighting systems or implement new projects, this guide serves as a valuable resource, ensuring that you’re equipped with the knowledge necessary to thrive in the competitive landscape of SIC LED technology.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SIC LED | Basic configuration, widely available, lower cost | General lighting, commercial spaces | Pros: Cost-effective, easy to source. Cons: Lower efficiency compared to advanced types. |

| High-Output SIC LED | Enhanced brightness, designed for larger areas | Warehouses, stadiums, outdoor events | Pros: Superior brightness, long-range illumination. Cons: Higher initial investment. |

| Tunable White SIC LED | Adjustable color temperature for dynamic lighting | Retail, hospitality, healthcare | Pros: Versatile ambiance control. Cons: More complex installation and control systems. |

| Smart SIC LED | Integrated with IoT technology for remote management | Smart buildings, energy management | Pros: Energy savings, remote control capabilities. Cons: Higher upfront costs and potential tech issues. |

| RGB SIC LED | Capable of producing various colors through mixing | Entertainment, advertising, events | Pros: Creative lighting solutions. Cons: May require more maintenance and expertise to operate. |

Standard SIC LEDs are the most common type, offering a basic configuration that is cost-effective and widely available. They are best suited for general lighting applications in commercial spaces, such as offices and retail environments. When considering purchasing standard SIC LEDs, B2B buyers should evaluate their specific lighting needs and budget constraints, as these LEDs provide sufficient illumination at a lower price point, though they may not offer the same energy efficiency or longevity as more advanced options.

High-output SIC LEDs are designed for environments requiring enhanced brightness, making them ideal for large areas such as warehouses and outdoor events. They provide superior illumination and can cover extensive spaces with fewer fixtures. B2B buyers should consider the initial investment, as these LEDs typically come with a higher price tag, but the long-term benefits in terms of reduced energy consumption and maintenance can justify the cost.

Tunable white SIC LEDs allow users to adjust the color temperature, providing flexibility to create different atmospheres. This feature is particularly beneficial in settings like retail, hospitality, and healthcare, where ambiance can significantly impact customer experience and employee productivity. Buyers should assess their operational needs and the complexity of installation, as these systems may require additional controls and programming but can enhance the overall environment.

Smart SIC LEDs integrate with IoT technology, enabling remote management and energy monitoring. They are particularly advantageous for smart buildings and energy management systems, allowing businesses to optimize their energy usage effectively. While the upfront costs may be higher, the potential for energy savings and improved operational efficiency makes them a compelling choice for B2B buyers focused on sustainability and cost reduction in the long run.

RGB SIC LEDs can produce a wide spectrum of colors by mixing red, green, and blue light. This versatility makes them popular in entertainment, advertising, and event settings, where dynamic lighting can enhance visual appeal. B2B buyers interested in creative applications should consider the complexity of operation and maintenance, as RGB systems may require specialized knowledge to implement effectively, but they offer unique opportunities for branding and atmosphere creation.

Related Video: Light Emitting Diode (LED) Explained (Working, Advantages and Types of LED Explained)

| Industry/Sector | Specific Application of sic led | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Headlights and Taillights | Enhanced visibility and energy efficiency | Compliance with automotive standards and regulations |

| Agriculture | Grow Lights for Indoor Farming | Increased crop yield and reduced energy consumption | UV spectrum requirements and energy efficiency ratings |

| Consumer Electronics | Display Technology in TVs and Monitors | Superior color accuracy and energy savings | Compatibility with existing technology and durability standards |

| Telecommunications | Optical Communication Systems | High-speed data transmission and lower latency | Fiber optic integration and long-term reliability |

| Industrial Lighting | Factory and Warehouse Lighting | Improved productivity and safety | Compliance with safety regulations and energy efficiency needs |

In the automotive sector, sic LED technology is utilized for headlights and taillights, providing superior brightness and energy efficiency compared to traditional lighting systems. This not only enhances visibility for drivers but also reduces the overall energy consumption of vehicles. International buyers, particularly from regions like Europe and the UAE, should consider sourcing sic LEDs that comply with stringent automotive standards to ensure safety and performance.

Sic LEDs are increasingly being adopted in agriculture, particularly for indoor farming applications like grow lights. These lights emit specific wavelengths that promote plant growth, resulting in increased crop yields and reduced energy consumption. For buyers in Africa and South America, understanding the specific UV spectrum requirements is crucial for selecting the right sic LED solutions that align with local agricultural practices and energy efficiency goals.

In consumer electronics, sic LED technology is revolutionizing display technology used in TVs and monitors. The enhanced color accuracy and energy savings offered by sic LEDs make them an attractive option for manufacturers looking to improve product performance while reducing operational costs. Buyers from Europe and the Middle East should focus on the compatibility of sic LEDs with existing technologies to ensure seamless integration into their product lines.

Sic LEDs are pivotal in telecommunications, particularly in optical communication systems where they facilitate high-speed data transmission. Their ability to provide lower latency and increased bandwidth makes them essential for modern communication infrastructure. B2B buyers from regions like Africa and the Middle East must consider sourcing sic LEDs that offer long-term reliability and compatibility with fiber optic systems to enhance their telecommunications capabilities.

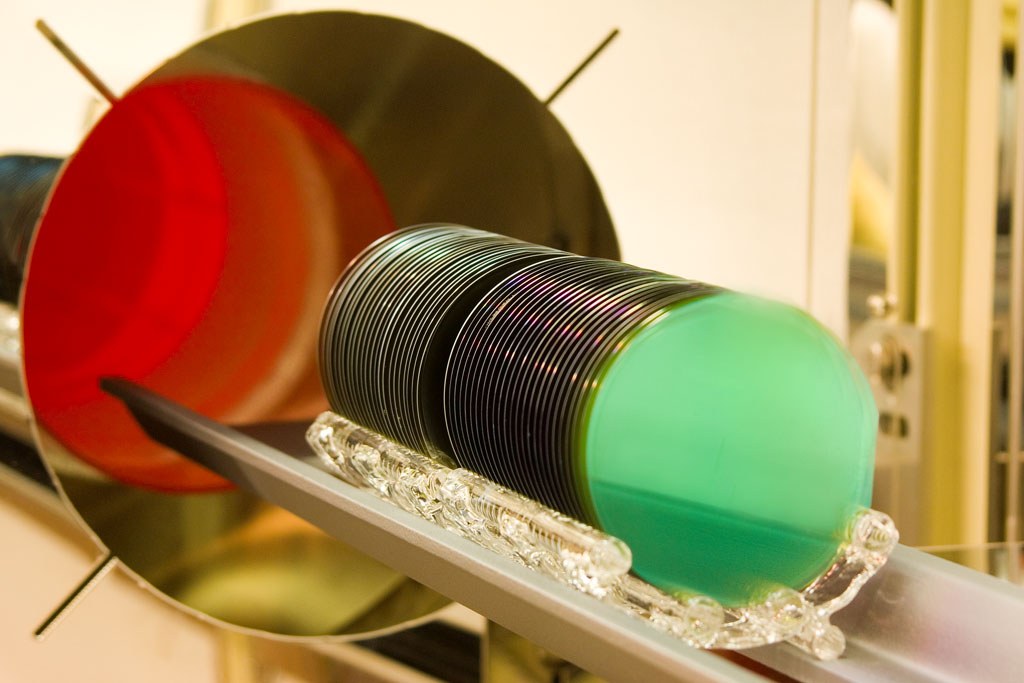

A stock image related to sic led.

In industrial settings, sic LEDs are used for factory and warehouse lighting, significantly improving productivity and safety. The bright, efficient lighting reduces workplace accidents and enhances overall operational efficiency. Buyers in South America and Africa should ensure that the sourced sic LEDs comply with local safety regulations and energy efficiency standards to maximize their investment and operational benefits.

Related Video: The Uses of Static Electricity - GCSE Physics | kayscience.com

The Problem: B2B buyers often struggle to source high-quality 'sic led' products that meet international standards, particularly in emerging markets like Nigeria or Brazil. The lack of reliable suppliers and the prevalence of counterfeit products can lead to significant losses. Buyers may find themselves overwhelmed by numerous options that vary greatly in quality, making it difficult to select a supplier that aligns with their needs.

The Solution: To overcome sourcing challenges, buyers should implement a rigorous supplier evaluation process. Begin by conducting thorough research on potential suppliers, focusing on those with a proven track record in the 'sic led' market. Utilize platforms such as Alibaba or TradeKey to compare suppliers and read reviews from other buyers. It's also beneficial to request samples before committing to a bulk purchase, allowing you to assess the product quality firsthand. Forming partnerships with reputable local distributors can also facilitate easier access to quality products while minimizing risks associated with international shipping and customs. Additionally, consider attending industry trade shows or expos to connect with suppliers directly and establish relationships that can lead to better deals and more reliable product sourcing.

The Problem: International buyers often face difficulties in understanding the technical specifications of 'sic led' products, leading to miscommunication with suppliers and potential mismatches between product capabilities and project requirements. This is particularly prevalent in regions like the Middle East, where buyers may not have the technical expertise to fully grasp the nuances of specifications such as thermal conductivity, lumens per watt, or wavelength.

The Solution: To bridge the knowledge gap, buyers should invest time in educating themselves about the fundamental aspects of 'sic led' technology. Online courses, webinars, and manufacturer resources can provide valuable insights into technical specifications and performance metrics. Engaging with industry experts through forums or LinkedIn groups can also enhance understanding and provide practical tips. When communicating with suppliers, use a standardized specification sheet that outlines your project requirements clearly. This will help ensure that both parties are aligned on expectations, minimizing the risk of errors. Additionally, ask suppliers to provide detailed product datasheets and certifications to verify that the products meet the necessary standards for your specific market.

The Problem: Compliance with local regulations and standards is a major pain point for B2B buyers of 'sic led' products, particularly in regions like Europe and South America where regulations can be stringent. Buyers may find it challenging to ensure that the products they source comply with environmental standards, safety regulations, and energy efficiency requirements, leading to potential legal issues and product recalls.

The Solution: To navigate compliance challenges effectively, buyers should familiarize themselves with the regulatory landscape in their target markets. This includes understanding the specific compliance requirements related to 'sic led' products, such as CE marking in Europe or ANATEL regulations in Brazil. Collaborating with legal experts or consultants who specialize in international trade can provide clarity on these regulations. Additionally, prioritize working with suppliers who are transparent about their compliance processes and can provide the necessary documentation, such as safety certifications and test reports. Establishing a compliance checklist that outlines all necessary standards and regulations will help streamline the procurement process and ensure that all products meet local requirements before they are imported or sold. Regular audits of suppliers and their products can further safeguard against compliance issues, enhancing overall operational efficiency.

When selecting materials for silicon carbide (SiC) light-emitting diodes (LEDs), international B2B buyers must consider various factors that influence performance, durability, and compliance with industry standards. Below is an analysis of several common materials used in SiC LED applications, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Silicon Carbide (SiC) is a semiconductor material known for its high thermal conductivity, wide bandgap, and excellent electric field breakdown strength. These properties make SiC suitable for high-power and high-temperature applications. SiC LEDs can operate at elevated temperatures without significant performance degradation, making them ideal for various industrial and automotive applications.

Gallium Nitride (GaN) is another semiconductor material often used in LED technology. GaN provides a similar performance profile to SiC, particularly in terms of efficiency and thermal management.

Aluminum Gallium Nitride (AlGaN) is frequently used in conjunction with GaN to create a wider bandgap, allowing for UV and blue light emission. This material is particularly useful in applications requiring specific wavelengths.

Epoxy Resin is commonly used for encapsulating SiC LEDs, providing protection against environmental factors such as moisture and dust.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, several considerations are crucial:

| Material | Typical Use Case for sic led | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | High-power, high-temperature LEDs | High thermal conductivity and durability | Higher manufacturing costs | High |

| Gallium Nitride (GaN) | General LED applications | High efficiency and established processes | Susceptible to defects | Medium |

| Aluminum Gallium Nitride (AlGaN) | UV and blue light emission | Enables a wider range of wavelengths | More expensive and complex to manufacture | High |

| Epoxy Resin | LED encapsulation | Excellent moisture resistance | Limited thermal conductivity | Medium |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing materials for SiC LEDs, ensuring optimal performance and compliance with regional standards.

The manufacturing process of Silicon Carbide (SiC) LEDs involves several critical stages that ensure the production of high-quality and reliable semiconductor devices. The primary stages include:

Material Preparation: The process begins with the selection and preparation of raw materials, particularly high-purity silicon carbide. This material is chosen for its superior thermal conductivity, hardness, and electronic properties, which are essential for LED applications. The preparation also includes the creation of SiC substrates, which are typically produced through methods like the modified Lely method or physical vapor transport (PVT).

Forming: During this stage, the SiC substrate undergoes various processes to form the desired crystal structure. Techniques such as epitaxial growth are crucial, as they allow for the deposition of thin layers of semiconductor material onto the substrate. The quality of this layer is vital, as it directly affects the efficiency and performance of the LED.

Assembly: After forming the semiconductor layers, the next step is assembly. This involves the integration of additional components such as phosphors, which are used to convert light from the LED to the desired color. The assembly process also includes the attachment of electrodes, which are necessary for the electrical operation of the LED.

Finishing: The final stage is finishing, which includes the encapsulation of the LED to protect it from environmental factors and enhance its performance. This may involve the application of coatings or the use of lens systems to optimize light output. Quality at this stage is crucial, as it impacts both the longevity and reliability of the final product.

For B2B buyers, understanding the international quality standards that govern SiC LED manufacturing is essential. Key standards include:

ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is applicable to any organization, regardless of its size or industry. It ensures that companies consistently provide products that meet customer and regulatory requirements.

CE Marking: Particularly relevant for the European market, CE marking signifies that the product complies with EU safety, health, and environmental protection standards. For SiC LEDs, compliance with CE standards can significantly enhance marketability in Europe.

API Standards: For buyers in sectors like oil and gas, adherence to American Petroleum Institute (API) standards ensures that products meet the necessary safety and quality benchmarks, which is particularly important in high-risk environments.

Quality Control (QC) in SiC LED manufacturing is a multi-faceted process that involves various checkpoints and testing methodologies:

Incoming Quality Control (IQC): This initial checkpoint involves assessing the raw materials and components before they enter the production line. Buyers should ensure that suppliers have robust IQC procedures to verify the quality of incoming materials.

In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is essential. IPQC includes inspections and tests at various points in the production process to identify defects early. Techniques such as statistical process control (SPC) may be employed to track production quality.

Final Quality Control (FQC): This step takes place once the manufacturing process is complete. FQC involves rigorous testing of the finished products to ensure they meet all specifications. Common testing methods include photometric measurements, thermal cycling tests, and electrical performance assessments.

To ensure the reliability and performance of SiC LEDs, several testing methods are commonly employed:

Photometric Testing: This evaluates the light output and efficiency of the LED, including parameters such as luminous flux and efficacy.

Thermal Testing: Given that thermal management is crucial for LED performance, tests are conducted to assess the thermal resistance and operational temperature ranges.

Electrical Testing: This includes measurements of forward voltage, current, and overall electrical performance under various conditions to ensure the LED operates within specified parameters.

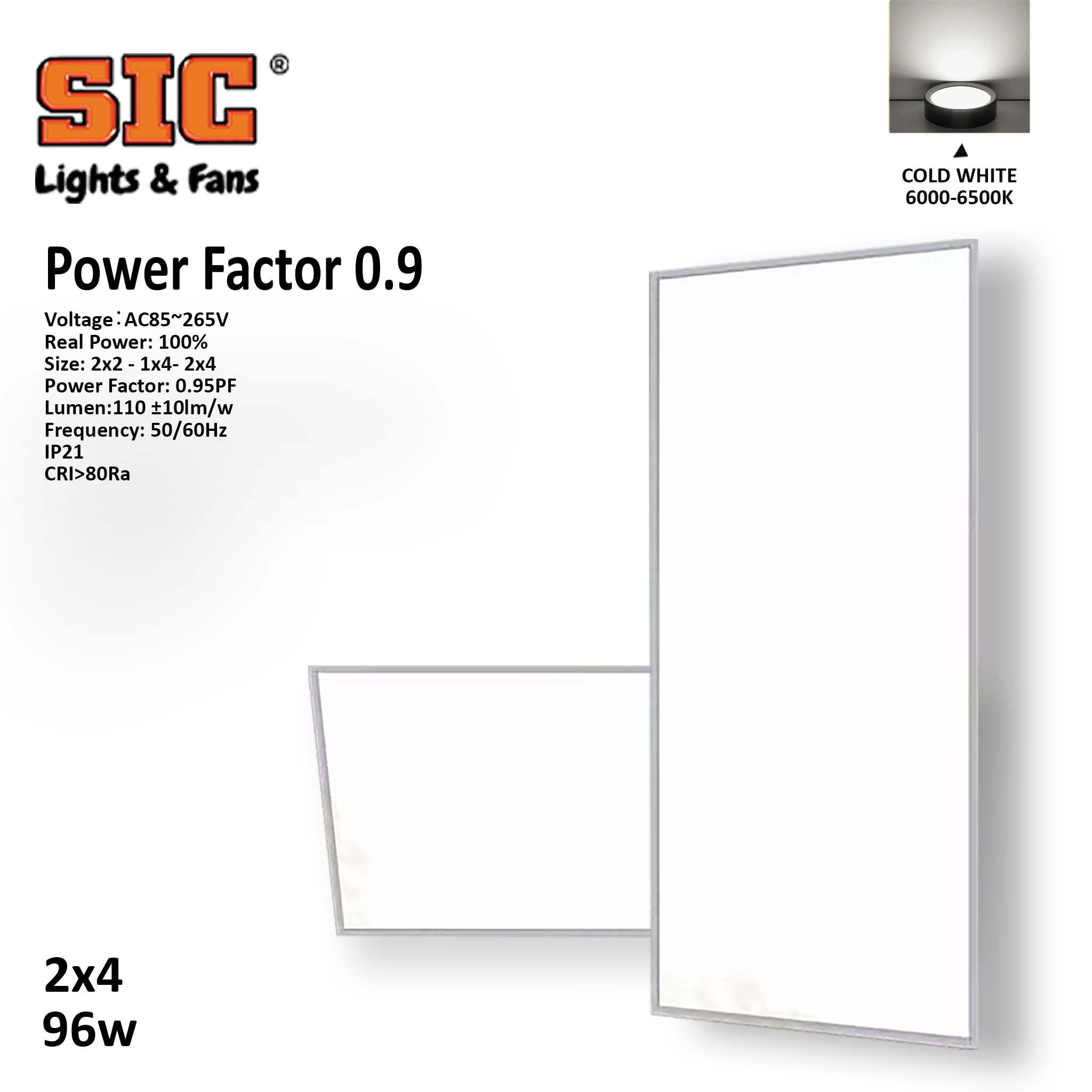

A stock image related to sic led.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial for making informed purchasing decisions. Here are actionable strategies:

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures in place. These reports should include data from IQC, IPQC, and FQC stages.

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct thorough evaluations of the manufacturing process and product quality.

When sourcing SiC LEDs internationally, buyers should be aware of several nuances related to quality control and certification:

Regional Regulations: Different regions may have specific regulations and standards. Buyers should familiarize themselves with local requirements in their respective markets, such as GCC regulations in the Middle East or ANVISA in Brazil.

Certification Validity: Ensure that any certifications provided by suppliers are current and valid. Outdated certifications can indicate lapses in compliance or quality assurance.

Cultural and Logistical Considerations: Understanding cultural attitudes towards quality and compliance can influence supplier relationships. Additionally, logistical challenges may impact the supply chain, necessitating robust contingency plans.

By being well-informed about the manufacturing processes and quality assurance practices associated with SiC LEDs, international B2B buyers can make better purchasing decisions and ensure they source high-quality products that meet their operational needs.

To assist international B2B buyers in procuring 'sic led' products effectively, this guide provides a structured checklist. By following these steps, you can ensure that your sourcing process is thorough, efficient, and aligned with your business needs.

Before initiating the procurement process, clearly outline your technical requirements for 'sic led' products. This includes specifications such as brightness, color temperature, energy efficiency, and size.

- Why It Matters: Defining these parameters helps you filter potential suppliers and ensures that the products meet your operational needs.

- What to Look For: Ensure that your specifications are aligned with industry standards to facilitate comparisons across different suppliers.

Investigate the current market landscape for 'sic led' products. Identify key players, pricing trends, and recent technological advancements.

- Why It Matters: Understanding the market allows you to make informed decisions and negotiate better terms with suppliers.

- What to Look For: Pay attention to reviews, case studies, and market reports that provide insights into supplier reliability and product performance.

Thoroughly vet suppliers before making a commitment. Request detailed company profiles, case studies, and references from previous clients, especially those in similar industries or regions.

- Why It Matters: Evaluating suppliers helps mitigate risks associated with quality and delivery issues.

- What to Look For: Focus on suppliers with a proven track record, positive customer feedback, and the ability to meet your specific technical requirements.

Ensure that potential suppliers hold relevant certifications for 'sic led' products, such as ISO 9001 for quality management or CE marking for compliance with European standards.

- Why It Matters: Certifications demonstrate a supplier's commitment to quality and adherence to industry regulations, which is crucial for international transactions.

- What to Look For: Request documentation that verifies these certifications and check their validity.

Before finalizing your order, request samples of the 'sic led' products. This allows you to evaluate the quality and performance of the products firsthand.

- Why It Matters: Testing samples helps identify any potential issues before making a large investment.

- What to Look For: Assess the samples against your defined specifications and consider how they perform in real-world applications.

Once you have shortlisted potential suppliers, engage in negotiations regarding pricing, delivery schedules, and payment terms.

- Why It Matters: Effective negotiation can lead to cost savings and more favorable terms that benefit your business.

- What to Look For: Be clear about your expectations and ensure that all terms are documented to avoid misunderstandings later.

Develop a clear communication strategy for ongoing discussions with your chosen supplier. This should include regular updates on production timelines and any potential issues.

- Why It Matters: Open lines of communication can help resolve problems quickly and maintain a strong supplier relationship.

- What to Look For: Ensure that both parties agree on preferred communication channels and frequency of updates to facilitate smooth interactions.

By following this checklist, B2B buyers from Africa, South America, the Middle East, and Europe can streamline their sourcing process for 'sic led' products, ensuring they meet their business requirements efficiently and effectively.

When sourcing Sic LEDs, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The raw materials for Sic LEDs, including silicon carbide substrates and other semiconductor materials, constitute a significant portion of the total cost. Prices can fluctuate based on global supply and demand dynamics.

Labor: Labor costs vary by region, with manufacturing hubs in Asia often offering lower labor rates compared to European or American counterparts. It's essential to consider the skill level of the workforce as well, as high-quality production may require specialized expertise.

Manufacturing Overhead: This includes expenses related to factory utilities, maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead, impacting overall pricing.

Tooling: Initial tooling costs for production can be substantial, particularly for custom designs. Buyers should evaluate whether they can share tooling costs across multiple orders to mitigate upfront expenses.

Quality Control (QC): Ensuring product quality often involves additional costs for testing and certifications. Compliance with international standards can elevate QC costs but is essential for market entry in many regions.

Logistics: Shipping costs can vary widely based on the destination, mode of transport, and current geopolitical factors. Buyers need to assess the total logistics expenses, including tariffs and insurance, as they contribute significantly to the final cost.

Margin: Suppliers will include their profit margins in the pricing structure, which can vary based on competition and perceived value. Understanding how margins fluctuate with volume and order frequency is vital for effective negotiation.

Several factors can influence the pricing of Sic LEDs, particularly for international buyers:

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs to maximize cost efficiency.

Specifications and Customization: Custom specifications can increase costs due to the need for specialized production processes. Buyers should weigh the benefits of customization against potential price increases.

Material Quality and Certifications: Higher quality materials and certifications can lead to increased costs but often result in better performance and reliability. Buyers should consider the Total Cost of Ownership (TCO) when evaluating these factors.

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge a premium for their products but often provide better quality assurance and customer service.

Incoterms: Understanding Incoterms is crucial for determining who bears the shipping costs and risks. Buyers should select terms that minimize their exposure to unexpected costs during transport.

For buyers in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and supplier capabilities. Benchmarking against competitors can provide leverage during negotiations.

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield discounts and priority during shortages.

Consider Total Cost of Ownership: When evaluating pricing, consider not just the upfront cost but also the long-term implications, including maintenance, energy efficiency, and potential downtime.

Flexibility in Orders: Be open to adjusting order quantities or delivery schedules to meet supplier needs, which can lead to more favorable pricing.

Utilize Multiple Suppliers: Don’t rely on a single supplier. Engaging multiple suppliers can create competition and provide leverage for negotiating better terms.

It's essential to recognize that pricing for Sic LEDs can vary widely based on market conditions, supplier negotiations, and specific buyer needs. Always request indicative prices and ensure clarity on what is included in the quoted costs. This diligence will help avoid unexpected expenses and ensure a smooth procurement process.

By being informed about these cost components, price influencers, and negotiation strategies, international B2B buyers can make more strategic purchasing decisions when sourcing Sic LEDs.

When evaluating solutions for your business needs, understanding the available alternatives to a product or method is crucial. This section delves into the competitive landscape of 'sic led', comparing it to several viable alternatives. By analyzing key aspects such as performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that align with their operational goals.

| Comparison Aspect | Sic Led | Alternative 1: OLED | Alternative 2: Traditional LED |

|---|---|---|---|

| Performance | High brightness, excellent color accuracy | Superior contrast and color depth | Good brightness but limited color accuracy |

| Cost | Higher initial investment | Moderate cost with premium features | Generally lower upfront cost |

| Ease of Implementation | Requires specialized installation | Straightforward installation | Simple installation process |

| Maintenance | Low maintenance, long lifespan | Moderate maintenance, shorter lifespan | Very low maintenance, long lifespan |

| Best Use Case | Industrial applications requiring high performance | Home theaters and premium displays | General lighting and basic displays |

OLED (Organic Light Emitting Diode) technology is known for its exceptional contrast and vibrant color reproduction. This makes it an excellent choice for applications where visual quality is paramount, such as in home theaters or high-end displays. However, OLED panels can be susceptible to burn-in and have a shorter lifespan compared to Sic Led solutions, which may lead to higher long-term costs despite their moderate initial price.

Traditional LED lighting is widely recognized for its cost-effectiveness and ease of installation. It serves well in general lighting applications, making it a popular choice for businesses looking to minimize upfront expenses. However, the performance in terms of color accuracy and brightness is not on par with Sic Led technology. While traditional LEDs require minimal maintenance, they do not offer the same level of performance, especially in demanding industrial settings.

Selecting the appropriate lighting solution involves a thorough analysis of your specific requirements. Consider factors such as the application environment, budget constraints, and performance expectations. For instance, if your business demands high brightness and color accuracy in industrial settings, Sic Led may be the optimal choice. On the other hand, for general lighting needs with budget limitations, traditional LED solutions may suffice. Ultimately, aligning your choice with your operational goals will ensure you invest wisely in a solution that enhances productivity and efficiency.

When considering Sic LED for your business, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

Material Grade

- Sic LED typically utilizes silicon carbide (SiC) as a substrate. This material is renowned for its high thermal conductivity and efficiency. For B2B buyers, selecting the right grade ensures optimal performance and longevity of the LED components, which translates to reduced maintenance costs and higher reliability in applications.

Wavelength Range

- The wavelength of light emitted by Sic LED can vary depending on the application. Common ranges include 450 nm for blue light and 660 nm for red light. Understanding the wavelength is vital for buyers focused on specific lighting applications, such as horticulture or general illumination, as it directly impacts the efficacy and suitability for their needs.

Current Rating

- The current rating indicates the maximum current the LED can handle without degrading. Typically measured in milliamps (mA), this specification is critical for ensuring that the LED operates efficiently within the desired parameters. For international buyers, knowing the current rating helps in designing circuits that prevent overdriving the LEDs, thereby extending their lifespan.

Thermal Resistance

- Thermal resistance measures how effectively the LED can dissipate heat. A lower thermal resistance indicates better heat management, which is crucial for maintaining performance and avoiding failures. This specification is particularly important for buyers in regions with higher ambient temperatures, such as parts of Africa and the Middle East, where heat management is a critical factor in LED longevity.

Luminous Efficacy

- This metric measures the amount of visible light produced per watt of electrical power consumed, typically expressed in lumens per watt (lm/W). Higher luminous efficacy translates to lower energy costs and improved sustainability, making it a significant factor for B2B buyers aiming to enhance energy efficiency in their operations.

Familiarity with industry terminology is essential for navigating the procurement process effectively. Here are some common terms you should know:

OEM (Original Equipment Manufacturer)

- An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is important for buyers who may need to source Sic LED from companies that can integrate them into their own products, ensuring compatibility and quality.

MOQ (Minimum Order Quantity)

- MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to determine the feasibility of a purchase, especially for smaller businesses that may not require large quantities.

RFQ (Request for Quotation)

- An RFQ is a formal request issued to suppliers to bid on specific products or services. For B2B buyers, issuing an RFQ is a strategic way to compare prices and terms from multiple suppliers, ensuring they receive the best value for their investment in Sic LED.

Incoterms (International Commercial Terms)

- These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. Understanding Incoterms is crucial for buyers engaged in cross-border transactions, as they dictate responsibilities for shipping, insurance, and tariffs.

Lead Time

- Lead time is the amount of time it takes from placing an order until it is fulfilled. For international buyers, knowing the lead time can help in planning inventory and ensuring that projects remain on schedule, particularly in fast-paced markets.

Certification Standards

- These are regulatory standards that products must meet to ensure safety and performance. Familiarity with certification standards relevant to Sic LED (such as CE, RoHS, or UL) is essential for buyers to ensure compliance with local regulations and quality assurance.

By understanding these technical properties and trade terms, B2B buyers can navigate the Sic LED market more effectively, ensuring they make informed decisions that align with their operational goals and market demands.

The SIC LED sector is experiencing a significant transformation driven by various global factors. Demand for energy-efficient lighting solutions is rising due to growing environmental concerns and regulations aimed at reducing carbon footprints. This trend is particularly relevant for international B2B buyers in Africa, South America, the Middle East, and Europe, where energy costs are a critical consideration. Emerging technologies such as smart lighting systems, which integrate IoT capabilities, are enhancing the functionality and efficiency of LED solutions.

Additionally, the shift towards remote work and smart cities is fueling demand for advanced lighting solutions that can be controlled and monitored through mobile applications. B2B buyers should also be aware of the importance of local partnerships, as regional suppliers can offer insights into market preferences and compliance with local regulations. This localized approach helps mitigate risks associated with shipping and customs delays, particularly for buyers in rapidly developing markets.

Sustainability and ethical sourcing are becoming non-negotiable aspects of the procurement process in the SIC LED sector. The environmental impact of LED manufacturing and disposal is significant; therefore, buyers should seek suppliers that prioritize sustainable practices. This includes using recyclable materials, reducing waste, and minimizing the carbon footprint throughout the supply chain.

Ethical sourcing also extends to labor practices. B2B buyers should evaluate potential suppliers for their adherence to fair labor standards and their commitment to social responsibility. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier's commitment to sustainability. By prioritizing these aspects, buyers not only enhance their brand reputation but also align with the growing consumer demand for environmentally responsible products.

The SIC LED sector has evolved significantly since the introduction of LED technology in the early 1960s. Initially used for indicator lights, the technology has undergone rapid advancements, making it a viable alternative to traditional incandescent and fluorescent lighting. By the early 2000s, improvements in efficiency and reductions in production costs led to widespread adoption in both commercial and residential applications.

The integration of smart technology into LED systems marked a new era, allowing for greater control and customization. This evolution has opened up new markets and opportunities for B2B buyers, particularly in sectors focused on energy efficiency and sustainability. As the technology continues to advance, staying informed about the latest innovations and sourcing trends will be crucial for international buyers looking to capitalize on the SIC LED market.

How do I solve issues related to sourcing sic led products internationally?

When sourcing sic led products, international buyers should first identify reliable suppliers through platforms like Alibaba or Global Sources. Conduct thorough due diligence by checking reviews, certifications, and past performance. Additionally, engage in direct communication to clarify product specifications, lead times, and shipping logistics. Establishing a sample order can also help assess product quality before committing to larger purchases. Networking at trade fairs can further connect you with trustworthy manufacturers.

What is the best way to evaluate sic led suppliers for my business needs?

To evaluate sic led suppliers effectively, consider factors such as their production capacity, experience in the industry, and compliance with international quality standards. Request references from previous clients and verify their certifications (e.g., ISO, CE). Assess their customer service responsiveness and willingness to provide customization options. An on-site visit, if possible, can also provide insights into their operational capabilities and quality control processes.

What customization options are available for sic led products?

Most sic led manufacturers offer customization options to meet specific business requirements, including size, color temperature, and brightness levels. When approaching suppliers, clearly outline your specifications and desired features. Some suppliers may also provide design assistance to ensure the product aligns with your brand identity. Be sure to discuss any additional costs associated with customizations and the impact on lead times.

What are the typical minimum order quantities (MOQ) for sic led products?

Minimum order quantities for sic led products can vary significantly based on the supplier and the complexity of the product. Generally, MOQs can range from 100 to 1,000 units. It's advisable to negotiate MOQs with suppliers, especially for new partnerships or smaller businesses. Some manufacturers might offer lower MOQs for sample orders, allowing you to test the market without a significant upfront investment.

What payment terms should I expect when sourcing sic led products?

Payment terms for sic led products typically range from 30% upfront and 70% upon delivery to full payment in advance. Suppliers may also accept letters of credit for larger orders. It's crucial to clarify payment methods accepted (e.g., bank transfers, PayPal) and any additional fees involved. Establishing a clear agreement on payment terms can help mitigate risks and ensure a smoother transaction process.

How can I ensure quality assurance (QA) for sic led products?

To ensure quality assurance for sic led products, request certifications and compliance documents from suppliers that demonstrate adherence to international standards. Conduct pre-shipment inspections through third-party QA firms to verify product quality before shipment. Establish clear quality benchmarks in your contract, including acceptable defect rates and warranties. Regular communication with suppliers during production can also help address potential issues early on.

What logistics considerations should I keep in mind when importing sic led products?

Logistics plays a crucial role in the successful importation of sic led products. Consider factors such as shipping methods (air freight vs. sea freight), customs clearance procedures, and tariffs applicable to your region. Engage with a reliable freight forwarder who can assist with documentation and navigate customs regulations. Additionally, factor in lead times for shipping to avoid delays in product availability.

How can I handle potential disputes with sic led suppliers?

To effectively handle disputes with sic led suppliers, maintain clear documentation of all agreements, communications, and transactions. Establish a dispute resolution clause in your contract that outlines the steps to resolve issues amicably. Open communication is key—address concerns promptly and professionally. If necessary, consider mediation or arbitration as a means to resolve conflicts without resorting to legal action, which can be costly and time-consuming.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of Sic LED technology presents a myriad of opportunities for international B2B buyers. Understanding the unique advantages of Sic LED, such as energy efficiency, durability, and superior performance, can significantly impact procurement decisions. By leveraging these benefits, businesses in Africa, South America, the Middle East, and Europe can improve their operational efficiency and reduce long-term costs.

Strategic sourcing not only enhances product quality but also fosters strong supplier relationships that are crucial for navigating global supply chains. Buyers are encouraged to conduct thorough market research, evaluate potential suppliers based on quality and sustainability practices, and negotiate favorable terms that align with their business objectives.

Looking ahead, the demand for Sic LED technology is expected to grow, driven by advancements in smart lighting solutions and sustainable practices. B2B buyers should stay abreast of emerging trends and technologies to remain competitive. Engaging with suppliers and industry experts will be essential in harnessing the full potential of Sic LED innovations. Embrace the journey of strategic sourcing today to secure your position in this evolving market.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina