Navigating the global market for sic mirrors presents significant challenges for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. As industries increasingly rely on high-quality reflective surfaces for applications ranging from optical devices to automotive manufacturing, sourcing the right sic mirror can be daunting. Buyers must contend with varying supplier standards, material specifications, and regional compliance regulations that can complicate the procurement process.

This comprehensive guide offers a detailed exploration of sic mirrors, covering essential aspects such as types, applications, and supplier vetting processes. We delve into the various materials and technologies used in the production of sic mirrors, enabling buyers to understand the nuances that affect performance and pricing. Additionally, we provide insights into cost structures, helping businesses budget effectively while ensuring quality.

By equipping international B2B buyers with actionable insights and practical resources, this guide empowers decision-makers to make informed purchasing choices. Whether you are looking to source sic mirrors for innovative projects or streamline your supply chain, understanding the global landscape is crucial. With this information at your fingertips, you can navigate the complexities of the market with confidence, fostering successful partnerships and achieving your business objectives.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SIC Mirror | Basic reflective surface, often made of glass | Retail displays, offices | Pros: Cost-effective, widely available. Cons: Limited durability, prone to breakage. |

| Anti-Glare SIC Mirror | Special coating to reduce glare | Photography studios, design firms | Pros: Enhanced visibility, ideal for creative work. Cons: Higher cost than standard mirrors. |

| Safety SIC Mirror | Made from shatterproof materials | Public spaces, schools | Pros: Increased safety, ideal for high-traffic areas. Cons: Heavier and more expensive. |

| Smart SIC Mirror | Integrated technology for interactive features | Hotels, luxury retail | Pros: Modern appeal, multifunctional. Cons: Requires power source, higher maintenance. |

| Decorative SIC Mirror | Unique shapes and designs for aesthetic appeal | Interior design, hospitality | Pros: Enhances decor, customizable. Cons: Can be costly, limited functional use. |

Standard SIC mirrors are the most common type found in various settings, characterized by their straightforward reflective surface, typically made from glass. They are cost-effective and widely available, making them suitable for applications such as retail displays and office environments. B2B buyers should consider their fragility, as these mirrors can break easily, leading to potential replacement costs.

Anti-glare SIC mirrors feature a special coating that minimizes reflections and glare, making them ideal for environments like photography studios and design firms where clarity is crucial. These mirrors enhance visibility and reduce eye strain, providing a better user experience. However, they come at a higher price point than standard mirrors, which is an important consideration for budget-conscious buyers.

Safety SIC mirrors are constructed from shatterproof materials, making them a preferred choice for public spaces such as schools and malls. Their primary advantage lies in increased safety, especially in high-traffic areas where breakage could lead to injuries. While they are heavier and more expensive than standard options, the investment often pays off in terms of safety and durability.

Smart SIC mirrors integrate advanced technology, offering interactive features that cater to modern business needs, such as information displays in hotels and luxury retail environments. They provide a sleek and contemporary appeal while serving multifunctional purposes. However, they require a power source and may involve higher maintenance costs, which B2B buyers should factor into their purchasing decisions.

Decorative SIC mirrors are designed with unique shapes and aesthetics, making them popular in interior design and hospitality sectors. They can enhance the overall decor and create a welcoming atmosphere. However, buyers should be aware that these mirrors can be costly and may offer limited functionality compared to other types. Customization options can further increase expenses, so careful budgeting is essential.

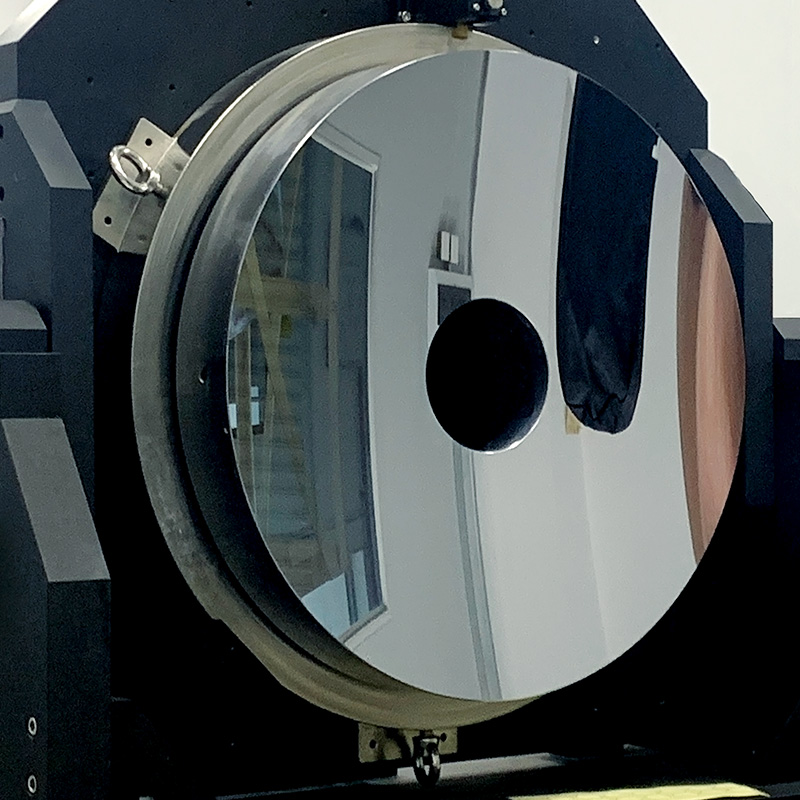

Related Video: Discover High Precision Optics: Silicon Carbide Mirror

| Industry/Sector | Specific Application of sic mirror | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Satellite optics and sensors | Enhanced imaging capabilities for surveillance | Compliance with aerospace standards and certifications |

| Renewable Energy | Solar concentrators | Improved efficiency in solar energy collection | Durability under extreme weather conditions |

| Electronics | High-performance semiconductor devices | Superior thermal management and efficiency | Compatibility with existing production processes |

| Medical Equipment | Imaging devices for diagnostics | High precision and clarity in medical imaging | Regulatory compliance and quality assurance standards |

| Automotive | Advanced driver-assistance systems (ADAS) | Increased safety and performance | Supplier reliability and technological advancements |

In the aerospace sector, sic mirrors are pivotal in enhancing satellite optics and sensors. Their ability to withstand extreme temperatures and environmental conditions makes them ideal for space applications. This technology addresses challenges such as image distortion and signal degradation, which are critical for accurate surveillance and reconnaissance. Buyers must ensure that their suppliers comply with aerospace standards and certifications, focusing on quality and reliability.

A stock image related to sic mirror.

Sic mirrors are increasingly employed in solar concentrators, where they significantly improve the efficiency of solar energy collection. By reflecting and concentrating sunlight onto photovoltaic cells, these mirrors enhance energy output, making solar solutions more viable. For international buyers, particularly from regions with high solar potential like Africa and South America, sourcing durable materials that can withstand harsh weather conditions is essential for long-term performance.

In the electronics industry, sic mirrors are used in high-performance semiconductor devices to manage heat effectively. Their thermal conductivity properties help in dissipating heat, thus improving device longevity and performance. B2B buyers in this sector should consider compatibility with existing manufacturing processes and the technological advancements of suppliers to ensure seamless integration into their product lines.

Sic mirrors are integral to imaging devices used in diagnostics, providing high precision and clarity that are essential for accurate medical assessments. The use of these mirrors helps solve problems related to image quality and resolution in medical imaging technologies. Buyers must prioritize suppliers who meet stringent regulatory compliance and quality assurance standards to ensure patient safety and device reliability.

In the automotive sector, sic mirrors are crucial for advanced driver-assistance systems (ADAS), which enhance vehicle safety and performance. These mirrors facilitate improved sensor capabilities, contributing to features like adaptive cruise control and lane-keeping assistance. Buyers should focus on supplier reliability and the latest technological advancements to ensure they are integrating the best solutions for their automotive applications.

Related Video: Uses of Mirrors and Lenses in Optical Devices | Grade 10 Science DepEd MELC Quarter 2 Module 5

The Problem: B2B buyers often face challenges in ensuring the quality of 'sic mirror' products, especially when sourcing from international suppliers. Issues can arise from varying manufacturing standards, leading to discrepancies in product quality and performance. For instance, a buyer in South America might receive mirrors that do not meet their specifications or are prone to defects, resulting in financial losses and potential harm to their business reputation. This situation becomes even more complicated when the buyer lacks direct access to quality control measures or industry standards in the supplier’s region.

The Solution: To mitigate these quality concerns, B2B buyers should establish clear quality standards and specifications prior to sourcing 'sic mirror' products. Begin by conducting thorough research on potential suppliers, focusing on their certifications and previous client reviews. It is advisable to request product samples before making bulk purchases. Additionally, consider implementing a third-party inspection service to verify the quality of products before shipment. This proactive approach not only ensures that the mirrors meet your specifications but also fosters a stronger relationship with suppliers, based on transparency and trust.

The Problem: Import regulations can vary significantly across regions, creating a daunting landscape for B2B buyers looking to import 'sic mirror' products. For instance, a buyer in Africa may struggle with customs procedures, tariffs, and documentation requirements that can delay shipments and increase costs. The complexity of navigating these regulations can lead to frustration, unexpected expenses, and a negative impact on the supply chain.

The Solution: To effectively navigate these import regulations, B2B buyers should engage with a customs broker who specializes in the importation of similar products. This expert can provide insights on the specific documentation required and help streamline the process. Additionally, staying informed about local import laws and any changes in tariffs is crucial. Joining trade associations or forums related to the industry can also offer valuable resources and networking opportunities to connect with others who have successfully navigated similar challenges.

The Problem: Many B2B buyers may not fully understand the various applications and innovations associated with 'sic mirror' technology, which can lead to missed opportunities. For example, a buyer in Europe might be aware of traditional uses but may not consider advanced applications such as smart mirrors or those equipped with augmented reality features. This lack of knowledge can hinder their ability to make informed purchasing decisions that align with market trends and customer demands.

The Solution: To enhance understanding of 'sic mirror' applications, buyers should invest time in market research and attend industry conferences or trade shows. These events often showcase the latest innovations and provide insights into emerging trends. Additionally, collaborating with suppliers who are knowledgeable about current technologies can provide valuable information about product capabilities and applications. Engaging with industry publications and online platforms can further enhance awareness of how 'sic mirror' can be utilized in various sectors, such as retail, healthcare, and hospitality. By staying informed, buyers can make strategic decisions that meet evolving market demands and enhance their competitive edge.

When selecting materials for sic mirrors, it is crucial to consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in the production of sic mirrors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Silicon carbide (SiC) is a widely used material for sic mirrors due to its exceptional thermal and mechanical properties. SiC can withstand high temperatures (up to 1600°C) and has excellent thermal conductivity, making it suitable for applications requiring rapid heat dissipation. Additionally, it exhibits high corrosion resistance, which is essential for environments exposed to harsh chemicals.

Pros and Cons of Silicon Carbide

The primary advantage of SiC is its durability and ability to maintain structural integrity under extreme conditions. However, the manufacturing complexity of SiC mirrors can lead to higher production costs. This material is ideal for applications in aerospace and defense, where performance is critical.

Glass is another common material for sic mirrors, particularly in applications where optical clarity is essential. Glass can be engineered to provide various optical properties and is relatively easy to manufacture.

Pros and Cons of Glass

While glass is less expensive than SiC and offers good optical performance, it lacks the thermal resistance and durability of SiC. Glass mirrors may not perform well in high-temperature applications, making them less suitable for industries like aerospace. International buyers should consider the specific optical requirements of their applications when choosing glass.

A stock image related to sic mirror.

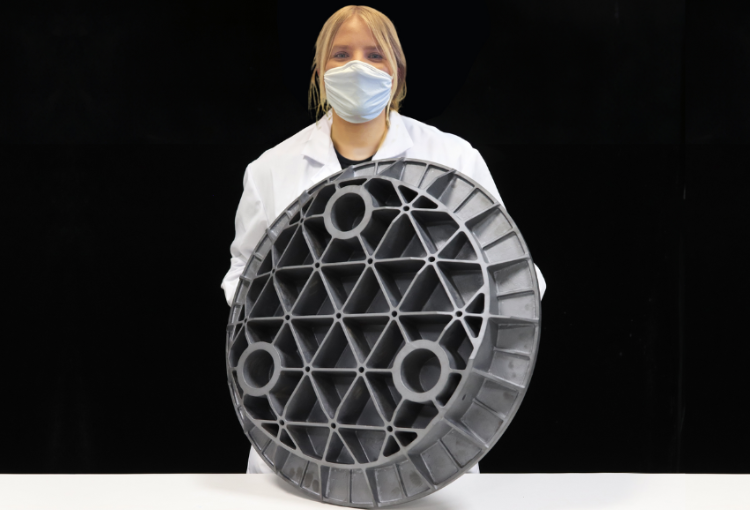

Aluminum is often used in the backing of sic mirrors due to its lightweight and good thermal conductivity. This material is particularly advantageous in applications requiring reduced weight, such as satellite systems.

Pros and Cons of Aluminum

Aluminum is cost-effective and easy to work with, allowing for simpler manufacturing processes. However, it has lower corrosion resistance compared to SiC and may require additional coatings for protection in harsh environments. Buyers from regions with high humidity or corrosive atmospheres should be cautious when selecting aluminum.

Composite materials, such as carbon fiber reinforced polymers, are increasingly popular for sic mirrors due to their lightweight and high strength-to-weight ratio. These materials can be engineered to meet specific performance criteria.

Pros and Cons of Composite Materials

The primary advantage of composites is their ability to be tailored for specific applications, offering flexibility in design. However, they can be more expensive and complex to manufacture than traditional materials. Buyers should evaluate the specific performance requirements and cost implications when considering composites.

| Material | Typical Use Case for sic mirror | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | Aerospace, defense applications | High thermal resistance | High manufacturing complexity | High |

| Glass | Optical applications, low-stress uses | Good optical clarity | Poor thermal resistance | Medium |

| Aluminum | Satellite systems, lightweight designs | Cost-effective, lightweight | Lower corrosion resistance | Low |

| Composite Materials | High-performance, customized applications | Tailored properties, lightweight | Higher cost, complex manufacturing | High |

In conclusion, selecting the right material for sic mirrors requires careful consideration of performance requirements, manufacturing capabilities, and cost implications. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should also be aware of compliance with local standards and preferences when making their decisions.

The manufacturing of silicon carbide (SiC) mirrors involves several critical stages that ensure the final product meets the high standards required for various applications, particularly in aerospace, defense, and optics. Here are the main stages involved in the production process:

Material Preparation

The process begins with sourcing high-quality silicon carbide powder. This material is chosen for its excellent thermal and mechanical properties. The powder is then subjected to a purification process to eliminate impurities, which can significantly affect the mirror's performance. Advanced techniques, such as chemical vapor deposition (CVD), may also be employed to create SiC layers with uniform properties.

Forming Techniques

The prepared silicon carbide is shaped into the desired mirror form. Common methods include:

- Sintering: This involves heating the SiC powder to a temperature below its melting point, allowing the particles to bond and form a solid structure.

- Hot Pressing: This technique combines heat and pressure to densify the material, improving its mechanical strength.

- CNC Machining: Once the basic shape is formed, computer numerical control (CNC) machining is used to achieve precise dimensions and surface finishes.

Assembly

For mirrors that require additional components (like mounts or coatings), the assembly stage comes next. This involves integrating optical coatings that enhance reflectivity and protect the SiC surface. Proper alignment and bonding techniques are critical to ensure that the components function as intended.

Finishing Processes

The final stage includes polishing and coating the mirror. Precision polishing ensures that the surface achieves the necessary smoothness and flatness required for optical performance. Various coatings, such as anti-reflective or reflective coatings, are applied to optimize the mirror's functionality for specific applications.

Quality assurance (QA) is integral to the manufacturing process of SiC mirrors, ensuring that each product meets international standards and customer specifications. Key aspects of QA include:

Adherence to International Standards

Compliance with international standards like ISO 9001 is critical for establishing a quality management system. This standard ensures that manufacturers follow a structured approach to quality, focusing on customer satisfaction and continuous improvement. Additionally, other industry-specific standards such as CE marking and API certifications may apply depending on the application of the SiC mirrors.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to detect any deviations from quality standards. This may include regular checks on the dimensions and properties of the SiC.

- Final Quality Control (FQC): After finishing, each mirror undergoes rigorous testing to verify its performance characteristics. This includes optical testing for reflectivity, surface quality assessments, and dimensional checks.

Common Testing Methods for SiC Mirrors

Various testing methods are employed to assess the quality of SiC mirrors:

- Interferometry: Used to evaluate surface accuracy and flatness.

- Spectrophotometry: Measures the reflectivity and transmission characteristics of the mirror.

- Thermal Testing: Assesses the thermal stability and performance under varying temperature conditions.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring product reliability. Here are some strategies:

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and adherence to standards firsthand. This can include checking the equipment, production flow, and documentation practices.

Quality Reports and Certifications

Requesting regular quality reports from suppliers can provide insights into their QC processes. Look for certifications that demonstrate compliance with international standards, such as ISO 9001, and industry-specific certifications.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspectors can verify that products meet specified standards and provide detailed reports on their findings.

Understanding the nuances of quality control and certification is vital for international buyers. Here are key considerations:

Regional Standards and Regulations

Different regions may have specific standards that must be adhered to. For example, products sold in Europe may require CE marking, while those in the Middle East might need to comply with local regulations. Familiarizing yourself with these requirements is crucial for compliance and market access.

Cultural and Logistical Challenges

Buyers from diverse regions may face unique challenges in communication and logistics. It’s important to establish clear communication channels with suppliers to discuss quality expectations and resolve any issues promptly.

Building Trust with Suppliers

Long-term partnerships with reliable suppliers can facilitate smoother transactions and better quality assurance. Establishing trust involves regular communication, transparent practices, and mutual understanding of quality expectations.

By focusing on the manufacturing processes and quality assurance measures outlined above, international B2B buyers can make informed decisions when sourcing SiC mirrors, ensuring they receive high-quality products that meet their specific needs.

Sourcing 'sic mirror' for your business requires a strategic approach to ensure that you meet your specific needs while maximizing value. This practical checklist will guide international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—through essential steps in the procurement process. Following these steps will help you make informed decisions, mitigate risks, and foster successful supplier relationships.

Before engaging suppliers, it's vital to clearly outline the technical requirements of the 'sic mirror' you need. This includes dimensions, materials, and any specific features that are critical for your application.

- Consider industry standards and regulations relevant to your market.

- Document your needs in a detailed specification sheet to share with potential suppliers.

Understanding the market landscape is essential for identifying potential suppliers and gauging the price range for 'sic mirror.'

- Analyze competitors’ sourcing strategies and review industry reports for insights.

- Utilize online platforms and trade shows to discover suppliers and product innovations.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Verify their experience and specialization in manufacturing 'sic mirror.'

- Look for testimonials and reviews to gauge reliability and customer satisfaction.

Before placing a large order, request samples or prototypes of the 'sic mirror' to assess quality and functionality.

- Evaluate the samples against your specifications to ensure they meet your requirements.

- Use this opportunity to test the supplier's responsiveness and willingness to accommodate adjustments.

Once you have selected potential suppliers, initiate negotiations focusing on pricing, delivery schedules, and payment terms.

- Be clear about your budget constraints and seek competitive quotes from multiple suppliers.

- Negotiate for favorable terms, such as bulk discounts or flexible payment options, to enhance your cash flow.

It’s essential to ensure that your chosen supplier complies with relevant industry certifications and standards, particularly if you are sourcing from different regions.

- Check for certifications like ISO or other quality management standards that indicate reliability and quality assurance.

- Request documentation to confirm compliance with safety and environmental regulations.

Effective communication is key to a successful sourcing partnership. Develop a clear communication plan that outlines how you will interact with the supplier throughout the procurement process.

- Set regular check-ins to monitor progress and address any concerns promptly.

- Use collaborative tools to share updates and feedback, ensuring both parties are aligned on expectations.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for 'sic mirror,' making informed decisions that contribute to long-term business success.

When sourcing sic mirrors, understanding the various cost components is crucial for international B2B buyers. The primary elements include:

Materials: The cost of silicon carbide (SiC) is a significant factor. Prices can fluctuate based on global supply chains and demand. Buyers should consider the purity and grade of SiC, as higher quality materials will increase costs.

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it’s essential to balance this with quality assurance.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Understanding the overhead structure can provide insights into overall pricing strategies.

Tooling: Custom tooling can incur high upfront costs but may lead to lower unit costs for large production runs. Buyers should evaluate whether the tooling costs can be amortized over a sufficient volume to justify the investment.

Quality Control (QC): Rigorous QC processes are necessary to ensure that the sic mirrors meet industry standards. This can add to the overall cost but is critical for maintaining product integrity and customer satisfaction.

Logistics: Shipping and handling costs can vary widely based on the distance, mode of transport, and any tariffs or duties applicable. For international buyers, understanding the logistics cost structure is vital to avoid unexpected expenses.

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market competition and the perceived value of the product. Negotiating this margin can lead to cost savings.

Several factors can influence the pricing of sic mirrors:

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing needs without overcommitting.

Specifications and Customization: Custom features or unique specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

Material Quality and Certifications: Higher quality materials and certified products tend to command premium prices. Buyers should weigh the benefits of certification against the additional costs.

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers may charge more, but they often provide better quality assurance and service.

Incoterms: Understanding the agreed Incoterms is crucial as it determines who is responsible for shipping costs, insurance, and risk. This can greatly affect the total cost of ownership.

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

Conduct Market Research: Understand the market landscape and the pricing strategies of various suppliers. This knowledge can strengthen your negotiating position.

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term relationships often yield more favorable conditions.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with the product, including maintenance, logistics, and potential wastage. This perspective can justify higher upfront costs if they lead to savings in the long run.

Be Transparent About Your Needs: Clearly communicate your volume requirements and any constraints you have. This transparency can lead to more tailored solutions from suppliers.

Explore Alternative Suppliers: Don’t hesitate to compare quotes from different suppliers. This can create competitive pressure that may lead to better pricing.

International buyers should be aware of specific pricing nuances when sourcing sic mirrors:

Currency Fluctuations: Exchange rate volatility can impact final costs. Consider negotiating prices in a stable currency or using hedging strategies.

Import Duties and Taxes: Be aware of any import tariffs or taxes that may apply when bringing sic mirrors into your country. These can significantly affect the final price.

Cultural Differences: Understanding cultural nuances can help in negotiations. Different regions may have varying expectations regarding communication styles and negotiation tactics.

Prices for sic mirrors can vary widely based on the aforementioned factors. Buyers should seek updated quotes from suppliers to get accurate pricing tailored to their specific needs and circumstances.

In the competitive landscape of B2B solutions, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe, understanding alternatives to a product or method is essential. The Sic Mirror serves a specific purpose, but evaluating other viable options can help businesses make informed decisions based on performance, cost, and usability.

| Comparison Aspect | Sic Mirror | Alternative 1: Digital Twin | Alternative 2: Augmented Reality (AR) |

|---|---|---|---|

| Performance | High accuracy in reflective data | Real-time data simulation | Immersive visualization |

| Cost | Moderate initial investment | High initial setup cost | Variable costs depending on technology |

| Ease of Implementation | Straightforward integration | Complex, requires extensive planning | Requires specialized training |

| Maintenance | Low maintenance needs | Regular software updates needed | High maintenance due to tech updates |

| Best Use Case | Effective for monitoring static environments | Ideal for dynamic systems | Best for training and interactive presentations |

The Digital Twin technology allows businesses to create a virtual representation of their physical assets. This method excels in real-time data simulation, providing insights into system behavior and performance. However, it typically requires a higher initial investment and complex implementation processes. The need for constant updates and maintenance can also lead to increased operational costs over time, making it less favorable for companies with limited budgets or resources.

Augmented Reality (AR) offers an immersive experience that enhances the user's interaction with their environment. This technology can be particularly effective for training purposes or customer engagement through interactive presentations. While AR provides a unique user experience, it often comes with significant costs associated with technology setup and training. Additionally, the high maintenance requirements due to frequent software updates can strain resources, making it less ideal for businesses seeking a low-maintenance solution.

Choosing the right solution depends on several factors, including your specific business needs, budget constraints, and the desired level of interactivity. For businesses prioritizing straightforward implementation and low maintenance, Sic Mirror may be the best fit. However, if your operations require real-time monitoring and simulation, exploring Digital Twin technology could offer substantial benefits despite the higher costs. Alternatively, if immersive training or customer engagement is paramount, AR might be worth the investment. Ultimately, a thorough assessment of your business objectives and available resources will guide you in selecting the most suitable solution.

When considering the procurement of silicon carbide (SiC) mirrors, understanding their technical properties is crucial for B2B buyers looking to make informed decisions. Here are some key specifications that define the quality and usability of SiC mirrors:

Material Grade

- SiC mirrors are typically classified by their material grade, which affects their performance and application. Higher-grade materials exhibit superior thermal stability and mechanical strength, making them ideal for high-performance optics used in aerospace and military applications. For buyers, selecting the appropriate material grade ensures the mirror can withstand environmental stresses and maintain optical clarity.

Surface Flatness

- Surface flatness is a critical parameter measured in nanometers (nm). A flatter surface ensures minimal optical distortion, which is vital for applications requiring high precision, such as telescopes and laser systems. Buyers must consider the required flatness specifications to meet their operational needs, as this can significantly impact the performance of optical systems.

Thermal Conductivity

- The ability of SiC mirrors to dissipate heat efficiently is measured by thermal conductivity, typically expressed in watts per meter per Kelvin (W/m·K). High thermal conductivity is essential for applications where rapid temperature changes occur, such as in high-energy laser systems. For international buyers, understanding thermal conductivity can influence the choice of SiC mirrors based on their specific operational environments.

Tolerances

- Tolerances refer to the allowable variation in dimensions and surface quality. Tight tolerances are essential for ensuring that mirrors fit precisely within their intended systems. In B2B transactions, specifying tolerances helps manufacturers deliver products that meet exacting standards, thereby reducing the risk of operational failures.

Weight and Density

- The weight and density of SiC mirrors are important for applications where weight savings are critical, such as in aerospace engineering. Lighter mirrors can lead to lower transportation costs and easier installation. Buyers should assess the weight specifications to align with their overall project requirements and budget constraints.

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the SiC mirror market:

OEM (Original Equipment Manufacturer)

- An OEM refers to a company that produces components that are used in another company's end product. In the context of SiC mirrors, OEMs may produce mirrors for larger systems, such as telescopes or laser devices. Buyers should ensure that the OEM can meet their specific quality and performance criteria.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory planning, especially for smaller businesses or projects with limited needs. Buyers should negotiate MOQs that align with their operational capacity.

RFQ (Request for Quotation)

- An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. This process allows buyers to compare offers from multiple suppliers, ensuring they secure the best deal for SiC mirrors. Clear RFQs can streamline procurement and improve supplier relationships.

Incoterms (International Commercial Terms)

- Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms helps buyers understand their liabilities and costs associated with international shipping, which is critical when sourcing SiC mirrors globally.

Lead Time

- Lead time is the period required from placing an order to receiving the product. For SiC mirrors, lead times can vary based on customization and manufacturing processes. Buyers should consider lead times in their project planning to avoid delays in production schedules.

By grasping these essential properties and terms, international B2B buyers can navigate the procurement of SiC mirrors more effectively, ensuring they make informed choices that align with their operational needs and strategic goals.

The sic mirror sector is witnessing significant transformation driven by global demand for advanced optics and reflective materials. As international B2B buyers from Africa, South America, the Middle East, and Europe look to enhance their supply chains, several key trends have emerged. Firstly, there is a growing focus on high-performance materials that offer superior durability and optical clarity, which are crucial for applications in automotive, aerospace, and electronics sectors. This trend is fueled by technological advancements and the increasing demand for precision-engineered products.

Moreover, the integration of digital technologies into sourcing processes is reshaping how companies in this sector operate. The use of artificial intelligence (AI) and machine learning for inventory management and predictive analytics allows buyers to optimize their procurement strategies, reducing lead times and costs. Additionally, a shift towards regional sourcing is becoming more prevalent, particularly as companies aim to mitigate risks associated with global supply chain disruptions. This is especially relevant for buyers in the Middle East and Africa, where local partnerships can enhance reliability and reduce transportation costs.

Another emerging trend is the rising importance of customization and personalization in product offerings. B2B buyers are increasingly seeking suppliers who can provide tailored solutions that meet specific project requirements. This shift not only enhances customer satisfaction but also fosters long-term partnerships, which are vital in competitive markets like Europe and South America.

Sustainability is becoming a critical consideration for international B2B buyers in the sic mirror sector. The environmental impact of production processes and material sourcing is under scrutiny, leading to a demand for sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials. This is particularly significant in regions like Europe, where stringent regulations and consumer preferences are pushing for greener alternatives.

Ethical sourcing is equally important, as buyers seek transparency in supply chains. Companies that adhere to ethical labor practices and provide fair working conditions are more likely to gain the trust and loyalty of B2B clients. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier's commitment to sustainability and ethical practices, making them preferable choices for conscientious buyers.

Furthermore, incorporating recycled materials into the production of sic mirrors not only reduces waste but also aligns with the growing trend of circular economy practices. Buyers who prioritize suppliers with 'green' certifications can enhance their brand reputation and appeal to environmentally-conscious consumers, ultimately driving business growth.

The sic mirror sector has evolved significantly over the past few decades, shaped by advancements in materials science and changing market demands. Originally, the focus was primarily on basic reflective materials; however, as technology progressed, the industry began to embrace silicon carbide (SiC) due to its superior thermal and mechanical properties.

In the 1980s and 1990s, the introduction of precision manufacturing techniques revolutionized the sector, enabling the production of high-quality sic mirrors suitable for various applications, including telescopes and laser systems. This evolution has paved the way for the current landscape, where the emphasis is on high-performance, customized solutions tailored to the specific needs of international B2B buyers. Understanding this historical context is essential for buyers as it highlights the ongoing innovations and trends that influence sourcing decisions today.

In summary, navigating the sic mirror sector requires a keen understanding of market dynamics, a commitment to sustainability, and awareness of the historical evolution of the industry. By aligning sourcing strategies with these insights, international B2B buyers can make informed decisions that drive their business success.

How do I ensure the quality of sic mirrors when sourcing internationally?

To guarantee the quality of sic mirrors, it's crucial to conduct thorough supplier vetting. Start by requesting samples to assess the craftsmanship and material quality. Look for manufacturers with established quality control processes and certifications, such as ISO standards. Additionally, consider visiting the production facility if feasible, or hiring a third-party inspection service to conduct quality checks before shipment. This proactive approach minimizes risks and ensures that the products meet your specifications and standards.

What is the best way to negotiate payment terms for sic mirror purchases?

Negotiating favorable payment terms is essential for cash flow management in B2B transactions. Aim for terms that align with your business cycle, such as net 30 or net 60 days. Consider offering a larger upfront payment for a discount or negotiating partial payments tied to production milestones. Additionally, utilizing escrow services can protect both parties, ensuring that funds are released only when agreed-upon conditions are met. Clear communication about expectations is vital to fostering a successful partnership.

What are the typical minimum order quantities (MOQ) for sic mirrors?

Minimum order quantities (MOQ) for sic mirrors can vary significantly by supplier and product type. Generally, manufacturers may set MOQs ranging from 50 to 500 units, depending on production capabilities and material costs. It's advisable to discuss your specific needs with potential suppliers, as some may offer flexibility for first-time orders or smaller businesses. Building a strong relationship with your supplier can also lead to more favorable terms over time.

How can I customize sic mirrors to meet my specific requirements?

Customization of sic mirrors typically involves specifying dimensions, finishes, and unique design elements. When approaching a supplier, provide detailed specifications and any design files you have. Some manufacturers may offer design assistance to help refine your ideas. Be prepared to discuss lead times and potential cost implications for customization, as these factors can affect your overall budget and delivery schedule.

What logistics considerations should I keep in mind when importing sic mirrors?

When importing sic mirrors, consider logistics factors such as shipping methods, duties, and customs regulations. Choose between air or sea freight based on urgency and cost-effectiveness. Ensure you understand the import tariffs applicable in your country to avoid unexpected expenses. Collaborating with a freight forwarder can streamline the process, as they can manage documentation and compliance, ensuring a smooth customs clearance.

How do I handle disputes or issues with sic mirror suppliers?

Disputes with suppliers can arise from quality issues, delays, or miscommunication. To handle such situations effectively, maintain open lines of communication to discuss concerns promptly. Document all interactions and agreements in writing to provide clarity. If a resolution cannot be reached, consider mediation or arbitration as a potential path forward. Establishing a clear contract with defined terms can also help mitigate disputes before they escalate.

What certifications should I look for in sic mirror suppliers?

When sourcing sic mirrors, look for suppliers with relevant certifications that indicate quality and compliance with industry standards. ISO 9001 certification demonstrates a commitment to quality management, while ISO 14001 indicates an adherence to environmental management practices. Additionally, check for certifications specific to your region or industry, such as CE marking in Europe, which can assure compliance with safety regulations.

How can I assess the reliability of sic mirror suppliers?

To assess the reliability of sic mirror suppliers, start by researching their business history, client reviews, and case studies. Request references from past clients to gauge their experiences regarding quality, delivery times, and customer service. Consider using trade platforms that provide supplier ratings and feedback. Engaging in initial smaller orders can also be a strategic way to evaluate their reliability before committing to larger purchases.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the strategic sourcing of sic mirror offers significant advantages for B2B buyers across Africa, South America, the Middle East, and Europe. By adopting a strategic approach, businesses can not only streamline procurement processes but also secure high-quality materials that meet their specific operational needs. The importance of evaluating suppliers based on factors such as reliability, cost-effectiveness, and sustainability cannot be overstated. This ensures that your sourcing decisions align with long-term business goals and market demands.

As you navigate the complex landscape of international sourcing, consider leveraging digital tools and platforms that facilitate better supplier interactions and transparency. The rise of digital marketplaces and data analytics can significantly enhance your decision-making capabilities, allowing you to identify the best suppliers and negotiate favorable terms.

Looking ahead, the demand for sic mirror is likely to grow, driven by advancements in technology and increasing applications across various industries. International B2B buyers should remain proactive in exploring new suppliers and fostering relationships that can adapt to evolving market trends. By staying informed and agile, you can position your business for success in a competitive landscape. Engage with industry experts, attend trade shows, and utilize professional networks to expand your sourcing options.

In summary, the strategic sourcing of sic mirror is not just a procurement function; it is a critical driver of business success. Embrace these insights and take action today to enhance your sourcing strategy for a sustainable future.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina