In the rapidly evolving landscape of power electronics, sourcing Silicon Carbide (SiC) MOSFETs presents both opportunities and challenges for international B2B buyers. The demand for energy-efficient solutions is surging, particularly in regions such as Africa, South America, the Middle East, and Europe, where industries are increasingly focused on sustainability and performance. This guide aims to empower buyers by offering a thorough exploration of SiC MOSFET technology, including the various types available, their applications across different sectors, and strategic insights into supplier vetting and cost considerations.

By understanding the unique advantages of SiC MOSFETs—such as their superior efficiency, reliability, and reduced cooling requirements—buyers can make informed decisions that align with their operational goals. This comprehensive resource will delve into the technical specifications and performance metrics that set SiC MOSFETs apart from traditional silicon alternatives, addressing key questions around integration and scalability in diverse applications.

Furthermore, the guide will provide actionable strategies for evaluating suppliers, ensuring that buyers can navigate the complexities of the global market with confidence. Whether you are in the automotive, renewable energy, or industrial sectors, this guide is designed to facilitate your journey towards selecting the best SiC MOSFET solutions that meet your specific needs.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CoolSiC™ MOSFET | Low gate charge, high efficiency, temperature-independent losses | Photovoltaic inverters, motor drives | Pros: High reliability, reduced cooling needs. Cons: Higher initial cost compared to traditional MOSFETs. |

| HybridPACK™ Drive MOSFET | Integrated gate driver, compact design, optimized for automotive | Automotive traction inverters | Pros: Space-saving, high power density. Cons: Limited to automotive applications. |

| Easy Modules | Excellent thermal management, low stray inductance | Industrial power supplies, UPS systems | Pros: Simplified design, robust construction. Cons: May require additional components for complex systems. |

| CIPOS™ Maxi IPM | Integrated multi-channel driver, compact, high-performance | Industrial drives, robotics | Pros: Excellent integration, high efficiency. Cons: Requires specific driver compatibility. |

| SiC MOSFET 650V and 1200V | High voltage ratings, low reverse recovery loss | Battery charging, DC-DC converters | Pros: Versatile applications, improved efficiency. Cons: Potential over-specification for low power needs. |

CoolSiC™ MOSFETs are recognized for their low gate charge and high efficiency, making them suitable for various applications, including photovoltaic inverters and motor drives. They operate with temperature-independent switching losses, ensuring consistent performance even under variable conditions. For B2B buyers, the primary consideration is the balance between the higher upfront costs and the long-term savings achieved through reduced cooling needs and increased reliability.

HybridPACK™ Drive MOSFETs are specifically designed for automotive traction inverters, combining high power density with an integrated gate driver for enhanced performance. Their compact design allows for efficient space utilization in automotive applications. B2B buyers should consider the trade-off between the compact benefits and the limited application range, ensuring that their choice aligns with automotive project requirements.

Easy Modules are designed for robust thermal management and low stray inductance, making them ideal for industrial power supplies and UPS systems. They simplify the design process and provide a reliable solution for medium power applications. Buyers should weigh the benefits of easier integration against the potential need for additional components in more complex systems.

CIPOS™ Maxi IPM offers a highly integrated solution with multi-channel drivers, making it ideal for industrial drives and robotics. Its compact design and high efficiency significantly reduce the footprint of power systems. B2B purchasers should consider compatibility with existing systems and the specific driver requirements to maximize performance.

SiC MOSFETs rated at 650V and 1200V provide flexibility for a range of applications, including battery charging and DC-DC converters. Their low reverse recovery loss enhances efficiency, which is crucial for energy-sensitive projects. Buyers must assess their actual voltage needs, as over-specification can lead to unnecessary costs in less demanding applications.

Related Video: Types of MOSFET | FET Types Simplified | #mosfet #fets #electronics #analogelectronics #transistor

| Industry/Sector | Specific Application of sic-mosfet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Photovoltaic Inverters | Enhanced efficiency and reduced energy costs | Ensure high voltage ratings (up to 2000V) and reliability certifications. |

| Automotive | Traction Inverters | Improved power density and vehicle performance | Look for high-temperature operation and robustness in harsh environments. |

| Industrial Automation | Servo and Motor Drives | Increased operational efficiency and lower maintenance costs | Focus on low switching losses and compatibility with existing systems. |

| Energy Storage Systems | Battery Charging Systems | Faster charging cycles and longer battery life | Assess the thermal management capabilities and integration ease. |

| Telecommunications | Server and Telecom Power Supplies | Higher reliability and reduced downtime | Verify compliance with international standards and power density needs. |

In the renewable energy sector, SiC-MOSFETs are pivotal in photovoltaic inverters, which convert DC electricity generated by solar panels into AC electricity for grid use. Their high efficiency translates to lower energy losses, making them ideal for maximizing energy output. For international buyers, particularly in regions like Africa and South America where solar adoption is increasing, sourcing high-voltage SiC-MOSFETs (up to 2000V) with robust reliability certifications is essential to ensure long-term operational success.

In the automotive industry, SiC-MOSFETs are utilized in traction inverters that drive electric and hybrid vehicles. They provide improved power density, which enhances vehicle performance and range. For buyers in Europe and the Middle East, it is crucial to consider suppliers that offer components capable of withstanding high temperatures and harsh conditions, ensuring reliability and efficiency in electric vehicle applications.

SiC-MOSFETs are increasingly used in servo and motor drives within industrial automation, enabling higher operational efficiency and lower maintenance costs. Their low switching losses contribute to energy savings, making them a cost-effective solution for manufacturers. Buyers should prioritize sourcing SiC-MOSFETs that are compatible with existing systems and provide temperature-independent performance, especially in regions like Poland where industrial automation is rapidly advancing.

In energy storage systems, SiC-MOSFETs are critical for battery charging applications, allowing for faster charge cycles and extending battery life. This is particularly beneficial in applications where downtime must be minimized. International buyers should evaluate the thermal management capabilities of the MOSFETs, ensuring they can handle the demands of high-frequency operation while maintaining efficiency.

In the telecommunications sector, SiC-MOSFETs enhance server and telecom power supplies by providing higher reliability and reducing downtime. Their efficiency leads to lower operational costs, which is vital for telecom operators. Buyers should ensure that the components sourced comply with international standards and meet the specific power density requirements of their systems, especially in regions with growing telecommunication infrastructure like South America and Africa.

Related Video: What is Field Effect Transistor - FET - JFET - MOSFET - Applications of MOSFET

The Problem:

International B2B buyers, particularly in energy-intensive sectors, often face challenges with high switching losses when using traditional MOSFET technologies. This inefficiency not only escalates operational costs but also complicates thermal management. For example, a manufacturer in South America utilizing silicon-based MOSFETs in their photovoltaic inverters may experience significant heat generation, leading to increased cooling requirements and reduced system reliability.

The Solution:

To address high switching losses, B2B buyers should consider switching to Silicon Carbide (SiC) MOSFETs, such as Infineon's CoolSiC™ series. These devices exhibit significantly lower switching losses compared to their silicon counterparts, thanks to their temperature-independent characteristics and low gate charge. Buyers should ensure they source SiC MOSFETs with specifications that match their voltage and current requirements. Additionally, employing advanced thermal management techniques—like heat sinks designed for high power density—can further enhance efficiency and reliability. Investing in proper driver ICs specifically designed for SiC technology will also facilitate optimal performance and ease of integration into existing systems.

The Problem:

B2B buyers frequently encounter compatibility issues when integrating new SiC MOSFETs into their existing designs. For instance, an industrial automation company in Europe may struggle to replace aging silicon MOSFETs with SiC solutions due to mismatches in gate drive requirements or layout constraints. This can lead to delays in product development and increased costs as modifications are needed to accommodate new components.

The Solution:

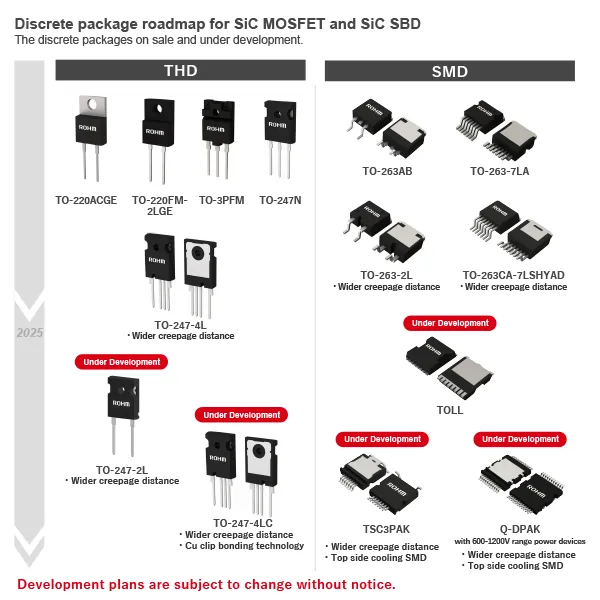

To mitigate compatibility issues, B2B buyers should conduct a thorough analysis of their current systems before transitioning to SiC MOSFETs. This includes evaluating the existing PCB layout, driver circuits, and thermal management solutions. Sourcing SiC MOSFETs that feature a Kelvin connection, like those offered in the TO-247-4 pin package, can simplify integration by providing a reliable reference point for gate driving. Furthermore, leveraging design simulation tools can help assess the impact of SiC devices on the overall system performance before implementation, enabling a smoother transition and minimizing unexpected costs.

The Problem:

Many international B2B buyers, particularly those new to the semiconductor landscape, may lack a comprehensive understanding of the benefits offered by SiC MOSFETs. This gap in knowledge can hinder their ability to make informed purchasing decisions. For example, a telecommunications company in Africa might overlook the potential cost savings and efficiency improvements that SiC technology can deliver in their power supply systems.

The Solution:

To bridge the knowledge gap, B2B buyers should invest time in educational resources, including webinars, whitepapers, and case studies that highlight the advantages of SiC MOSFETs. Engaging with suppliers who offer technical support can also provide valuable insights into the practical applications of SiC technology. Buyers should specifically look for detailed product documentation that outlines performance metrics, such as switching frequency capabilities and thermal characteristics, which can aid in making data-driven decisions. Additionally, attending industry conferences and exhibitions can facilitate networking with experts and peers, fostering a deeper understanding of how SiC MOSFETs can be leveraged for competitive advantage in their specific markets.

When selecting materials for Silicon Carbide (SiC) MOSFETs, it is essential to understand the properties and implications of various materials used in their construction. Here, we analyze four common materials: Silicon Carbide, Aluminum Nitride, Gallium Nitride, and Silicon. Each material has unique characteristics that can significantly impact performance, durability, and cost.

Key Properties: Silicon Carbide is known for its high thermal conductivity, wide bandgap, and exceptional electric field strength. It operates efficiently at high temperatures (up to 200°C) and high voltages (up to 2000 V).

Pros & Cons: The primary advantage of SiC is its ability to handle high power densities and improve efficiency, which reduces cooling requirements. However, the manufacturing process can be complex and costly, making SiC MOSFETs more expensive than traditional silicon-based devices.

Impact on Application: SiC MOSFETs are ideal for applications in renewable energy systems, electric vehicles, and industrial power supplies where efficiency and thermal management are critical.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should consider the availability of local suppliers who can meet these standards.

Key Properties: Aluminum Nitride (AlN) offers excellent thermal conductivity and electrical insulation properties. It can operate effectively at high temperatures, making it suitable for high-performance applications.

Pros & Cons: AlN provides significant thermal management benefits, which can enhance the reliability of SiC MOSFETs. However, it is more brittle than other materials, which can complicate manufacturing and handling processes.

Impact on Application: AlN is particularly beneficial in applications requiring efficient heat dissipation, such as power amplifiers and high-frequency circuits.

Considerations for International Buyers: Buyers should be aware of the specific thermal management requirements in their regions. Compliance with local and international standards is also essential to ensure product reliability.

Key Properties: Gallium Nitride (GaN) is characterized by a wide bandgap and high electron mobility, allowing for high-frequency operation and efficiency.

Pros & Cons: GaN devices are compact and lightweight, making them suitable for space-constrained applications. However, they can be sensitive to voltage spikes and require careful handling during manufacturing.

Impact on Application: GaN is often used in RF applications, power converters, and electric vehicle charging systems due to its efficiency and performance at high frequencies.

Considerations for International Buyers: Buyers must consider the availability of GaN technology in their regions and ensure that suppliers comply with relevant standards. This is particularly important in Europe, where regulations can be stringent.

Key Properties: Silicon is the most commonly used semiconductor material, known for its good thermal and electrical properties at a lower cost compared to SiC and GaN.

Pros & Cons: While silicon is cost-effective and widely available, it cannot match the performance of SiC or GaN at high temperatures and voltages. This limits its application in high-power scenarios.

Impact on Application: Silicon is suitable for low to medium power applications, such as consumer electronics and basic industrial equipment.

Considerations for International Buyers: Buyers should evaluate the cost-benefit ratio of using silicon versus advanced materials like SiC or GaN based on their specific application needs.

| Material | Typical Use Case for SiC MOSFET | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Electric vehicles, renewable energy systems | High efficiency and thermal management | High manufacturing cost | High |

| Aluminum Nitride | Power amplifiers, high-frequency circuits | Excellent thermal conductivity | Brittle, complicates manufacturing | Medium |

| Gallium Nitride | RF applications, power converters | Compact size, high-frequency operation | Sensitive to voltage spikes | High |

| Silicon | Consumer electronics, basic industrial equipment | Cost-effective and widely available | Limited performance at high power | Low |

This guide provides a comprehensive overview of the materials used in SiC MOSFETs, allowing international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

A stock image related to sic-mosfet.

The manufacturing process of Silicon Carbide (SiC) MOSFETs involves several critical stages that ensure the production of high-quality devices. Each stage plays a vital role in determining the performance and reliability of the final product.

The first step in SiC MOSFET manufacturing is material preparation. SiC substrates are usually sourced from high-purity silicon carbide crystals. The material undergoes extensive purification to remove any impurities that could affect electrical characteristics. Key techniques in this stage include:

Following material preparation, the next phase is forming, where the actual MOSFET structures are created on the SiC wafers. This stage includes several sophisticated techniques:

The assembly stage involves integrating the individual components into a functional MOSFET device. Key processes in this stage include:

Finishing processes are essential for ensuring that the SiC MOSFETs meet the required specifications and performance standards. This stage typically includes:

Quality assurance is critical in the manufacturing of SiC MOSFETs to ensure reliability and performance. International standards such as ISO 9001 are widely adopted, focusing on quality management systems. Additionally, industry-specific certifications like CE and API may also be relevant depending on the application of the SiC MOSFETs.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity. Common checkpoints include:

Testing is an integral part of the QC process, and several methods are commonly employed:

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control of suppliers is crucial. Here are actionable strategies:

When sourcing SiC MOSFETs internationally, buyers should be aware of the nuances in quality certification. Different regions may have varying requirements and standards. For instance:

In conclusion, the manufacturing processes and quality assurance protocols for SiC MOSFETs are intricate and vital for producing reliable and high-performance devices. International B2B buyers must be diligent in verifying these processes to ensure they are sourcing the best products for their applications.

In today's energy-conscious landscape, sourcing Silicon Carbide (SiC) MOSFETs is essential for companies looking to enhance efficiency and reliability in their electronic applications. This guide provides a practical checklist to help international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—navigate the procurement process effectively.

Establishing clear technical specifications is fundamental to ensuring that the SiC MOSFETs you source meet your application requirements. Consider parameters such as voltage ratings (e.g., 400V to 2000V), switching frequency, and thermal performance. This clarity will help you communicate your needs effectively with suppliers and ensure compatibility with your systems.

Identify suppliers with a strong reputation in the SiC MOSFET market. Look for companies that have established credibility through certifications, industry awards, and positive customer reviews. Supplier reputation often correlates with product quality and reliability, which are critical for high-performance applications.

Before making any commitments, it is crucial to verify the certifications of potential suppliers. Look for ISO certifications and compliance with international standards relevant to semiconductor manufacturing. These certifications are indicators of quality management systems and can assure you of the reliability of the products.

Once you have shortlisted potential suppliers, request samples of the SiC MOSFETs for testing. This step is critical to evaluate the performance of the products in your specific application environment. Conduct thorough testing to assess parameters such as efficiency, thermal performance, and reliability under load.

Technical support is essential when integrating new technology into existing systems. Evaluate the level of technical assistance offered by the supplier, including documentation, design support, and troubleshooting. Strong after-sales service can significantly reduce downtime and enhance your operational efficiency.

Once you have completed the evaluation process, proceed to negotiate pricing and terms. Consider the total cost of ownership, including shipping, customs duties, and potential tariffs, particularly if you are sourcing from abroad. Aim for favorable payment terms that align with your cash flow needs.

After successful negotiations, finalize the purchase order. Ensure that all terms discussed, including delivery schedules, warranty conditions, and payment terms, are clearly outlined in the contract. This document serves as a reference point for both parties and helps mitigate potential disputes.

By following this checklist, B2B buyers can streamline the sourcing process for SiC MOSFETs, ensuring that they acquire high-quality components that meet their specific needs.

When sourcing Silicon Carbide (SiC) MOSFETs, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Materials: The quality of silicon carbide and other materials significantly impacts the price. High-purity SiC is more expensive but essential for achieving the desired efficiency and reliability in applications like photovoltaic inverters and motor drives.

Labor: Skilled labor is required in the manufacturing process, especially for high-precision components. Labor costs can vary by region, influencing the final product price.

Manufacturing Overhead: This includes the costs associated with running production facilities, such as utilities, maintenance, and administrative expenses. Advanced manufacturing techniques for SiC technology can lead to higher overhead costs.

Tooling: Specialized tooling and equipment for SiC MOSFET production are capital-intensive. The initial investment in high-quality tooling can lead to better production efficiency and lower long-term costs.

Quality Control (QC): Rigorous testing and quality assurance processes ensure that the SiC MOSFETs meet industry standards. These costs are crucial but add to the overall price.

Logistics: Transporting SiC MOSFETs, particularly for international buyers, involves logistics costs that can vary based on distance, shipping method, and Incoterms.

Margin: Manufacturers typically include a margin to cover risks and ensure profitability. This margin can vary based on market conditions and the supplier's business model.

Several factors influence the pricing of SiC MOSFETs, which international buyers should consider:

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Larger orders often lead to discounts, making bulk purchasing an attractive option for businesses.

Specifications and Customization: Custom specifications or unique requirements can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

Materials: The choice of materials not only affects performance but also pricing. Premium materials lead to higher costs but often result in better performance and reliability.

Quality and Certifications: Components with industry certifications typically command higher prices. However, these certifications can lead to long-term savings by reducing failure rates and warranty claims.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their products due to their proven track record.

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the overall cost.

International B2B buyers can employ several strategies to optimize their sourcing costs:

Negotiate Volume Discounts: Leverage bulk purchasing to negotiate better pricing. Suppliers are often willing to provide discounts for larger orders, which can significantly reduce costs.

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the initial purchase price, consider the TCO. This includes operational costs, maintenance, and potential savings from increased efficiency and reliability.

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times. Additionally, local suppliers may offer better support and communication.

Be Aware of Pricing Nuances: Understand that prices can fluctuate based on market demand, raw material costs, and technological advancements. Staying informed about these factors can enhance negotiation leverage.

Request Transparent Pricing: Ask suppliers for a breakdown of costs. This transparency allows for better understanding and negotiation of specific components, leading to potential savings.

Sourcing SiC MOSFETs requires a thorough understanding of the cost structure and pricing influencers. By considering the various cost components, leveraging negotiation strategies, and focusing on total cost of ownership, international buyers can make informed purchasing decisions that align with their business goals. Always remember that prices may vary, and it is advisable to obtain multiple quotes to ensure competitive sourcing.

When considering power electronics solutions, it's essential to evaluate the available alternatives to Silicon Carbide (SiC) MOSFETs. This analysis will help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, make informed decisions based on performance, cost, and application suitability.

| Comparison Aspect | Sic-Mosfet | Alternative 1: Silicon IGBT | Alternative 2: GaN FETs |

|---|---|---|---|

| Performance | High efficiency, low switching losses | Moderate efficiency, higher losses at high frequencies | Very high efficiency, excellent thermal performance |

| Cost | Higher initial investment | Generally lower cost | Higher cost than SiC but lower than IGBT |

| Ease of Implementation | Requires specialized drivers | Easier to implement with existing designs | Complex integration, requires advanced design capabilities |

| Maintenance | Long lifespan, low maintenance | Moderate maintenance required | Generally low maintenance |

| Best Use Case | High-frequency applications, renewable energy | Medium voltage applications, industrial drives | High-frequency applications, RF systems |

Silicon Insulated Gate Bipolar Transistors (IGBTs) are a common alternative to SiC MOSFETs. They are known for their robustness and lower initial costs, making them a popular choice in various applications, especially in medium voltage systems. However, they have higher switching losses at elevated frequencies, which can lead to increased heat generation and lower overall efficiency compared to SiC MOSFETs. IGBTs are more suited for applications where cost is a primary concern, but they may not perform as well in high-frequency or high-efficiency scenarios.

Gallium Nitride (GaN) FETs represent another advanced technology competing with SiC MOSFETs. They offer superior performance in high-frequency applications, making them ideal for RF and power conversion systems. GaN devices can achieve higher efficiency and thermal performance than IGBTs. However, their complexity in integration and higher cost can be barriers for some applications. Additionally, GaN technology requires careful design considerations to maximize its advantages, which might necessitate a skilled workforce.

When selecting the right power electronic solution, B2B buyers should assess their specific application requirements and constraints. SiC MOSFETs excel in high-frequency applications, delivering exceptional efficiency and reliability, making them suitable for renewable energy systems and electric vehicles. In contrast, IGBTs may be preferred for cost-sensitive projects with moderate performance needs. Meanwhile, GaN FETs are ideal for high-frequency applications but come with a steeper learning curve and higher costs. Ultimately, buyers should align their choice with their technical capabilities, budget constraints, and long-term operational goals to ensure optimal performance and return on investment.

When considering Silicon Carbide (SiC) MOSFETs for your applications, understanding their critical specifications is vital for making informed purchasing decisions. Below are some of the most important technical properties that B2B buyers should evaluate:

SiC MOSFETs are available in a range of voltage ratings, typically from 400 V to 2000 V. This specification indicates the maximum voltage the device can handle without breaking down. For applications like photovoltaic inverters or electric vehicle traction inverters, selecting a MOSFET with an appropriate voltage rating is crucial to ensure reliability and performance under operational conditions.

Gate charge is the amount of charge required to switch the MOSFET on and off. SiC MOSFETs exhibit lower gate charge values compared to traditional silicon-based devices, which leads to faster switching times and reduced power losses. For buyers, this translates to improved efficiency and lower heat generation, making it essential to consider when designing power electronic systems.

This property measures the resistance between the drain and source terminals when the MOSFET is in the "on" state. A lower Rds(on) results in reduced conduction losses, enhancing the overall efficiency of the system. Buyers should prioritize SiC MOSFETs with low Rds(on) values to optimize energy savings and thermal management in their applications.

Thermal performance indicates how well the device can dissipate heat during operation. SiC MOSFETs are known for their superior thermal conductivity compared to silicon counterparts. This characteristic allows for higher power density and efficiency in applications such as motor drives and power supplies, making it a key consideration for B2B buyers focused on long-term reliability and performance.

Switching losses occur during the transitions between on and off states. SiC MOSFETs have temperature-independent switching losses, which means they maintain efficiency across a wide temperature range. This feature is particularly beneficial for high-frequency applications, allowing for smaller and lighter designs without sacrificing performance.

Navigating the procurement landscape for SiC MOSFETs requires familiarity with specific industry jargon. Here are some essential terms that every international B2B buyer should understand:

An OEM is a company that manufactures products that are sold under another company's brand name. For buyers, understanding the OEM relationships can provide insights into product quality and support options available for SiC MOSFETs.

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as it affects inventory management and cash flow. Always inquire about MOQs when negotiating with suppliers to avoid overcommitting.

An RFQ is a document used to invite suppliers to bid on supplying a specific product or service. For buyers, sending an RFQ can help gather competitive pricing and terms, facilitating better decision-making.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers to manage shipping costs, risk, and liability effectively.

Lead time is the amount of time it takes for a supplier to fulfill an order. For buyers, knowing the lead time is essential for project planning and ensuring timely delivery of SiC MOSFETs for critical applications.

Certification standards refer to the various industry benchmarks that a product must meet to ensure quality and safety. Familiarity with these standards can help buyers ensure that the SiC MOSFETs they procure meet regulatory requirements and industry expectations.

A stock image related to sic-mosfet.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing SiC MOSFETs, ensuring that they select the right products for their specific applications.

The global market for Silicon Carbide (SiC) MOSFETs is experiencing significant growth, driven by the increasing demand for energy-efficient power electronics across various industries. Key drivers include the transition towards renewable energy sources, such as solar and wind power, where SiC MOSFETs are critical in photovoltaic inverters and battery charging applications. Additionally, the automotive sector is rapidly adopting SiC technology for electric vehicles (EVs), where high efficiency and thermal management are paramount.

Emerging trends indicate a shift towards integrated solutions, combining SiC MOSFETs with advanced gate drivers for improved performance. Manufacturers are focusing on reducing the size of components while enhancing power density and reliability, which is crucial for applications in industrial automation and telecommunications. Moreover, international B2B buyers are increasingly looking for suppliers who can provide not only competitive pricing but also technical support and customization options tailored to specific applications, especially in regions like Africa and South America where infrastructure development is a priority.

In markets like Europe, particularly in Poland and other Eastern European countries, there is a growing emphasis on sourcing locally to minimize supply chain disruptions. As the geopolitical landscape evolves, B2B buyers are urged to consider suppliers with robust logistics and distribution capabilities that can adapt to changing market conditions.

Sustainability is becoming a pivotal factor in the procurement decisions of B2B buyers, especially in the SiC-MOSFET sector. The environmental impact of semiconductor manufacturing is significant, with energy-intensive processes and resource consumption. Buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as reducing carbon footprints and using recycled materials in production.

Ethical sourcing is equally crucial. Buyers should seek manufacturers who maintain transparent supply chains and comply with international labor standards. Certifications like ISO 14001 for environmental management and ISO 26000 for social responsibility are indicators of a supplier's commitment to sustainable practices. This focus not only helps mitigate environmental risks but also enhances brand reputation and compliance with regulatory requirements, particularly in European markets where sustainability regulations are stringent.

Investing in "green" materials and technologies not only aligns with global sustainability goals but also meets the growing consumer demand for environmentally responsible products. B2B buyers should consider collaborating with suppliers that demonstrate innovation in sustainable practices, which can lead to cost savings and competitive advantages in the long run.

The evolution of SiC-MOSFET technology has been marked by significant advancements in material science and semiconductor manufacturing techniques. Initially developed in the 1970s, SiC technology has matured over the decades, driven by the need for more efficient power conversion solutions in various applications. The introduction of CoolSiC™ MOSFETs, for instance, has revolutionized power electronics by offering higher efficiency and better thermal performance compared to traditional silicon-based devices.

For B2B buyers, understanding this evolution is crucial. It highlights the importance of investing in the latest technologies that offer tangible benefits such as reduced energy consumption and longer operational lifetimes. As SiC devices continue to evolve, they present opportunities for innovation in product design and application efficiency, making it essential for buyers to stay informed about technological advancements and emerging trends in the market.

How do I solve the challenge of selecting the right SiC MOSFET for my application?

Selecting the right SiC MOSFET begins with understanding your application requirements, including voltage, current ratings, and switching frequency. Evaluate the specific needs of your design, such as thermal management and efficiency targets. Consider the available product specifications from reputable manufacturers, focusing on features like low switching losses, high efficiency, and temperature independence. Engaging with suppliers for technical support can also guide you in making informed decisions tailored to your operational context.

What is the best SiC MOSFET for high-temperature environments?

For high-temperature applications, look for SiC MOSFETs that offer superior thermal performance and reliability. Models designed for automotive or industrial applications often feature enhanced thermal management capabilities. Check specifications for maximum junction temperature ratings and thermal resistance values. Additionally, consider devices with advanced packaging technologies that improve heat dissipation, ensuring optimal performance even in extreme conditions.

What are the key advantages of using SiC MOSFETs over traditional silicon-based devices?

SiC MOSFETs provide several advantages compared to traditional silicon devices, including higher efficiency, improved thermal conductivity, and greater power density. They enable faster switching speeds, which reduces switching losses and enhances overall system performance. Their ability to operate at higher voltages and temperatures makes them ideal for demanding applications such as electric vehicles, renewable energy systems, and industrial drives, ultimately leading to lower cooling requirements and cost savings.

How can I ensure quality and reliability when sourcing SiC MOSFETs internationally?

To ensure quality and reliability when sourcing SiC MOSFETs, prioritize suppliers with established reputations and proven track records. Request certification documents, such as ISO and RoHS compliance, to verify quality standards. Conduct thorough supplier audits and consider their manufacturing processes and quality assurance measures. Furthermore, ask for samples to evaluate performance in your specific applications before committing to larger orders.

What should I consider regarding minimum order quantities (MOQ) when sourcing SiC MOSFETs?

When sourcing SiC MOSFETs, MOQs can vary significantly among suppliers. It's essential to assess your project scale and budget constraints. Some manufacturers may allow smaller MOQs for initial orders, especially for new customers, while others may require higher quantities for cost-effectiveness. Communicate your needs clearly with potential suppliers and explore options for bulk purchasing or long-term agreements that can provide flexibility in order sizes.

What are the typical payment terms when purchasing SiC MOSFETs from international suppliers?

Payment terms for international purchases of SiC MOSFETs can vary widely. Common arrangements include upfront payments, letters of credit, or net payment terms (like net 30 or net 60 days). Always negotiate terms that align with your cash flow requirements and consider the creditworthiness of the supplier. Additionally, be aware of any potential currency exchange risks and explore options for hedging if necessary.

How do I manage logistics and shipping for international orders of SiC MOSFETs?

Managing logistics for international orders involves coordinating with suppliers to understand shipping methods, costs, and estimated delivery times. Choose reliable freight forwarders experienced in electronics to minimize risks during transport. Ensure compliance with local customs regulations and consider insurance options for high-value shipments. It's also advisable to track shipments closely and maintain communication with suppliers to address any potential delays proactively.

What customization options are available for SiC MOSFETs to meet specific application needs?

Many manufacturers offer customization options for SiC MOSFETs to better suit specific application requirements. This can include adjustments in voltage ratings, packaging types, and thermal management solutions. Engage with suppliers early in the design phase to discuss your needs and explore available modifications. Custom solutions can enhance performance and integration into your existing systems, making it crucial to communicate your specifications clearly and thoroughly.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

The strategic sourcing of Silicon Carbide (SiC) MOSFETs is essential for businesses aiming to enhance their operational efficiency and reduce costs in high-performance applications. With their superior efficiency, reliability, and reduced thermal management needs, SiC MOSFETs are transforming sectors such as renewable energy, automotive, and industrial automation. Buyers from Africa, South America, the Middle East, and Europe should focus on leveraging the advantages of SiC technology to optimize their supply chains and product designs.

Investing in SiC MOSFETs allows companies to achieve significant reductions in switching losses, which translates to lower operational costs and improved system reliability. The ability to operate at higher frequencies and temperatures also enables a more compact design, reducing the overall system complexity. This strategic choice not only enhances product performance but also aligns with sustainability goals, a crucial factor for international buyers today.

As the market evolves, international buyers should stay informed about advancements in SiC technology and consider partnerships with reputable suppliers to ensure access to cutting-edge products. Engaging in ongoing training and knowledge-sharing initiatives can also empower teams to maximize the benefits of SiC MOSFETs in their applications.

In conclusion, the strategic sourcing of SiC MOSFETs presents a unique opportunity for businesses to innovate and thrive in a competitive landscape. Embrace this technology and explore partnerships that will position your organization for success in the future.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina