In today’s interconnected economy, understanding sic nedir is crucial for B2B buyers aiming to optimize their sourcing strategies across diverse international markets. This term encompasses a range of products and technologies that are rapidly shaping industries worldwide, from manufacturing to infrastructure development. For businesses operating or sourcing in regions such as Africa, South America, the Middle East, and Europe—including key markets like Spain and Australia—grasping the nuances of sic nedir is a competitive imperative.

This guide delivers a comprehensive exploration of sic nedir, designed specifically to empower international buyers with actionable insights. It covers the essential types and classifications, enabling buyers to identify the best-fit solutions for their specific needs. Detailed analysis of materials and manufacturing processes highlights quality benchmarks and innovation trends, ensuring procurement of reliable and cutting-edge offerings. Rigorous quality control standards and certifications are examined to help assess supplier credibility and product compliance.

Moreover, the guide provides an in-depth review of the global supplier landscape, spotlighting reputable manufacturers and distributors across key regions. Transparent discussion of cost structures and pricing variables equips buyers to negotiate effectively and forecast budgets with confidence. A dedicated FAQ section addresses common concerns, facilitating swift resolution of sourcing challenges.

By consolidating this knowledge, the guide serves as an indispensable resource for international B2B buyers, enabling informed decisions that balance quality, cost-efficiency, and supply chain resilience. Whether expanding into new markets or strengthening existing partnerships, buyers will find strategic value in mastering the complexities of sic nedir to drive sustainable growth and innovation.

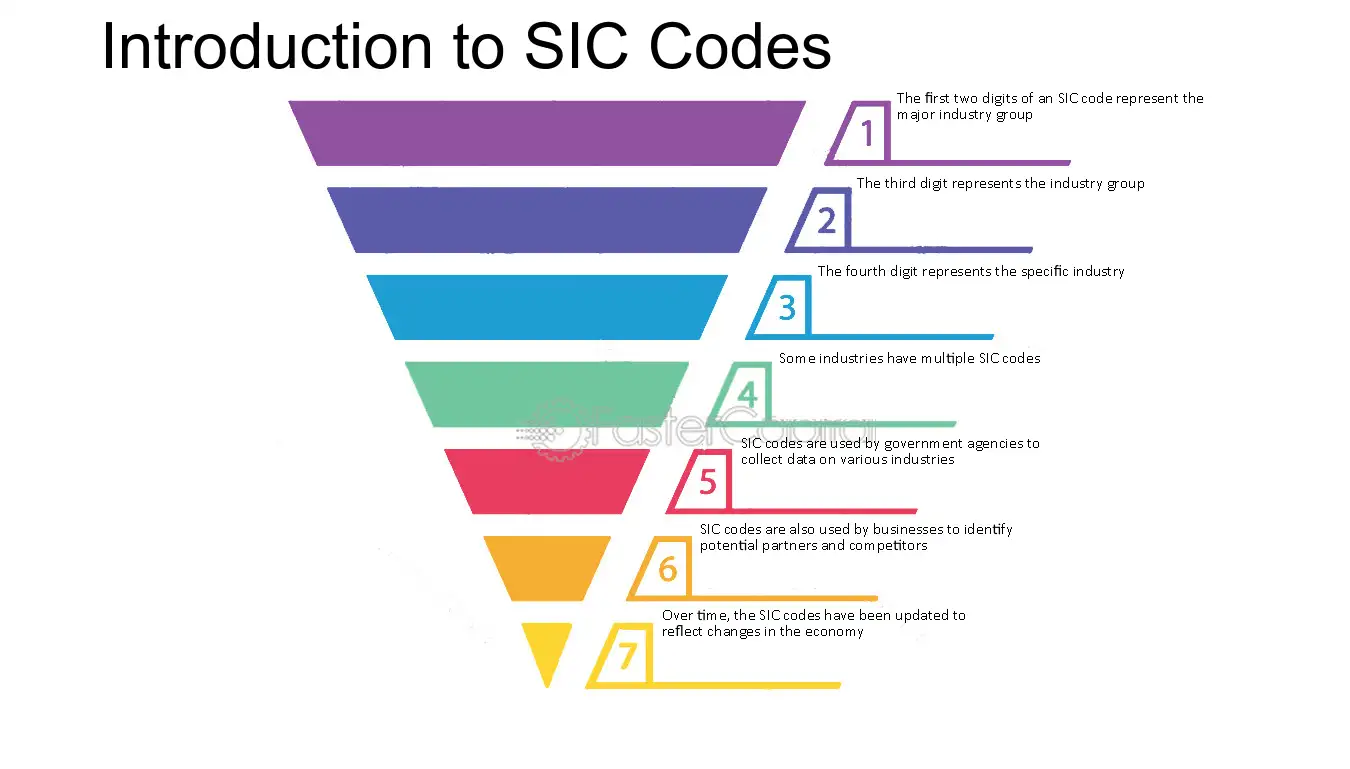

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SIC Nedır | Basic model with core functionalities, widely adopted | General business classification, regulatory compliance | + Cost-effective, widely recognized – Limited customization |

| Enhanced SIC Nedır | Includes advanced data analytics and sector-specific codes | Industry-specific market analysis, strategic sourcing | + Detailed insights, sector tailored – Higher cost, complexity |

| Digital SIC Nedır | Integrated with GIS and digital mapping tools | Infrastructure planning, spatial data-driven decisions | + Real-time data, visual mapping – Requires tech integration |

| Customized SIC Nedır | Tailored codes and features per client or region | Niche markets, local regulatory adaptation | + Highly relevant, flexible – Longer implementation, higher price |

| Hybrid SIC Nedır | Combines standard and digital features with AI enhancements | Predictive analytics, cross-sector B2B intelligence | + Cutting-edge insights, predictive – Complexity, requires expertise |

Standard SIC Nedır

This type represents the foundational classification system, offering basic categorization widely accepted across multiple markets. It is ideal for businesses seeking straightforward compliance and general market understanding without the need for complex analysis. For B2B buyers, this model is cost-effective and easy to implement but may lack the depth required for specialized industries or strategic decision-making.

Enhanced SIC Nedır

Designed with additional industry-specific codes and analytical capabilities, the Enhanced version provides deeper insights tailored to particular sectors such as manufacturing, logistics, or services. B2B buyers benefit from more precise market segmentation and competitive intelligence, enabling targeted sourcing and partnership strategies. However, the added complexity and cost require buyers to evaluate their analytical needs carefully.

Digital SIC Nedır

Integrating with Geographic Information Systems (GIS) and digital mapping platforms, this variation supports spatial analysis and real-time data visualization. It is particularly useful for infrastructure projects, urban planning, and logistics companies operating across regions. Buyers should consider their technological readiness and integration capabilities since this version demands IT infrastructure and training but offers significant advantages in data-driven decision-making.

Customized SIC Nedır

Customization allows adaptation of classification codes to specific local regulations or niche markets, making it highly relevant for businesses operating in diverse international environments such as Africa, the Middle East, or South America. This flexibility helps companies comply with local standards and better understand regional market dynamics. The trade-off is a longer deployment time and higher costs, so buyers must plan accordingly.

Hybrid SIC Nedır

This advanced type merges traditional classification with digital tools and AI-powered analytics to deliver predictive insights and cross-sector intelligence. It supports sophisticated B2B strategies like forecasting market trends and identifying emerging opportunities. While offering substantial competitive advantages, it requires buyers to have access to expert knowledge and be prepared for a more complex implementation process.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of sic nedir | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics & Semiconductors | High-power electronic devices and power modules | Enhances thermal conductivity and electrical efficiency, improving device performance and lifespan | Quality of raw SiC crystals, purity levels, and supplier reliability, especially for demanding export markets |

| Automotive | Electric vehicle (EV) powertrain components | Enables higher efficiency and durability in inverters and converters, reducing energy loss and improving range | Compliance with automotive standards, scalability of supply, and cost competitiveness for global markets |

| Aerospace & Defense | High-temperature and high-voltage components | Provides superior thermal stability and mechanical strength under extreme conditions | Certification requirements, traceability, and adherence to international quality standards |

| Renewable Energy | Power electronics for solar inverters and wind turbines | Improves energy conversion efficiency and reliability in harsh environments | Long-term supply contracts, technical support, and regional logistics capabilities |

| Industrial Manufacturing | High-frequency, high-voltage switching devices | Increases operational efficiency and reduces downtime in heavy machinery and industrial automation | Customization options, technical specifications compliance, and after-sales service in international trade |

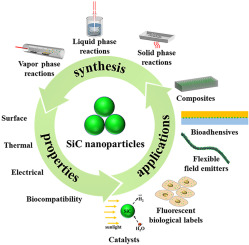

Silicon Carbide (SiC) is extensively used in the Electronics & Semiconductors industry for manufacturing high-power electronic devices such as power modules and diodes. Its superior thermal conductivity and electrical properties allow devices to operate at higher voltages and temperatures, thus enhancing performance and longevity. International buyers from Africa, South America, and Europe must prioritize sourcing SiC with high purity and consistent crystalline quality to meet stringent device requirements and ensure compatibility with global electronic standards.

In the Automotive sector, particularly in electric vehicles (EVs), SiC components are critical in powertrain systems including inverters and converters. These components benefit from SiC’s ability to reduce energy loss and heat generation, thereby extending EV driving range and improving efficiency. Buyers should focus on suppliers who comply with automotive industry certifications and can scale production to meet growing EV demand in regions like Europe and the Middle East.

For Aerospace & Defense, SiC is valued for its exceptional thermal stability and mechanical strength under extreme environmental conditions. It is used in high-temperature and high-voltage components that demand reliability and durability. Sourcing considerations for international B2B buyers include rigorous certification processes, component traceability, and adherence to international defense quality standards, which are crucial for maintaining operational integrity in aerospace applications.

In the Renewable Energy industry, SiC is applied in power electronics for solar inverters and wind turbine controllers. Its use enhances energy conversion efficiency and system reliability, especially in harsh outdoor environments. Buyers in Africa and South America should evaluate suppliers based on their ability to provide long-term supply agreements, technical support, and efficient logistics to ensure uninterrupted operation of renewable energy installations.

Lastly, Industrial Manufacturing leverages SiC in high-frequency, high-voltage switching devices used in heavy machinery and automation systems. SiC’s robustness improves operational efficiency and reduces downtime, a significant advantage in manufacturing environments. For international buyers, customization capabilities, strict adherence to technical specifications, and comprehensive after-sales service are vital to successfully integrating SiC components into industrial processes across diverse markets.

Related Video: LABORATORY APPARATUS AND THEIR USES

Key Properties: Silicon carbide is renowned for its exceptional hardness, high thermal conductivity, and outstanding resistance to thermal shock. It can withstand temperatures exceeding 1600°C and offers excellent chemical inertness, especially against acids and alkalis.

Pros & Cons: SiC ceramics provide superior wear resistance and mechanical strength, making them ideal for harsh environments. However, their brittleness can pose challenges during manufacturing and handling. The production cost is relatively high due to complex sintering processes.

Impact on Application: SiC is highly suitable for applications involving abrasive slurries, high-temperature gas flows, and corrosive media. Its stability under extreme conditions ensures longevity and reliability in pumps, valves, and seals.

International B2B Considerations: Buyers from Africa, South America, the Middle East, and Europe should verify compliance with international standards such as ASTM C799 and ISO 9001 for quality assurance. European markets, including Spain, often demand RoHS and REACH compliance. Additionally, availability of local suppliers or distributors can affect lead times and logistics costs.

Key Properties: RSiC is produced by recrystallizing silicon carbide powder, resulting in a material with improved toughness and thermal shock resistance compared to standard SiC. It maintains excellent corrosion resistance and can operate at temperatures up to 1400°C.

Pros & Cons: RSiC offers a good balance between mechanical strength and thermal stability, with lower brittleness than pure SiC. Its manufacturing process is less complex than sintered SiC, reducing costs slightly. However, it still commands a premium price relative to traditional ceramics.

Impact on Application: Ideal for pumps and mechanical seals in chemical processing industries, RSiC performs well with aggressive chemicals and abrasive fluids. Its enhanced toughness reduces failure rates in dynamic applications.

International B2B Considerations: For buyers in emerging markets like Africa and South America, sourcing RSiC may require partnering with specialized suppliers in Europe or Asia. Ensuring conformity to DIN EN 60672 or ASTM standards can facilitate smoother import/export processes. Middle Eastern buyers should also consider material certification for compliance with local petrochemical industry regulations.

Key Properties: RBSC is manufactured by infiltrating porous silicon carbide with molten silicon, creating a composite material with good thermal conductivity and moderate mechanical strength. It withstands temperatures up to 1300°C and exhibits good corrosion resistance.

Pros & Cons: RBSC is more cost-effective than sintered SiC and RSiC, with easier machinability. However, it has lower strength and toughness, limiting its use in highly abrasive or high-pressure environments.

Impact on Application: Suitable for less demanding applications such as furnace components, heat exchangers, and some chemical processing parts where moderate corrosion resistance suffices. Its machinability allows for complex shapes and custom designs.

International B2B Considerations: Buyers from regions with budget constraints, like parts of Africa and South America, may prefer RBSC for cost-sensitive projects. However, they must assess application requirements carefully to avoid premature failure. Compliance with ASTM C799 and ISO 9001 is recommended to ensure material consistency.

Key Properties: SiC whisker reinforced ceramics incorporate microscopic SiC fibers to improve toughness and fracture resistance. This composite material retains excellent thermal stability and chemical resistance, withstanding temperatures up to 1600°C.

Pros & Cons: The whisker reinforcement significantly enhances mechanical properties, making SiCw suitable for highly stressed components. Manufacturing complexity and cost are higher due to the reinforcement process. Additionally, handling requires safety precautions due to whisker inhalation risks.

Impact on Application: SiCw is preferred in advanced industrial applications such as aerospace, automotive, and high-performance chemical reactors where durability under stress is critical.

International B2B Considerations: European and Middle Eastern buyers often require detailed material safety data sheets (MSDS) and compliance with occupational health standards. For African and South American markets, the higher cost may restrict use to specialized sectors. Verification against ASTM C1424 and ISO 22196 standards can assure quality and performance.

| Material | Typical Use Case for sic nedir | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) Ceramics | High-temperature seals, pumps, abrasive environments | Exceptional hardness and thermal shock resistance | Brittle, high manufacturing complexity | High |

| Silicon Carbide Recrystallized (RSiC) | Chemical processing seals and components | Improved toughness and thermal stability | Premium price, limited local availability | High |

| Silicon Carbide Reaction Bonded (RBSC) | Furnace parts, heat exchangers, moderate corrosion | Cost-effective, easy to machine | Lower strength and toughness | Medium |

| Silicon Carbide Whisker Reinforced (SiCw) | Aerospace, automotive, high-stress chemical reactors | Enhanced fracture resistance and durability | High cost, complex manufacturing, safety concerns | High |

The manufacturing of sic nedir involves a series of well-defined stages designed to ensure product integrity, performance, and compliance with international standards. Understanding these stages helps B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe make informed sourcing decisions.

Material selection and preparation form the foundation of the manufacturing process. High-quality raw materials are sourced, often including specialized composites or metals depending on the exact nature of sic nedir. Raw materials undergo:

This stage is critical as it directly impacts the durability and functionality of the final product.

The core manufacturing of sic nedir typically involves advanced forming techniques tailored to the product’s application:

These methods ensure that the product meets strict specifications required by industrial applications.

Post-forming, components of sic nedir are assembled using automated or manual processes. This stage often involves:

Proper assembly is vital for product reliability and longevity, especially for B2B applications demanding high performance.

Final finishing enhances product quality and market readiness:

Attention to finishing details reflects a supplier’s commitment to quality and customer satisfaction.

Robust QA/QC frameworks are indispensable for maintaining consistent product quality and regulatory compliance. International B2B buyers should be familiar with the standards and practices that suppliers implement.

Suppliers with multiple certifications demonstrate a higher level of quality commitment and easier market entry.

B2B buyers should request detailed QC reports from each checkpoint to assess supplier reliability.

These tests confirm that the product meets technical and safety specifications essential for industrial applications.

For international buyers, especially those operating across continents, verifying supplier QC capabilities is critical to mitigate risks and ensure product conformity.

Illustrative Image (Source: Google Search)

Buyers should prepare detailed audit checklists tailored to their product requirements and industry standards.

Thorough documentation review helps in assessing supplier transparency and process control.

This approach provides an unbiased quality assessment, reducing the risk of receiving substandard products.

Understanding regional differences in quality expectations and certification requirements is essential for smooth international procurement.

B2B buyers should collaborate with suppliers early to clarify certification needs and QC documentation to avoid costly delays or compliance issues.

By thoroughly understanding the manufacturing and quality assurance landscape of sic nedir, international B2B buyers can secure reliable, high-quality products tailored to their market needs.

Understanding the cost and pricing dynamics of sourcing sic nedir products is essential for international B2B buyers aiming to optimize procurement budgets and secure competitive advantages. The pricing structure is multifaceted, influenced by several key cost components and external factors. This analysis breaks down these elements and offers practical buyer strategies for markets across Africa, South America, the Middle East, and Europe, including Spain and Australia.

Buyers from diverse regions should be mindful of varying import duties, local taxes, and customs procedures that influence landed costs differently across countries. For instance, European buyers, including Spain, often face stringent certification requirements, while African and South American buyers may prioritize suppliers offering flexible payment terms or consignment stock options. Australian buyers typically value suppliers with robust environmental and sustainability credentials, which can affect pricing.

Disclaimer: Pricing for sic nedir products can vary widely depending on supplier, order specifics, and market conditions. The insights provided here are indicative and intended to guide informed decision-making rather than represent fixed price points.

By comprehensively understanding these cost drivers and pricing influences, international B2B buyers can strategically source sic nedir products with enhanced cost-efficiency, risk management, and supplier collaboration.

Understanding the essential technical properties of sic nedir is crucial for international buyers to ensure product suitability, quality consistency, and compliance with their industry standards.

Material Composition/Grade

This defines the chemical and physical makeup of sic nedir. Material grade affects durability, performance, and compatibility with other materials in your supply chain. For B2B buyers, specifying the correct grade ensures the product meets operational requirements and regulatory standards across different regions like Africa, South America, or Europe.

Dimensional Tolerance

Tolerance indicates the acceptable deviation in size or measurements from the specified standard. Precise tolerances are vital in industries where sic nedir components must fit or function with high accuracy. Buyers should negotiate tolerance levels based on their application to minimize waste and avoid costly adjustments.

Thermal Stability

This property measures the ability of sic nedir to maintain performance under varying temperature conditions. For buyers in regions with extreme climates or in industries involving heat exposure, understanding thermal stability helps in selecting the right variant that won’t degrade or deform during use or transport.

Surface Finish and Coating

The surface quality, including texture and protective coatings, affects corrosion resistance, friction, and aesthetic appeal. Buyers aiming for long-term durability or specific functional requirements (e.g., electrical insulation, chemical resistance) must clarify surface finish standards with suppliers.

Mechanical Strength

This includes tensile strength, hardness, and impact resistance. Knowing these metrics allows buyers to assess whether sic nedir can withstand operational stresses. This is particularly important for applications in heavy industries or infrastructure projects common in emerging markets and developed economies alike.

Compliance and Certification

Certifications such as ISO, ASTM, or regional standards verify that sic nedir meets internationally recognized quality and safety benchmarks. For cross-border trade, buyers should insist on documented compliance to facilitate customs clearance and reduce liability risks.

Familiarity with industry jargon and trade terms empowers buyers to negotiate effectively, streamline procurement, and avoid misunderstandings.

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or products used in another company’s end product. Buyers working with OEMs often receive customized sic nedir tailored to specific machinery or systems, ensuring compatibility and quality.

MOQ (Minimum Order Quantity)

This is the smallest amount of sic nedir a supplier is willing to sell. Understanding MOQ helps buyers plan inventory, manage costs, and negotiate better terms, especially important for SMEs or buyers entering new markets.

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, delivery times, and terms for sic nedir. Crafting clear RFQs reduces back-and-forth communication and accelerates decision-making in international procurement.

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) that define the responsibilities of buyers and sellers for shipping, insurance, and customs clearance. Choosing the right Incoterm is critical for cost control and risk management across different regions.

Lead Time

The total time from placing an order for sic nedir to receiving it. Lead times impact production schedules and inventory planning; buyers should verify realistic lead times to avoid delays in supply chains.

Batch Number / Lot Number

Identification codes assigned to production batches of sic nedir to track quality and traceability. This is essential for quality control, warranty claims, and compliance with import regulations in various markets.

By mastering these technical properties and trade terms, international buyers from Africa, South America, the Middle East, and Europe can optimize their procurement strategies, enhance supplier communication, and secure better terms in the competitive global marketplace for sic nedir.

The sic nedir sector is experiencing transformative growth driven by global digitalization, evolving buyer expectations, and increasing cross-border trade. For B2B buyers across Africa, South America, the Middle East, and Europe—including markets like Spain and Australia—understanding these dynamics is essential for competitive sourcing and supply chain optimization.

Key market drivers include the rapid adoption of advanced technologies such as AI-powered analytics, blockchain for transparent transactions, and IoT-enabled supply chain monitoring. These innovations are enabling buyers to enhance procurement efficiency, reduce costs, and improve decision-making accuracy. Additionally, regional economic shifts, such as Africa's expanding industrial base and South America's resource diversification, present unique sourcing opportunities and challenges.

Emerging trends emphasize localized sourcing strategies combined with global supplier networks to mitigate geopolitical risks and supply disruptions. For instance, Middle Eastern buyers are increasingly integrating nearshoring options to balance cost and speed, while European buyers focus on supplier diversification to comply with stringent regulatory frameworks. Another notable trend is the rise of digital marketplaces and platforms facilitating real-time supplier discovery, contract management, and compliance verification, streamlining international transactions.

Moreover, data-driven procurement is becoming standard, with businesses leveraging predictive analytics to anticipate demand fluctuations and optimize inventory. This trend is particularly relevant for sectors reliant on sic nedir products, where timing and quality consistency are critical. Buyers should prioritize partners who demonstrate agility, robust digital capabilities, and a commitment to continuous innovation.

Sustainability has evolved from a niche consideration to a core pillar in the sic nedir sector’s supply chain strategies. Environmental impact—from raw material extraction to manufacturing and logistics—is under increasing scrutiny, particularly in Europe and Australia where regulatory frameworks demand transparent, responsible sourcing.

International B2B buyers are now prioritizing ethical supply chains that ensure fair labor practices, reduced carbon footprints, and minimal ecological disruption. This shift is fueled by rising consumer and stakeholder awareness, compelling suppliers to adopt green certifications such as ISO 14001 (Environmental Management) and certifications related to sustainable materials use.

In the context of sic nedir, buyers should seek suppliers who utilize renewable resources, implement waste reduction programs, and engage in circular economy practices. For example, sourcing from suppliers who optimize energy consumption and minimize water use in production processes can significantly reduce environmental impact. Transparency tools like blockchain also enable traceability of sustainability claims, reinforcing buyer confidence.

Furthermore, ethical sourcing extends beyond environmental concerns to include social responsibility—ensuring safe working conditions and supporting local communities. Buyers in Africa and South America, regions often rich in natural resources but vulnerable to exploitative practices, can leverage sustainability commitments to foster long-term partnerships that align with global ESG (Environmental, Social, Governance) standards.

The sic nedir sector has evolved substantially over the past two decades, transitioning from traditional, often fragmented supply chains to highly integrated global networks. Initially centered around localized production and manual sourcing methods, the sector embraced digital transformation early in the 2010s, enabling real-time communication and streamlined procurement processes.

Historically, the sector’s growth was propelled by increased globalization and the rise of emerging markets, which expanded supplier bases and diversified sourcing options. Over time, heightened regulatory environments, especially in Europe, introduced rigorous quality and sustainability standards, reshaping procurement priorities.

Today, the sector stands at the intersection of technology-driven innovation and sustainability imperatives, with buyers and suppliers collaborating more closely than ever to meet complex, evolving market demands. This historical progression underscores the importance of adaptability and strategic foresight for international B2B buyers navigating the sic nedir landscape.

How can I effectively vet suppliers of sic nedir to ensure reliability and quality?

Vetting suppliers involves a multi-step approach: start by verifying their business licenses and certifications relevant to sic nedir production. Request references and check previous client feedback, especially from international buyers. Conduct factory audits or use third-party inspection services to assess production capabilities and quality control processes. Evaluate their responsiveness and transparency during initial communications. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers with experience exporting to these regions to ensure smoother logistics and cultural alignment.

Is customization of sic nedir possible, and how should I approach this with suppliers?

Many suppliers offer customization options including formulation adjustments, packaging, and labeling to meet specific market requirements. Clearly communicate your technical specifications, regulatory needs, and target market preferences upfront. Request samples of customized products before finalizing orders. Negotiate minimum order quantities (MOQs) for customized batches as they may differ from standard products. Ensure that any customization agreements are documented in contracts to avoid misunderstandings.

Illustrative Image (Source: Google Search)

What are typical minimum order quantities (MOQs) and lead times for sic nedir in international B2B trade?

MOQs vary widely depending on the supplier’s scale and product type but typically range from several hundred to a few thousand units. Lead times depend on order size, customization, and production schedules, usually spanning 4 to 12 weeks. Buyers should clarify MOQs and lead times early in negotiations and plan procurement cycles accordingly. For regions with longer shipping times like Africa and South America, factor in additional transit and customs clearance durations to avoid stockouts.

What payment terms are commonly accepted by sic nedir suppliers internationally, and how can I mitigate payment risks?

Common payment terms include letters of credit (L/C), telegraphic transfers (T/T), and escrow services. Letters of credit offer strong protection by ensuring payment only after delivery compliance. For new suppliers, use smaller initial payments or escrow to mitigate risk. Negotiate payment schedules that balance cash flow and supplier trust, such as 30% upfront and 70% after inspection. Always confirm payment methods accepted for your region, as some suppliers may have restrictions or preferences based on geography.

What quality assurance and certifications should I require from sic nedir suppliers?

Request suppliers’ quality management certifications such as ISO 9001 or industry-specific standards relevant to sic nedir. Certifications related to safety, environmental compliance, and product-specific quality (e.g., GMP, CE marking) are valuable indicators. Ask for third-party lab test reports and sample batch analysis results. Implement incoming inspection protocols and consider periodic third-party audits to maintain consistent quality, especially when dealing with remote international suppliers.

How should I plan logistics and shipping for sic nedir to regions like Africa, South America, the Middle East, and Europe?

Choose suppliers experienced in exporting to your target region to leverage their knowledge of customs, tariffs, and shipping routes. Decide between air freight for speed or sea freight for cost-efficiency based on urgency and volume. Ensure all shipping documentation (commercial invoice, packing list, certificates of origin) is complete and accurate to prevent customs delays. Collaborate with reliable freight forwarders familiar with your destination’s import regulations. Consider insurance to protect against transit risks.

What strategies can help resolve disputes or quality issues with sic nedir suppliers?

Establish clear contract terms covering product specifications, delivery schedules, and dispute resolution mechanisms, such as arbitration clauses specifying jurisdiction. Maintain detailed documentation of all communications and transactions. If quality issues arise, promptly notify the supplier with evidence such as photos or third-party inspection reports. Negotiate corrective actions like replacement shipments or refunds. For persistent issues, leverage trade associations or international mediation services specialized in cross-border B2B conflicts.

How can I ensure compliance with local regulations when importing sic nedir?

Research import regulations, product standards, and labeling requirements in your country before placing orders. Work with suppliers who understand these regulations and can provide compliant documentation. Engage local customs brokers or legal advisors to navigate complex regulatory environments, especially in Africa and the Middle East where rules can vary significantly. Staying informed about changes in trade policies or tariffs helps avoid costly delays or penalties. Prioritize suppliers with experience in regulatory compliance to streamline market entry.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of sic nedir offers international B2B buyers a competitive edge by optimizing supplier relationships, enhancing cost efficiencies, and ensuring compliance with evolving market standards. Understanding the nuances of this product category enables buyers from Africa, South America, the Middle East, and Europe to tailor procurement strategies that align with regional demands and regulatory frameworks.

Illustrative Image (Source: Google Search)

Key takeaways include the importance of thorough supplier evaluation, leveraging digital tools for transparent sourcing, and fostering sustainable partnerships that support long-term value creation. Emphasizing data-driven decision-making and cross-border collaboration will help mitigate risks associated with supply chain disruptions and quality inconsistencies.

Looking ahead, the strategic sourcing landscape for sic nedir will increasingly integrate innovation and sustainability, driven by global market trends and technological advancements. International buyers are encouraged to proactively engage with trusted suppliers, invest in continuous market intelligence, and embrace agile sourcing models to stay ahead. By doing so, they will not only secure superior procurement outcomes but also contribute to resilient and responsible supply chains worldwide.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina