In today’s interconnected economy, sourcing sic properties efficiently and reliably is a critical success factor for businesses operating across Africa, South America, the Middle East, and Europe. These specialized materials and components underpin numerous industrial applications, making their quality, availability, and cost pivotal to maintaining competitive advantage and operational excellence. For international B2B buyers, navigating the complexities of global sic properties markets requires not only a deep understanding of product specifications but also insights into manufacturing standards, supplier landscapes, and regional market dynamics.

This comprehensive guide is designed to empower procurement professionals and decision-makers by delivering a detailed roadmap to sourcing sic properties with confidence. It covers the full spectrum of essential topics: from the various types and grades of sic properties available, to the critical materials science behind their performance; from manufacturing processes and quality control protocols to identifying trustworthy suppliers and evaluating cost structures. Special attention is given to market trends and regional considerations relevant to buyers in key territories such as the UAE and Brazil, ensuring the guide’s practical relevance and strategic value.

By leveraging this knowledge, international buyers will be equipped to make informed sourcing decisions that optimize product quality, reduce supply chain risks, and enhance overall value. Whether entering new markets or consolidating existing supplier networks, this guide serves as an authoritative resource to streamline procurement processes and drive sustainable growth in the competitive global landscape of sic properties.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Residential SIC | Primarily residential zoning with limited commercial use | Housing developments, mixed-use projects | Pros: Stable demand, community appeal; Cons: Limited commercial flexibility |

| Commercial SIC | Zoned for retail, office, and service industries | Retail centers, office parks, service hubs | Pros: High revenue potential; Cons: Higher investment, zoning complexity |

| Industrial SIC | Designated for manufacturing, warehousing, and heavy industry | Factories, logistics centers, production plants | Pros: Supports large-scale operations; Cons: Environmental regulations, location constraints |

| Agricultural SIC | Land used for farming, livestock, and related activities | Agribusiness, food processing units | Pros: Essential for food supply chains; Cons: Seasonal variability, land use restrictions |

| Mixed-Use SIC | Combines residential, commercial, and sometimes industrial uses | Urban development, smart city projects | Pros: Maximizes land use, diversified income; Cons: Complex planning, regulatory hurdles |

Residential SIC properties are primarily zoned for housing and often include provisions for limited commercial activities such as local shops or community services. These properties are ideal for developers targeting residential communities or mixed-use developments with a focus on living spaces. For B2B buyers, especially in growing urban areas of Africa and South America, residential SIC offers stable demand due to increasing housing needs. Key considerations include local zoning laws, infrastructure availability, and demographic trends to ensure sustainable investment.

Commercial SIC properties cater to retail, office, and service-based businesses, making them suitable for companies looking to establish retail centers, office parks, or business hubs. These properties typically command higher rental yields but require careful assessment of location accessibility and market demand. For buyers in regions like the UAE and Europe, where commercial real estate markets are competitive, understanding local economic conditions and consumer behavior is crucial to maximizing returns.

Industrial SIC properties are designated for manufacturing, warehousing, and heavy industry operations. These sites are essential for businesses involved in production, logistics, and distribution. Key B2B purchasing considerations include proximity to transportation networks, compliance with environmental regulations, and availability of utilities. Buyers in emerging markets such as Africa or Brazil must also evaluate infrastructure readiness and potential for future industrial expansion to mitigate operational risks.

Agricultural SIC properties are intended for farming, livestock, and related agribusiness activities. These lands are fundamental to food production and supply chains, making them attractive for agribusiness investors and companies in food processing. However, buyers should account for seasonal variations, soil quality, water availability, and land use restrictions. In regions like South America and parts of Africa, agricultural SIC investments can benefit from government incentives but require thorough due diligence on local agricultural policies.

Mixed-Use SIC properties integrate residential, commercial, and sometimes industrial uses within a single development. This type is increasingly popular in urban planning, supporting smart city initiatives and maximizing land efficiency. For B2B buyers, mixed-use SIC offers diversified income streams and resilience against market fluctuations. However, these projects demand complex planning, coordination with multiple stakeholders, and adherence to stringent regulatory frameworks, particularly in developed markets like Europe and the Middle East.

Related Video: Silicon Carbide Explained - SiC Basics

| Industry/Sector | Specific Application of SiC Properties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | High-efficiency power semiconductor devices | Enables higher power density and energy savings | Quality certifications, thermal performance, supplier reliability |

| Automotive | Electric vehicle (EV) powertrain components | Improves efficiency, reduces weight, and enhances thermal management | Compliance with automotive standards, durability, and scalability |

| Renewable Energy | Solar inverters and wind turbine power converters | Increases conversion efficiency and operational lifespan | Long-term supply stability, product customization, and cost-effectiveness |

| Industrial Machinery | High-temperature, high-voltage components for heavy equipment | Enhances reliability under harsh conditions, reduces downtime | Material purity, performance testing, and after-sales technical support |

| Aerospace & Defense | High-performance electronic devices for avionics and radar | Provides superior thermal conductivity and robustness | Compliance with aerospace standards, traceability, and delivery precision |

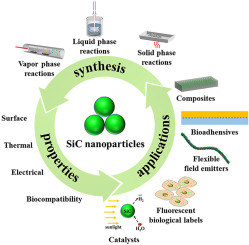

Silicon carbide (SiC) is transforming power electronics by enabling devices that operate at higher voltages, frequencies, and temperatures compared to traditional silicon-based components. This leads to more compact, efficient power converters and inverters critical for industries worldwide. For B2B buyers in regions like Africa and South America, sourcing SiC components with robust quality certifications ensures compatibility with local grid standards and maximizes energy efficiency, which is essential for power infrastructure projects.

In the automotive sector, SiC’s superior thermal conductivity and electrical properties are crucial for electric vehicle (EV) powertrains. SiC-based semiconductors help reduce energy loss and improve battery range, a key selling point in markets like the UAE and Brazil where EV adoption is growing rapidly. Buyers must prioritize suppliers who can meet stringent automotive quality standards (such as IATF 16949) and offer scalable production to support expanding EV manufacturing.

Renewable energy systems rely heavily on SiC for solar inverters and wind turbine converters due to its ability to handle high voltages and temperatures efficiently. This results in higher conversion efficiency and longer operational life, reducing maintenance costs. For international buyers, particularly in Europe and the Middle East, ensuring supplier reliability and the availability of customized solutions tailored to local climate conditions is critical for successful renewable energy deployments.

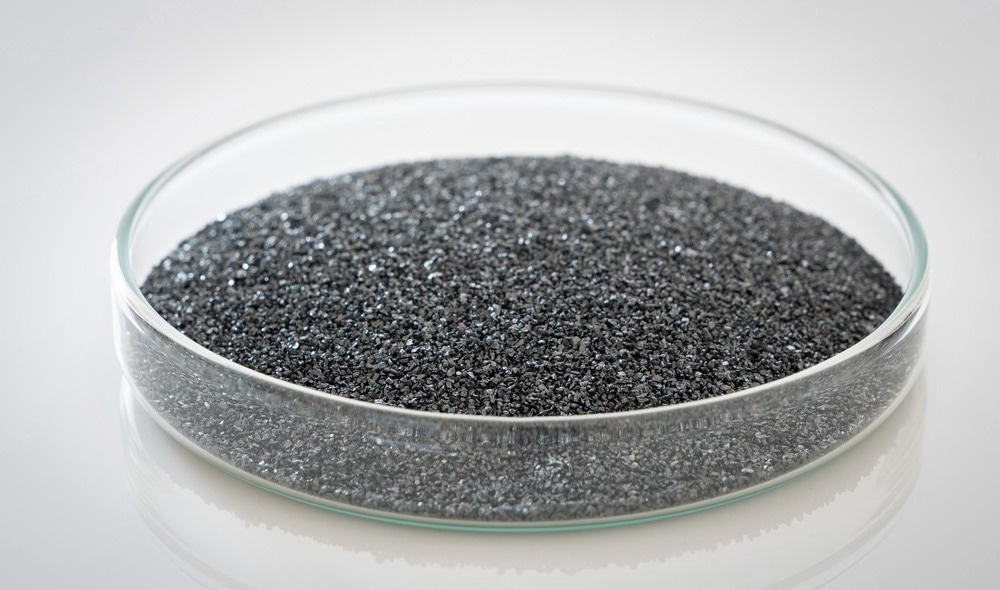

Illustrative Image (Source: Google Search)

Heavy industrial machinery benefits from SiC’s resilience in high-temperature and high-voltage environments. Components made from SiC improve system reliability and reduce downtime by withstanding harsh operating conditions. Buyers from Africa and South America should focus on material purity and rigorous performance testing when sourcing SiC components to guarantee durability and minimize costly disruptions in mining or manufacturing operations.

SiC’s robustness and excellent thermal management make it ideal for high-performance electronics in aerospace and defense applications, including avionics and radar systems. International B2B buyers must ensure suppliers comply with aerospace industry standards (e.g., AS9100) and provide full traceability of materials to meet stringent safety and reliability requirements. Precision in delivery schedules is also critical to align with complex project timelines in this sector.

Key Properties: Silicon carbide ceramics exhibit exceptional hardness, high thermal conductivity, and outstanding resistance to thermal shock and wear. They typically withstand temperatures up to 1600°C and pressures exceeding 100 MPa, with excellent chemical inertness against acids and alkalis.

Pros & Cons: SiC ceramics offer superior durability and corrosion resistance, making them ideal for harsh environments. However, manufacturing complexity is high due to the need for precise sintering processes, which can increase lead times and costs. The material’s brittleness requires careful handling during fabrication and assembly.

Impact on Application: SiC ceramics are widely used in high-temperature filtration, mechanical seals, and pump components exposed to abrasive or corrosive fluids. Their resistance to chemical attack makes them suitable for aggressive media like acids prevalent in mining and chemical industries across Africa and South America.

International B2B Considerations: Buyers in regions like the UAE and Brazil must ensure compliance with ASTM C799 or DIN EN 60672 standards for ceramic materials. Local manufacturing capabilities may be limited, so sourcing from established suppliers with proven quality certifications (ISO 9001, ISO 14001) is critical. Import regulations and tariffs in these regions also influence cost-effectiveness.

Key Properties: SiC composites combine the high strength and thermal stability of silicon carbide with enhanced toughness due to fiber reinforcement. They maintain performance at temperatures above 1400°C and show improved fracture resistance compared to monolithic ceramics.

Pros & Cons: These composites provide excellent mechanical properties and reduced brittleness, enabling use in dynamic or impact-prone applications. The downside is higher production complexity and cost, as fiber alignment and bonding require advanced manufacturing techniques.

Impact on Application: Ideal for aerospace, automotive, and power generation sectors where high strength-to-weight ratios and thermal stability are crucial. They perform well under cyclic thermal and mechanical loads, common in European and Middle Eastern industrial applications.

International B2B Considerations: Compliance with JIS R 1601 or ASTM C1275 standards is often required in Japan and Europe, influencing procurement decisions. Buyers in Africa and South America should evaluate supplier capabilities in composite fabrication and consider lead times for custom orders. Regional preferences may favor composites for high-performance applications despite the higher cost.

Key Properties: SiC coatings provide a thin, dense layer of silicon carbide on substrates, offering enhanced surface hardness, chemical resistance, and thermal stability. Coatings typically withstand temperatures up to 1200°C and improve substrate durability without significant weight increase.

Pros & Cons: Coatings are cost-effective compared to bulk ceramics and allow existing metal parts to gain SiC properties. However, coating adhesion and uniformity can be challenging, and the protective layer may wear off under extreme mechanical stress.

Impact on Application: Widely used in chemical reactors, heat exchangers, and semiconductor manufacturing equipment where surface corrosion and wear resistance are critical. Suitable for environments with moderate mechanical load but aggressive chemical exposure.

International B2B Considerations: Buyers from the Middle East and Europe should verify coating standards such as ASTM B487 and ensure compatibility with local environmental regulations. Coating suppliers with strong R&D capabilities are preferred for customized solutions. In regions like Brazil, availability of coating services may be limited, necessitating international sourcing.

Key Properties: SiC powders are raw materials for manufacturing ceramics, composites, and coatings. They vary in particle size and purity, affecting sintering behavior and final product properties. High-purity powders (>99%) are essential for electronic-grade applications.

Pros & Cons: Powders offer flexibility for custom material formulations and are generally lower cost than finished SiC products. However, handling fine powders requires strict safety and environmental controls, and inconsistent quality can impact end-product performance.

Impact on Application: Used extensively in abrasive media, refractory linings, and electronic substrates. Powder quality directly influences mechanical strength and thermal conductivity of finished SiC components.

International B2B Considerations: Buyers in Africa and South America must assess supplier quality certifications and import logistics for powders, which may be subject to hazardous material regulations. European and Middle Eastern buyers often require compliance with ISO 9001 and REACH standards for chemical safety.

| Material | Typical Use Case for sic properties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide Ceramics | High-temperature, corrosion-resistant components | Exceptional hardness and chemical resistance | Brittle, complex manufacturing | High |

| Silicon Carbide Composites | Aerospace, automotive, power generation parts | High strength-to-weight ratio and toughness | Higher production complexity and cost | High |

| Silicon Carbide Coatings | Surface protection in chemical reactors and exchangers | Cost-effective enhancement of substrate durability | Coating adhesion issues under mechanical stress | Medium |

| Silicon Carbide Powders | Raw material for ceramics, abrasives, electronics | Flexibility in custom formulations | Requires strict handling and quality control | Low |

Silicon carbide (SiC) properties are critical in industries requiring high durability, thermal stability, and electrical performance. For B2B buyers evaluating suppliers, understanding the typical manufacturing stages and techniques is essential to ensure product reliability and performance.

The initial phase involves sourcing high-purity raw materials, primarily silicon and carbon sources. These are combined through a carbothermal reduction process at elevated temperatures (typically 2,000°C or higher) to synthesize SiC powder. Key considerations include:

Once the SiC powder is ready, the material undergoes shaping through methods such as:

Each technique impacts the microstructure and mechanical properties of the final product.

Post-forming, components may be assembled if multi-part structures are needed. Sintering follows, where parts are heated below melting points in controlled atmospheres to:

Advanced sintering methods include pressure-assisted sintering or spark plasma sintering, delivering superior material properties.

Finishing ensures dimensional accuracy and surface quality, involving:

Robust quality assurance (QA) and quality control (QC) frameworks are indispensable for maintaining consistent SiC product quality, especially for international B2B transactions.

Buyers should verify that suppliers maintain certifications relevant to their industry and regional market requirements.

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier QC is vital to mitigate risks associated with import quality and compliance.

Demanding transparent documentation builds trust and facilitates smoother customs clearance.

Engaging independent inspection agencies can provide unbiased verification of product quality and compliance before shipment. This is particularly recommended for:

Clear communication about QC requirements is critical. Buyers should specify standards, testing frequencies, and acceptance criteria in contracts and purchase orders. Providing translated documentation may reduce misunderstandings.

Illustrative Image (Source: Google Search)

Quality can be compromised during transit, especially for fragile SiC components. Buyers should confirm that suppliers implement adequate packaging and handling protocols, with QC checks post-delivery when possible.

Summary for B2B Buyers:

Understanding the comprehensive manufacturing stages and rigorous quality control protocols for SiC properties empowers buyers to select reliable suppliers. Prioritizing internationally recognized certifications, conducting supplier audits, and leveraging third-party inspections are effective strategies to mitigate risk and ensure product performance. Tailoring QC verification to regional regulatory nuances further enhances procurement success across diverse global markets.

When sourcing sic properties, it is critical for international B2B buyers to dissect the cost structure carefully to optimize procurement strategies and negotiate effectively. The primary cost components include:

Several factors directly influence the final price of sic properties, which buyers must consider during sourcing:

For B2B buyers from Africa, South America, the Middle East, and Europe, navigating the pricing landscape of sic properties requires strategic approaches:

Prices for sic properties are indicative and can vary widely based on market dynamics, supplier capabilities, and specific buyer requirements. It is advisable to obtain multiple quotes and conduct thorough due diligence to ensure competitive and fair pricing aligned with quality expectations.

By thoroughly understanding these cost components and price influencers, international B2B buyers can make informed sourcing decisions, optimize procurement budgets, and establish resilient supply chains for sic properties.

When sourcing silicon carbide (SiC) properties, understanding the critical technical specifications is essential for ensuring product performance and compatibility with your industrial applications. Below are the most important properties to consider:

Material Grade

SiC comes in various grades depending on purity, crystalline structure, and intended use. High-purity grades (e.g., electronic or semiconductor-grade SiC) are crucial for applications requiring electrical insulation or thermal management, while lower grades suit abrasive or refractory uses. Selecting the right grade directly affects product quality and operational reliability.

Particle Size and Distribution

The size of SiC particles influences surface finish, sintering behavior, and mechanical strength. Uniform particle size distribution ensures consistent performance, especially in polishing, grinding, and additive manufacturing. Buyers should specify particle size ranges to meet their process requirements.

Density and Porosity

Density indicates the compactness of the SiC material, impacting thermal conductivity and mechanical strength. Low porosity is preferred for structural components to prevent weaknesses and enhance durability. These parameters are critical for applications in harsh environments like aerospace or automotive parts.

Tolerance and Dimensional Accuracy

Tolerance defines the allowable deviation in dimensions, which is vital for components that must fit precisely within assemblies. Tight tolerance levels minimize waste and rework, reducing overall production costs. Buyers should clarify tolerance requirements upfront to ensure supplier compliance.

Thermal Conductivity

SiC’s high thermal conductivity makes it ideal for heat dissipation applications. Knowing the exact thermal conductivity helps in designing cooling systems or electronic substrates. Buyers should request detailed thermal specs tailored to their operating temperatures.

Electrical Resistivity

This property determines SiC’s behavior as a semiconductor or insulator. Electrical resistivity varies by doping level and crystalline form, impacting performance in electronics or sensor applications. Understanding this helps buyers match materials with their electrical design needs.

Navigating international SiC procurement requires familiarity with key trade terms that define order processes, logistics, and contractual obligations. Here are terms every B2B buyer should know:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or components used in another company’s final product. Understanding OEM relationships helps buyers assess product origin, quality standards, and potential customization options.

MOQ (Minimum Order Quantity)

The smallest amount a supplier is willing to sell. MOQs impact inventory planning and cash flow, especially for buyers in emerging markets who may prefer smaller, more frequent orders to reduce risk.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting price and delivery details for specific SiC products. Crafting clear, detailed RFQs ensures accurate quotations and efficient supplier evaluation.

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities for shipping, insurance, and customs between buyers and sellers. Examples include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Correct use of Incoterms reduces misunderstandings and unexpected costs during cross-border transactions.

Lead Time

The period between order placement and delivery. Understanding lead times is crucial for production scheduling and inventory management, especially when sourcing from overseas suppliers.

Certificate of Analysis (CoA)

A document provided by the supplier detailing the chemical and physical properties of the SiC batch. CoAs are essential for quality assurance and regulatory compliance, providing buyers with confidence in product consistency.

By mastering these technical specifications and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can make informed decisions, optimize procurement strategies, and establish strong supplier partnerships in the SiC market. Clear communication on these points reduces risk, controls costs, and ensures that the purchased materials meet the exacting demands of your industry applications.

The global sic properties sector is experiencing dynamic growth, driven by increasing demand for innovative, efficient, and scalable solutions across industrial, commercial, and residential applications. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding regional market nuances and emerging trends is critical to making informed sourcing decisions.

Key market drivers include rapid urbanization, infrastructure development, and the digital transformation of supply chains. Countries like the UAE and Brazil are investing heavily in smart city projects and sustainable infrastructure, creating opportunities for sic properties that integrate advanced semiconductor technologies or smart materials. Buyers from these regions benefit from sourcing partners who can offer customized, scalable property solutions aligned with local regulatory frameworks and environmental standards.

Emerging sourcing trends highlight a shift toward digital procurement platforms and AI-driven supply chain analytics. These technologies enhance transparency, reduce lead times, and optimize cost structures. Additionally, modular and prefabricated sic property components are gaining traction, enabling faster deployment and lower installation costs. This is particularly relevant in regions where construction timelines are tight, such as in Middle Eastern real estate developments or rapidly expanding African urban centers.

International buyers should also be aware of geopolitical and trade considerations impacting supply chains. Tariffs, export controls, and regional trade agreements influence sourcing strategies, necessitating diversified supplier networks and localized inventory hubs. Partnering with suppliers who have a strong presence in target regions can mitigate risks and improve responsiveness.

Sustainability is no longer optional in the sic properties sector; it is a fundamental expectation for global B2B buyers. The environmental footprint of manufacturing, transporting, and installing sic property components is under intense scrutiny, prompting buyers to prioritize eco-friendly materials and sustainable supply chain practices.

Key environmental impacts include energy consumption during production, waste generation, and carbon emissions associated with logistics. To address these challenges, sourcing managers are increasingly seeking suppliers that offer green certifications, such as ISO 14001 for environmental management or LEED certification for building materials. Additionally, the use of recycled or bio-based materials in sic properties is gaining momentum, reducing reliance on virgin resources and lowering overall carbon footprints.

Ethical sourcing extends beyond environmental concerns to encompass labor practices, transparency, and corporate social responsibility. Buyers from regions with stringent regulatory environments, such as the EU, expect suppliers to comply with fair labor standards and provide full traceability of materials. This is particularly important for companies operating in emerging markets like Africa and South America, where supply chain risks can be higher.

By integrating sustainability criteria into procurement policies, international buyers not only mitigate risks but also enhance their brand reputation and align with global ESG (Environmental, Social, Governance) frameworks. Collaborating with suppliers committed to continuous improvement in sustainability can unlock long-term value and competitive advantage.

The sic properties sector has evolved significantly over the past few decades, transitioning from traditional construction materials to advanced, technology-infused components. Initially dominated by conventional manufacturing processes, the sector embraced digital innovation with the advent of Industry 4.0, integrating IoT sensors and smart materials to enhance property functionality.

Illustrative Image (Source: Google Search)

This evolution is particularly relevant for B2B buyers as it signals a shift from simple procurement to strategic sourcing of technologically sophisticated solutions. Early adopters in Europe and the Middle East paved the way for standards and certifications that now influence global sourcing practices. Meanwhile, emerging markets in Africa and South America are rapidly catching up by adopting modular and sustainable sic property solutions tailored to their unique infrastructural challenges.

Understanding this historical trajectory enables buyers to anticipate future trends, such as increased automation in manufacturing and the rise of circular economy models, ensuring their sourcing strategies remain resilient and forward-looking.

How can I effectively vet suppliers of sic properties to ensure reliability and compliance?

To vet suppliers, start by requesting detailed company profiles, including certifications, financial statements, and client references. Verify their compliance with international standards relevant to sic properties, such as ISO certifications or local regulatory approvals. Conduct virtual or in-person factory audits when possible, and use third-party inspection services to validate production capabilities. Engage in pilot orders to assess product quality and delivery reliability before scaling up. Prioritize suppliers with transparent communication and proven export experience, especially those familiar with regulations in Africa, South America, the Middle East, and Europe.

What customization options are typically available for sic properties, and how should I approach these requests?

Customization can range from material specifications, dimensions, and finishes to packaging and branding. Clearly outline your technical requirements and intended application early in discussions. Collaborate closely with suppliers to understand feasibility and cost implications, and request prototypes or samples to validate custom features. Ensure all customization agreements are documented in contracts, including lead times and quality standards. For international buyers, confirm that customizations comply with destination country regulations to avoid import issues.

What are the common minimum order quantities (MOQs) and lead times for sic properties, and how flexible are suppliers in these areas?

MOQs for sic properties vary by supplier and product complexity, often influenced by production batch sizes and raw material sourcing. Lead times typically range from 4 to 12 weeks, depending on customization and order volume. Many suppliers offer flexibility on MOQs for first-time buyers or trial orders but may charge a premium. Negotiate lead times by planning orders well in advance and considering seasonal demand fluctuations. For buyers in regions with longer shipping times, factor in transit duration when confirming delivery schedules.

Which payment terms are standard for international B2B transactions involving sic properties, and how can I mitigate financial risks?

Common payment terms include Letters of Credit (L/C), Telegraphic Transfers (T/T), and Escrow services. L/Cs provide strong security for both parties but can involve higher banking fees. T/T payments often require an upfront deposit (30-50%) with the balance upon shipment or delivery. To reduce risks, use escrow services or work with reputable trade finance institutions. Always ensure payment terms are clearly outlined in contracts, and verify supplier bank details independently to prevent fraud.

What quality assurance measures and certifications should I expect from suppliers of sic properties?

Suppliers should provide quality assurance documentation such as ISO 9001 certification, product-specific standards, and third-party inspection reports. Request samples for independent testing where possible. Confirm that suppliers have robust quality control processes throughout production, including raw material verification, in-process inspections, and final product testing. Certifications relevant to your market—such as CE marking for Europe or local regulatory approvals—are critical to ensure compliance and smooth customs clearance.

How can I optimize logistics for shipping sic properties internationally, especially to Africa, South America, the Middle East, and Europe?

Choose suppliers with experience exporting to your target regions and who offer multimodal shipping options (sea, air, road). Consolidate shipments to reduce freight costs and work with freight forwarders familiar with local customs regulations. Ensure all export documentation, including commercial invoices, packing lists, and certificates of origin, are accurate and complete. Consider Incoterms carefully to clarify responsibilities for shipping, insurance, and customs duties. Plan for potential delays in customs clearance and factor these into your delivery timelines.

What steps should I take if a dispute arises regarding product quality or delivery terms with a supplier?

Begin by communicating clearly and promptly with the supplier to seek an amicable resolution. Document all correspondence and keep records of contracts, specifications, and delivery notes. If the issue persists, use mediation or arbitration clauses specified in your contract to resolve disputes without litigation. Engage third-party inspection or certification bodies to provide unbiased assessments if needed. For international disputes, understand the governing law and jurisdiction agreed upon in contracts to streamline legal recourse.

Are there specific regulatory or import considerations I should be aware of when purchasing sic properties from different regions?

Yes, import regulations vary significantly across Africa, South America, the Middle East, and Europe. Familiarize yourself with product-specific restrictions, required certifications, tariffs, and customs duties in your country. Some regions require pre-import approvals or registration of suppliers and products. Engage customs brokers or trade consultants to navigate complex regulations and avoid shipment delays or penalties. Staying updated on changes in trade policies, such as sanctions or trade agreements, is essential to maintain compliance and optimize sourcing strategies.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic sourcing of sic properties presents a critical opportunity for international B2B buyers to enhance operational efficiency and secure competitive advantages in dynamic markets. By prioritizing a rigorous evaluation of suppliers, leveraging regional market insights, and embracing innovative procurement technologies, businesses from Africa, South America, the Middle East, and Europe can optimize cost structures while ensuring quality and compliance.

Key takeaways include the importance of building strong, transparent supplier relationships, conducting comprehensive risk assessments tailored to regional nuances, and adopting flexible sourcing strategies that accommodate market volatility. These elements not only mitigate supply chain disruptions but also foster long-term value creation.

Looking ahead, the evolving global landscape demands that buyers remain agile and informed, continuously integrating sustainability and digital transformation into their sourcing frameworks. International B2B buyers are encouraged to deepen market intelligence, invest in collaborative partnerships, and harness data-driven decision-making to navigate complexities effectively.

Embracing strategic sourcing for sic properties is not just a procurement choice but a forward-thinking business imperative—position your enterprise to thrive by acting decisively today.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina