In today's competitive landscape, sourcing high-quality silicium poudre can be a significant challenge for international B2B buyers, particularly those in emerging markets such as Africa, South America, the Middle East, and Europe. The demand for this versatile material is on the rise, driven by its applications across various industries, including electronics, construction, and health supplements. This guide offers a comprehensive overview of silicium poudre, covering its types, applications, and the key factors to consider when evaluating suppliers.

By delving into the nuances of sourcing silicium poudre, this resource empowers buyers to make informed purchasing decisions. It addresses critical questions about supplier vetting, cost implications, and market trends, equipping stakeholders with the insights needed to navigate the complexities of the global market effectively. Whether you are a procurement manager in Brazil seeking reliable suppliers or a business owner in the UAE looking to expand your product offerings, understanding the dynamics of silicium poudre is essential for achieving operational success.

Through this guide, you will gain the knowledge necessary to optimize your sourcing strategies and enhance your competitive edge in the ever-evolving B2B landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silica Gel | Amorphous form, highly porous, absorbs moisture | Desiccants, packaging, pharmaceuticals | Pros: Effective moisture control; Cons: Limited reusability. |

| Colloidal Silica | Fine particles dispersed in a liquid, high surface area | Coatings, adhesives, cosmetics | Pros: Enhances stability and thickness; Cons: Requires careful handling. |

| Fumed Silica | Produced from silicon tetrachloride, ultra-fine powder | Reinforcement in rubber and plastics | Pros: Improves mechanical properties; Cons: Can be costly. |

| Silicon Dioxide Powder | Naturally occurring, often used in food and supplements | Food additives, dietary supplements | Pros: Generally recognized as safe; Cons: Potential sourcing issues. |

| Silicate Minerals | Naturally occurring silicates, used in various industrial sectors | Construction, ceramics, glass manufacturing | Pros: Abundant and versatile; Cons: Quality can vary significantly. |

Silica Gel is an amorphous form of silicon dioxide that is highly porous, allowing it to absorb moisture effectively. It is widely used in packaging and pharmaceuticals as a desiccant to protect products from humidity. B2B buyers should consider its effectiveness in moisture control, particularly in humid climates, while being aware of its limited reusability after saturation.

Colloidal Silica consists of fine silica particles dispersed in a liquid, providing a high surface area that enhances stability in various applications. It is commonly used in coatings, adhesives, and cosmetics to improve texture and consistency. Buyers should evaluate its compatibility with their formulations and ensure proper handling to maintain its properties.

Fumed Silica is produced through the combustion of silicon tetrachloride and is known for its ultra-fine particle size. It is primarily used as a reinforcing agent in rubber and plastics, significantly improving their mechanical properties. While it offers substantial benefits, buyers should be mindful of its higher cost compared to other silica forms and assess the balance between performance and price.

Silicon Dioxide Powder, a naturally occurring form of silica, is commonly utilized as a food additive and in dietary supplements for its anti-caking properties. It is generally recognized as safe, making it an attractive option for food manufacturers. However, buyers need to consider potential sourcing issues, especially if they require high purity levels for specific applications.

Silicate Minerals are naturally occurring compounds that include various forms of silicates. They are utilized in construction, ceramics, and glass manufacturing due to their abundance and versatility. B2B buyers should assess the quality of the silicates they source, as the properties can vary widely depending on the mineral composition and processing methods.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of silicium poudre | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Semiconductor manufacturing | Enhances conductivity and efficiency of devices | Quality of purity, supplier certifications, and compliance with international standards |

| Construction | Production of concrete and cement | Improves durability and strength of building materials | Sourcing from reliable suppliers to ensure consistent quality and performance |

| Agriculture | Fertilizers and soil conditioners | Enhances soil health and crop yield | Availability of organic certifications and regional regulations compliance |

| Cosmetics | Formulations for skin and hair care products | Provides structural integrity and enhances product effectiveness | Sourcing from suppliers with proven safety and efficacy in cosmetic applications |

| Pharmaceuticals | Drug formulations and delivery systems | Improves bioavailability and stability of active ingredients | Compliance with pharmaceutical-grade standards and sourcing from certified facilities |

In the electronics sector, silicium poudre is critical for semiconductor manufacturing. It is used to create silicon wafers, which are foundational components in electronic devices. By enhancing conductivity, silicium poudre contributes to the efficiency and performance of devices such as smartphones and computers. International buyers, particularly from regions like Africa and South America, must ensure that the sourced silicium poudre meets stringent purity standards to avoid defects in electronic components.

Silicium poudre is increasingly used in the construction industry, particularly in the production of concrete and cement. Its addition enhances the durability and strength of building materials, making structures more resilient to environmental factors. Buyers in the Middle East and Europe should focus on sourcing high-quality silicium poudre from reputable suppliers, as the consistency of the material significantly affects the overall integrity of construction projects.

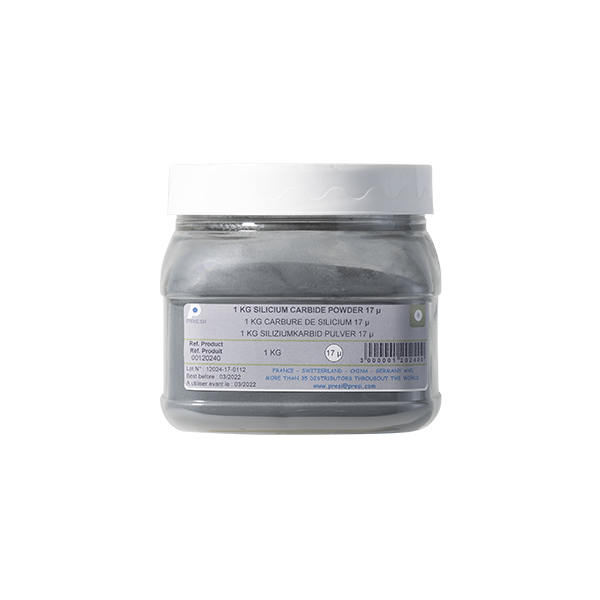

A stock image related to silicium poudre.

In agriculture, silicium poudre is utilized in fertilizers and soil conditioners. It plays a crucial role in improving soil health and increasing crop yields by enhancing nutrient availability and plant resilience against pests and diseases. Buyers, especially in regions like Africa and South America, should consider sourcing organic-certified silicium poudre to align with sustainable farming practices and meet local regulatory requirements.

Silicium poudre is an essential ingredient in the formulation of various cosmetic products, including skin and hair care items. It provides structural integrity and improves the effectiveness of these products. For B2B buyers in Europe and the Middle East, it is crucial to source silicium poudre from suppliers who can guarantee safety and efficacy in cosmetic applications, as well as compliance with regional cosmetic regulations.

In the pharmaceutical industry, silicium poudre is utilized in drug formulations and delivery systems. It enhances the bioavailability and stability of active ingredients, which is vital for the effectiveness of medications. Buyers from regions such as Brazil and the UAE should prioritize sourcing silicium poudre from certified facilities that comply with pharmaceutical-grade standards to ensure the highest quality in their formulations.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: International B2B buyers often face challenges with the quality consistency of silicium poudre, particularly when sourcing from different suppliers across Africa, South America, the Middle East, and Europe. Variations in production methods, raw material purity, and adherence to international standards can lead to discrepancies in product quality. This inconsistency can affect downstream applications, resulting in costly rework, project delays, and potential damage to client relationships.

The Solution: To mitigate these quality concerns, buyers should prioritize establishing partnerships with reputable suppliers who have a proven track record in the industry. Implementing a rigorous supplier evaluation process is crucial. This includes requesting certifications, such as ISO compliance, and conducting regular audits to ensure adherence to quality standards. Additionally, buyers can invest in third-party quality testing services to independently verify the quality of silicium poudre before it is integrated into their production processes. By building relationships with suppliers who offer transparent quality assurance practices, buyers can significantly reduce the risk of inconsistency.

The Problem: B2B buyers often grapple with the complex regulatory landscape surrounding the import and use of silicium poudre. Different regions have varying regulations regarding safety, environmental impact, and usage in products, especially in the cosmetics and food industries. Non-compliance can lead to fines, product recalls, and reputational damage, making it essential for buyers to stay informed about these regulations.

The Solution: To effectively navigate these regulatory challenges, buyers should engage with legal and compliance experts who specialize in international trade and materials. Developing a comprehensive compliance checklist tailored to the specific regulations of each target market can streamline the process. Buyers should also consider joining industry associations that provide resources and updates on regulatory changes. Additionally, maintaining open communication with suppliers about their compliance with local regulations can help ensure that all products meet required standards before importation. Investing time and resources in compliance education can ultimately save significant costs associated with regulatory breaches.

The Problem: Many B2B buyers lack awareness of the diverse applications and benefits of silicium poudre, leading to underutilization of this valuable material. This limited understanding can hinder their ability to innovate and differentiate their products in competitive markets, particularly in sectors such as construction, cosmetics, and health supplements.

The Solution: To address this knowledge gap, buyers should actively seek educational resources and training opportunities that focus on the properties and applications of silicium poudre. Collaborating with research institutions or industry experts can provide insights into how silicium poudre can enhance product formulations, improve structural integrity in construction materials, or serve as a beneficial additive in dietary supplements. Additionally, hosting workshops or webinars with suppliers can foster an environment of knowledge sharing, enabling buyers to leverage silicium poudre more effectively in their applications. By becoming advocates for the material’s benefits, buyers can unlock new opportunities for product development and market expansion.

When selecting silicium poudre for various applications, international B2B buyers must consider the specific properties, advantages, and limitations of the materials involved. Below, we analyze several common materials used in silicium poudre production, focusing on their performance characteristics, suitability for end products, and considerations relevant to buyers from Africa, South America, the Middle East, and Europe.

Silicon dioxide is a prevalent form of silicium poudre, known for its high melting point (about 1,600°C) and excellent thermal stability. It exhibits good chemical resistance, making it suitable for various applications, including glass and ceramics.

Pros:

- High durability and thermal resistance.

- Non-reactive, making it ideal for food-grade applications.

Cons:

- Can be expensive due to processing and purity requirements.

- Limited flexibility in applications requiring high reactivity.

Impact on Application: Silicon dioxide is compatible with various media, including acids and bases, but may not be suitable for reducing environments.

Considerations for International Buyers: Compliance with local regulations and standards (e.g., ASTM, DIN) is crucial. Buyers should ensure that the sourced material meets food safety standards if intended for food-related applications.

Silicon carbide is known for its exceptional hardness and thermal conductivity, making it a preferred choice in abrasive applications and high-temperature environments.

Pros:

- High thermal conductivity and strength.

- Excellent wear resistance, suitable for demanding applications.

Cons:

- Higher manufacturing complexity and cost.

- Limited availability in certain regions.

Impact on Application: SiC is particularly effective in high-pressure applications and environments where mechanical strength is critical.

Considerations for International Buyers: Buyers must verify the sourcing of SiC to ensure compliance with environmental regulations, especially in regions with stringent standards like the EU.

Amorphous silica is a non-crystalline form of silicon dioxide, often used in cosmetics, food, and pharmaceuticals due to its absorbent properties.

Pros:

- Highly versatile with a range of applications.

- Generally lower cost compared to crystalline forms.

Cons:

- Lower mechanical strength compared to crystalline silica.

- Potential regulatory scrutiny in certain applications.

Impact on Application: Amorphous silica is suitable for applications requiring absorbency, but it may not withstand high temperatures.

Considerations for International Buyers: Compliance with health and safety standards is essential, particularly for buyers in the cosmetics and food industries.

Silicon metal is a pure form of silicon used primarily in the production of silicones and as an alloying agent in aluminum production.

Pros:

- High purity levels enhance performance in electronic applications.

- Cost-effective for large-scale production.

Cons:

- Lower corrosion resistance compared to other silicium powders.

- Limited application in high-temperature environments.

Impact on Application: Silicon metal is crucial for applications in electronics and aluminum alloys, where purity is paramount.

Considerations for International Buyers: Buyers should ensure that the silicon metal complies with international quality standards and certifications, especially for electronic applications.

| Material | Typical Use Case for silicium poudre | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Dioxide (SiO2) | Glass and ceramics production | High durability and thermal resistance | Limited flexibility in reactive applications | High |

| Silicon Carbide (SiC) | Abrasives and high-temperature applications | Exceptional hardness and thermal conductivity | Higher manufacturing complexity and cost | High |

| Amorphous Silica | Cosmetics and pharmaceuticals | Versatile and lower cost | Lower mechanical strength | Medium |

| Silicon Metal | Electronics and aluminum alloys | High purity for enhanced performance | Lower corrosion resistance | Medium |

In conclusion, understanding the properties and implications of different silicium poudre materials is crucial for international B2B buyers. By considering specific applications, compliance requirements, and cost factors, buyers can make informed decisions that align with their operational needs and market standards.

The manufacturing process of silicium poudre, or silicon powder, involves several critical stages that ensure the final product meets the required specifications for various industrial applications. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

A stock image related to silicium poudre.

The first step in the manufacturing of silicium poudre is the preparation of raw materials. Silicium is primarily sourced from silica-rich materials, such as quartz sand. This raw material undergoes a purification process to remove impurities, which may include iron, aluminum, and other metal oxides. The purity level is crucial, as it directly affects the quality of the final product.

After purification, the silica is subjected to high temperatures in a furnace, where it is reduced using carbon sources such as coke. This reduction process converts silica (SiO₂) into silicon (Si). The resulting silicon is then cooled and crushed into smaller particles, which are subsequently milled to achieve the desired powder size.

Once the raw silicon is prepared, the forming stage involves grinding and milling the silicon into a fine powder. Various techniques are employed during this stage, including ball milling and jet milling, which help achieve the necessary particle size and distribution.

Ball Milling: This method uses spherical grinding media to break down the silicon into finer particles. It is effective for producing uniform particle sizes but may introduce some contamination if not properly managed.

Jet Milling: In this technique, high-velocity jets of air or steam are used to impact the silicon particles against each other, resulting in a fine powder with a narrow particle size distribution. Jet milling is advantageous for producing high-purity silicon powder.

The finishing stage involves sieving and classifying the milled silicon powder to ensure it meets specific particle size requirements. Additional treatments, such as surface coating or chemical treatments, may be applied to enhance certain properties of the powder, such as flowability or reactivity.

Packaging is also an essential part of the finishing process. Silicium poudre is typically packaged in moisture-resistant bags or containers to prevent contamination and degradation during transportation and storage.

Quality assurance is critical in the manufacturing of silicium poudre to ensure the product meets international standards and customer specifications. Implementing a robust quality control (QC) system helps mitigate risks associated with product quality and safety.

International standards play a significant role in ensuring product quality. For silicium poudre, compliance with ISO 9001 (Quality Management Systems) is essential. This standard focuses on consistently meeting customer requirements and enhancing satisfaction through effective quality management practices.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in the European Economic Area and API (American Petroleum Institute) standards for certain applications may also apply. These certifications indicate that the product meets specific safety, health, and environmental protection requirements.

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they are used in production.

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from specifications are detected and corrected promptly.

Final Quality Control (FQC): After production, the final product undergoes rigorous testing to verify that it meets all quality standards before packaging and shipping.

To ensure the quality of silicium poudre, several testing methods are commonly employed, including:

Particle Size Analysis: Techniques such as laser diffraction or sieve analysis are used to determine the particle size distribution of the powder.

Chemical Composition Analysis: Methods like X-ray fluorescence (XRF) or inductively coupled plasma (ICP) spectroscopy are employed to analyze the elemental composition and purity of the silicon powder.

Flowability Testing: Ensuring the powder has the right flow characteristics is essential for its application. Tests like the Carr Index or Hausner Ratio are used to assess this property.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control systems, and adherence to industry standards. This firsthand observation can provide valuable insights into the supplier's capabilities.

Quality Assurance Reports: Requesting detailed QA reports, including testing results and compliance certificates, can help buyers assess the reliability of the product.

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the supplier's products and processes can provide an unbiased assessment of quality and compliance with international standards.

B2B buyers must navigate various nuances related to quality control and certification when sourcing silicium poudre. Factors such as regional standards, language barriers in documentation, and varying interpretations of international standards can complicate the procurement process.

Understanding the specific quality requirements and certifications relevant to their region or industry is essential for buyers. Additionally, establishing clear communication with suppliers regarding quality expectations and compliance can help mitigate misunderstandings.

By focusing on these comprehensive manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing silicium poudre, ensuring they receive a product that meets their specific needs and regulatory requirements.

Sourcing silicium poudre (silicon powder) requires a systematic approach to ensure quality and compliance with industry standards. This guide provides a step-by-step checklist tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. By following these steps, you can streamline the procurement process and mitigate risks associated with sourcing this essential material.

Clearly outline the technical requirements for the silicium poudre you need. This includes the purity level, particle size, and form (e.g., amorphous or crystalline). Establishing these specifications upfront ensures that suppliers understand your needs and can provide products that meet your quality standards.

Conduct thorough research to identify potential suppliers of silicium poudre. Look for manufacturers with a proven track record and positive reviews in the market.

Before engaging with a supplier, verify their certifications and compliance with international standards. This step is critical to ensure that the silicium poudre adheres to safety and quality regulations.

Always request samples of silicium poudre before making a bulk purchase. Testing samples allows you to verify the quality and suitability of the product for your specific applications.

Once you have identified a suitable supplier and verified the product quality, enter into negotiations regarding pricing, delivery times, and payment terms. Clear agreements can prevent misunderstandings later in the procurement process.

Building a long-term relationship with your supplier can lead to better pricing, priority service, and improved collaboration on future projects.

Sourcing silicium poudre effectively involves careful planning and execution. By following this checklist, international B2B buyers can enhance their procurement processes, ensuring they obtain high-quality materials that meet their operational needs.

When sourcing silicium poudre, understanding the cost structure is crucial for B2B buyers. The main components influencing the total cost include:

Materials: The primary raw material for silicium poudre is silica, which is derived from quartz or silicate minerals. Prices can fluctuate based on availability and market demand.

Labor: Labor costs are influenced by the region of manufacturing. For instance, labor costs in Europe may be significantly higher than in Africa or South America, impacting the overall pricing.

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Higher manufacturing standards and advanced technology can lead to increased overhead costs.

Tooling: The initial investment in machinery and tools is a significant factor, especially if custom specifications are required.

Quality Control (QC): Ensuring the consistency and purity of silicium poudre involves rigorous testing and quality assurance processes. This adds an additional layer to the cost structure.

Logistics: Transportation costs can vary widely based on the shipping distance, mode of transport, and the complexity of customs regulations, especially for international shipments.

Margin: Suppliers typically add a profit margin to cover their costs and risks, which can vary based on the supplier’s pricing strategy and market competition.

Several factors can significantly influence the pricing of silicium poudre:

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. B2B buyers should consider negotiating MOQs to achieve better pricing.

Specifications and Customization: Custom formulations or specific particle sizes may incur additional costs. Ensure that the specifications required are clearly communicated to avoid unexpected price increases.

Material Quality and Certifications: Higher quality materials and additional certifications (such as ISO or organic certifications) can lead to increased costs. Buyers should weigh the benefits of certification against their budget.

Supplier Factors: Supplier reputation, reliability, and service can impact pricing. Established suppliers may charge a premium for their reliability and consistency.

Incoterms: The choice of Incoterms (such as FOB, CIF, etc.) can affect the total landed cost of silicium poudre. Understanding these terms is essential to avoid hidden costs related to shipping and insurance.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can help optimize costs:

Negotiate Terms: Always engage in negotiations regarding price, payment terms, and delivery schedules. Suppliers may have flexibility that can lead to cost savings.

Focus on Total Cost of Ownership (TCO): Evaluate the total cost beyond the initial purchase price. Consider factors such as logistics, storage, and potential wastage to determine the most cost-effective option.

Understand Pricing Nuances: Be aware of regional pricing dynamics. For example, suppliers in South America may offer more competitive rates due to lower labor costs compared to Europe.

Evaluate Multiple Suppliers: Don’t settle for the first quote. Gathering multiple quotes can provide insights into market pricing and help identify the best value.

Consider Long-term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and terms over time, as well as increased reliability.

It's important to note that prices for silicium poudre can vary widely based on the aforementioned factors, and the information provided here is indicative. Buyers should conduct thorough market research and request detailed quotations from multiple suppliers to obtain accurate pricing tailored to their specific needs.

In the landscape of B2B solutions, understanding alternatives to silicium poudre is crucial for making informed purchasing decisions. Silicium poudre, a form of silicon, is often leveraged in various industries for its beneficial properties. However, there are other materials and methods that can serve similar purposes. This analysis will compare silicium poudre against two viable alternatives: organic silica and polymer-based additives.

| Comparison Aspect | Silicium Poudre | Organic Silica | Polymer-Based Additives |

|---|---|---|---|

| Performance | Strong binding properties, enhances structural integrity | Improves bioavailability, supports skin and joint health | Versatile in application, offers stability and flexibility |

| Cost | Moderate pricing | Generally higher due to sourcing | Varies widely based on type and application |

| Ease of Implementation | Relatively straightforward | Requires specific formulation knowledge | Easy to integrate in various applications |

| Maintenance | Low maintenance once applied | Needs regular dosage adjustments | Minimal maintenance required |

| Best Use Case | Construction, cosmetics | Health supplements, cosmetics | Food processing, plastics, coatings |

Organic silica is derived from natural sources, such as bamboo or horsetail, and is renowned for its high bioavailability. This form of silica is particularly beneficial in health supplements aimed at improving skin elasticity, joint health, and overall well-being. While its effectiveness in the health sector is well-established, the cost can be significantly higher due to sourcing and processing. Furthermore, companies may need to invest in specialized knowledge for formulation, which can add complexity to its implementation.

Polymer-based additives are synthetic materials that can enhance the properties of various products, such as flexibility, durability, and stability. These additives are highly versatile and are often used in food processing, coatings, and plastics. The cost can vary widely depending on the type and intended application. One of the main advantages is their ease of integration into existing processes, making them appealing to manufacturers. However, they may not offer the same health benefits associated with silica, limiting their use in health-focused products.

When selecting the right solution, B2B buyers should consider several factors, including performance requirements, budget constraints, and application environments. Silicium poudre is an excellent choice for industries focused on structural integrity and durability. In contrast, organic silica is suited for health and cosmetic applications but at a higher cost. Polymer-based additives provide flexibility and ease of use across various sectors but may lack the specific benefits that silica offers. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make decisions that align with their strategic objectives and operational needs.

Understanding the technical properties of silicium poudre is crucial for international B2B buyers to make informed purchasing decisions. Here are some of the most critical specifications:

Material grade refers to the quality and purity of the silicium poudre. It is essential to specify the required grade based on the intended application, whether in electronics, construction, or food industries. Higher-grade silicium may be required for high-tech applications, while lower grades may suffice for construction materials. Ensuring the right grade can affect product performance and compliance with industry standards.

The particle size of silicium poudre plays a significant role in its reactivity and application. Fine particles are often more reactive and suitable for applications in pharmaceuticals or cosmetics, while coarser particles may be used in construction. Buyers should specify the desired particle size distribution to ensure compatibility with their processes and end products.

Tolerance levels indicate the acceptable variations in the properties of silicium poudre, such as particle size or chemical composition. This specification is vital for manufacturers who require consistency in their raw materials to maintain product quality. Clear tolerance levels help avoid production delays and ensure that the end products meet safety and regulatory requirements.

Moisture content affects the stability and usability of silicium poudre. Excess moisture can lead to clumping and reduced effectiveness, particularly in chemical reactions. Buyers should inquire about the moisture content to ensure that the material remains effective during storage and use, particularly in regions with high humidity.

Specific surface area refers to the total surface area of a material per unit mass. This property is particularly important in applications such as catalysis and pharmaceuticals, where surface interactions are critical. A higher specific surface area can enhance reactivity and performance, making it a key factor for buyers in these industries.

Understanding the chemical composition of silicium poudre is essential for regulatory compliance and application suitability. Different applications may require specific formulations or the absence of certain impurities. Buyers should request a detailed analysis of the chemical composition to ensure that the material meets their needs and complies with industry regulations.

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms relevant to silicium poudre:

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding the role of OEMs is crucial when sourcing silicium poudre for use in products where the buyer’s brand is prominent.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure they can meet their production needs without overcommitting resources.

An RFQ is a document sent to suppliers requesting a quote for specific products or services. It is a vital part of the procurement process, allowing buyers to compare prices and terms from different suppliers effectively.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for B2B buyers to understand costs, risks, and obligations related to the transport of silicium poudre.

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is crucial for supply chain management, particularly for international buyers who need to plan for delays in shipping or production.

Certification refers to the process of verifying that a product meets specific standards or regulations. For silicium poudre, certifications may include quality management systems (like ISO) or compliance with environmental regulations. Buyers should ensure that their suppliers provide relevant certifications to avoid compliance issues.

By grasping these technical properties and trade terminologies, international B2B buyers can streamline their procurement processes and ensure they make well-informed purchasing decisions regarding silicium poudre.

The silicium poudre market is witnessing a significant transformation driven by various global factors. One of the primary drivers is the increasing demand for silicium in industries such as construction, electronics, and healthcare. The rise of technology and digitalization has led to a surge in applications for silicium, particularly in semiconductors and photovoltaic cells. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for strategic sourcing.

Emerging B2B tech trends are reshaping the silicium poudre supply chain. Digital platforms and e-commerce are becoming prevalent, enabling buyers to access suppliers globally with ease. Additionally, advancements in manufacturing technologies are leading to more efficient production processes, reducing costs and enhancing product quality. Buyers must stay abreast of these technological innovations to leverage competitive pricing and superior product offerings.

Market dynamics are also influenced by geopolitical factors and trade policies, which can affect supply chains. Buyers from Africa and South America may face challenges related to import tariffs and trade agreements. Therefore, it is vital to assess local regulations and international trade policies when sourcing silicium poudre. Establishing strong relationships with reliable suppliers can mitigate risks and ensure a consistent supply of quality materials.

Sustainability has become a cornerstone of sourcing strategies in the silicium poudre sector. The environmental impact of silicium production is a growing concern, as traditional mining and processing methods can lead to ecological degradation. B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as responsible sourcing and waste reduction.

Ethical supply chains are essential for building brand reputation and customer loyalty. Buyers should seek out suppliers that adhere to environmental regulations and are certified with 'green' certifications. Certifications such as ISO 14001 for environmental management systems and other recognized sustainability standards can provide assurance of a supplier's commitment to ethical practices. This not only enhances the credibility of buyers' operations but also contributes positively to global sustainability efforts.

Moreover, incorporating recycled silicium into supply chains is gaining traction. Utilizing recycled materials not only reduces environmental impact but also aligns with the circular economy principles that many companies are adopting. By choosing suppliers that offer recycled silicium poudre, international B2B buyers can significantly reduce their carbon footprint while meeting the growing consumer demand for sustainable products.

The use of silicium in various industries dates back to the early 20th century when it was primarily utilized in steel manufacturing and as a semiconductor material. As technology progressed, the demand for silicium powder increased, particularly in electronics and solar energy sectors. The evolution of silicium processing techniques has led to the development of high-purity silicium powders, which are now essential in applications ranging from advanced materials to health supplements.

In the B2B context, the historical reliance on silicium has evolved into a sophisticated market that emphasizes quality and sustainability. As industries recognize the vital role of silicium in technological advancements, the sourcing strategies have shifted towards more ethical and sustainable practices. This historical perspective not only informs current market dynamics but also highlights the importance of adapting to changing consumer preferences and regulatory environments.

Understanding the evolution of silicium poudre allows B2B buyers to make informed decisions, ensuring they align with both market trends and sustainability goals.

How do I ensure the quality of silicium poudre from suppliers?

To ensure the quality of silicium poudre, request certificates of analysis (CoA) from suppliers, which confirm the chemical composition and purity levels. Additionally, consider conducting third-party testing to verify the material's specifications. Establishing a clear communication channel with suppliers about quality standards and requirements can also help maintain consistency. It's advisable to visit the manufacturing facilities if possible, or engage with suppliers who have a proven track record of quality assurance.

What are the main applications of silicium poudre in various industries?

Silicium poudre is widely used across industries such as electronics, construction, and cosmetics. In electronics, it serves as a semiconductor material, while in construction, it is utilized in the production of glass and ceramics. In the cosmetics sector, silicium poudre enhances the texture of products and is used in skin care formulations. Understanding the specific application needs in your industry will help you source the appropriate grade of silicium poudre.

What is the minimum order quantity (MOQ) for silicium poudre?

The MOQ for silicium poudre can vary significantly depending on the supplier and the specific grade of the material. Generally, MOQs can range from 100 kg to several tons. It's essential to communicate your needs clearly and explore options with different suppliers. Some may offer flexibility for trial orders, especially for new customers, allowing you to assess quality before committing to larger quantities.

How can I negotiate payment terms with silicium poudre suppliers?

Negotiating payment terms involves discussing options such as upfront payments, letters of credit, or payment upon delivery. It's common in B2B transactions to ask for net 30 or net 60 terms, allowing time for product inspection and sale before full payment is due. Establishing a good relationship with your supplier can also lead to more favorable terms. Always ensure that terms are documented in your contract to avoid misunderstandings later.

What should I consider when vetting suppliers for silicium poudre?

When vetting suppliers, assess their reputation, production capacity, and compliance with international standards. Look for customer reviews and case studies that demonstrate reliability and quality. Check if they have certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, consider their responsiveness to inquiries and willingness to provide samples for testing before placing a bulk order.

How does logistics impact the sourcing of silicium poudre?

Logistics plays a critical role in sourcing silicium poudre, especially for international buyers. Consider factors like shipping costs, delivery times, and customs regulations in your country. Working with suppliers who have established logistics networks can facilitate smoother transactions. It's also beneficial to discuss incoterms (International Commercial Terms) to clarify responsibilities for shipping and insurance.

What customization options are available for silicium poudre?

Customization options for silicium poudre can include variations in particle size, purity levels, and formulations tailored to specific applications. Suppliers may also offer packaging solutions that meet your needs. Discuss your requirements upfront with potential suppliers to explore available options. Customization can often enhance performance in your specific applications and improve overall satisfaction with the product.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the competitive landscape of silicium poudre sourcing, strategic procurement practices are paramount for international B2B buyers, especially in emerging markets like Africa, South America, the Middle East, and Europe. Understanding the diverse applications of silicium, from its role in construction materials to its significance in health and wellness products, can inform smarter purchasing decisions. Buyers should prioritize suppliers who demonstrate sustainable sourcing practices and can offer high-quality silicium that meets specific industry standards.

What are the key advantages of implementing strategic sourcing for silicium poudre? By establishing strong relationships with reliable suppliers, businesses can not only secure better pricing but also improve supply chain resilience. This approach allows for greater flexibility in adapting to market fluctuations and ensures access to innovative product developments.

Looking ahead, international B2B buyers are encouraged to stay informed about the evolving market trends and regulatory changes surrounding silicium applications. Engaging with industry experts and participating in trade events can provide valuable insights. Now is the time to leverage these strategies to enhance your sourcing capabilities and drive competitive advantage in your markets. Embrace the potential of silicium poudre to support your business growth and sustainability initiatives.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina