In today's interconnected global market, navigating the complexities of smeta certificacion can be a daunting task for international B2B buyers. Whether you're sourcing sustainable suppliers or ensuring compliance with ethical standards, the challenge of finding reliable partners who meet the rigorous requirements of SMETA (Sedex Members Ethical Trade Audit) certification is paramount. This guide is designed to equip you with the knowledge and tools necessary to effectively evaluate potential suppliers, understand various certification types, and assess the applications of SMETA in diverse business contexts.

This comprehensive resource will delve into the nuances of SMETA certification, covering critical aspects such as supplier vetting processes, cost implications, and the benefits of compliance for businesses in Africa, South America, the Middle East, and Europe. By understanding the specific requirements and standards associated with SMETA, you can make informed purchasing decisions that align with your corporate social responsibility goals while enhancing your supply chain transparency.

Furthermore, this guide aims to empower B2B buyers by offering actionable insights and best practices tailored to your regional challenges and market dynamics. From understanding the certification landscape to exploring the financial implications of compliance, you'll gain the confidence to navigate the global market effectively. Join us as we explore how to leverage SMETA certification to not only meet regulatory demands but also build lasting partnerships that foster ethical business practices.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMETA 2-Pillar | Focuses on labor and health & safety aspects | Manufacturing, Supply Chain Management | Pros: Streamlined audit process; Cons: Limited scope may miss environmental issues. |

| SMETA 4-Pillar | Includes labor, health & safety, environment, and ethics | Diverse industries including retail and food | Pros: Comprehensive assessment; Cons: More time-consuming and costly. |

| SMETA 5-Pillar | Adds an additional focus on business integrity | High-stakes industries like finance and tech | Pros: Enhanced risk management; Cons: Requires extensive documentation. |

| SMETA 6-Pillar | Introduces stakeholder engagement and community impact | Corporate Social Responsibility (CSR) initiatives | Pros: Strengthens brand reputation; Cons: May require cultural adaptation. |

| SMETA Ethical Audit | Focuses on ethical sourcing and corporate governance | Sourcing, Procurement | Pros: Builds consumer trust; Cons: May not align with all regulatory standards. |

SMETA 2-Pillar certification is primarily centered on labor practices and health & safety standards. It is suitable for companies that want a streamlined approach to compliance without delving into environmental or ethical considerations. This type is particularly relevant for manufacturing firms and supply chain management sectors that prioritize worker safety and labor rights. Buyers should consider the limited scope of this certification, as it may not cover all aspects of corporate responsibility.

The SMETA 4-Pillar certification expands the focus to include environmental and ethical aspects alongside labor and health & safety. It is ideal for businesses in diverse sectors such as retail and food that require a more holistic view of their operational impact. While it offers a comprehensive assessment that can enhance a company's credibility, buyers should be aware that this certification process can be more time-consuming and costly compared to the 2-Pillar version.

SMETA 5-Pillar certification includes a critical focus on business integrity, making it essential for high-stakes industries like finance and technology. This certification ensures that organizations not only comply with labor and environmental standards but also uphold ethical business practices. For B2B buyers, this type provides enhanced risk management through rigorous documentation requirements. However, the extensive nature of the audit may pose challenges for smaller firms with limited resources.

The SMETA 6-Pillar certification introduces stakeholder engagement and community impact as significant factors in corporate accountability. This certification is particularly beneficial for companies pursuing Corporate Social Responsibility (CSR) initiatives. It helps strengthen brand reputation and stakeholder trust, which is increasingly important in today's market. However, buyers should consider the potential need for cultural adaptations, especially when engaging with diverse international markets.

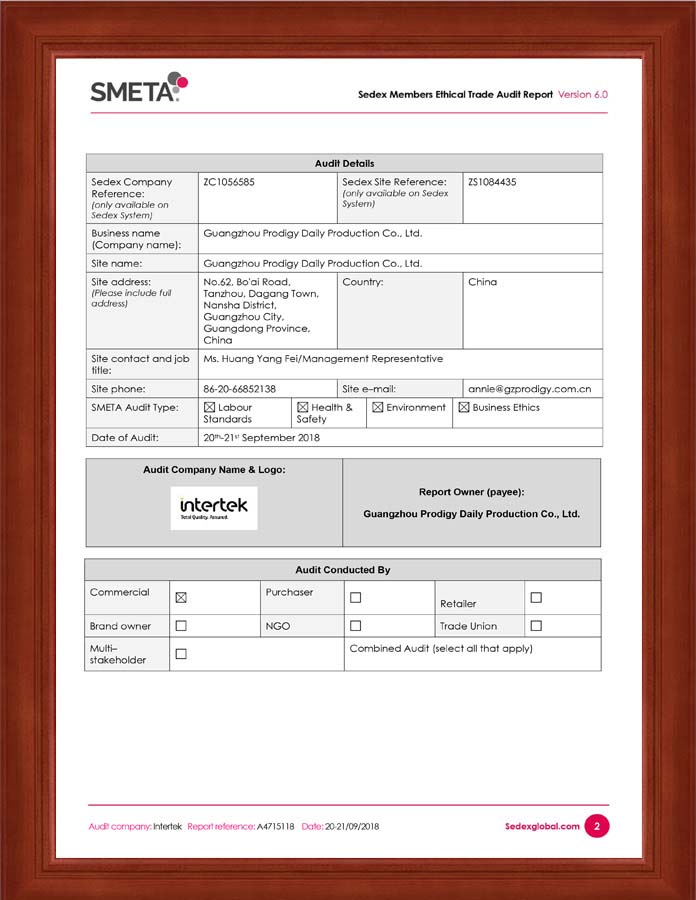

A stock image related to smeta certificacion.

The SMETA Ethical Audit focuses on ethical sourcing and corporate governance, making it highly relevant for sourcing and procurement activities. This type of certification helps businesses build consumer trust by demonstrating a commitment to ethical practices. However, buyers should be mindful that it may not align with all regulatory standards across different regions, which could impact their operational strategies.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

| Industry/Sector | Specific Application of smeta certificacion | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Supply Chain Transparency and Ethical Sourcing | Enhances brand reputation and consumer trust | Verify supplier compliance and ethical practices |

| Retail | Vendor Audits and Compliance Checks | Mitigates risk and ensures quality standards | Assess vendor certifications and audit frequency |

| Agriculture and Food Safety | Traceability in Food Supply Chains | Reduces liability and ensures product quality | Evaluate traceability systems and supplier reliability |

| Textiles and Apparel | Labor Practices and Environmental Standards | Improves market access and sustainability image | Investigate labor practices and environmental impact |

| Electronics | Responsible Sourcing of Raw Materials | Minimizes operational risks and enhances compliance | Ensure adherence to ethical sourcing guidelines |

In the manufacturing sector, 'smeta certificacion' serves as a critical tool for ensuring supply chain transparency and ethical sourcing. By implementing SMETA standards, companies can assess their suppliers' compliance with labor laws, health and safety regulations, and environmental practices. This not only enhances brand reputation but also builds consumer trust, particularly in regions like Europe and North America where ethical sourcing is increasingly important. For international buyers from Africa and South America, ensuring that suppliers meet these standards can help avoid potential backlash and enhance market competitiveness.

In the retail industry, 'smeta certificacion' is essential for conducting vendor audits and compliance checks. Retailers can utilize SMETA to evaluate their suppliers’ adherence to ethical practices, ensuring that products are sourced responsibly. This mitigates risks associated with product recalls and reputational damage, which can be particularly significant in the Middle Eastern markets where consumer awareness is high. For buyers, assessing vendor certifications and audit frequency is crucial to maintaining quality standards and fostering long-term supplier relationships.

In agriculture and food safety, 'smeta certificacion' enhances traceability within food supply chains. By adhering to SMETA guidelines, businesses can track the origins of their food products, ensuring compliance with safety standards and reducing liability in case of foodborne illnesses. This is particularly relevant for international buyers in Africa and South America, where food safety regulations are becoming more stringent. Evaluating traceability systems and supplier reliability is essential for businesses looking to build a trustworthy brand in competitive markets.

The textiles and apparel industry benefits significantly from 'smeta certificacion' through its focus on labor practices and environmental standards. Adopting SMETA guidelines helps companies improve their market access by aligning with sustainability goals demanded by consumers, especially in Europe. For international buyers, investigating labor practices and environmental impact is vital to ensure that their supply chains are not only compliant but also socially responsible, which can lead to enhanced brand loyalty and customer satisfaction.

In the electronics sector, 'smeta certificacion' plays a pivotal role in the responsible sourcing of raw materials. By ensuring that suppliers adhere to ethical sourcing guidelines, businesses can minimize operational risks associated with non-compliance and supply chain disruptions. This is particularly relevant for international buyers looking to navigate complex supply chains in regions like the UAE and Indonesia. Ensuring adherence to these guidelines is crucial for maintaining compliance and safeguarding corporate reputation in a highly competitive market.

Related Video: What are all the Laboratory Apparatus and their uses?

The Problem:

International B2B buyers, especially those sourcing from diverse regions like Africa and South America, often face the challenge of varying compliance requirements when obtaining 'smeta certificacion'. Each country may have distinct regulations and expectations regarding labor standards, health and safety, and environmental impact. This inconsistency can create confusion and lead to non-compliance, resulting in delays, financial penalties, or even loss of market access.

The Solution:

To effectively navigate these complexities, buyers should conduct thorough research on the specific requirements for 'smeta certificacion' in each target market. Engaging with local consultants or compliance experts can provide invaluable insights into regional standards. Additionally, utilizing a centralized compliance management system can help track and manage certification requirements across different countries. This system should include a checklist tailored to each region’s standards, allowing businesses to ensure all necessary documentation is in place before initiating the certification process. Regular audits and updates to this system will help maintain compliance and adapt to any regulatory changes.

The Problem:

A significant pain point for B2B buyers is the lack of transparency and accountability from suppliers regarding their adherence to 'smeta certificacion' standards. Many buyers find themselves questioning whether their suppliers genuinely meet the ethical and operational benchmarks required for certification. This skepticism can hinder trust and complicate long-term partnerships, especially in regions where oversight may be limited.

The Solution:

To combat this issue, B2B buyers should implement a rigorous supplier vetting process that includes requesting documentation of past 'smeta certificacion' audits and reports. Establishing a clear communication channel for ongoing dialogue about compliance can enhance transparency. Additionally, considering third-party audits can provide an objective assessment of a supplier’s practices. Buyers might also create a scorecard system to evaluate suppliers based on their compliance performance, fostering a competitive environment where suppliers are incentivized to maintain high standards. Regularly scheduled reviews and feedback loops will further strengthen these relationships.

The Problem:

The financial implications of obtaining 'smeta certificacion' can be daunting, particularly for small and medium-sized enterprises (SMEs) in developing regions. Many buyers struggle with the high costs associated with the certification process, including audit fees, training expenses, and potential operational disruptions during compliance adjustments. This financial burden can deter companies from pursuing certification, even when it is essential for accessing certain markets.

The Solution:

B2B buyers should explore various funding options to alleviate the financial strain of 'smeta certificacion'. This could include seeking grants or subsidies offered by local governments or international organizations aimed at promoting ethical business practices. Collaborating with industry associations can also provide access to shared resources, reducing individual costs. Furthermore, investing in training programs for staff can help internalize compliance processes, making it easier and more cost-effective to maintain standards over time. Buyers should also consider negotiating with certification bodies for reduced fees based on the scale of their operations or potential market impact, thus making the certification process more financially feasible.

When pursuing SMETA certification, the selection of materials plays a critical role in ensuring compliance and performance. Below, we analyze four common materials that are frequently used in products seeking this certification, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and high-temperature tolerance. It typically withstands temperatures up to 1,600°F (870°C) and is resistant to a variety of chemicals, making it suitable for a wide range of applications.

Pros & Cons: The durability of stainless steel is one of its strongest attributes, providing a long lifespan with minimal maintenance. However, it can be more expensive than other materials, and its manufacturing processes can be complex, requiring specialized equipment and skilled labor.

Impact on Application: Stainless steel is compatible with food and beverage applications, which is crucial for SMETA certification in sectors like food safety and hygiene. Its non-reactive nature ensures that it does not contaminate products.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the stainless steel used meets international standards such as ASTM A240 or DIN 1.4301. It is also essential to consider local sourcing options to reduce costs and improve supply chain efficiency.

Key Properties: Aluminum is lightweight, with a good strength-to-weight ratio, and it offers decent corrosion resistance when treated. It can typically withstand temperatures up to 1,200°F (650°C).

Pros & Cons: One of the main advantages of aluminum is its cost-effectiveness compared to stainless steel. However, it is less durable and can be prone to deformation under high stress, which may limit its application in certain industries.

Impact on Application: Aluminum is widely used in packaging and lightweight structural components, making it suitable for various SMETA-certified products. Its compatibility with food-grade applications is also a plus.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that comply with local standards, such as JIS 6061 in Japan or EN AW-6060 in Europe. Understanding these standards can help ensure compliance and avoid costly rejections during audits.

Key Properties: Polypropylene (PP) is a thermoplastic known for its chemical resistance and flexibility. It can operate effectively at temperatures up to 200°F (93°C) and is resistant to many solvents and acids.

Pros & Cons: The main advantage of polypropylene is its low cost and ease of manufacturing, making it a popular choice for mass production. However, it has lower mechanical strength compared to metals, which may limit its use in high-stress applications.

Impact on Application: Polypropylene is commonly used in packaging and disposable products, which are critical for SMETA certification in sectors like consumer goods. Its recyclability also aligns with sustainability goals.

Considerations for International Buyers: Buyers should ensure that the polypropylene grades selected meet relevant standards such as ASTM D4101. Additionally, understanding the local recycling regulations can enhance compliance with environmental standards.

Key Properties: Glass is non-reactive and can withstand a wide range of temperatures, typically up to 1,000°F (538°C). Its transparency allows for easy inspection of contents, which is beneficial in many applications.

Pros & Cons: Glass is highly durable and can be recycled indefinitely, making it an environmentally friendly option. However, it is heavier and more fragile than other materials, which can complicate logistics and increase shipping costs.

Impact on Application: Glass is ideal for packaging in the food and beverage industry, ensuring product integrity and safety. Its inert nature means it does not leach chemicals into products, aligning with SMETA standards.

Considerations for International Buyers: Buyers must consider local regulations regarding glass packaging, including safety standards and recycling mandates. Familiarity with standards like ASTM C162 or DIN 52322 can facilitate smoother compliance processes.

| Material | Typical Use Case for SMETA Certification | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage equipment | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Packaging and lightweight structures | Cost-effective and lightweight | Lower durability under stress | Medium |

| Polypropylene | Disposable products and packaging | Low cost and ease of manufacturing | Lower mechanical strength | Low |

| Glass | Food and beverage packaging | Highly durable and recyclable | Heavy and fragile | Medium |

This comprehensive guide provides actionable insights for international B2B buyers, enabling informed decisions in material selection for SMETA certification.

Understanding the manufacturing processes involved in achieving SMETA certification is crucial for B2B buyers looking for reliable suppliers. The main stages of manufacturing typically include material preparation, forming, assembly, and finishing. Each stage plays a significant role in ensuring that products meet the quality and ethical standards set by SMETA.

Material preparation involves selecting high-quality raw materials that comply with ethical sourcing guidelines. For instance, a supplier might use sustainably sourced metals or eco-friendly plastics. This stage often includes processes such as cutting, shaping, and treating materials to ensure they meet specifications. Buyers should inquire about the supplier's material sourcing practices and whether they hold certifications that guarantee sustainability.

The forming stage employs various techniques such as molding, stamping, and machining to create product components. Techniques vary by industry; for example, in textiles, weaving and knitting are prevalent, while in electronics, PCB manufacturing is crucial. International B2B buyers should assess the technologies used by suppliers and ensure they are up to date with current industry standards and innovations.

Assembly is where individual components come together to form the final product. This process may involve manual assembly, automated systems, or a combination of both. Implementing lean manufacturing principles can enhance efficiency and reduce waste. Buyers should request details on the assembly process, including workforce training and automation levels, as these factors can significantly influence product quality and consistency.

Finishing processes include painting, coating, and surface treatment, which are essential for protecting products and enhancing aesthetics. For SMETA compliance, it’s crucial that finishing processes adhere to environmental regulations and quality standards. Buyers should verify that suppliers use non-toxic materials and follow industry best practices for waste disposal and emissions control.

Quality assurance (QA) is integral to the SMETA certification process, ensuring that products not only meet quality standards but also adhere to ethical and social responsibility benchmarks.

SMETA certification aligns with several international standards, including ISO 9001, which focuses on quality management systems. Additionally, industry-specific standards such as CE marking for safety in Europe or API standards for oil and gas equipment also play a vital role. B2B buyers should ensure that their suppliers are compliant with these standards, as it reflects a commitment to quality and safety.

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. These include:

Buyers should inquire about the specific QC measures their suppliers have in place at each stage, as this can help mitigate risks associated with product defects.

Various testing methods are employed to ensure product quality, including:

Understanding the testing methods used by suppliers can help buyers gauge the reliability and durability of the products they are sourcing.

Verification of a supplier's quality control processes is essential for mitigating risks. Here are several strategies that international B2B buyers can employ:

Conducting regular audits of suppliers can provide insights into their manufacturing practices and adherence to quality standards. Buyers should look for suppliers that are open to audits and can provide documentation of past audits, including corrective actions taken.

Suppliers should provide comprehensive reports on their QC processes, including data on defect rates, testing outcomes, and compliance with international standards. Buyers should request these reports as part of their supplier evaluation process.

Third-party inspections can offer an unbiased assessment of a supplier's quality control practices. Engaging an independent firm to evaluate the supplier's operations and product quality can provide an additional layer of assurance, especially for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

International buyers should be aware of the specific nuances related to quality control and certification in different regions. For instance, in Europe, compliance with EU regulations is paramount, while in the Middle East, buyers may prioritize suppliers with ISO certifications that align with local standards.

Understanding these nuances not only aids in supplier selection but also helps in building long-term relationships based on trust and reliability. By focusing on these aspects, B2B buyers can ensure that their supply chains remain robust and compliant with international standards, ultimately enhancing their competitive edge in the global market.

In the competitive landscape of international trade, obtaining SMETA certification is essential for companies aiming to demonstrate ethical practices in their supply chain. This guide provides a practical checklist for B2B buyers seeking to procure SMETA certification, ensuring compliance with global standards and enhancing credibility in the marketplace. By following these steps, buyers can streamline their sourcing process and mitigate risks associated with supplier partnerships.

Before initiating the sourcing process, familiarize yourself with the specific requirements of SMETA certification. This includes understanding the key pillars: labor standards, health and safety, environment, and business ethics. Knowing these criteria will help you evaluate potential suppliers effectively.

Compile a list of suppliers who offer SMETA certification services or products. Utilize industry networks, online platforms, and trade shows to source potential candidates. A broad supplier base increases your chances of finding a partner that meets your specific needs.

Verifying that potential suppliers hold valid SMETA certifications is critical. Review their certification documents and check for any recent audits or renewals. This step helps ensure that the supplier adheres to the necessary ethical standards.

A stock image related to smeta certificacion.

Investigate the supplier's performance history by reviewing case studies and testimonials from previous clients. Understanding their track record will provide insight into their reliability and compliance with SMETA standards.

If feasible, conduct an on-site audit of the supplier’s operations. This step is crucial for verifying their commitment to SMETA principles. An on-site visit allows you to assess working conditions and environmental practices firsthand.

Once you have identified a suitable supplier, negotiate clear terms and conditions regarding the SMETA certification process. This includes timelines, costs, and responsibilities for both parties. Clear agreements help prevent misunderstandings and ensure accountability.

After securing SMETA certification, establish a system for ongoing compliance monitoring. Regular assessments will ensure that suppliers maintain their standards over time, protecting your business from risks associated with unethical practices.

By following this step-by-step checklist, international B2B buyers can effectively navigate the SMETA certification procurement process, ensuring ethical sourcing and reinforcing their commitment to responsible business practices.

When engaging in SMETA certification sourcing, understanding the cost structure is crucial for international B2B buyers. The primary components that influence the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials: The choice of materials directly impacts the cost. High-quality, certified materials may incur higher upfront costs but can lead to long-term savings through reduced returns and increased customer satisfaction.

Labor: Labor costs vary significantly by region. For example, labor in South America may be less expensive than in Europe, but the quality and availability of skilled labor can also affect overall costs and timelines.

Manufacturing Overhead: This includes costs associated with facility operations, utilities, and indirect labor. Buyers should evaluate suppliers' overhead costs as they can significantly influence pricing.

Tooling: Custom tooling can be a significant initial investment, particularly for specific product requirements. Understanding the tooling costs upfront can aid in budgeting for your sourcing projects.

Quality Control (QC): Implementing rigorous QC processes ensures compliance with SMETA standards but can add to the overall cost. Buyers should weigh the cost of QC against the potential risks of non-compliance.

Logistics: Shipping costs, including freight, insurance, and customs duties, must be factored into the overall cost. This can vary widely depending on the origin of the materials and the destination market.

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding average margins in your industry can help you negotiate better pricing.

Several factors can influence pricing in SMETA certification sourcing, and being aware of these can help buyers make informed decisions.

Volume/MOQ: Minimum order quantities (MOQ) and volume discounts can significantly reduce per-unit costs. Buyers should assess their purchasing strategy to maximize savings.

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define requirements to avoid unexpected expenses.

Materials: The choice of materials not only affects cost but also compliance with sustainability and ethical sourcing standards.

Quality and Certifications: Products that require additional certifications or meet higher quality standards often come at a premium. Buyers should prioritize essential certifications to balance cost and compliance.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record but can offer better quality assurance.

Incoterms: Understanding Incoterms is essential for international transactions. They determine who is responsible for shipping, insurance, and tariffs, significantly affecting overall costs.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can enhance cost-efficiency.

Negotiation Strategies: Engage suppliers in transparent discussions about pricing. Leverage volume purchasing and long-term relationships to negotiate better terms.

Total Cost of Ownership (TCO): Focus on TCO rather than just the initial purchase price. Consider long-term costs, including maintenance, logistics, and potential risks associated with non-compliance.

Pricing Nuances for International Buyers: Be aware of currency fluctuations and economic conditions in supplier countries, as these can affect costs. Additionally, local regulations may impose extra costs that should be factored into your calculations.

Supplier Audits: Conducting audits on potential suppliers can help you gauge their capabilities and compliance with SMETA standards, ensuring that you make informed decisions.

Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower you during negotiations and help you identify the best suppliers.

It is important to note that the prices for SMETA certification sourcing can vary widely based on numerous factors, including supplier location, market conditions, and the specific requirements of your project. Therefore, the figures discussed should be considered indicative and subject to change. Always conduct thorough research and consult with multiple suppliers to obtain accurate quotes tailored to your needs.

When considering the certification of supply chains and labor practices, Smeta Certificacion is a widely recognized option. However, it's essential for international B2B buyers to explore alternatives that may better suit their specific operational needs, budget constraints, or compliance requirements. This section compares Smeta Certificacion with two viable alternatives: the Ethical Trading Initiative (ETI) Base Code and the ISO 45001 Occupational Health and Safety Management System.

| Comparison Aspect | Smeta Certificacion | Ethical Trading Initiative (ETI) Base Code | ISO 45001 Occupational Health and Safety Management System |

|---|---|---|---|

| Performance | High, with a focus on ethical audits | High, emphasizes labor rights | High, focuses on workplace safety |

| Cost | Moderate to high | Moderate | Moderate to high |

| Ease of Implementation | Requires training and resources | Relatively straightforward | May require comprehensive training and system changes |

| Maintenance | Regular audits needed | Periodic reviews | Ongoing monitoring and periodic audits |

| Best Use Case | Supply chains needing ethical verification | Companies focused on labor rights | Organizations prioritizing health and safety |

The Ethical Trading Initiative (ETI) Base Code is a framework that ensures ethical labor practices throughout supply chains.

Pros:

- Focus on Labor Rights: The ETI Base Code emphasizes fair wages, safe working conditions, and the right to unionize, making it particularly appealing for companies in regions with labor exploitation concerns.

- International Recognition: Its widespread acceptance can enhance a company's reputation among socially conscious consumers and partners.

Cons:

- Implementation Complexity: While the framework is straightforward, adapting existing practices to meet ETI standards may require significant changes in operations.

- Less Comprehensive on Environmental Factors: Unlike Smeta, which includes environmental considerations, the ETI Base Code primarily focuses on labor rights, which may not suit companies looking for a holistic approach.

ISO 45001 is an international standard for occupational health and safety (OHS), aimed at reducing workplace hazards and improving employee safety.

Pros:

- Comprehensive Safety Focus: ISO 45001 provides a robust framework for managing workplace health and safety risks, which is crucial for industries with high accident rates.

- Global Acceptance: Being an ISO standard, it is recognized worldwide, facilitating smoother international operations and compliance.

Cons:

- Higher Implementation Demands: The certification process may be resource-intensive, requiring specialized training and modifications to existing safety management systems.

- Limited Scope: While it excels in safety, it does not address labor rights or ethical sourcing, which may be a drawback for companies prioritizing social responsibility.

Choosing the right certification solution depends on a company's specific objectives, operational context, and the regions in which they operate. For businesses primarily concerned with ethical labor practices, the ETI Base Code may be the most appropriate choice. However, if the focus is on workplace safety and health, ISO 45001 could provide the necessary framework. Smeta Certificacion remains a strong contender for those seeking a comprehensive approach that covers both ethical labor practices and environmental considerations. Ultimately, B2B buyers should assess their unique needs, industry standards, and stakeholder expectations before making a decision.

Understanding the technical properties associated with SMETA (Sedex Members Ethical Trade Audit) certification is crucial for B2B buyers seeking to ensure compliance and ethical practices in their supply chains. Here are several critical specifications that play a vital role in the certification process:

Material grade refers to the classification of materials based on their properties and intended use. In the context of SMETA certification, it is important for buyers to ensure that the materials used in production meet specific ethical and sustainability standards. This can impact product quality and safety, affecting the overall reputation of the business in international markets.

Tolerance levels define the acceptable limits of variation in a product's dimensions or performance. For B2B buyers, understanding tolerance is essential to ensure that the products sourced meet the required specifications and standards. Non-compliance with tolerance levels can lead to defective products, increased costs, and potential legal issues, particularly in regions with stringent quality controls.

Compliance standards encompass the regulations and guidelines that businesses must adhere to for ethical and sustainable operations. SMETA certification specifically evaluates a company's adherence to labor rights, health and safety, and environmental practices. Buyers should prioritize suppliers who not only meet these standards but also demonstrate a commitment to continuous improvement.

Sustainability metrics provide quantifiable measures of a company's environmental impact and resource usage. Buyers looking for SMETA-certified suppliers should consider these metrics as they reflect a supplier's commitment to sustainability, which is increasingly important to consumers and regulatory bodies alike. Understanding these metrics can enhance a buyer's ability to select partners that align with their corporate social responsibility goals.

Navigating the world of SMETA certification also requires familiarity with key trade terminology. Here are some commonly used terms that can facilitate better communication and decision-making:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, identifying OEMs that comply with SMETA standards can help ensure that the supply chain is ethical and meets quality expectations. This is particularly important in industries where product integrity is paramount.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure that production runs are economically viable. Buyers should negotiate MOQs that align with their purchasing capabilities while ensuring compliance with SMETA standards.

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for products or services. For those involved in SMETA certification, including specific compliance requirements in an RFQ can help streamline the sourcing process and ensure that suppliers are vetted for ethical practices.

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and logistics. Understanding Incoterms is essential for B2B buyers to clarify their obligations regarding shipping costs, risks, and delivery timelines. Familiarity with these terms can help mitigate potential disputes and enhance supply chain efficiency.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing products from SMETA-certified suppliers. This understanding not only enhances operational efficiency but also promotes ethical practices in global trade, ultimately benefiting businesses and consumers alike.

The smeta certificación sector is witnessing transformative market dynamics driven by globalization, technological advancements, and a heightened focus on corporate social responsibility. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their supply chains, understanding these dynamics becomes crucial.

One of the key trends is the increasing adoption of digital platforms for sourcing and compliance verification. Technologies like blockchain and AI are streamlining processes, enhancing transparency, and reducing risks associated with supplier verification. Furthermore, the shift towards sustainable practices is gaining traction, with buyers prioritizing suppliers that demonstrate compliance with environmental and social governance (ESG) standards.

Emerging markets are also playing a significant role in shaping sourcing trends. For instance, countries in Africa and South America are becoming attractive sourcing destinations due to their rich natural resources and labor market. However, navigating these markets requires a nuanced understanding of local regulations and cultural contexts. Buyers must also be aware of the varying certification standards across regions, which can impact sourcing decisions.

Sustainability and ethical sourcing have become paramount in the smeta certificación sector, reflecting a global shift towards environmentally responsible business practices. The environmental impact of sourcing decisions is under scrutiny, with buyers increasingly aware of the carbon footprint associated with their supply chains. This has led to a growing demand for 'green' certifications and materials, which not only mitigate environmental damage but also enhance brand reputation.

Ethical supply chains are now a key consideration for B2B buyers. Certifications like smeta provide assurance that suppliers adhere to fair labor practices and environmental regulations. Buyers from regions such as the Middle East and Europe, where ethical consumerism is on the rise, are particularly focused on sourcing from suppliers who can demonstrate compliance with these standards. By prioritizing ethical sourcing, businesses can build stronger relationships with customers and stakeholders, ultimately leading to increased loyalty and market share.

Moreover, incorporating sustainable practices into procurement strategies can yield significant cost savings over time. For instance, investing in energy-efficient technologies or sustainable materials can reduce operational costs and enhance competitiveness in the global marketplace.

The smeta certificación sector has evolved significantly since its inception, adapting to the changing landscape of global trade and sourcing practices. Initially developed as a response to concerns about labor practices and environmental impact in supply chains, smeta has become a benchmark for ethical sourcing across various industries.

Over the years, the certification process has incorporated a broader range of criteria, including social, environmental, and ethical standards. This evolution reflects the growing recognition of the interconnectedness of these factors in ensuring sustainable business practices. For B2B buyers, understanding the historical context of smeta certification is essential in appreciating its relevance today.

As businesses increasingly operate on a global scale, the importance of smeta certification cannot be overstated. It provides a framework for risk management, ensuring that suppliers meet stringent standards that align with buyer values and regulatory requirements. By leveraging smeta certification, international B2B buyers can enhance their credibility, mitigate risks, and foster trust in their supply chains.

How do I ensure my supplier is SMETA certified?

To verify a supplier's SMETA certification, request a copy of their certification document, which should detail the scope and validity period. Additionally, you can check the official Sedex website or contact Sedex directly for an up-to-date list of certified members. Engaging in direct communication with your supplier about their commitment to ethical standards can also provide insights into their practices and transparency.

What benefits does SMETA certification offer to my business?

SMETA certification demonstrates your commitment to ethical sourcing and compliance with labor standards, which can enhance your brand reputation. It can also facilitate access to new markets, as many retailers and brands require suppliers to hold recognized certifications. Furthermore, it helps mitigate risks associated with unethical practices, ensuring a more sustainable supply chain.

What is the typical process for obtaining SMETA certification?

The process typically involves an initial assessment of your company’s practices, followed by an audit conducted by a qualified third-party auditor. The audit evaluates labor standards, health and safety, environment, and business ethics. After successful completion, your organization receives the certification, which is valid for three years, provided that periodic audits are conducted to maintain compliance.

How can I negotiate payment terms with SMETA-certified suppliers?

When negotiating payment terms, consider the supplier's cash flow requirements and your purchasing volume. It's beneficial to establish trust through transparent discussions. Offering to pay a portion upfront can facilitate better terms, while also ensuring that the supplier feels secure in their transaction. Additionally, discussing various payment options, like letters of credit or installment payments, can lead to a mutually agreeable solution.

What are the Minimum Order Quantities (MOQs) for SMETA-certified suppliers?

MOQs can vary significantly depending on the supplier, product type, and market demand. Typically, larger suppliers may have higher MOQs due to production costs, while smaller suppliers may be more flexible. It’s crucial to communicate your needs clearly and explore options for smaller test orders to assess product quality before committing to larger quantities.

How do I assess the quality assurance processes of SMETA-certified suppliers?

To evaluate a supplier’s quality assurance (QA) processes, request detailed documentation of their QA protocols, including testing methods and compliance standards. You may also inquire about their history of product recalls or quality issues. Conducting site visits or audits, if feasible, can provide firsthand insight into their operational practices and commitment to quality control.

What logistics considerations should I keep in mind when sourcing from SMETA-certified suppliers?

Logistics considerations include shipping times, costs, and the supplier's capability to handle international freight. Understand the supplier's logistics infrastructure and their experience with export regulations in your region. It’s also wise to discuss potential risks related to delays, customs clearance, and how the supplier plans to mitigate these issues to ensure timely delivery.

How does SMETA certification impact international trade agreements?

SMETA certification can significantly enhance your position in international trade agreements by providing assurance to partners regarding ethical practices. Many businesses and governments prioritize suppliers with recognized certifications, which can lead to preferential treatment in negotiations. Additionally, it can simplify compliance with local regulations concerning labor rights and environmental standards, facilitating smoother trade operations.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In today's competitive landscape, strategic sourcing of suppliers with smeta certification is crucial for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the value of ethical sourcing not only enhances your brand reputation but also aligns with the growing consumer demand for sustainable and socially responsible practices. By prioritizing suppliers who hold smeta certification, businesses can ensure compliance with international labor standards, which is increasingly important in global trade.

How can strategic sourcing with smeta certification elevate your business operations? By leveraging this certification, companies can mitigate risks associated with labor violations and improve supply chain transparency. Moreover, this proactive approach to sourcing can lead to stronger partnerships with suppliers, fostering innovation and resilience in your supply chain.

As we look to the future, the importance of smeta certification in strategic sourcing will only continue to grow. B2B buyers are encouraged to integrate ethical sourcing practices into their procurement strategies. Embrace the opportunity to build a responsible supply chain that not only meets compliance standards but also resonates with consumers' values. Take action now to enhance your sourcing strategy and position your business for sustainable growth in the global marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina