In today's rapidly evolving global market, understanding "smeta nedir" is crucial for B2B buyers looking to enhance their supply chain management and ensure compliance with international standards. This guide addresses a key challenge faced by businesses: the need for transparency and reliability in sourcing products and services. By delving into the intricacies of smeta, this resource equips international buyers, particularly from Africa, South America, the Middle East, and Europe, with the knowledge necessary to make informed purchasing decisions.

The guide provides a comprehensive overview of various aspects related to smeta, including its types, applications, and the importance of supplier vetting. It explores how businesses can assess potential suppliers effectively and highlights the cost implications associated with implementing smeta standards. With actionable insights and practical tips, this guide empowers B2B buyers to navigate the complexities of global sourcing while ensuring compliance with ethical and quality benchmarks.

By leveraging the insights offered in this guide, businesses can mitigate risks, enhance their reputation, and ultimately drive growth. Whether you are a seasoned buyer or new to international trade, understanding smeta is essential for fostering trust and building lasting partnerships in the global marketplace. Prepare to unlock the potential of your sourcing strategy with the knowledge provided in this comprehensive guide.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMETA 2-Pillar | Focus on labor and health & safety standards | Supplier audits, ethical sourcing | Pros: Streamlined; Cons: Limited scope |

| SMETA 4-Pillar | Includes additional environmental and management systems | Comprehensive supplier assessments | Pros: Holistic; Cons: More complex implementation |

| SMETA 5-Pillar | Adds a focus on business ethics and management systems | Extensive supplier evaluations | Pros: Thorough; Cons: Resource-intensive |

| SMETA 6-Pillar | Incorporates additional focus on supply chain management | Global supply chain assessments | Pros: Enhanced risk management; Cons: High costs |

| SMETA 7-Pillar | Emphasizes continuous improvement and stakeholder engagement | Long-term supplier partnerships | Pros: Sustainable growth; Cons: Requires commitment |

The SMETA 2-Pillar audit primarily focuses on labor standards and health & safety. This variation is ideal for businesses looking to quickly assess the ethical practices of their suppliers without delving into environmental concerns. B2B buyers should consider this option when they need a straightforward audit that can be completed promptly, as it is less resource-intensive than its counterparts. However, its limited scope may not satisfy all stakeholders, particularly in industries where environmental impact is a critical concern.

The SMETA 4-Pillar audit expands its focus to include environmental and management systems alongside labor and health & safety. This makes it suitable for B2B companies seeking a more comprehensive evaluation of their suppliers. Buyers can leverage this type when they need to ensure compliance with broader sustainability standards. While this approach offers a more holistic view of supplier practices, it can be more complex to implement and may require additional resources for thorough evaluations.

The SMETA 5-Pillar audit adds business ethics to the existing pillars, making it a robust choice for companies aiming for extensive supplier evaluations. It is particularly relevant for B2B buyers who prioritize ethical sourcing and sustainability. The depth of this audit means it can provide significant insights into supplier operations. However, the thoroughness required can lead to resource-intensive processes, which may not be feasible for all businesses.

The SMETA 6-Pillar audit incorporates supply chain management into the traditional SMETA framework. This variation is particularly beneficial for global companies that need to assess risks across their supply chains comprehensively. B2B buyers should consider this type when evaluating suppliers in complex or high-risk regions. While it offers enhanced risk management capabilities, the costs associated with implementing such an extensive audit can be high, which may deter smaller businesses.

The SMETA 7-Pillar audit emphasizes continuous improvement and stakeholder engagement, making it ideal for businesses looking to foster long-term partnerships with their suppliers. This type is particularly relevant for organizations committed to sustainable growth and ethical practices. However, it requires a significant commitment to ongoing assessments and improvements, which may not be suitable for all B2B buyers, especially those with limited resources.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

| Industry/Sector | Specific Application of smeta nedir | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Supply Chain Audits | Enhanced transparency and risk management | Ensure compliance with local regulations and standards |

| Retail | Ethical Sourcing and Supplier Assessments | Improved brand reputation and customer loyalty | Verify supplier certifications and audit frequency |

| Agriculture | Sustainability Assessments for Supply Chains | Increased access to international markets | Assess local agricultural practices and certifications |

| Textiles and Apparel | Labor Rights Compliance Monitoring | Mitigation of risks associated with labor violations | Evaluate supplier labor practices and audit reports |

| Construction | Environmental Impact Assessments | Reduced environmental liabilities and costs | Assess local environmental regulations and compliance |

In the manufacturing sector, smeta nedir is primarily used for conducting thorough supply chain audits. This process helps businesses identify potential risks and ensure compliance with ethical standards. For international B2B buyers, particularly those sourcing from regions like Africa and South America, understanding local regulations and supplier practices is crucial. By implementing smeta audits, manufacturers can enhance transparency, leading to improved risk management and a stronger supply chain.

Retail businesses utilize smeta nedir for ethical sourcing and supplier assessments. This application focuses on verifying that suppliers adhere to social and environmental standards, which is increasingly important for consumers. For B2B buyers in Europe, particularly in France, this can significantly enhance brand reputation and customer loyalty. Buyers should ensure that suppliers possess the necessary certifications and maintain regular audits to uphold these standards.

In agriculture, smeta nedir is applied for sustainability assessments within supply chains. This approach allows businesses to evaluate their suppliers' environmental practices and ethical sourcing methods. For international buyers, especially from the Middle East, this can facilitate access to global markets by meeting sustainability criteria. It is essential for buyers to assess local agricultural practices and ensure that suppliers comply with relevant certifications to maintain credibility.

The textiles and apparel industry employs smeta nedir for monitoring labor rights compliance. This application is vital for mitigating risks associated with labor violations, which can lead to severe reputational damage. B2B buyers, particularly those in Europe, must evaluate suppliers’ labor practices and review audit reports to ensure adherence to ethical standards. Regular assessments help maintain compliance and foster a responsible supply chain.

In the construction sector, smeta nedir is crucial for conducting environmental impact assessments. This application helps businesses identify and mitigate potential environmental liabilities, leading to cost savings and compliance with regulations. For international B2B buyers, especially those operating in Europe, understanding local environmental regulations is essential. Buyers should ensure that their suppliers are compliant and have a track record of responsible environmental practices to avoid penalties and enhance project sustainability.

Related Video: Uses of Metals - Science 9

The Problem:

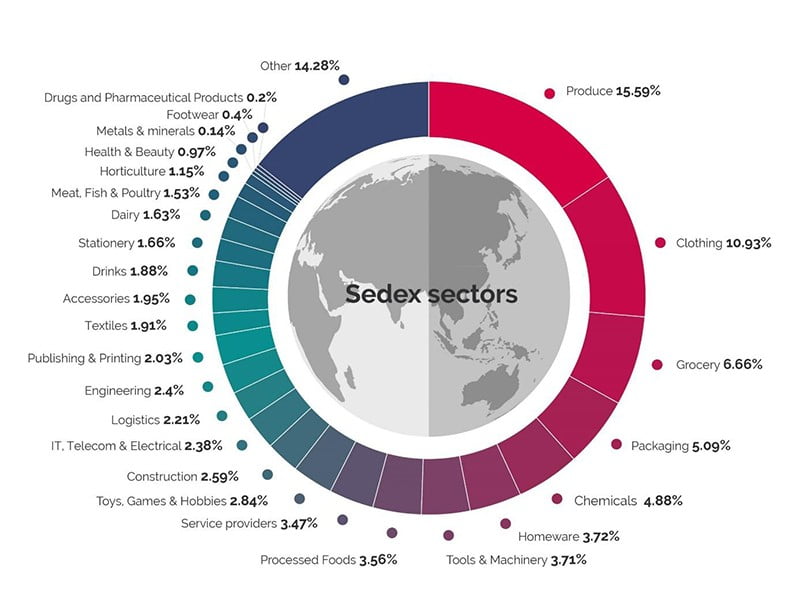

B2B buyers, especially from regions like Africa and South America, often struggle to understand the compliance requirements associated with 'smeta nedir' (which translates to "what is smeta"). The ambiguity surrounding the SMETA (Sedex Members Ethical Trade Audit) framework can lead to confusion about what specific practices need to be implemented to meet international standards. This lack of clarity can result in significant delays in supplier onboarding, potential loss of contracts, and reputational damage due to non-compliance.

The Solution:

To address this challenge, it is vital for buyers to invest in thorough training and resources about SMETA. Start by engaging with reputable consultants or organizations that specialize in ethical auditing and compliance. Create a checklist that aligns with SMETA's four pillars: Labor, Health & Safety, Environment, and Ethics. Additionally, consider joining industry groups or networks that focus on ethical trade practices, where members can share insights and experiences. This proactive approach not only enhances understanding but also strengthens your business’s commitment to ethical sourcing, ensuring smoother supplier relationships.

The Problem:

Another common pain point for B2B buyers is the inconsistency in supplier compliance with SMETA standards. Suppliers may claim adherence to ethical practices but fail to deliver consistently due to a lack of internal processes or understanding of what 'smeta nedir' entails. This inconsistency can lead to audits revealing gaps in compliance, which can ultimately jeopardize business relationships and supply chain integrity.

The Solution:

To mitigate this risk, buyers should establish a robust supplier evaluation process that includes regular audits and assessments based on SMETA criteria. Develop a clear communication strategy outlining compliance expectations and provide suppliers with resources to help them understand and implement these standards. Consider conducting joint training sessions that involve both your team and the suppliers to foster a collaborative approach towards compliance. By creating a transparent feedback loop, you can encourage suppliers to take ownership of their compliance status, leading to improved adherence over time.

The Problem:

International B2B buyers often find it challenging to access reliable information and resources regarding SMETA audits. This is particularly true for businesses operating in the Middle East and parts of Europe where local resources may be limited or not aligned with international standards. Without access to credible data, buyers struggle to make informed decisions about their supply chains, which can lead to costly mistakes and missed opportunities.

The Solution:

To overcome this information gap, buyers should leverage technology and digital platforms that specialize in ethical sourcing and SMETA audits. Invest in subscription-based services that provide access to audit reports, best practice guides, and industry benchmarks. Additionally, consider forming strategic partnerships with organizations like Sedex or local ethical trade associations that can offer training and resources tailored to your specific region. Engaging in forums or webinars can also enhance knowledge sharing and keep you updated on the latest developments in SMETA compliance, enabling more informed decision-making in your supply chain management.

When selecting materials for applications related to "smeta nedir," it's crucial to consider the properties, advantages, and limitations of each material. This strategic material selection guide will analyze four common materials used in various applications, providing insights that are particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe.

Stainless steel is widely recognized for its excellent corrosion resistance and durability, making it a preferred choice in many industrial applications. With a temperature rating that can exceed 800°C (1472°F) and pressure ratings up to 1500 psi, stainless steel is suitable for high-stress environments. Its resistance to oxidation and staining enhances its lifespan, particularly in harsh climates.

Pros & Cons: The primary advantage of stainless steel is its longevity and low maintenance requirements. However, it can be more expensive than other materials, which may increase overall project costs. Manufacturing complexity can also be a concern, as stainless steel often requires specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, chemicals, and gases, making it versatile for various applications. However, buyers should ensure compliance with international standards such as ASTM A240 or DIN 1.4301.

Carbon steel is another common material choice, known for its strength and affordability. It typically has a temperature rating of up to 500°C (932°F) and can handle moderate pressure levels. While it offers good mechanical properties, it lacks the corrosion resistance of stainless steel.

Pros & Cons: Carbon steel is cost-effective and easy to fabricate, making it an attractive option for many projects. However, its susceptibility to rust and corrosion can lead to higher long-term maintenance costs, particularly in humid or corrosive environments.

Impact on Application: Carbon steel is suitable for applications involving non-corrosive media. Buyers should consider protective coatings or treatments to enhance durability, particularly in regions with high humidity or salt exposure.

Aluminum is lightweight and has excellent corrosion resistance, making it a popular choice for applications where weight is a critical factor. It can withstand temperatures up to 400°C (752°F) and is often used in aerospace and automotive industries.

Pros & Cons: The key advantage of aluminum is its low weight, which can reduce shipping costs and ease installation. However, it is generally less strong than steel and can be more expensive, especially for high-grade alloys.

Impact on Application: Aluminum is compatible with various media but may not be suitable for high-pressure applications. International buyers should ensure compliance with standards such as ASTM B221 and consider the specific alloy grades that meet their application needs.

Plastics, including PVC and polyethylene, are increasingly being used in applications requiring chemical resistance and lightweight properties. These materials can handle temperatures up to 80°C (176°F) and are often used in piping and storage solutions.

Pros & Cons: Plastics are cost-effective and easy to manufacture, making them ideal for large-scale production. However, they may not offer the same durability or temperature resistance as metals, which can limit their applications.

Impact on Application: Plastics are suitable for a variety of chemicals but may degrade under UV exposure or extreme temperatures. Buyers should consider local regulations regarding plastic materials and ensure compliance with standards such as ASTM D1784.

| Material | Typical Use Case for smeta nedir | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing equipment | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Structural components | Cost-effective and strong | Susceptible to corrosion | Low |

| Aluminum | Aerospace and automotive parts | Lightweight and corrosion-resistant | Generally less strong than steel | Medium |

| Plastic | Piping and storage solutions | Cost-effective and easy to fabricate | Limited durability and temperature resistance | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions based on material properties, advantages, and limitations tailored to their specific regional needs and compliance requirements.

The manufacturing process for SMETA (Sedex Members Ethical Trade Audit) compliant products involves several critical stages, ensuring that ethical practices and quality standards are upheld throughout production. Understanding these stages is essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

The first step in the manufacturing process is material preparation, where sourcing high-quality raw materials is paramount. Suppliers must ensure that materials are ethically sourced, aligning with SMETA's focus on labor rights and environmental sustainability.

Forming and assembly are crucial phases where raw materials are transformed into finished products. Various techniques are employed, depending on the type of product being manufactured.

Finishing processes are the final steps that enhance product quality and aesthetic appeal. This stage can involve painting, coating, or applying protective finishes.

Quality control (QC) is integral to maintaining high standards throughout the manufacturing process. Implementing a robust QC system can significantly reduce defects and improve product reliability.

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that processes meet customer and regulatory requirements. Specific industry standards, such as CE marking for products sold in Europe or API standards for oil and gas equipment, further refine these guidelines.

Quality control checkpoints are critical for ensuring product integrity at various stages of the manufacturing process. Key checkpoints include:

To ensure compliance with quality standards, various testing methods are employed throughout the manufacturing process:

To ensure that suppliers adhere to quality control practices, B2B buyers can take several proactive steps:

B2B buyers from Africa, South America, the Middle East, and Europe must navigate various certification requirements and quality nuances:

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions that align with their operational and ethical standards. Understanding these nuances will not only help in selecting reliable suppliers but also in building sustainable business relationships across borders.

In the realm of international B2B procurement, understanding the nuances of sourcing 'smeta nedir' is essential for making informed decisions. This guide provides a practical checklist designed to streamline the sourcing process, ensuring that buyers from Africa, South America, the Middle East, and Europe can efficiently procure high-quality products and services while minimizing risks.

Clearly outlining your technical requirements is crucial for successful procurement. This step ensures that all parties have a mutual understanding of the product or service needed. Consider specifying dimensions, materials, performance criteria, and any industry standards that must be met. This clarity helps prevent misunderstandings and sets the foundation for supplier negotiations.

Understanding the market landscape is vital before engaging with potential suppliers. Research current trends, pricing benchmarks, and competitor offerings. Leverage local trade associations, industry reports, and online platforms to gather insights. This knowledge will empower you to make competitive and informed sourcing decisions.

Compile a list of potential suppliers based on your market research. Look for companies that specialize in 'smeta nedir' and have a proven track record. Utilize platforms such as Alibaba, Global Sources, or industry-specific directories to find suppliers. Pay attention to their geographical location, as proximity can affect shipping times and costs.

Before proceeding with any supplier, ensure they possess the necessary certifications and compliance documents. This verification process is crucial for maintaining quality standards and regulatory compliance. Look for certifications relevant to your industry, such as ISO, CE, or local standards. Confirm these credentials through independent verification if necessary.

Once you have shortlisted suppliers, request samples of their products or services. This step allows you to assess quality and ensure that the product meets your specifications. Evaluate the samples based on durability, functionality, and compliance with your outlined technical specifications. This hands-on assessment can significantly reduce the risk of dissatisfaction after placing a larger order.

With your potential suppliers vetted and samples reviewed, it's time to negotiate terms. Discuss pricing, payment terms, delivery schedules, and any warranties or service agreements. Be prepared to negotiate to achieve the best value while ensuring that the supplier can meet your requirements. Building a mutually beneficial relationship can lead to better collaboration in the long term.

Effective communication is key to a successful sourcing relationship. Establish clear lines of communication with your chosen supplier to facilitate ongoing dialogue. Utilize tools such as email, video conferencing, and project management software to maintain transparency. Regular updates and feedback can help preempt potential issues and foster a stronger partnership.

By following these steps, B2B buyers can navigate the complexities of sourcing 'smeta nedir' effectively. This structured approach not only mitigates risks but also enhances the potential for successful procurement outcomes.

When sourcing smeta nedir, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The quality and type of materials used significantly impact the overall cost. Premium materials may enhance product longevity but will increase the initial outlay.

Labor: Labor costs vary by region and supplier. In regions like Africa and South America, labor may be more affordable, while Europe might see higher wages impacting costs.

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities and facility maintenance. Efficient production processes can help mitigate these expenses.

Tooling: Depending on the complexity of the smeta nedir product, tooling costs can vary. Custom tooling may be necessary for unique designs, adding to the upfront investment.

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can also increase costs. Buyers should weigh the benefits of quality assurance against the potential for increased expenses.

Logistics: Shipping and handling costs are crucial, particularly for international transactions. Factors like distance, shipping method, and customs duties can significantly influence total costs.

Margin: The supplier’s profit margin is a crucial consideration. Understanding typical margins in the industry can help buyers gauge whether they are receiving a fair price.

Several factors can influence the pricing of smeta nedir. These include:

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate their MOQ to maximize cost-efficiency.

Specifications and Customization: Customized products may incur additional costs. Clearly defining requirements upfront can help avoid unexpected charges later.

Materials: The choice of materials directly affects pricing. Sustainable or high-performance materials may command a premium but can lead to long-term savings in durability and performance.

Quality and Certifications: Products that meet international quality standards or possess certifications may be priced higher. However, these certifications often provide assurance of product reliability.

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Working with reputable suppliers might come at a premium but can ensure better quality and service.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining who bears the costs and risks associated with shipping. This can significantly impact the total cost of ownership.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips:

Negotiate Wisely: Always engage in negotiations to secure the best price. Be prepared to discuss volume discounts and payment terms.

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs over the product's life cycle, including maintenance and disposal.

Understand Pricing Nuances: Different regions may have varying pricing structures due to economic conditions, labor costs, and material availability. Researching these nuances can provide leverage in negotiations.

Establish Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing, improved service, and enhanced collaboration over time.

Stay Informed About Market Trends: Regularly monitor market trends and pricing shifts in the smeta nedir sector to make informed purchasing decisions.

While the insights provided aim to guide B2B buyers in understanding the cost and pricing dynamics of smeta nedir sourcing, it is essential to note that prices can vary widely based on specific circumstances, supplier agreements, and market conditions. Always seek detailed quotations tailored to your specific needs and circumstances.

In the ever-evolving landscape of B2B solutions, buyers are often faced with multiple options that can achieve similar objectives. Understanding the strengths and weaknesses of each alternative is crucial for making an informed decision. In this section, we will compare 'smeta nedir' with two viable alternatives: ISO 14001 Certification and the Global Reporting Initiative (GRI) Standards. This comparison will help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, identify the best solution for their specific needs.

| Comparison Aspect | Smeta Nedir | ISO 14001 Certification | Global Reporting Initiative (GRI) Standards |

|---|---|---|---|

| Performance | Comprehensive auditing approach | Focused on environmental management | Emphasizes sustainability reporting |

| Cost | Moderate initial investment | Higher costs due to certification fees | Variable costs, depending on reporting scope |

| Ease of Implementation | Requires specialized knowledge | Structured approach, may require external consultants | Flexible, but can be complex for beginners |

| Maintenance | Regular audits and updates needed | Periodic audits necessary | Annual updates to reporting standards |

| Best Use Case | Supply chain transparency | Environmental management systems | Corporate sustainability reporting |

Pros: 'Smeta nedir' stands out for its comprehensive auditing capabilities, providing a detailed view of supply chain transparency. This makes it particularly valuable for companies looking to enhance their social responsibility and ensure compliance with international labor standards.

Cons: However, the implementation of 'smeta nedir' can be complex and may require specialized knowledge, which could lead to additional training costs. Regular audits and updates can also place a burden on resources.

Pros: ISO 14001 Certification is widely recognized and demonstrates a commitment to environmental management. It provides a structured approach that can enhance operational efficiency and reduce waste, making it an excellent choice for businesses focused on environmental sustainability.

Cons: The costs associated with ISO 14001 can be significant, particularly due to certification fees and potential consulting services required for implementation. Companies may also face challenges in maintaining compliance through periodic audits.

Pros: GRI Standards are highly flexible and can be tailored to various organizational needs. They are ideal for companies focused on sustainability reporting, allowing them to communicate their environmental, social, and governance (ESG) performance effectively.

Cons: On the downside, the GRI Standards can be complex, especially for organizations new to sustainability reporting. The variable costs associated with implementation can also lead to uncertainty, particularly for smaller businesses.

Selecting the right solution among 'smeta nedir', ISO 14001 Certification, and GRI Standards requires a thorough assessment of your organization's objectives, resources, and market demands. B2B buyers should consider the specific goals they aim to achieve—be it supply chain transparency, environmental management, or sustainability reporting. Conducting a cost-benefit analysis and engaging with stakeholders can further refine the decision-making process. By aligning the chosen solution with strategic business objectives, companies can enhance their operational efficiency and foster long-term growth.

A stock image related to smeta nedir.

Understanding the essential technical properties of SMETA (Sedex Members Ethical Trade Audit) is crucial for international B2B buyers. These properties ensure compliance with ethical trade standards, helping businesses to maintain a competitive edge in the global market.

Material Grade

Material grade refers to the quality of the raw materials used in production. In the context of SMETA, the emphasis is on sustainable and ethically sourced materials. For buyers, selecting suppliers who adhere to high material grades can significantly impact product quality and brand reputation.

Tolerance

Tolerance indicates the allowable variation in physical dimensions of a product. It is critical in ensuring that products meet specific requirements and function correctly. For B2B buyers, understanding tolerances is vital for quality assurance and minimizing the risk of production delays or product failures.

Certifications

Certifications are formal attestations that a supplier complies with specific standards, such as ethical labor practices or environmental management. In the SMETA framework, certifications provide buyers with confidence that their suppliers uphold ethical standards. This is particularly important in regions where compliance may vary.

Traceability

Traceability refers to the ability to track the origin of materials and products throughout the supply chain. For international buyers, ensuring traceability is essential for risk management and maintaining transparency. This helps mitigate potential reputational damage due to unethical practices within the supply chain.

Product Lifecycle Assessment (LCA)

LCA evaluates the environmental impact of a product from cradle to grave. Understanding LCA is important for B2B buyers focused on sustainability. By choosing suppliers who conduct LCAs, businesses can reduce their ecological footprint and promote responsible sourcing.

Familiarity with industry-specific jargon can streamline communication and negotiations for B2B buyers. Here are some essential terms to know:

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers as it affects product quality and supply chain dynamics.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ helps in planning purchases more effectively.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should use RFQs to compare prices, terms, and capabilities from multiple suppliers, ensuring they make informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international transactions, as they clarify obligations and minimize disputes.

Lead Time

Lead time refers to the time it takes from placing an order to receiving it. Understanding lead times is crucial for B2B buyers to plan their inventory and production schedules effectively. Longer lead times can impact cash flow and operational efficiency.

SLA (Service Level Agreement)

An SLA is a contract that outlines the expected level of service between a supplier and a buyer. For B2B buyers, SLAs ensure clarity on delivery timelines, quality standards, and penalties for non-compliance, ultimately fostering a reliable supplier relationship.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions and build strong partnerships in compliance with SMETA standards.

The smeta nedir sector is witnessing transformative changes driven by globalization, technological advancements, and increasing consumer awareness. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are navigating a complex landscape characterized by rapid market evolution. Key drivers include the rise of digital platforms that facilitate sourcing processes and the increasing demand for transparency within supply chains. Advanced B2B technologies such as Artificial Intelligence (AI) and blockchain are becoming integral in optimizing procurement strategies, enhancing supplier selection, and ensuring compliance with various regulations.

Emerging trends also indicate a shift towards localized sourcing, particularly in the context of geopolitical tensions and supply chain disruptions. This trend is significant for buyers in regions like Europe, where proximity to suppliers can mitigate risks associated with international logistics. Furthermore, the growing emphasis on e-commerce and digital marketplaces is reshaping how companies approach procurement, making it essential for B2B buyers to leverage these platforms to enhance their sourcing capabilities.

Sustainability and ethical sourcing are increasingly becoming focal points for B2B buyers in the smeta nedir sector. The environmental impact of production processes is under scrutiny, prompting companies to adopt sustainable practices that minimize ecological footprints. For buyers from Africa and South America, understanding the implications of sourcing materials from environmentally responsible suppliers is crucial, as it aligns with global movements toward sustainability.

Moreover, ethical supply chains are not just a regulatory requirement; they are becoming a competitive advantage. Buyers should prioritize suppliers that are certified with recognized 'green' standards, such as ISO 14001 or Fair Trade certifications, which signal commitment to sustainable practices. Engaging with suppliers who utilize recycled materials or implement energy-efficient processes can significantly enhance a company’s reputation and compliance with emerging regulations in Europe and the Middle East, where consumers increasingly demand transparency in sourcing.

The smeta nedir sector has evolved significantly over the past few decades, driven by globalization and technological innovation. Initially focused on compliance and basic quality standards, the sector has expanded to encompass broader social and environmental criteria. This evolution is particularly relevant for B2B buyers who must now navigate a landscape where ethical sourcing and sustainability are paramount.

Historically, buyers relied on traditional sourcing methods, often resulting in opaque supply chains. However, with the rise of digital technologies, buyers now have access to a wealth of information, allowing for more informed decision-making. Understanding this historical context enables B2B buyers to appreciate the current emphasis on ethical practices and technological integration, which are essential for successful procurement strategies in today’s market.

A stock image related to smeta nedir.

In conclusion, navigating the smeta nedir sector requires a strategic approach that considers market dynamics, sustainability, and historical context. By leveraging technology and prioritizing ethical sourcing, international B2B buyers can enhance their competitive edge and build resilient supply chains.

How do I ensure the credibility of suppliers when sourcing smeta nedir?

To verify the credibility of suppliers, conduct thorough due diligence by checking their business licenses, certifications, and compliance with international standards. Utilize platforms that offer supplier ratings and reviews, and consider requesting references from previous clients. Participating in industry trade shows can also provide insights into a supplier's reputation and reliability. Additionally, engaging third-party inspection services can help validate product quality and supplier integrity before committing to large orders.

What are the key factors to consider when evaluating smeta nedir suppliers?

When evaluating suppliers for smeta nedir, focus on their experience in your industry, production capacity, and adherence to quality standards. Assess their financial stability to ensure they can fulfill large orders consistently. It's also essential to review their ability to customize products to meet specific requirements, their Minimum Order Quantities (MOQ), and their responsiveness to inquiries. Lastly, consider their logistics capabilities, including shipping times and costs, to ensure timely delivery.

What are the common payment terms for international B2B transactions involving smeta nedir?

Common payment terms in international B2B transactions often include options like Letter of Credit (LC), advance payments, or payment upon delivery. Payment terms may vary depending on the supplier's location and the buyer's negotiation power. It's crucial to establish clear terms before finalizing any agreement to avoid misunderstandings. Always ensure that the payment method chosen provides adequate security and protection against potential fraud.

How can I negotiate favorable terms with suppliers of smeta nedir?

To negotiate favorable terms, research market prices and competitor offerings to strengthen your position. Build a relationship with the supplier by demonstrating your commitment to a long-term partnership, which can lead to better pricing and terms. Be transparent about your needs, such as payment terms and delivery schedules, and be willing to compromise on certain aspects. Consider leveraging bulk orders or long-term contracts to negotiate discounts or better conditions.

What quality assurance measures should I implement when sourcing smeta nedir?

Implementing quality assurance measures involves setting clear product specifications and standards before placing orders. Require suppliers to provide samples for testing and verification. Conduct periodic audits and inspections during production and before shipment to ensure compliance with your quality standards. Establish a clear return policy for defective products and maintain open communication with suppliers to address any quality issues promptly.

What logistics considerations should I keep in mind when importing smeta nedir?

When importing smeta nedir, consider shipping methods, costs, and delivery timelines. Evaluate whether air freight or sea freight best meets your needs based on urgency and budget. Understand the customs regulations in your country to ensure compliance and avoid delays. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate any complexities related to international shipping.

How can I customize smeta nedir products to meet my business needs?

To customize smeta nedir products, start by clearly defining your requirements, including specifications, materials, and design. Communicate these needs to potential suppliers early in the negotiation process. Many suppliers are open to customization, especially for bulk orders, so be prepared to discuss any additional costs or lead times associated with customized products. Building a collaborative relationship with your supplier can facilitate the customization process.

What are the typical lead times for sourcing smeta nedir products?

Lead times for sourcing smeta nedir can vary significantly based on factors such as supplier location, production capacity, and order complexity. Generally, expect lead times to range from a few weeks to several months. To mitigate delays, plan your orders well in advance and maintain communication with your suppliers regarding production schedules. Understanding the supplier's workflow can help you better anticipate lead times and make informed purchasing decisions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In today's global marketplace, understanding the nuances of strategic sourcing is crucial for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The concept of "smeta nedir" not only emphasizes the importance of ethical sourcing but also highlights the need for transparency and compliance within supply chains. Buyers should leverage this framework to enhance supplier relationships, reduce risks, and improve overall operational efficiency.

Adopting a strategic sourcing approach enables organizations to align their procurement strategies with their broader business goals. This alignment fosters innovation, cost savings, and improved product quality. B2B buyers are encouraged to assess their current sourcing practices critically and identify areas for improvement, particularly in supplier selection and risk management.

Looking ahead, the landscape of strategic sourcing will continue to evolve. Buyers must remain agile and responsive to market changes, technological advancements, and shifting consumer expectations. Embracing sustainability and ethical practices will not only meet regulatory demands but also resonate with increasingly conscious consumers.

In conclusion, international B2B buyers should take proactive steps to integrate strategic sourcing principles into their operations. By prioritizing ethical practices and fostering strong supplier partnerships, businesses can position themselves for long-term success in an interconnected global economy. Engage with your suppliers today and explore the transformative potential of strategic sourcing for your organization.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina