In today’s competitive global market, sourcing the right structure of silicon carbide (SiC) can pose significant challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, including key markets such as Spain and Germany. Buyers often grapple with identifying reliable suppliers, understanding the diverse applications of SiC, and navigating the complexities of pricing and quality assurance. This comprehensive guide is designed to empower international B2B buyers by providing in-depth insights into the various types and applications of SiC, supplier vetting strategies, and cost considerations.

The guide delves into the structural characteristics of SiC, its role in advanced manufacturing, and its significance in industries such as electronics, automotive, and renewable energy. By outlining best practices for assessing supplier credibility and product quality, this resource aims to facilitate informed purchasing decisions. Additionally, it addresses common questions such as how to evaluate the performance metrics of SiC structures and what factors influence their pricing in different markets.

By equipping buyers with actionable insights and a thorough understanding of the SiC landscape, this guide not only enhances procurement strategies but also fosters long-term partnerships with trusted suppliers, ultimately driving business success in an increasingly interconnected world.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Structural Steel | High strength-to-weight ratio, ductility, and recyclability | Construction, manufacturing, energy | Pros: Durable and versatile; Cons: Susceptible to corrosion without treatment. |

| Reinforced Concrete | Combines concrete's compressive strength with steel's tensile strength | Infrastructure, commercial buildings | Pros: Fire-resistant and cost-effective; Cons: Heavier and more labor-intensive to work with. |

| Timber Structures | Renewable resource, aesthetic appeal, and good insulation | Residential buildings, eco-friendly projects | Pros: Sustainable and lightweight; Cons: Vulnerable to pests and requires maintenance. |

| Composite Materials | Combination of materials to enhance properties | Aerospace, automotive, advanced manufacturing | Pros: Lightweight and high strength; Cons: Often more expensive and complex to source. |

| Precast Concrete | Factory-made components for quicker assembly | Large-scale construction, bridges | Pros: Speedy installation and quality control; Cons: Transport costs and limited customization. |

Structural steel is recognized for its high strength-to-weight ratio, making it ideal for large buildings and infrastructure projects. Its ductility allows it to withstand stress and deformation without breaking, while its recyclability aligns with sustainability goals. B2B buyers in construction and manufacturing should consider the potential need for protective coatings to prevent corrosion, as untreated steel may degrade over time.

Reinforced concrete combines the compressive strength of concrete with the tensile strength of steel reinforcement, making it a preferred choice for infrastructure and commercial buildings. This material is fire-resistant, cost-effective, and can be molded into various shapes. Buyers should evaluate the initial labor and material costs against the long-term durability and maintenance needs, particularly in regions with extreme weather conditions.

Timber structures are increasingly favored for their aesthetic appeal and sustainability. As a renewable resource, timber offers excellent insulation properties, making it suitable for residential buildings and eco-friendly projects. B2B buyers should weigh the initial lower costs and ease of construction against the long-term maintenance requirements, including protection against pests and moisture.

A stock image related to structure of sic.

Composite materials are engineered to combine the best properties of different materials, resulting in lightweight yet strong structures. They are widely used in aerospace and automotive industries due to their superior performance characteristics. However, B2B buyers must consider the higher costs and potential sourcing challenges, as composites often require specialized suppliers and manufacturing processes.

Precast concrete involves the manufacturing of concrete components in a controlled environment, allowing for faster assembly on-site. This method is particularly advantageous for large-scale construction projects, such as bridges and commercial buildings, where time and quality control are critical. Buyers should assess transport logistics and the need for customization, as these factors can impact overall project timelines and costs.

Related Video: Silicon Carbide Explained - SiC Basics

| Industry/Sector | Specific Application of structure of sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight structural components for aircraft | Enhanced fuel efficiency and reduced operational costs | Compliance with stringent safety standards and regulations |

| Automotive | High-performance brake systems | Improved safety and performance of vehicles | Need for precise specifications and certifications |

| Electronics | Semiconductor substrates | Increased device performance and reliability | Availability of quality assurance and testing capabilities |

| Renewable Energy | Structural components in wind turbines | Greater energy output and durability | Sourcing from suppliers with experience in sustainability |

| Construction | Reinforcement in concrete structures | Enhanced load-bearing capacity and longevity | Consideration of local building codes and environmental impact |

In the aerospace industry, the structure of silicon carbide (SiC) is utilized to create lightweight components that significantly enhance fuel efficiency. SiC's high strength-to-weight ratio allows for the design of parts that can withstand extreme conditions while minimizing weight. For international B2B buyers, particularly those from Europe, stringent compliance with safety regulations is paramount. Suppliers must demonstrate adherence to these standards and provide evidence of rigorous testing to ensure reliability in high-stakes applications.

In automotive applications, the structure of SiC is critical for developing high-performance brake systems. SiC components can withstand high temperatures and provide superior wear resistance, which translates to improved vehicle safety and performance. B2B buyers in South America and Africa must focus on sourcing SiC materials that meet specific automotive industry standards, ensuring that suppliers can deliver consistent quality and performance under varying environmental conditions.

A stock image related to structure of sic.

The electronics sector leverages the structure of SiC for semiconductor substrates, which are essential for high-performance devices. SiC substrates enable higher voltage operations and greater thermal conductivity, leading to more reliable electronic components. Buyers from the Middle East should prioritize sourcing from suppliers that offer comprehensive quality assurance processes and testing capabilities to ensure the longevity and reliability of these crucial materials in their applications.

In renewable energy, particularly in wind turbines, SiC is used for structural components that enhance durability and energy output. The robust nature of SiC contributes to the longevity of wind turbine structures, allowing for higher efficiency in energy generation. Buyers in Africa should consider sourcing from manufacturers who prioritize sustainability and can provide evidence of their environmental impact, as this aligns with the growing demand for eco-friendly solutions in energy production.

In the construction industry, the structure of SiC is vital for reinforcing concrete structures, providing enhanced load-bearing capacity and longevity. This application is particularly relevant for large-scale infrastructure projects. European buyers must be aware of local building codes and environmental regulations when sourcing SiC materials, ensuring that their suppliers can meet these requirements while delivering high-quality, durable products.

The Problem:

B2B buyers often face challenges in navigating the complex landscape of structural integrity standards associated with the structure of sic (standard industrial classification). This can lead to confusion regarding compliance, which is critical for ensuring safety and operational efficiency. Buyers may struggle with differing regulations across regions, particularly when sourcing materials or services from international suppliers. This uncertainty can result in costly delays, potential legal issues, and compromised project timelines.

The Solution:

To effectively address these concerns, B2B buyers should invest time in understanding the specific structural integrity standards relevant to their industry and region. This involves consulting official regulatory bodies and industry associations that provide guidelines and updates on compliance. Engaging with local experts or consultants who specialize in structural engineering can also provide insights into best practices and regional differences in standards. Additionally, creating a checklist of compliance requirements tailored to your projects can help streamline the sourcing process and ensure that all parties involved are aligned with the necessary regulations.

The Problem:

Another common pain point for international B2B buyers is the difficulty in sourcing high-quality materials that meet the specifications of the structure of sic. This challenge is especially pronounced when dealing with diverse suppliers from different regions, where quality assurance practices may vary significantly. Poor quality materials can lead to structural failures, safety hazards, and increased costs due to rework or replacement.

The Solution:

To mitigate this issue, buyers should establish a robust supplier evaluation process that includes rigorous quality control measures. This can involve requesting material certifications, conducting on-site audits of suppliers, and seeking references from previous clients. Utilizing platforms that aggregate supplier reviews and ratings can also provide valuable insights into the reliability of potential vendors. Moreover, forming strategic partnerships with trusted suppliers who have a proven track record can enhance the quality assurance process. By prioritizing quality and transparency in sourcing, buyers can significantly reduce risks associated with material quality.

The Problem:

B2B buyers frequently encounter challenges in managing project timelines due to delays in the procurement of materials or services related to the structure of sic. These delays can stem from various factors, including supplier lead times, logistics issues, and unforeseen regulatory hurdles. Such setbacks not only jeopardize project completion but can also strain relationships with clients and stakeholders.

The Solution:

To effectively manage timelines, buyers should implement a proactive project management strategy that includes clear timelines and contingency plans. This involves establishing a detailed project schedule that accounts for potential delays and setting milestones for critical procurement activities. Utilizing project management software can facilitate better tracking of timelines and enhance communication among all stakeholders. Additionally, building a network of reliable suppliers with flexible lead times can provide alternatives in case of unexpected delays. Regularly reviewing project progress and adjusting plans accordingly will help keep projects on track and maintain stakeholder confidence.

By addressing these common pain points with actionable strategies, B2B buyers can navigate the complexities of the structure of sic more effectively, leading to improved project outcomes and strengthened supplier relationships.

Silicon Carbide (SiC) structures are increasingly utilized in various applications due to their superior properties. The selection of the right material is crucial for ensuring optimal performance in demanding environments. Below, we analyze four common materials used in the structure of SiC, focusing on their properties, pros and cons, and specific considerations for international B2B buyers.

Key Properties: SiC is known for its high thermal conductivity, exceptional hardness, and excellent corrosion resistance. It can withstand high temperatures (up to 1600°C) and has a high pressure rating.

Pros & Cons:

- Pros: SiC offers outstanding durability and thermal stability, making it ideal for high-performance applications. Its resistance to oxidation and chemical attack enhances its lifespan.

- Cons: The main drawback is its high manufacturing cost and complexity, which can limit its use in budget-sensitive projects.

Impact on Application: SiC is particularly suitable for high-temperature applications, such as semiconductor devices and power electronics, where efficiency and reliability are paramount.

Considerations for International Buyers: Buyers from Europe, Africa, and South America should be aware of compliance with standards such as ASTM and DIN, which can affect sourcing and manufacturing processes.

Key Properties: Alumina is a ceramic material known for its high hardness and excellent thermal stability. It can withstand temperatures up to 1700°C and is chemically inert.

Pros & Cons:

- Pros: Alumina is relatively low-cost compared to SiC and offers good mechanical strength and wear resistance.

- Cons: Its brittleness can be a limitation in applications requiring high impact resistance.

Impact on Application: Alumina is often used in applications such as insulators and substrates for electronic components due to its dielectric properties.

Considerations for International Buyers: Compliance with JIS standards is crucial for buyers in Japan and may also be relevant for European buyers focusing on quality assurance.

Key Properties: Boron nitride exhibits high thermal conductivity and excellent electrical insulation properties. It can operate at temperatures up to 900°C in air.

Pros & Cons:

- Pros: BN is lightweight and offers excellent thermal shock resistance, making it suitable for high-performance applications.

- Cons: The primary limitation is its relatively high cost compared to traditional materials like alumina.

Impact on Application: BN is commonly used in applications requiring thermal management and electrical insulation, such as in semiconductor packaging.

Considerations for International Buyers: Buyers should consider the availability of BN in their region, as sourcing can be more challenging compared to more common materials.

Key Properties: TiO2 is known for its excellent photocatalytic properties and good thermal stability, with operational temperatures up to 600°C.

Pros & Cons:

- Pros: TiO2 is cost-effective and widely available, making it an attractive option for various applications.

- Cons: Its lower thermal conductivity compared to SiC and BN limits its use in high-performance applications.

Impact on Application: TiO2 is often used in coatings and as a pigment in various industries, including construction and automotive.

Considerations for International Buyers: Buyers should ensure compliance with environmental regulations, particularly in Europe, where sustainability is a key focus.

| Material | Typical Use Case for structure of SiC | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide (SiC) | High-performance electronics | Outstanding durability and thermal stability | High manufacturing cost and complexity | High |

| Alumina (Al2O3) | Insulators and substrates | Good mechanical strength and wear resistance | Brittleness limits impact resistance | Medium |

| Boron Nitride (BN) | Semiconductor packaging | Excellent thermal shock resistance | Relatively high cost | High |

| Titanium Dioxide (TiO2) | Coatings and pigments | Cost-effective and widely available | Lower thermal conductivity | Low |

This analysis provides a comprehensive overview of the strategic material selection for SiC structures, enabling international B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

The manufacturing processes for Silicon Carbide (SiC) structures involve several key stages that ensure the material's integrity and performance. Understanding these stages is crucial for international B2B buyers looking to source high-quality SiC products.

The first stage in manufacturing SiC structures is material preparation, which involves the selection and processing of raw materials. High-purity silicon and carbon sources are combined in specific ratios to create SiC powder. The powder is then subjected to high-temperature treatment in a controlled environment to achieve the desired crystalline structure. This process is critical, as impurities can significantly affect the performance of the final product.

Once the SiC powder is prepared, the next step is forming. This can be achieved through various methods, including:

These forming techniques must be meticulously controlled to ensure uniformity and precision in the final product.

In cases where SiC structures require assembly, such as in electronic devices or complex mechanical systems, various techniques are employed:

The assembly stage is critical for achieving the desired functionality and reliability of the final product.

The final stage in the manufacturing process is finishing. This includes surface treatments, grinding, and polishing to achieve the required surface quality and dimensional accuracy. Finishing processes not only enhance the aesthetic appeal of SiC structures but also improve their performance characteristics, such as wear resistance and thermal conductivity.

Quality assurance (QA) in the manufacturing of SiC structures is vital to ensure product reliability and compliance with international standards. B2B buyers must be aware of the QA processes to verify the quality of the products they are sourcing.

International standards play a significant role in ensuring the quality of SiC products. Some key standards include:

Understanding these standards helps B2B buyers assess the credibility of their suppliers.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Implementing these checkpoints helps mitigate risks associated with defects or non-compliance.

B2B buyers can adopt several strategies to verify the quality control measures of their suppliers:

By employing these verification methods, buyers can enhance their confidence in the products they are sourcing.

Various testing methods are employed to ensure the quality and performance of SiC structures. These include:

Understanding these testing methods allows B2B buyers to make informed decisions about the quality of SiC products.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for SiC structures is essential. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure they source high-quality products that meet their specific needs. Engaging in thorough verification processes and understanding relevant standards will further enhance their procurement strategies in the competitive global market.

To successfully navigate the procurement of the 'structure of sic', international B2B buyers must follow a systematic approach. This guide provides a step-by-step checklist to ensure that you make informed decisions and select the best suppliers for your needs.

Before initiating the sourcing process, it is essential to establish clear technical specifications for the structure of sic you require. This includes understanding the material properties, design constraints, and performance expectations. Detailed specifications help in communicating your needs effectively to potential suppliers, ensuring that you receive relevant proposals.

Conduct thorough market research to identify potential suppliers and gain insights into the competitive landscape. Understanding market trends, pricing strategies, and supplier capabilities is crucial for making informed decisions.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don't just rely on their website; seek third-party reviews and testimonials to gain a comprehensive view of their reliability.

Once you have shortlisted potential suppliers, request samples or prototypes of their products. This step allows you to assess the quality and suitability of the structures before making a bulk purchase.

Engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, lead times, and after-sales support. A clear agreement can prevent misunderstandings and establish a solid foundation for a long-term partnership.

Assess potential risks associated with your chosen suppliers. This includes evaluating their financial stability, supply chain reliability, and compliance with international standards. A comprehensive risk assessment helps in mitigating issues that may arise during production or delivery.

After selecting a supplier, finalize your order with clear documentation. Once the procurement process is underway, monitor the supplier's performance against the agreed specifications and timelines.

By following this practical sourcing guide, B2B buyers can enhance their procurement process for the structure of sic, ensuring that they select qualified suppliers who can meet their specific needs efficiently.

When analyzing the cost structure of sourcing structures of silicon carbide (SiC), several components play a crucial role. These include:

Materials: The primary cost driver is the raw materials used in the production of SiC structures. This includes silicon and carbon sources, which can fluctuate based on market demand and geopolitical factors. Buyers should consider sourcing from regions with stable supply chains.

Labor: Labor costs vary significantly by region. For instance, labor in Africa and South America may be lower than in Europe, but the skill level may also differ. Understanding local labor markets is essential for accurate cost estimations.

Manufacturing Overhead: This encompasses utilities, factory rent, and administrative expenses. Manufacturing facilities with advanced technology may incur higher overhead but can lead to more efficient production and lower long-term costs.

Tooling: The cost of molds and dies for SiC structures can be substantial, especially for custom designs. Buyers should assess whether the tooling cost can be amortized over large production volumes to improve cost efficiency.

Quality Control (QC): Ensuring the structural integrity and performance of SiC products often requires rigorous testing and quality assurance processes, which can add to the overall cost. Buyers should prioritize suppliers with robust QC measures to mitigate risks.

Logistics: Shipping costs, including freight and customs duties, can significantly impact the total price. Understanding Incoterms is vital as they dictate who bears these costs, influencing the overall pricing strategy.

Margin: Supplier margins can vary widely based on competition, market conditions, and the specific value-added services offered. Establishing a clear understanding of what constitutes a fair margin will aid in negotiation.

Several factors influence the pricing of SiC structures, and being aware of these can help buyers negotiate better deals:

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Buyers should evaluate their purchasing capabilities and negotiate for lower prices based on anticipated volume.

Specifications and Customization: Custom designs typically incur higher costs. Buyers should balance the need for customization with the potential for standardization to achieve cost savings.

Material Quality and Certifications: Higher quality materials and necessary certifications can increase costs. Buyers should determine which certifications are essential for their market and negotiate with suppliers accordingly.

Supplier Factors: Supplier reputation, reliability, and history can influence pricing. Established suppliers may charge a premium, but they often provide better quality and service. Conducting thorough supplier assessments is crucial.

Incoterms: Understanding the implications of different Incoterms can affect the total landed cost of goods. Buyers should be clear about who is responsible for shipping, insurance, and duties, as this can alter the final price significantly.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, implementing strategic approaches can lead to significant cost savings:

Negotiation Strategies: Engage suppliers in open discussions about pricing, especially for bulk orders or long-term contracts. Highlighting your purchasing potential can incentivize suppliers to offer better terms.

Total Cost of Ownership (TCO): Consider all costs associated with sourcing SiC structures, including maintenance, logistics, and potential downtime. A lower purchase price may not always equate to lower overall costs.

Pricing Nuances: Be aware that pricing can vary based on geopolitical factors, currency fluctuations, and local market conditions. Regularly review and adjust your sourcing strategy to adapt to these changes.

Supplier Diversification: Avoid relying on a single supplier. Building relationships with multiple suppliers can create competition and provide alternative options in case of supply chain disruptions.

While this analysis provides an overview of cost components and pricing influencers, actual prices may vary based on specific circumstances, market conditions, and supplier negotiations. Always conduct thorough market research and supplier assessments before making purchasing decisions.

When considering the structure of silicon carbide (SiC), it’s essential for B2B buyers to evaluate alternative solutions that can meet similar performance standards. This analysis will compare the structure of SiC with other viable alternatives, focusing on critical aspects such as performance, cost, ease of implementation, maintenance, and best use cases. The insights provided here will aid international buyers, especially from regions like Africa, South America, the Middle East, and Europe, in making informed decisions.

| Comparison Aspect | Structure of SiC | Alternative 1: Gallium Nitride (GaN) | Alternative 2: Silicon (Si) |

|---|---|---|---|

| Performance | High thermal conductivity, excellent electrical properties | High efficiency, good thermal performance | Adequate performance, lower thermal conductivity |

| Cost | Higher initial investment, but lower operational costs | Moderate cost, competitive with SiC | Lower upfront cost, but higher operational costs |

| Ease of Implementation | Requires specialized handling and expertise | Relatively easy to implement | Widely understood and implemented |

| Maintenance | Low maintenance due to high durability | Low maintenance, but requires careful handling | Moderate maintenance needs |

| Best Use Case | High-power applications, automotive, and aerospace | RF applications, power electronics | General-purpose electronics, consumer products |

Gallium Nitride is gaining traction as a robust alternative to SiC, particularly in RF applications and power electronics. Its ability to operate at high frequencies and voltages makes it suitable for various high-efficiency applications. However, while GaN offers a moderate cost structure and relatively easy implementation, its thermal performance can be less optimal compared to SiC under extreme conditions. For B2B buyers, GaN is an excellent choice for applications requiring high efficiency but may not be ideal for environments where thermal management is critical.

Silicon remains a staple in the electronics industry due to its lower initial cost and widespread familiarity among manufacturers. While it offers adequate performance for general-purpose applications, its thermal conductivity and efficiency lag behind those of SiC and GaN. For businesses looking for cost-effective solutions in consumer electronics or less demanding applications, silicon might be the best choice. However, buyers should be aware of the higher operational costs associated with silicon, especially in high-performance settings.

Choosing the right structural solution involves understanding specific business needs and application requirements. Buyers should assess the performance demands of their projects, budget constraints, and the technical expertise available within their teams. For high-power and high-efficiency applications, SiC stands out as a premium choice, while GaN offers a balance of performance and cost for RF applications. Meanwhile, silicon remains a viable option for more general applications where cost is a significant factor. By weighing these considerations, international B2B buyers can select the solution that best aligns with their operational goals and market demands.

Understanding the technical specifications of Silicon Carbide (SiC) structures is crucial for international B2B buyers, especially when sourcing materials for high-performance applications. Here are some key properties to consider:

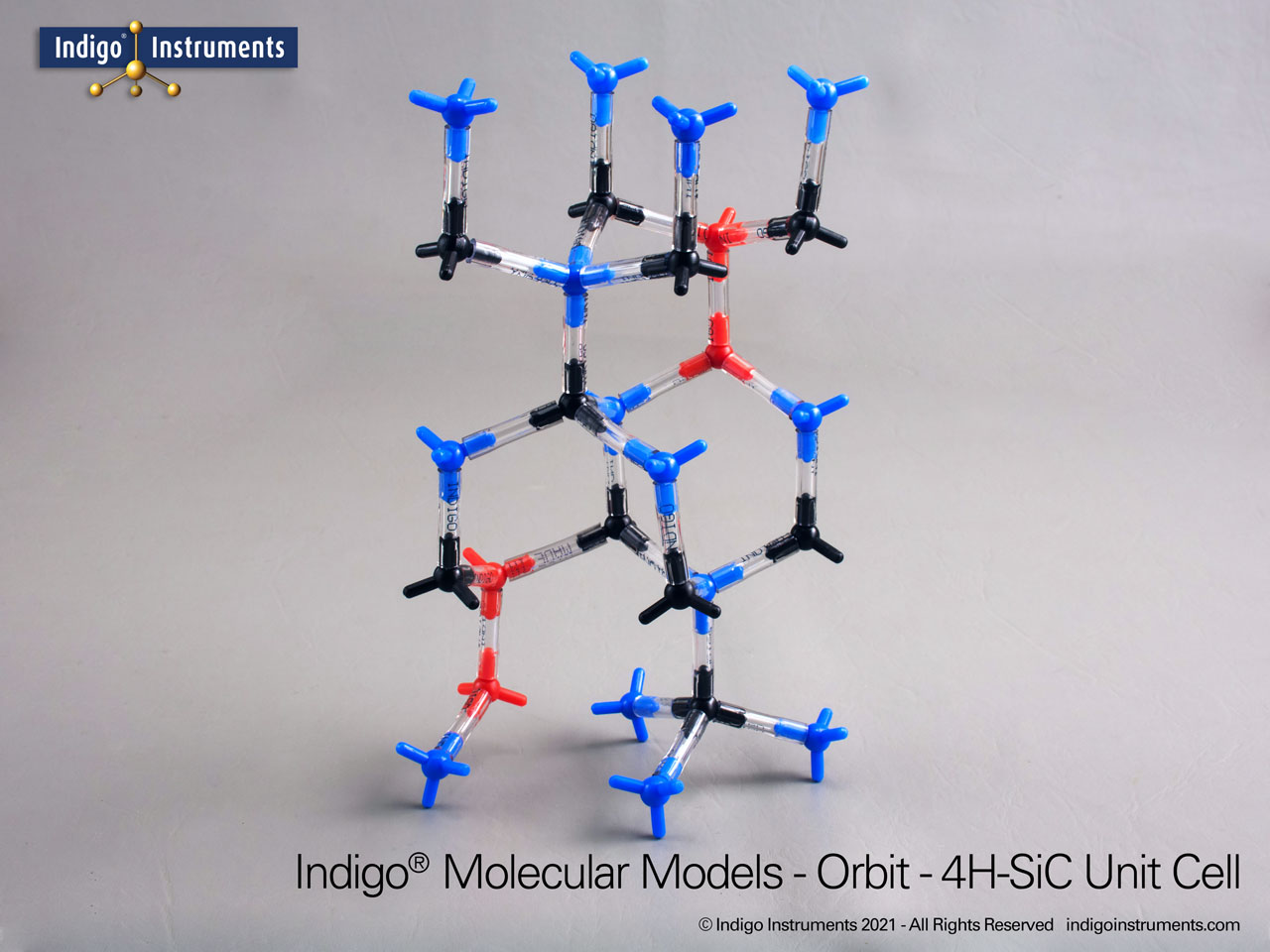

Material grades for SiC indicate the purity and quality of the silicon carbide. High-grade SiC (e.g., 4H-SiC or 6H-SiC) is often preferred for applications requiring high thermal conductivity and mechanical strength. B2B buyers must ensure they select the appropriate material grade to meet the specific demands of their projects, as this affects both performance and longevity.

Tolerance refers to the allowable deviation from specified dimensions. For SiC structures, precise tolerances are critical in applications such as semiconductor manufacturing or aerospace components. A tighter tolerance ensures that parts fit correctly and function as intended, minimizing the risk of failure. Buyers should clearly communicate tolerance requirements to suppliers to avoid costly errors.

Thermal conductivity is a measure of how well a material can conduct heat. SiC has excellent thermal conductivity, making it suitable for high-temperature applications. For B2B buyers, this property is vital for ensuring that components can dissipate heat effectively, reducing the risk of overheating in electronic devices or power systems.

The hardness of SiC is essential for applications where wear resistance is crucial, such as in cutting tools or abrasive materials. SiC ranks high on the Mohs scale of hardness, which means it can withstand significant stress and abrasion. Buyers must assess the hardness requirements based on the intended use to select the right SiC grade.

The electrical conductivity of SiC varies significantly between its polytypes. While it is primarily a semiconductor, its ability to conduct electricity under certain conditions makes it suitable for high-voltage applications. Buyers should consider the electrical properties of SiC when designing systems that require efficient power management.

Familiarizing yourself with industry jargon can significantly streamline the procurement process. Here are some common trade terms relevant to SiC structures:

An OEM refers to a company that produces components that are used in another company's end product. In the context of SiC, buyers often deal with OEMs for custom components tailored to specific applications. Understanding OEM relationships can help buyers ensure that they receive the right quality and specifications.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For SiC structures, MOQs can impact purchasing decisions, especially for smaller companies or startups. Buyers should negotiate MOQs to align with their budget and project requirements.

An RFQ is a document sent to suppliers requesting a price quote for specific products. B2B buyers should prepare detailed RFQs that include specifications such as material grade, tolerance levels, and quantities to receive accurate quotes and avoid misunderstandings.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers as they determine shipping costs, insurance, and liability during transport. Familiarity with these terms can help buyers negotiate better shipping agreements and avoid unexpected costs.

Lead time refers to the time taken from placing an order to delivery. In the context of SiC structures, lead time can be critical, particularly for projects with tight deadlines. Buyers should inquire about lead times upfront to ensure timely delivery and project continuity.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions, streamline their procurement processes, and ultimately enhance their operational efficiencies in sourcing SiC structures.

The structure of the SIC (Standard Industrial Classification) sector is increasingly shaped by global drivers such as urbanization, technological advancements, and the push for sustainable construction practices. Urbanization, particularly in Africa and South America, is driving demand for more resilient and innovative structural solutions. Technological trends, including Building Information Modeling (BIM) and advanced materials like composites and prefabricated components, are redefining sourcing strategies for international B2B buyers. Companies are now leveraging these technologies to enhance project efficiency and reduce costs, making them crucial for competitive advantage.

In the Middle East and Europe, regulatory pressures for sustainability are influencing sourcing trends. Buyers are seeking suppliers who demonstrate compliance with environmental standards and who can provide innovative solutions that meet stringent building codes. Additionally, there is a growing emphasis on digital procurement tools, enabling buyers to streamline their sourcing processes and access global suppliers more effectively. This trend is particularly relevant for European buyers in countries like Germany and Spain, where digital transformation in procurement is accelerating.

Sustainability has become a pivotal factor in the sourcing strategies of international B2B buyers within the structure of the SIC sector. Environmental impacts associated with traditional construction materials, such as high carbon emissions from concrete production, are prompting buyers to explore greener alternatives. This shift is not merely a trend but a response to increasing regulatory requirements and market demand for sustainable practices.

Ethical sourcing is also gaining traction, with buyers prioritizing suppliers who can demonstrate transparency and social responsibility throughout their supply chains. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management) are becoming essential for suppliers looking to establish credibility in the market. By prioritizing ethical and sustainable sourcing, buyers can mitigate risks associated with supply chain disruptions and enhance their brand reputation in an increasingly eco-conscious market.

The structure of the SIC sector has evolved significantly over the decades, shaped by technological innovations and changing market needs. Initially, the sector was heavily reliant on traditional materials and construction methods, which often led to inefficiencies and environmental concerns. However, the introduction of advanced materials and technologies in the late 20th century began to transform the industry, paving the way for more efficient and sustainable practices.

In recent years, the emergence of digital technologies has further revolutionized sourcing and procurement processes. International buyers are now better equipped to analyze market trends, assess supplier capabilities, and make informed decisions that align with their sustainability goals. This historical evolution underscores the importance of adaptability and innovation for businesses seeking to thrive in the competitive landscape of the SIC sector today.

How do I assess the quality of suppliers for structure of SIC?

To assess the quality of suppliers for structure of SIC, conduct thorough background checks, including reviewing their certifications and previous projects. Utilize platforms such as trade directories or industry-specific forums to gather feedback from other buyers. Additionally, request samples or prototypes to evaluate material quality and craftsmanship. Establish communication to gauge responsiveness and support, as reliable suppliers often provide excellent customer service.

What are the typical payment terms for international B2B transactions involving structure of SIC?

Payment terms for international B2B transactions can vary, but common practices include a deposit of 30-50% upfront, with the balance due upon delivery or after inspection. It's crucial to negotiate terms that protect both parties, such as letters of credit or escrow services. Always clarify the preferred payment methods (e.g., wire transfer, PayPal) and be aware of any additional fees that may apply, especially with currency exchange.

What are the minimum order quantities (MOQ) for structure of SIC products?

Minimum order quantities (MOQ) can vary significantly among suppliers, often ranging from 100 to 1,000 units or more, depending on the material and customization requirements. When negotiating, consider discussing lower MOQs if you’re testing a new market or product line. Some suppliers may offer flexibility for new clients or on initial orders, so it’s worthwhile to communicate your needs clearly.

What customization options should I consider when sourcing structure of SIC?

When sourcing structure of SIC, consider customization options such as size, material type, and design specifications. Discuss your project requirements with suppliers to explore available modifications. Ensure that your customization requests align with the supplier's capabilities and timelines, as this can affect production costs and lead times. Collaborating closely with the supplier can lead to innovative solutions tailored to your specific needs.

How do I handle logistics and shipping for international orders of structure of SIC?

Handling logistics for international orders requires a clear understanding of shipping options, costs, and timelines. Work with freight forwarders who specialize in international trade to navigate customs regulations and import/export documentation. Evaluate shipping methods such as air freight for speed or sea freight for cost-efficiency. Always factor in lead times for production and potential delays at customs to ensure timely delivery.

What quality assurance measures should I implement when sourcing structure of SIC?

Implement quality assurance measures by setting clear expectations with your supplier regarding quality standards and inspection processes. Consider third-party inspections at various production stages to ensure compliance with specifications. Establish a protocol for addressing defects or discrepancies upon delivery, including return policies or warranty agreements. Regular communication and feedback loops with suppliers can also enhance product quality over time.

What are the best practices for vetting international suppliers of structure of SIC?

Vetting international suppliers involves a multi-step process, including researching their business history, checking references, and reviewing online feedback. Engage in direct communication to assess their responsiveness and willingness to collaborate. Additionally, consider visiting their facilities if possible or requesting virtual tours to gauge their operations. Establishing a trial order can also help evaluate their capabilities before committing to larger contracts.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the realm of strategic sourcing for the structure of silicon carbide (SiC), international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must prioritize supplier relationships and adaptability. Engaging with suppliers who demonstrate innovation in structural engineering can lead to significant cost efficiencies and enhanced product performance. Understanding local market dynamics and regional regulations is essential for successful procurement strategies, allowing buyers to navigate complexities effectively.

Strategic sourcing not only streamlines procurement processes but also fosters sustainability and resilience in supply chains. By leveraging data-driven insights and technological advancements, businesses can optimize their sourcing strategies, ensuring they remain competitive in a rapidly evolving market landscape. Emphasizing sustainable materials and ethical practices further aligns sourcing efforts with global sustainability goals, appealing to conscious consumers and stakeholders alike.

As the demand for high-performance materials continues to rise, international buyers should proactively seek partnerships with innovative suppliers who are committed to research and development in structural applications of SiC. Embrace this opportunity to enhance your sourcing strategies and stay ahead in the market. Act now to explore new avenues for collaboration and innovation—your future success in the structure of SiC depends on it.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina