Silicon carbide (SiC) is an essential semiconductor material valued for its remarkable physical and electrical properties. It is widely used in many industries thanks to its excellent thermal conductivity, wide bandgap, and outstanding mechanical strength. SiC is found in multiple polytypes, with 4H-SiC and 6H-SiC being two of the most significant. This article will provide an in-depth comparison of these two polytypes, covering their crystal structures, unique characteristics, and applications.

What is Silicon Carbide?

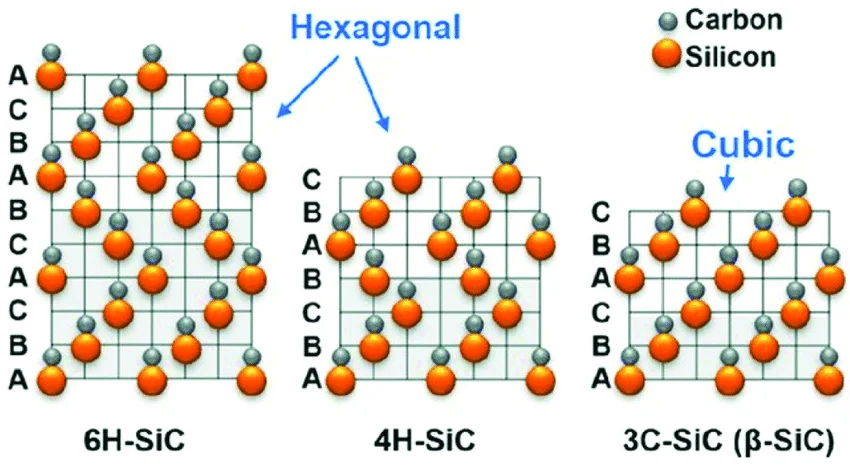

Silicon carbide (SiC) is a covalent compound made of silicon and carbon atoms, with the chemical formula SiC. It is recognized for its diverse polytypes, including 3C, 4H, and 6H, which vary in terms of atomic arrangements and stacking sequences. These polytypes exhibit distinct physical and electrical properties, making each type suited for different technological needs.

The Crystal Structure of Silicon Carbide

The crystal structure of silicon carbide directly influences its overall properties. Both 4H-SiC and 6H-SiC share a hexagonal crystal system, but they differ in stacking sequences. 4H-SiC follows an ABCB pattern, while 6H-SiC exhibits an ABABAB arrangement. These slight structural variations lead to significant differences in material behavior, including symmetry, lattice spacing, and electrical performance.

Different Types of Silicon Carbide

SiC exists in multiple types based on the number of atomic layers in its structure. Common types include 3C, 4H, 6H, and 15R SiC. Of these, 4H-SiC and 6H-SiC are particularly prominent in the semiconductor sector. Despite both having exceptional properties, the subtle differences between them make each more suitable for specific applications.

Key Differences Between 4H-SiC and 6H-SiC

Crystal Structure

The primary distinction between 4H-SiC and 6H-SiC lies in their crystal arrangements. 4H-SiC, with its ABCB stacking pattern, exhibits greater symmetry compared to the ABABAB stacking sequence of 6H-SiC. This difference plays a crucial role in their respective growth rates, defect densities, and overall quality.

Physical Properties

Both 4H-SiC and 6H-SiC demonstrate similar properties like high hardness and superior thermal conductivity. However, there is a key difference in thermal conductivity: 4H-SiC offers higher conductivity along its c-axis, whereas 6H-SiC performs better in the basal plane. This variation makes each polytype more suitable for specific heat dissipation requirements in electronic devices.

Electrical Properties

When it comes to electrical characteristics, 4H-SiC stands out due to its higher electron mobility, which makes it ideal for high-frequency and high-power applications. In contrast, 6H-SiC is better for applications that demand high-quality substrates with fewer deep-level defects, ensuring lower carrier recombination rates.

Applications of 4H-SiC and 6H-SiC

Both 4H-SiC and 6H-SiC are integral in semiconductor applications, but their unique properties make them suitable for different use cases. 4H-SiC is widely used in power electronics such as MOSFETs, Schottky diodes, and transistors, as well as in microwave and UV LED technologies. On the other hand, 6H-SiC is preferred for high-quality substrate production, including epitaxial growth and fabrication of advanced electronic devices.

4H-SiC vs. 6H-SiC: A Comparison

In conclusion, the main distinctions between 4H-SiC and 6H-SiC are based on their crystal structures, physical traits, and electrical performance. 4H-SiC is known for its higher thermal conductivity along the c-axis and better electron mobility, making it ideal for high-power applications. Meanwhile, 6H-SiC's lower defect density and carrier recombination rates make it an excellent choice for high-quality substrate applications. The right choice between these two polytypes depends on the precise needs of your semiconductor device.

Conclusion

Silicon carbide is a versatile material that continues to drive innovation in the semiconductor industry. By understanding the differences between 4H-SiC and 6H-SiC, engineers and scientists can select the most suitable polytype for their specific applications, whether in high-power electronics or high-quality substrates.

FAQs

Q1: Are 4H-SiC and 6H-SiC the only types of silicon carbide?

A: No, while 4H-SiC and 6H-SiC are the most commonly used, silicon carbide comes in other polytypes like 3C and 15R, each with different properties and applications.

Q2: Can 4H-SiC and 6H-SiC be used interchangeably in all devices?

A: Not always. The choice depends on the specific demands of the device. For example, 4H-SiC is preferred for high-power electronics, while 6H-SiC is ideal for substrate applications.

Q3: Which has better thermal conductivity, 4H-SiC or 6H-SiC?

A: 4H-SiC has higher thermal conductivity along the c-axis, while 6H-SiC shows superior thermal conductivity in the basal plane.

Q4: What are some typical uses of 4H-SiC?

A: 4H-SiC is commonly used in high-power electronic components like MOSFETs, Schottky diodes, and bipolar junction transistors.

Q5: Why is 6H-SiC preferred for substrate applications?

A: 6H-SiC is favored for substrates because it has lower defect densities and recombination rates, making it ideal for epitaxial growth and high-quality semiconductor fabrication.