Navigating the complexities of international trade can often feel overwhelming, particularly when it comes to understanding specific terminologies and their implications. For B2B buyers looking to decipher the meaning of "wat betekent sic," it is crucial to grasp not only the definition but also the broader context in which it operates. This guide delves into various aspects of sourcing, including types of products, applications, supplier vetting processes, and cost considerations. By equipping buyers with comprehensive insights into these areas, we aim to empower informed purchasing decisions that can enhance operational efficiency and drive business success.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe face unique challenges, including navigating cultural nuances and varying market dynamics. This guide addresses these challenges head-on, offering actionable strategies for effective engagement with suppliers and manufacturers. Whether you are sourcing high-quality materials or seeking reliable service providers, understanding the implications of "wat betekent sic" can significantly impact your negotiation strategies and overall procurement process.

In the pages that follow, expect a thorough exploration of key topics that will aid you in making sound decisions in the global marketplace. From identifying trustworthy suppliers to understanding cost structures, this guide is your essential resource for navigating the intricacies of international B2B transactions.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WAT (West Africa Time) | Time zone used in parts of Africa, GMT-1. | Scheduling international meetings and events. | Pros: Simplifies time coordination. Cons: Limited to specific regions. |

| WAT (Work and Travel) | Cultural exchange program for students and young professionals. | Talent acquisition and cultural exchange initiatives. | Pros: Enhances cultural diversity. Cons: May involve complex legalities. |

| WAT (What) | Informal abbreviation for "what", often used in communication. | Digital marketing and social media engagement. | Pros: Engages younger audiences. Cons: May lack professionalism in formal contexts. |

| WAT (Web Accessibility Tool) | Tools designed to ensure websites are accessible to all users. | Website development and compliance. | Pros: Improves user experience and compliance. Cons: Implementation can be resource-intensive. |

| WAT (Weighted Average Tenor) | Financial metric used in investment analysis. | Financial services and investment strategies. | Pros: Provides insight into investment risks. Cons: Can be complex for new investors. |

WAT, or West Africa Time, is a critical time zone for businesses operating in or with companies in West Africa. With a GMT offset of -1, understanding WAT is essential for scheduling meetings, coordinating projects, and ensuring timely communications. B2B buyers must consider this time zone when planning interactions to avoid miscommunication and delays, especially when working across different global time zones.

The Work and Travel (WAT) program promotes cultural exchange by allowing students and young professionals to gain international experience. For B2B buyers, leveraging this program can enhance workforce diversity and bring fresh perspectives into the company. However, businesses should be aware of the legal complexities involved in hiring international participants and ensure compliance with local regulations.

The abbreviation "WAT" is widely used in digital communication, particularly among younger audiences. Businesses can harness this informal language to create relatable content and engage effectively on social media platforms. While this strategy can enhance brand relatability, it is crucial to balance informality with professionalism, especially in formal business communications.

Web Accessibility Tools (WAT) are essential for ensuring that websites are usable by all individuals, including those with disabilities. For B2B buyers, investing in these tools not only enhances user experience but also ensures compliance with legal standards regarding accessibility. However, implementing these tools can require significant resources, so businesses must weigh the benefits against the costs involved.

Weighted Average Tenor (WAT) is a financial metric that reflects the average time until the cash flows from an investment are received. For B2B buyers in the financial sector, understanding WAT is crucial for assessing the risk and return profile of investments. While it provides valuable insights, the complexity of calculating WAT may pose challenges for less experienced investors, necessitating thorough analysis and expert guidance.

Related Video: Sicilian Defense ALL Variations Explained [Chess Opening Crash Course]

| Industry/Sector | Specific Application of wat betekent sic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Quality Control in Production Processes | Ensures product consistency and compliance | Evaluate suppliers' quality certifications and track record. |

| Logistics and Shipping | Documentation in International Trade | Reduces delays and misunderstandings in shipping | Assess suppliers’ understanding of regional regulations and languages. |

| Information Technology | Data Management and Analysis | Enhances decision-making through accurate data | Look for suppliers with robust data security and compliance measures. |

| Marketing and Advertising | Content Localization | Improves market penetration and customer engagement | Verify suppliers' expertise in cultural nuances and local language proficiency. |

| Finance and Accounting | Financial Reporting and Compliance | Ensures adherence to international standards | Check for suppliers with experience in local and international accounting standards. |

In the manufacturing sector, 'wat betekent sic' can refer to the specific standards and protocols that ensure quality control in production processes. By understanding these terms, international buyers can ensure that suppliers adhere to recognized quality benchmarks, thus minimizing defects and enhancing product reliability. This is particularly crucial for buyers from regions like Africa and South America, where local suppliers may not always meet international quality standards. Buyers should consider suppliers' quality certifications and their track record in maintaining compliance.

In the logistics and shipping industries, 'wat betekent sic' is often used to clarify documentation requirements in international trade. Misunderstandings in documentation can lead to significant delays and financial losses. By being well-versed in these terminologies, buyers can streamline their shipping processes and ensure that all necessary paperwork is accurately completed. For effective sourcing, it is essential to assess suppliers' understanding of regional regulations and languages to mitigate potential issues during transit.

In the realm of information technology, 'wat betekent sic' can be pivotal in managing and analyzing data accurately. The clarity provided by understanding these terms allows businesses to make informed decisions based on reliable data. This is especially important for international B2B buyers who rely on data for strategic planning and operational efficiency. When sourcing IT solutions, it is crucial to prioritize suppliers that have robust data security measures and compliance with international standards.

In marketing and advertising, understanding 'wat betekent sic' is vital for content localization efforts aimed at diverse markets. By accurately translating and adapting marketing materials, businesses can enhance their engagement with local audiences, thereby improving market penetration. This is particularly relevant for buyers in Europe and the Middle East, where cultural nuances play a significant role in consumer behavior. Buyers should verify suppliers' expertise in local languages and cultural contexts to ensure effective communication.

In finance and accounting, 'wat betekent sic' is crucial for understanding and adhering to financial reporting standards. This ensures that businesses comply with international accounting regulations, which is essential for maintaining transparency and building trust with stakeholders. For international buyers, especially in regions with varying financial regulations, sourcing suppliers with a strong grasp of both local and international standards is key to ensuring accurate financial reporting and compliance.

Related Video: Sci6 Q3 - Characteristics and Uses of Simple Machines

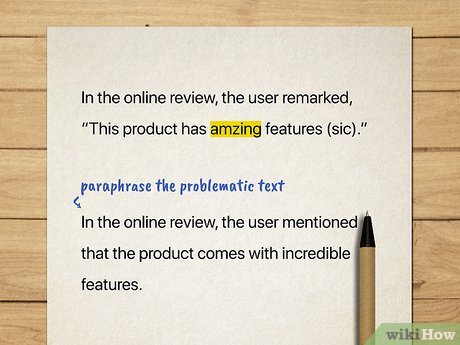

The Problem: B2B buyers often grapple with the complexities of understanding acronyms and terminology in multilingual settings, especially when dealing with international partners. For example, a business in Africa looking to negotiate contracts with a supplier in Europe may encounter the term "sic" in legal documents. The challenge arises when the buyer is unfamiliar with the implications of "sic," which can lead to misunderstandings or misinterpretations of the contract, potentially resulting in financial losses or legal disputes.

The Solution: To effectively navigate this challenge, buyers should invest time in creating a multilingual glossary of industry-specific terms, including "sic." Engaging a professional translator or a language consultant who specializes in legal and business terminology can ensure accurate interpretation and usage. Additionally, utilizing translation software can aid in real-time discussions, ensuring all parties understand the context. Furthermore, hosting a training session on key acronyms and their meanings can foster better communication among team members, reducing the likelihood of misunderstandings in future negotiations.

The Problem: Misinterpretation of terms like "sic" can have serious ramifications for businesses, particularly in sectors such as finance or law, where precision is paramount. A company in South America might receive a report containing the term "sic" indicating a transcription error or quoting a source verbatim. If the term is overlooked or misunderstood, it could lead to compliance issues or faulty financial reporting, ultimately impacting the company's reputation and legal standing.

The Solution: To mitigate this risk, B2B buyers should implement a robust review process for all documentation that includes potentially confusing terms. Establishing a checklist that highlights critical terms and their definitions can help ensure clarity. Additionally, incorporating a compliance officer or a legal advisor in the review stages can provide an extra layer of scrutiny. Regular workshops or webinars focused on common terminology and their implications can also prepare teams to identify and address these terms proactively, thereby minimizing the potential for error.

The Problem: In international B2B environments, teams often comprise members from various cultural backgrounds, leading to communication barriers. The term "wat betekent sic" might be misused or misunderstood during discussions about project specifications or deliverables. This confusion can lead to misaligned objectives, project delays, or even failure to meet client expectations, significantly affecting business relationships and outcomes.

The Solution: To enhance communication clarity, businesses should prioritize the establishment of a common language policy that includes detailed explanations of industry jargon and acronyms like "sic." Utilizing visual aids, such as infographics or presentations, that illustrate these terms can help bridge the knowledge gap. Furthermore, fostering an open communication culture where team members feel comfortable asking for clarification can significantly reduce misunderstandings. Regular team-building exercises that promote cultural awareness and sensitivity can also enhance mutual understanding, paving the way for more productive collaboration.

When selecting materials for applications related to 'wat betekent sic', it is essential to consider various factors such as performance, durability, and compatibility with specific media. Below, we analyze four common materials, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

A stock image related to wat betekent sic.

Stainless steel is renowned for its excellent corrosion resistance and strength, making it a popular choice in various industries. It typically has a temperature rating of up to 800°C (1472°F) and can withstand high pressure, which is essential for applications involving fluids or gases.

Pros: Stainless steel is durable, easy to clean, and highly resistant to rust and corrosion. It also has a long lifespan, which can reduce replacement costs over time.

Cons: The initial cost of stainless steel can be high compared to other materials. Additionally, its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and alkalis, making it suitable for chemical processing applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and South America should ensure that the grades used meet local regulations.

Carbon steel is widely used due to its high strength and affordability. It typically has a lower temperature rating than stainless steel, around 400°C (752°F), and is less resistant to corrosion.

Pros: Carbon steel is cost-effective and readily available, making it an attractive option for budget-conscious projects. It also possesses good tensile strength.

Cons: Its susceptibility to rust and corrosion can lead to higher maintenance costs. Additionally, it may not be suitable for applications involving corrosive substances.

Impact on Application: Carbon steel is often used in structural applications but may require protective coatings when exposed to harsh environments.

Considerations for International Buyers: Buyers should be aware of the need for protective treatments and ensure compliance with local standards. In Europe, for instance, EN standards are often referenced.

A stock image related to wat betekent sic.

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It can typically handle temperatures up to 100°C (212°F) and is often used in applications involving corrosive chemicals.

Pros: Polypropylene is highly resistant to a variety of chemicals, making it ideal for chemical storage and transport. It is also lightweight, which can reduce shipping costs.

Cons: Its temperature resistance is limited compared to metals, and it may not be suitable for high-pressure applications.

Impact on Application: Polypropylene is compatible with many acids and bases, making it a preferred choice for chemical processing industries.

Considerations for International Buyers: Buyers should verify that the polypropylene used meets industry-specific standards, such as those set by ASTM or ISO, especially in regions with stringent regulations like Europe.

Aluminum is a lightweight metal with excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 600°C (1112°F) and is used in various applications, from automotive to aerospace.

Pros: Aluminum is lightweight and resistant to corrosion, making it suitable for applications where weight savings are critical. It also has good thermal and electrical conductivity.

Cons: Aluminum is generally more expensive than carbon steel and can be less durable under high-stress conditions.

Impact on Application: Its lightweight nature makes aluminum ideal for applications where weight is a concern, such as in transport and aerospace sectors.

Considerations for International Buyers: Buyers should ensure that the aluminum grades used comply with local and international standards, particularly in industries with strict safety regulations.

| Material | Typical Use Case for wat betekent sic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing equipment | Excellent corrosion resistance | High initial cost | High |

| Carbon Steel | Structural applications | Cost-effective and strong | Susceptible to rust | Low |

| Polypropylene | Chemical storage tanks | Lightweight and chemically resistant | Limited temperature resistance | Medium |

| Aluminum | Aerospace components | Lightweight and corrosion-resistant | More expensive than carbon steel | High |

This comprehensive analysis and summary table provide international B2B buyers with actionable insights into material selection for applications related to 'wat betekent sic', ensuring informed decision-making based on properties, advantages, and compliance considerations.

Understanding the manufacturing processes involved in producing "wat betekent sic" is essential for international B2B buyers. The process typically encompasses several key stages, including material preparation, forming, assembly, and finishing. Each stage employs specific techniques that ensure the final product meets quality standards and customer expectations.

The first stage of manufacturing involves sourcing and preparing raw materials. This may include various types of metals, polymers, or composites, depending on the specific requirements of the product. Key techniques in this stage include:

The forming stage is critical in defining the physical attributes of the product. This involves transforming raw materials into specific shapes and forms using techniques such as:

Each technique requires precise control of temperature, pressure, and timing to ensure quality and consistency.

The assembly stage combines various components into a final product. This stage can be labor-intensive and involves several techniques:

Proper assembly techniques are crucial for ensuring the integrity and functionality of the final product.

Finishing processes enhance the aesthetic and functional qualities of the product. Common finishing techniques include:

The finishing stage is vital for creating a product that not only performs well but also meets customer expectations for quality and appearance.

For international B2B buyers, understanding quality assurance is crucial. Various international standards apply to manufacturing processes, including:

Being aware of these standards helps B2B buyers assess the credibility and reliability of potential suppliers.

Quality Control (QC) is an integral part of the manufacturing process, ensuring that products meet specified standards. Common QC checkpoints include:

Implementing rigorous QC checkpoints minimizes defects and enhances customer satisfaction.

Various testing methods are employed during the QC process to ensure product integrity and performance. Common methods include:

These testing methods are crucial for verifying compliance with quality standards and specifications.

For international B2B buyers, verifying supplier QC practices is essential for maintaining product quality. Effective methods include:

These actions help buyers ensure that suppliers adhere to high-quality standards, ultimately safeguarding their interests.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique QC challenges. Factors to consider include:

By being aware of these nuances, B2B buyers can navigate the complexities of international sourcing and ensure they procure high-quality products.

To effectively navigate the complexities of sourcing products or services related to "wat betekent sic," international B2B buyers must follow a structured approach. This guide provides a detailed checklist to streamline the procurement process, ensuring that you make informed decisions that align with your business needs.

Understanding your specific needs is crucial before engaging potential suppliers. Define the scope of what you are looking to procure, whether it's products, services, or information related to "wat betekent sic". This clarity will help you communicate effectively with suppliers and assess their offerings against your expectations.

Conduct thorough research to identify potential suppliers who specialize in "wat betekent sic" related offerings. Utilize online directories, trade associations, and industry forums to compile a list of candidates.

Before moving forward, it’s imperative to verify the credentials of potential suppliers. Request documentation that demonstrates their compliance with industry standards, certifications, and any relevant accreditations.

Whenever possible, ask for samples or demonstrations of the products or services. This step allows you to evaluate the quality and suitability of what you intend to procure.

Once you have narrowed down your options, solicit detailed quotes from the shortlisted suppliers. Pay attention not only to pricing but also to the terms of service, including payment options, delivery timelines, and return policies.

After selecting a preferred supplier, initiate discussions to negotiate contract terms. This includes pricing, delivery schedules, and warranty agreements.

Building a strong relationship with your supplier can facilitate smoother transactions in the future. Communicate openly about your experiences, and provide feedback to help them improve their offerings.

By following this step-by-step checklist, B2B buyers can effectively source products or services related to "wat betekent sic," minimizing risks and maximizing value in their procurement activities.

When analyzing the cost structure for sourcing related to 'wat betekent sic', several components play a crucial role:

Materials: The cost of raw materials can significantly affect the overall pricing. This includes the quality and type of materials required for production. Buyers should consider sourcing materials locally where possible to mitigate transportation costs.

Labor: Labor costs vary by region and can impact the total cost structure. Countries in Africa, South America, the Middle East, and Europe have differing labor rates, which can affect the pricing strategy. It's essential to evaluate the skill levels required for production and their availability in the sourcing region.

Manufacturing Overhead: This includes utilities, rent, and general administrative expenses associated with manufacturing. Understanding these costs helps buyers gauge the competitiveness of supplier pricing.

Tooling: Specific tools and molds may be necessary for production. The initial investment in tooling can be substantial, particularly for custom orders. Buyers should ask suppliers about tooling costs and amortization strategies.

Quality Control (QC): Ensuring product quality often incurs additional costs. Buyers should discuss QC processes with suppliers, as stringent quality measures may increase the price but are crucial for maintaining standards.

Logistics: Shipping and handling costs can vary widely based on distance, mode of transport, and volume. Understanding logistics is critical, especially for international shipments, where customs duties and tariffs may apply.

Margin: The supplier’s profit margin is an inherent part of pricing. Buyers should compare margins across different suppliers to identify the most cost-effective options.

Several factors influence pricing beyond the basic cost structure:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, so buyers should assess their purchasing power. Negotiating MOQs can yield better pricing structures.

Specifications and Customization: Custom specifications can drive up costs due to additional labor and material requirements. Buyers should clarify their needs upfront to avoid unforeseen expenses.

Material Quality and Certifications: Higher quality materials and specific certifications (like ISO or CE) can increase costs. Buyers should weigh the benefits of premium materials against their budget constraints.

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may charge a premium, but they often provide better service and quality assurance.

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can significantly affect pricing and should be clearly defined in contracts.

To navigate the complexities of sourcing effectively, international B2B buyers should consider the following tips:

Negotiate Wisely: Leverage volume purchases and establish long-term relationships with suppliers to negotiate better terms. Don't hesitate to request quotes from multiple suppliers to ensure competitive pricing.

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes all costs associated with acquiring, using, and disposing of a product. This approach helps identify the best long-term value.

Understand Pricing Nuances: Familiarize yourself with local market conditions, currency fluctuations, and economic factors that may affect pricing. This knowledge can aid in making informed purchasing decisions.

Be Cautious with Indicative Prices: Always request detailed quotes and be wary of indicative prices that may not reflect the final cost. Hidden fees can emerge, especially in international transactions.

By understanding these cost components and price influencers, buyers from regions like Africa, South America, the Middle East, and Europe can make more informed decisions in their sourcing strategies for 'wat betekent sic'.

When considering alternatives to 'wat betekent sic', it's essential to evaluate different methods or products that can achieve similar objectives. This analysis will help international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—make informed decisions based on their unique business needs and contexts.

| Comparison Aspect | 'Wat Betekent Sic' | Alternative 1 Name | Alternative 2 Name |

|---|---|---|---|

| Performance | High | Medium | High |

| Cost | Moderate | Low | High |

| Ease of Implementation | Easy | Moderate | Complex |

| Maintenance | Low | Low | High |

| Best Use Case | General understanding | Quick reference needs | In-depth analysis |

Quick reference tools, such as acronyms and slang dictionaries, provide a straightforward approach for users who need immediate clarification. They are typically low-cost and easy to implement, making them accessible for a wide range of users. However, they may lack depth and comprehensive understanding, which could be a downside for businesses that require detailed analyses or context-specific information.

In-depth analysis platforms offer a thorough understanding of terms and concepts, making them ideal for businesses that need detailed insights. These platforms can provide context, usage examples, and industry-specific applications, which enhance comprehension. However, they often come with a higher cost and require more time to implement. Additionally, maintaining such platforms can be resource-intensive, which may not suit all organizations.

Selecting the right solution involves assessing specific business requirements. For organizations needing quick, straightforward answers, tools like quick reference dictionaries may suffice. However, for those requiring comprehensive insights and context, investing in in-depth analysis platforms could be more beneficial. Ultimately, understanding the unique needs of your business—whether it be cost, implementation ease, or the depth of information required—will guide you in choosing the most suitable alternative to 'wat betekent sic'.

Understanding the technical properties associated with the term 'wat betekent sic' is crucial for international B2B buyers. Here are several key specifications that play a significant role in decision-making:

Material Grade

- Definition: This refers to the specific type of material used in manufacturing a product, which can affect its performance and durability.

- Importance: Selecting the right material grade ensures that the product meets industry standards and can withstand the intended use, reducing the risk of failures and returns.

Tolerance Levels

- Definition: Tolerance indicates the allowable variation in product dimensions or properties.

- Importance: In B2B transactions, precise tolerances are essential for parts that must fit together, such as in machinery or assembly lines. Understanding tolerance can help in avoiding costly production delays and ensuring product compatibility.

Surface Finish

- Definition: The texture and smoothness of a product’s surface, which can be critical for aesthetic and functional purposes.

- Importance: A proper surface finish can enhance product performance, prevent corrosion, and improve appearance, which is vital for market competitiveness.

Load Bearing Capacity

- Definition: This specification indicates how much weight or pressure a product can withstand without failure.

- Importance: For buyers, knowing the load-bearing capacity is crucial for safety and compliance, especially in construction and engineering applications.

Chemical Resistance

- Definition: The ability of a material to resist degradation when exposed to chemicals.

- Importance: In industries such as pharmaceuticals and food processing, understanding chemical resistance is vital to prevent contamination and ensure product integrity.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B contexts. Here are several important terms:

OEM (Original Equipment Manufacturer)

- Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

- Significance: Understanding OEM relationships can help buyers identify quality sources for components and assess compatibility with their existing systems.

MOQ (Minimum Order Quantity)

- Definition: The smallest number of units that a supplier is willing to sell.

- Significance: Knowing the MOQ is crucial for buyers to manage inventory and cash flow effectively, especially when sourcing products in bulk.

RFQ (Request for Quotation)

- Definition: A document issued by a buyer to solicit price bids from suppliers for specific products or services.

- Significance: Issuing an RFQ allows buyers to compare pricing and terms from multiple suppliers, ensuring competitive sourcing.

Incoterms (International Commercial Terms)

- Definition: A set of predefined international rules published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

- Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfer, and cost allocation, which are vital for international trade.

Lead Time

- Definition: The amount of time that passes from the start of a process until its completion.

- Significance: Understanding lead times is essential for buyers to plan inventory levels, production schedules, and delivery commitments effectively.

By mastering these technical properties and trade terms, B2B buyers can enhance their procurement processes, optimize supplier relationships, and ultimately drive more successful business outcomes.

The 'wat betekent sic' sector is experiencing transformative changes influenced by globalization and technological advancements. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must stay informed about these dynamics to remain competitive. Key drivers include the integration of digital platforms that streamline sourcing processes, enhance supply chain visibility, and foster collaboration among stakeholders. Additionally, the rise of artificial intelligence and machine learning is enabling predictive analytics, allowing buyers to anticipate market shifts and optimize purchasing strategies.

Emerging trends also reveal a shift towards localized sourcing as companies aim to reduce lead times and transportation costs. This is particularly relevant for buyers in Africa and South America, where regional supply chains are becoming more robust. Furthermore, the demand for personalized products and services is on the rise, compelling suppliers to adapt quickly to buyer preferences. Understanding these trends is crucial for international B2B buyers who seek to maximize efficiency and responsiveness in their sourcing strategies.

Sustainability and ethical sourcing are no longer optional considerations; they are essential components of modern B2B procurement strategies. Buyers are increasingly aware of the environmental impact of their sourcing decisions, prompting a shift towards sustainable practices. This includes prioritizing suppliers who adhere to eco-friendly practices and are certified for their environmental standards, such as ISO 14001 or Fair Trade certifications.

Moreover, ethical supply chains are gaining importance as consumers and businesses alike demand transparency and accountability. B2B buyers must ensure that their suppliers comply with labor laws and ethical sourcing standards to mitigate risks associated with reputational damage. By investing in 'green' materials and sustainable practices, companies not only contribute positively to the environment but also enhance their brand image, which is a significant competitive advantage in today's market.

Historically, the 'wat betekent sic' sector has evolved in response to changing economic landscapes and technological advancements. Initially characterized by traditional procurement methods, the sector has seen a significant shift towards digitalization over the past two decades. The advent of e-procurement platforms and online marketplaces has revolutionized how businesses source goods and services, making it easier for international buyers to connect with suppliers across the globe.

As market demands shifted towards customization and sustainability, the sector adapted by incorporating advanced sourcing technologies and ethical practices. This evolution has been particularly pronounced in regions such as Europe, where stringent regulations on sustainability and labor practices have spurred innovation in sourcing strategies. Understanding this historical context allows B2B buyers to appreciate the current landscape and anticipate future trends that may impact their procurement strategies.

How do I solve issues with supplier communication when sourcing 'wat betekent sic'?

Effective communication is crucial when sourcing products or services. Start by setting clear expectations with your suppliers regarding timelines, product specifications, and quality standards. Utilize communication tools like WhatsApp, Skype, or email to maintain regular contact. Additionally, consider language barriers; using simple language or hiring a translator can help ensure mutual understanding. Regular follow-ups and feedback loops can also address issues proactively, preventing misunderstandings that could derail your sourcing process.

What is the best method for vetting suppliers when sourcing 'wat betekent sic'?

To effectively vet suppliers, conduct thorough background checks, including reviewing their business history, client testimonials, and industry certifications. Utilize platforms like Alibaba or Global Sources to access supplier ratings and reviews. You should also request samples to assess product quality firsthand. Conducting a site visit, if feasible, allows you to evaluate the supplier's operational capabilities and compliance with international standards, which is particularly important for buyers from Africa, South America, and the Middle East.

How can I customize products when sourcing 'wat betekent sic'?

Customization is often a key factor in meeting specific market needs. Start by clearly defining your customization requirements, including design, materials, and functionality. Communicate these needs to your supplier early in the negotiation process. Many suppliers are open to customization but may require minimum order quantities (MOQs) to offset setup costs. Be prepared to discuss these aspects, and ensure that your supplier has the capability and flexibility to meet your customization requests.

What are the typical minimum order quantities (MOQ) when sourcing 'wat betekent sic'?

Minimum order quantities (MOQs) can vary significantly based on the supplier and the type of product. Typically, MOQs are set to cover production costs and are often higher for customized products. For standard products, MOQs might range from 100 to 1,000 units. It’s advisable to discuss MOQs upfront during negotiations to ensure they align with your purchasing capacity. If MOQs are too high, consider negotiating lower quantities or seeking out suppliers who specialize in smaller batch production.

What payment terms should I negotiate when sourcing 'wat betekent sic'?

When negotiating payment terms, it's essential to balance risk and cash flow. Common terms include 30% upfront and 70% upon delivery, but this can vary. Explore options like letters of credit or escrow services, especially for larger orders, to protect against supplier default. Discussing payment methods, such as PayPal or bank transfers, can also help streamline transactions. Ensure that any agreed-upon terms are documented in your contract to avoid disputes later.

How do I ensure quality assurance (QA) when sourcing 'wat betekent sic'?

Implementing a robust quality assurance process is vital for maintaining product standards. Start by defining your quality criteria clearly in the contract. Request regular updates and conduct inspections at various production stages. If possible, hire third-party quality inspectors to conduct checks before shipment. Establishing a solid relationship with your supplier can also facilitate better QA, as they will be more inclined to prioritize your quality standards when they understand your expectations.

What logistics considerations should I keep in mind when sourcing 'wat betekent sic'?

Logistics play a critical role in international sourcing. Consider factors such as shipping methods, lead times, and customs regulations. Engage with logistics providers who specialize in international shipping to understand the best routes and methods for your products. Be aware of potential delays at customs and factor these into your timelines. Additionally, ensure that your supplier is familiar with the shipping requirements specific to your region to avoid complications during transit.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the ever-evolving landscape of global trade, understanding the nuances of terms like "wat betekent sic" is crucial for international B2B buyers. Strategic sourcing not only enhances procurement efficiency but also fosters strong supplier relationships, especially for businesses in Africa, South America, the Middle East, and Europe. By leveraging local insights and market knowledge, companies can optimize their sourcing strategies, ensuring they remain competitive while meeting diverse customer needs.

The value of strategic sourcing extends beyond cost savings; it drives innovation and sustainability, enabling businesses to adapt to market fluctuations. As international buyers, it is essential to prioritize suppliers who align with your ethical and operational standards. This approach not only mitigates risks but also enhances brand reputation in the global marketplace.

Looking ahead, international B2B buyers should embrace digital transformation and data analytics to refine their sourcing strategies. By staying informed about industry trends and consumer preferences, businesses can make proactive decisions that lead to long-term success. Engage with suppliers who demonstrate agility and responsiveness, and don't hesitate to explore new markets. The journey towards effective strategic sourcing is ongoing, and the opportunities are limitless for those ready to take the next step.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina