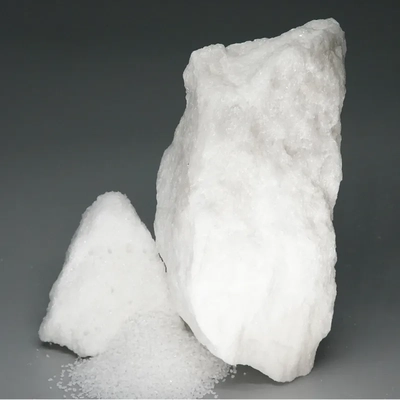

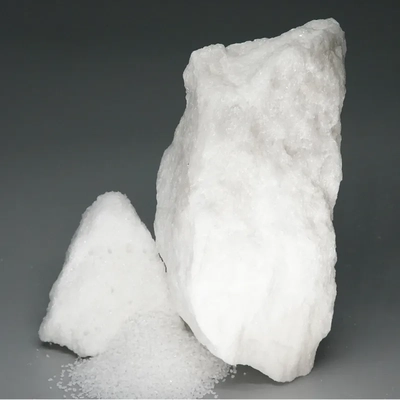

Low-Sodium White Fused Alumina for High-Tech Ceramics – a high-purity aluminum oxide abrasive with Na₂O < 0.1%, excellent thermal stability & chemical resistance. Ideal for advanced ceramics, refractory materials, and precision electronics. Available in various grit sizes. Contact us for bulk orders!

Our Low Sodium White Fused Alumina (WFA) is engineered for industries requiring exceptional purity and performance in abrasive and refractory applications. With industry-leading low Na₂O content, this premium material delivers superior performance in high-temperature environments and precision grinding operations.

Superior performance in processing hard materials like metals, ceramics, and stones.

Improves the stability and durability of the product under thermal stress..

Reduces the risk of cracks and deformation in high-temperature environments.

Long-lasting performance in abrasive applications such as blasting and surface finishing.

| Component | Specification |

|---|---|

| Al₂O₃ | ≥ 99.5% |

| Na₂O | ≤ 0.15% |

| SiO₂ | ≤ 0.10% |

| Fe₂O₃ | ≤ 0.05% |

| CaO | ≤ 0.03% |

| MgO | ≤ 0.03% |

| Property | Value |

|---|---|

| Mohs Hardness | 9.0 - 9.2 |

| Micro Hardness (Knoop) | 2100 - 2200 kg/mm² |

| Bulk Density | 1.75 - 1.95 g/cm³ |

| Specific Gravity | 3.95 - 4.05 g/cm³ |

| Melting Point | 2054°C |

| Color | White |

| Classification | Available Sizes |

|---|---|

| Macro Grits (FEPA F) | F12, F14, F16, F20, F22, F24, F30, F36, F40, F46, F54, F60, F70, F80, F90 |

| Medium Grits (FEPA F) | F100, F120, F150, F180 |

| Micro Grits (FEPA F) | F220, F230, F240, F280, F320, F360, F400, F500, F600, F800, F1000, F1200 |

| Powder (JIS) | #1500, #2000, #2500, #3000, #4000, #6000, #8000 |

| Custom Specifications | Available upon request |

We can offer 1MT/25Kg Woven plastic bags, and 25Kg Paper bags.

Our Black Silicon Carbide is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Founded in 2005, our company is a leading manufacturer of high-quality Silicon Carbide (SiC) and various types of fused alumina products. With nearly two decades of industry expertise, we have established a reputation for delivering durable and performance-driven materials for a wide range of applications, including abrasives, refractories, and ceramics.