In an increasingly competitive global market, sourcing the right abrasive materials can be a daunting challenge for international B2B buyers. Whether you are in South Africa looking for high-quality grinding wheels or in Colombia seeking durable sandpaper, the stakes are high. The abrasive industry encompasses a wide array of products designed for various applications, from metalworking to construction and automotive industries. This guide aims to provide a comprehensive overview of the abrasive market, covering essential topics such as types of abrasives, their applications, supplier vetting processes, and cost considerations.

As a buyer, understanding the nuances of abrasive materials can empower you to make informed purchasing decisions that align with your operational needs and budget constraints. This guide is tailored specifically for B2B buyers from Africa, South America, the Middle East, and Europe, offering actionable insights that address regional market dynamics and supplier reliability. By navigating through this resource, you will gain valuable knowledge on selecting the right abrasive products, ensuring quality assurance, and optimizing your supply chain processes.

Armed with this information, you can enhance your procurement strategy, foster stronger supplier relationships, and ultimately drive efficiency in your operations. Let’s dive into the intricacies of the global abrasive market and unlock the potential for your business growth.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Oxide | Durable, high cutting speed, and versatility | Metalworking, woodworking, and ceramics | Pros: Cost-effective, long-lasting; Cons: Can generate heat, may require cooling. |

| Silicon Carbide | Harder than aluminum oxide, excellent for hard materials | Glass, stone, and hard metals | Pros: Superior cutting ability; Cons: More expensive, less versatile than aluminum oxide. |

| Diamond Abrasives | Exceptional hardness, ideal for precision work | Electronics, jewelry, and optical materials | Pros: High precision, long lifespan; Cons: Very high cost, limited to specific applications. |

| Garnet | Natural abrasive, eco-friendly, and non-toxic | Blasting, waterjet cutting, and sanding | Pros: Environmentally friendly, effective for soft materials; Cons: Less durable than synthetic options. |

| Ceramic Abrasives | Uniform shape, high strength, and durability | Precision grinding and polishing | Pros: Consistent performance, good for fine finishes; Cons: Higher cost, may not suit all applications. |

Aluminum oxide abrasives are known for their durability and versatility, making them suitable for a variety of applications, including metalworking and woodworking. Their ability to maintain a sharp edge allows for efficient cutting and grinding. When purchasing aluminum oxide abrasives, B2B buyers should consider the grit size, as finer grits are better for polishing, while coarser grits are ideal for heavy material removal. Additionally, the heat generated during use can necessitate cooling methods to prevent damage to workpieces.

Silicon carbide abrasives are characterized by their exceptional hardness, making them particularly effective for cutting hard materials like glass and stone. This abrasive type is often preferred in applications requiring a finer finish. B2B buyers should evaluate the specific requirements of their projects, as silicon carbide may be more expensive than alternatives like aluminum oxide. It's also essential to consider its limited versatility, as it may not be suitable for softer materials.

Diamond abrasives are renowned for their unmatched hardness and precision, making them ideal for industries such as electronics and jewelry manufacturing. They offer a long lifespan and exceptional cutting capabilities, but their high cost can be a barrier for some buyers. When considering diamond abrasives, B2B purchasers should assess the specific applications and potential ROI, as their benefits often outweigh the initial investment in high-precision settings.

Garnet abrasives are natural and eco-friendly, making them a popular choice for applications such as blasting and waterjet cutting. They are effective on softer materials and provide a non-toxic option for various industrial processes. Buyers should keep in mind that while garnet is environmentally friendly, it may not be as durable as synthetic abrasives. Evaluating the trade-offs between environmental impact and performance will help B2B buyers make informed decisions.

Ceramic abrasives are known for their uniform shape and high strength, making them suitable for precision grinding and polishing applications. Their consistent performance ensures high-quality finishes, which is critical in industries where detail is paramount. However, B2B buyers should be aware that ceramic abrasives can come with a higher price tag. It is crucial to assess the specific needs of their projects to determine if the investment in ceramic abrasives is justified by the quality of results.

Related Video: Grit Blasting process Vs Sand Blasting process, Types of Grit Blasting abrasive materials

| Industry/Sector | Specific Application of Abrasive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Surface Preparation and Finishing | Enhances product durability and aesthetic appeal | Quality of abrasives, compatibility with materials, cost-effectiveness |

| Automotive Manufacturing | Grinding and Polishing Engine Components | Improves performance and extends lifespan of components | Precision requirements, consistency in supply, technical support |

| Construction and Building | Concrete Cutting and Surface Profiling | Increases efficiency in construction processes | Abrasive hardness, dust control measures, local availability |

| Electronics and Semiconductor | Wafer Dicing and Surface Cleaning | Ensures high precision and reliability in electronic devices | Cleanroom standards, material compatibility, supplier certifications |

| Woodworking and Furniture Making | Sanding and Finishing Wood Surfaces | Achieves smooth finishes and enhances product quality | Grit selection, environmental impact, supplier reputation |

In the metal fabrication sector, abrasives are essential for surface preparation and finishing. They help remove impurities, prepare surfaces for welding, and ensure a smooth finish on metal parts. This application not only enhances the durability of the final products but also improves their aesthetic appeal. International buyers, particularly from regions like Africa and South America, should consider the quality and compatibility of abrasives with different metals to ensure optimal results while keeping an eye on cost-effectiveness.

In automotive manufacturing, abrasives play a critical role in grinding and polishing engine components. This process improves the performance and extends the lifespan of vital parts such as crankshafts and camshafts. For B2B buyers in Europe and the Middle East, it is essential to focus on precision requirements and the consistency of supply from manufacturers. Technical support from suppliers can also significantly impact the effectiveness of the abrasives used.

In the construction and building industry, abrasives are widely used for concrete cutting and surface profiling. This application increases efficiency by allowing faster and cleaner cuts, which is crucial for project timelines. For international buyers, particularly in emerging markets, sourcing considerations should include the hardness of the abrasives, effective dust control measures, and the availability of products locally to reduce lead times and transportation costs.

Abrasives are vital in the electronics and semiconductor industries for wafer dicing and surface cleaning. These applications require high precision to ensure the reliability and performance of electronic devices. Buyers from Africa and South America must consider cleanroom standards, material compatibility, and supplier certifications to maintain quality and compliance with industry regulations.

In woodworking and furniture making, abrasives are primarily used for sanding and finishing wood surfaces. This process is crucial for achieving smooth finishes that enhance product quality and appeal to customers. B2B buyers in Europe should pay attention to grit selection to match specific project requirements, as well as the environmental impact of the abrasives used, ensuring they align with sustainability goals while selecting reputable suppliers.

Related Video: Industrial Sandblasting: VertiDrive - Abrasive Blasting Robot

The Problem: One of the most pressing challenges faced by B2B buyers, particularly in regions like Africa and South America, is the inconsistency in the quality of abrasive materials. This can lead to unpredictable results in manufacturing and finishing processes, resulting in increased costs and wasted resources. Buyers may find that the abrasives they sourced do not meet the necessary specifications for their applications, leading to subpar product quality and potential delays in production schedules.

The Solution: To mitigate this issue, B2B buyers should establish clear quality standards and specifications before sourcing abrasives. Engaging with suppliers who can provide detailed product information, including certifications and performance data, is crucial. Implementing a rigorous supplier evaluation process that includes sample testing can help ensure the abrasives meet the required standards. Additionally, developing long-term relationships with reliable suppliers can foster transparency and consistency, allowing buyers to negotiate better terms and receive priority support when issues arise.

The Problem: B2B buyers often struggle with choosing the appropriate type of abrasive for specific applications. With a wide variety of abrasives available—such as bonded, coated, and non-woven types—deciding which abrasive will deliver optimal performance can be overwhelming. This challenge is exacerbated in industries where precision is critical, such as aerospace or automotive manufacturing, as selecting the wrong abrasive can compromise product integrity and safety.

The Solution: To navigate this complexity, buyers should invest time in understanding the specific requirements of their applications. Conducting a thorough needs assessment, including factors like material type, desired finish, and processing speed, is essential. Consulting with technical experts or leveraging the knowledge of suppliers can provide valuable insights into the most suitable abrasive options. Additionally, investing in training for staff on abrasive properties and application techniques can enhance decision-making and lead to improved outcomes.

The Problem: Inefficient use of abrasives can lead to inflated operational costs, a concern that resonates strongly with buyers in the Middle East and Europe. When abrasives wear out too quickly or are used improperly, it can result in increased consumption rates and higher overall expenditures. This inefficiency is often compounded by a lack of understanding of the best practices for abrasive usage and maintenance, ultimately impacting the bottom line.

The Solution: Implementing a structured abrasive management program can significantly reduce operational costs. Buyers should start by conducting an audit of their current abrasive usage to identify patterns of inefficiency. Utilizing data analytics tools can help track abrasive performance and consumption rates. Additionally, establishing a routine maintenance schedule for equipment can extend the life of abrasives and enhance performance. Providing training to employees on optimal abrasive usage techniques, such as proper pressure application and speed settings, can further minimize waste and maximize productivity. By adopting these practices, buyers can achieve a more cost-effective operation while maintaining high-quality standards.

When selecting materials for abrasives, international B2B buyers must consider various factors that influence performance, application suitability, and overall cost-effectiveness. Below, we analyze four common abrasive materials, highlighting their properties, advantages, disadvantages, and specific considerations for buyers in regions such as Africa, South America, the Middle East, and Europe.

Aluminum oxide is one of the most widely used abrasive materials due to its excellent hardness and durability. It has a high temperature resistance, making it suitable for various applications, including grinding and polishing. Its corrosion resistance is moderate, which allows it to perform well in both dry and wet conditions.

Pros & Cons:

The primary advantage of aluminum oxide is its cost-effectiveness and availability. It is relatively easy to manufacture, leading to lower production costs. However, it may not be suitable for all applications, particularly those requiring very fine finishes or specific media compatibility.

Impact on Application:

Aluminum oxide is commonly used in sandpapers, grinding wheels, and blasting media. Buyers should consider the specific requirements of their applications, as the material's performance can vary based on the intended use.

Considerations for International Buyers:

Buyers in regions like South Africa and Colombia should ensure compliance with local standards such as ASTM or DIN. Additionally, understanding the market availability and sourcing options is crucial for maintaining supply chain efficiency.

Silicon carbide is known for its sharpness and ability to cut through hard materials. It has a high temperature rating and excellent corrosion resistance, making it suitable for applications involving ceramics, glass, and metals.

Pros & Cons:

The key advantage of silicon carbide is its superior cutting ability, which can lead to faster processing times. However, it is generally more expensive than aluminum oxide, and its brittleness can lead to chipping in certain applications.

Impact on Application:

Silicon carbide is often used in applications requiring a high degree of precision, such as automotive and aerospace industries. Buyers must evaluate the compatibility of silicon carbide with their specific media and materials.

Considerations for International Buyers:

For buyers in the Middle East and Europe, it’s essential to consider the environmental regulations surrounding the use of silicon carbide, as well as the availability of certified suppliers.

Garnet is a naturally occurring mineral that is highly effective for waterjet cutting and sandblasting applications. It has a good hardness rating and offers excellent durability, making it suitable for various industrial applications.

Pros & Cons:

The primary advantage of garnet is its eco-friendliness, as it is a natural material that poses fewer health risks compared to synthetic abrasives. However, garnet can be more expensive and less readily available in certain regions.

Impact on Application:

Garnet is particularly effective for applications requiring a clean finish, such as surface preparation and restoration. Buyers should assess the specific requirements of their applications to determine the suitability of garnet.

Considerations for International Buyers:

Buyers from South America should be aware of the sourcing challenges and potential import regulations for garnet. Understanding local market dynamics can aid in making informed purchasing decisions.

Ceramic abrasives are engineered materials that offer exceptional hardness and wear resistance. They are designed to withstand high temperatures and pressures, making them ideal for heavy-duty applications.

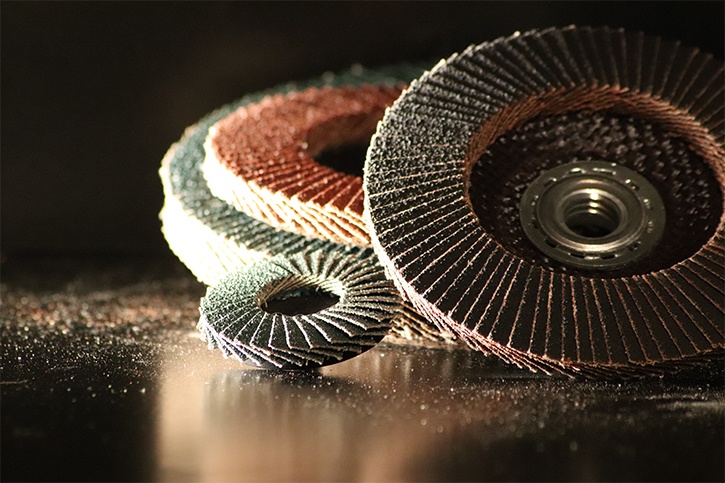

A stock image related to abrasive.

Pros & Cons:

The key advantage of ceramic abrasives is their longevity and efficiency, which can lead to reduced downtime and lower overall costs. However, they tend to be more complex to manufacture and may come at a higher price point.

Impact on Application:

Ceramic abrasives are commonly used in grinding and cutting applications where precision is critical. Buyers must evaluate the specific performance requirements of their applications to determine if ceramic abrasives are the right choice.

Considerations for International Buyers:

For buyers in Europe, compliance with EU regulations regarding material safety and environmental impact is crucial. Additionally, understanding the certification processes for ceramic abrasives can aid in ensuring quality.

| Material | Typical Use Case for Abrasive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Sandpapers, grinding wheels | Cost-effective and widely available | Limited fine finish capabilities | Low |

| Silicon Carbide | Precision grinding, automotive parts | Superior cutting ability | Higher cost and brittleness | High |

| Garnet | Waterjet cutting, sandblasting | Eco-friendly and clean finish | Higher cost and availability issues | Medium |

| Ceramic | Heavy-duty grinding and cutting | Longevity and efficiency | Complex manufacturing and cost | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

The manufacturing process for abrasives involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for international B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

Material Preparation: The first step involves selecting and preparing raw materials, which can include natural minerals like corundum or synthetic materials such as silicon carbide. The materials are often crushed, sorted, and cleaned to remove impurities. This stage is crucial as the quality of the raw materials directly influences the performance of the abrasives.

Forming: In this stage, the prepared materials are shaped into the desired form. Techniques such as pressing, molding, or casting are employed depending on the type of abrasive being manufactured. For example, bonded abrasives may be pressed into molds, while coated abrasives are typically manufactured by adhering abrasive grains to a backing material.

Assembly: This stage may involve assembling different components of the abrasive product, especially in cases like grinding wheels where a metal or plastic core is required. Ensuring proper alignment and secure attachment is crucial to prevent failures during operation.

Finishing: The final stage includes processes such as grinding, polishing, and coating to enhance the surface finish and performance characteristics of the abrasive. This is where products are fine-tuned to meet specific applications, ensuring they deliver optimal results for end-users.

Quality assurance is paramount in the abrasives industry to ensure product reliability and safety. International B2B buyers should be aware of various quality control standards and checkpoints throughout the manufacturing process.

ISO 9001 Certification: This widely recognized international standard for quality management systems (QMS) helps organizations demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Buyers should prioritize suppliers with ISO 9001 certification as it indicates a commitment to quality.

Industry-Specific Standards: Depending on the application, other certifications may apply. For example, the CE mark indicates compliance with European health, safety, and environmental protection standards, while the API (American Petroleum Institute) certification is essential for abrasives used in the oil and gas sector.

Effective quality control involves several checkpoints throughout the manufacturing process, ensuring that each stage meets established standards.

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Buyers should inquire about the supplier’s IQC processes and what metrics are used for assessment.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC is critical for monitoring production parameters. This may include checking for dimensional accuracy, consistency of grain distribution, and adherence to specific formulations. Regular audits of these processes can provide insight into the supplier's operational integrity.

Final Quality Control (FQC): After production, FQC involves rigorous testing of the finished product to verify its performance and safety. Common testing methods include hardness testing, grain size analysis, and performance testing under simulated operational conditions.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier's quality control measures is essential for mitigating risk.

Supplier Audits: Conducting on-site audits of suppliers can provide firsthand insights into their manufacturing processes and quality assurance practices. These audits can uncover potential issues and ensure compliance with international standards.

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess the effectiveness of their quality control measures. These reports should include data on testing results, non-conformance incidents, and corrective actions taken.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and product quality. This is particularly valuable for buyers who may not have the resources to perform thorough in-house evaluations.

Understanding the common testing methods used in abrasives quality control can help B2B buyers evaluate the reliability of their suppliers.

Grain Size Distribution Testing: This testing evaluates the distribution and size of the abrasive particles, which directly impacts cutting efficiency and surface finish. Techniques such as sieving and laser diffraction are commonly employed.

Hardness Testing: The hardness of abrasives is a critical factor in their performance. Methods like the Mohs hardness test or Vickers hardness test are utilized to ensure that the products meet the required specifications.

Performance Testing: This includes simulating real-world usage conditions to assess how the abrasives perform under stress. Tests may include grinding, cutting, or polishing trials to evaluate effectiveness and durability.

International B2B buyers need to navigate various quality control nuances that can impact their sourcing strategies.

Regional Compliance: Different regions may have specific regulations and standards that affect abrasives manufacturing. For example, European buyers must ensure compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), which governs the use of chemical substances.

Cultural Differences in Quality Standards: Buyers should be aware that quality perceptions can vary by region. What is considered a high standard in one country may differ in another. Engaging with local experts can help bridge these gaps.

Supply Chain Transparency: As buyers seek suppliers, it's essential to understand the entire supply chain. Transparency in sourcing and manufacturing processes not only builds trust but also ensures that quality control measures are adhered to at every stage.

By understanding the manufacturing processes and quality assurance measures in the abrasives industry, international B2B buyers can make informed decisions, mitigate risks, and ensure they source high-quality products that meet their specific needs.

Sourcing abrasives for industrial applications can be complex, especially for international B2B buyers. This practical checklist aims to streamline the procurement process, helping you make informed decisions that align with your operational needs and market conditions. Whether you are sourcing from Africa, South America, the Middle East, or Europe, following these steps will ensure you select the right suppliers and products.

Understanding your specific requirements is crucial before starting your sourcing journey. Define the type of abrasive materials needed (e.g., alumina, silicon carbide) and their applications (e.g., grinding, cutting).

Gathering data on available suppliers is vital for making an informed choice. Research both local and international suppliers to identify those who specialize in your required abrasive products.

Before committing, it's crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don't just rely on their website.

Ensuring that your chosen supplier meets industry standards is essential for product quality and compliance. Check for relevant certifications, such as ISO 9001, which indicates a commitment to quality management.

Before placing a large order, request samples of the abrasives you intend to purchase. This step allows you to assess quality, performance, and compatibility with your existing processes.

Once you have selected a supplier, it's time to discuss terms of sale, pricing, and delivery schedules. Clear negotiations will help avoid misunderstandings and ensure a smooth procurement process.

Building a long-term relationship with your supplier can lead to better pricing, priority service, and access to new products. Engage in regular communication to provide feedback and discuss future needs.

By following this step-by-step sourcing guide, you can enhance your procurement process for abrasives, ensuring that your operations remain efficient and competitive in the global market.

Understanding the cost structure of abrasives is crucial for international B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

Materials: The type of abrasive material (e.g., aluminum oxide, silicon carbide) significantly influences pricing. High-quality materials typically come at a premium but offer better performance and longevity.

Labor: Labor costs can vary dramatically based on geographic location. Regions with higher labor costs may result in increased pricing for abrasives. However, automation in manufacturing can help mitigate these costs.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and general administrative costs. Efficient manufacturing processes can lower overhead and thus, the overall cost of abrasives.

Tooling: Custom tooling can add to the cost, especially if unique specifications are required. Standardized tooling may reduce expenses, making it important to assess whether custom solutions are necessary.

Quality Control (QC): Rigorous quality assurance processes ensure that products meet specifications. While this can increase initial costs, it is essential for maintaining product integrity and reducing waste.

A stock image related to abrasive.

Logistics: Shipping and handling can significantly impact the total cost, particularly for international buyers. Factors such as distance, mode of transport, and shipping frequency should be evaluated.

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the abrasives market can help buyers negotiate better deals.

Several factors can influence the pricing of abrasives in the international market:

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Buyers should negotiate MOQs to optimize their pricing structure.

Specifications and Customization: Customized abrasives tailored to specific applications usually come at a higher price. Buyers must weigh the benefits of customization against the potential cost increase.

Material Quality and Certifications: Higher quality abrasives often come with certifications that ensure reliability and performance. While these may increase upfront costs, they can reduce long-term expenses related to product failure or inefficiency.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record but can offer better service and support.

Incoterms: The terms of delivery can affect pricing significantly. Different Incoterms (e.g., FOB, CIF) will determine who bears the costs and risks at different stages of the shipping process.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency in abrasive procurement:

Negotiate Effectively: Always approach negotiations with a clear understanding of your requirements and the market. Leverage competitive quotes to negotiate better terms and prices.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price, but the TCO, which includes maintenance, operational costs, and potential wastage. A lower initial cost may lead to higher long-term expenses.

Understand Pricing Nuances: Be aware of regional pricing variations and factors that can affect costs, such as tariffs, trade agreements, and currency fluctuations. This knowledge can be crucial for budgeting and forecasting.

Build Relationships with Suppliers: Establishing long-term relationships with reliable suppliers can lead to better pricing and priority service, especially during peak demand periods.

Monitor Market Trends: Stay updated on market trends, including material costs and technological advancements in abrasives. This awareness can provide leverage during negotiations and help in anticipating price changes.

Prices for abrasives can fluctuate based on market conditions, material availability, and geopolitical factors. Therefore, it is essential for buyers to seek updated quotes and conduct thorough market research to ensure they are making the best purchasing decisions.

In the quest for efficient manufacturing and processing solutions, B2B buyers often find themselves weighing the benefits of abrasives against various alternative methods. Understanding the comparative advantages and disadvantages of these options is crucial for making informed purchasing decisions. This section delves into how abrasives stack up against two alternative solutions: chemical polishing and laser cutting.

| Comparison Aspect | Abrasive | Chemical Polishing | Laser Cutting |

|---|---|---|---|

| Performance | High material removal rate; versatile on various materials | Effective for achieving a high-gloss finish; limited to certain materials | Exceptional precision; ideal for complex cuts |

| Cost | Moderate initial cost; ongoing material costs | Lower initial cost; potential recurring chemical costs | High initial investment; cost-effective for high-volume production |

| Ease of Implementation | Requires skilled labor; setup may vary | Generally straightforward; requires handling of chemicals | Requires specialized machinery and training |

| Maintenance | Regular maintenance needed for equipment; replacement costs | Minimal if chemicals are managed properly | Regular service required for machinery; potential for high downtime |

| Best Use Case | Ideal for heavy-duty applications; surface preparation | Best for decorative finishes on metals | Perfect for intricate designs and high-speed cutting |

Chemical polishing offers a clean, high-gloss finish without the physical wear on materials, making it a preferred choice for decorative applications. Its lower initial costs can be appealing, especially for businesses looking to reduce upfront expenditures. However, the reliance on chemicals can lead to ongoing costs and environmental concerns, particularly in regions with stringent regulations. Moreover, the process may not be suitable for all materials, limiting its versatility compared to abrasives.

Laser cutting is renowned for its precision and ability to handle complex shapes with ease. It excels in high-volume production scenarios where speed and accuracy are paramount. However, the initial investment in laser cutting equipment can be substantial, which may deter smaller businesses or those just starting. Additionally, while laser cutting minimizes material waste, it requires specialized training and maintenance, which can increase operational costs over time.

When selecting between abrasives and their alternatives, B2B buyers should evaluate their specific operational requirements, budget constraints, and long-term goals. For heavy-duty applications requiring material removal, abrasives are often the best choice. Conversely, if the focus is on achieving a decorative finish or intricate designs, chemical polishing or laser cutting may be more suitable. By carefully considering the performance, cost, ease of implementation, maintenance needs, and best use cases of each solution, buyers can make well-informed decisions that align with their business objectives.

Understanding the technical properties of abrasives is crucial for B2B buyers, especially when sourcing products from different regions like Africa, South America, the Middle East, and Europe. Here are key specifications to consider:

Material grade indicates the quality and performance of the abrasive material. Common grades include aluminum oxide, silicon carbide, and diamond. Higher grades typically offer better durability and efficiency, making them suitable for demanding applications. Buyers should assess the material grade to ensure it meets their operational requirements and enhances productivity.

Grit size refers to the size of the abrasive particles and is usually measured in mesh. Finer grits (higher numbers) provide a smoother finish, while coarser grits (lower numbers) are used for aggressive material removal. Understanding grit size allows buyers to select the right abrasive for specific applications, ensuring optimal performance and surface quality.

The bond type determines how the abrasive grains are held together. Common bond types include resin, ceramic, and metal. Each bond type offers different performance characteristics, such as heat resistance and flexibility. Buyers should evaluate the bond type based on their application needs, as it significantly impacts the abrasive's lifespan and effectiveness.

Tolerance refers to the permissible limit of variation in dimensions and properties of the abrasive product. It is critical for ensuring that abrasives fit correctly in machines and meet safety standards. Understanding tolerance helps buyers maintain quality control and minimize the risk of operational issues caused by improper fit or performance.

Hardness measures the abrasive's resistance to wear and scratching. Harder abrasives are generally more effective for tougher materials, while softer abrasives are better for delicate surfaces. Assessing hardness is vital for buyers to select the right abrasive that balances efficiency and safety in their operations.

Navigating the abrasive market requires familiarity with certain trade terminology. Here are some essential terms to know:

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking to source abrasives that fit specific machinery, ensuring compatibility and performance.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for buyers as it impacts inventory management and cash flow. Buyers should negotiate MOQs based on their project needs to avoid overstocking or underordering.

An RFQ is a document sent to suppliers requesting pricing and terms for a specific product or service. For buyers, issuing RFQs is a strategic way to gather competitive offers and ensure they are getting the best value for their abrasive purchases.

Incoterms (International Commercial Terms) are rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and logistics involved in sourcing abrasives from different countries.

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times helps buyers plan their procurement schedules effectively, ensuring they have the necessary abrasives available when needed to avoid production delays.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions, streamline procurement processes, and enhance their operational efficiencies.

The global abrasive market is experiencing significant growth, driven by an increase in manufacturing activities and the demand for high-performance materials. Key sectors such as automotive, aerospace, and metalworking are expanding rapidly, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The rise of automation and Industry 4.0 technologies is reshaping sourcing trends, as companies seek advanced abrasive solutions that enhance precision and efficiency.

Digital transformation is also influencing procurement processes, with B2B buyers increasingly relying on e-commerce platforms and data analytics to make informed purchasing decisions. These technologies enable buyers to evaluate suppliers more effectively, monitor market trends, and optimize their supply chains. For instance, in regions like South Africa and Colombia, local suppliers are adopting digital tools to improve their visibility and competitiveness, which can be advantageous for international buyers seeking reliable partners.

Furthermore, sustainability is becoming a crucial factor in sourcing decisions. Buyers are more inclined to select suppliers who demonstrate a commitment to eco-friendly practices, such as using recycled materials or minimizing waste during production. This shift not only aligns with global sustainability goals but also appeals to a growing consumer base that prioritizes environmentally responsible products.

The environmental impact of abrasive manufacturing is a pressing concern, particularly regarding the extraction of raw materials and energy consumption. As international B2B buyers become more conscious of these issues, the demand for ethical sourcing practices is on the rise. Companies are increasingly expected to maintain transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices comply with ethical standards.

To meet these expectations, many abrasive manufacturers are pursuing certifications that demonstrate their commitment to sustainability. Certifications such as ISO 14001 (Environmental Management) and OHSAS 18001 (Occupational Health and Safety) are becoming essential for companies looking to establish credibility in the market. Buyers should prioritize suppliers who hold these certifications, as they indicate adherence to recognized environmental and safety standards.

Moreover, the use of "green" materials in abrasive products is gaining traction. For example, abrasives made from recycled glass or bio-based composites are not only effective but also contribute to reducing the carbon footprint of production processes. B2B buyers who prioritize these options can position themselves as leaders in sustainability within their industries, catering to a market that increasingly values eco-friendly practices.

The abrasive sector has a rich history dating back to ancient civilizations, where natural materials like sand and emery were used for polishing and grinding. The industrial revolution marked a significant turning point, as the demand for efficient manufacturing processes led to the development of synthetic abrasives, which offered superior performance and consistency.

Over the decades, advancements in technology have transformed the abrasive landscape. The introduction of advanced ceramics and diamond abrasives has enhanced the capabilities of these products, making them indispensable across various industries. Today, the sector continues to evolve, integrating cutting-edge technologies such as artificial intelligence and machine learning to optimize production and improve product quality.

This historical context is vital for B2B buyers, as understanding the evolution of abrasive products can inform their purchasing strategies and help them identify innovative suppliers that are at the forefront of industry advancements.

How do I solve quality issues with abrasives sourced internationally?

To address quality issues with internationally sourced abrasives, establish clear quality assurance protocols before placing an order. Request samples to evaluate the product's performance under your specific conditions. Additionally, consider implementing third-party inspections or audits of the supplier’s facilities. Building strong communication channels with suppliers can also facilitate prompt resolution of any quality concerns. Finally, maintain a record of quality metrics to assess supplier reliability over time.

What is the best abrasive material for metalworking applications?

The optimal abrasive material for metalworking largely depends on the specific application and the type of metal being worked on. For general metal grinding and cutting, aluminum oxide is widely regarded for its durability and effectiveness. For stainless steel and other hard metals, zirconia alumina may offer superior performance. When selecting abrasives, consider factors such as grit size, bond type, and whether the application requires a cooler cutting action to prevent heat damage.

What are the key factors to consider when vetting abrasive suppliers?

When vetting suppliers for abrasives, prioritize factors such as production capacity, certifications (like ISO), and product range. Look for reviews and testimonials from other international buyers to gauge reliability and service quality. It's also essential to assess their ability to customize products based on your specific needs. Finally, consider the supplier's location and logistics capabilities to ensure timely delivery and cost-effective shipping options.

What is the minimum order quantity (MOQ) for abrasives in international trade?

Minimum order quantities (MOQ) for abrasives can vary significantly depending on the supplier and the type of abrasive. Typically, MOQs range from a few hundred to several thousand units. To negotiate favorable terms, communicate your needs clearly and consider establishing a long-term relationship with the supplier, which may lead to lower MOQs. Be prepared to discuss your projected usage to justify smaller orders if necessary.

What payment terms are commonly offered by abrasive suppliers?

Payment terms for abrasives can vary, but common practices include advance payment, letter of credit, or payment upon delivery. International buyers may benefit from negotiating favorable terms that align with their cash flow needs. It's crucial to clarify the payment schedule and any penalties for late payments upfront. Additionally, consider using secure payment methods that provide buyer protection to mitigate risks in international transactions.

How can I ensure timely logistics for my abrasive orders?

To ensure timely logistics for abrasive orders, work closely with your supplier to understand their shipping processes and lead times. Choose suppliers with established logistics networks and experience in international shipping. It’s also advisable to plan for potential delays by ordering well in advance and maintaining open communication with shipping partners. Utilizing tracking systems can help monitor the shipment's progress and address any issues promptly.

Can I customize abrasive products to meet specific application needs?

Yes, many abrasive suppliers offer customization options to tailor products to specific applications. This may include adjustments in grit size, bond types, or even shapes and sizes. When discussing customization, provide detailed specifications and requirements to the supplier. Collaborating closely with them during the design and testing phases can ensure that the final product meets your operational needs effectively.

What quality assurance measures should I implement when sourcing abrasives?

Implementing robust quality assurance measures is critical when sourcing abrasives. Start by defining clear quality standards and specifications that the products must meet. Request documentation such as certificates of conformity and test reports from suppliers. Conduct periodic audits or inspections of the supplier's production processes, and establish a system for feedback and corrective actions to address any quality deviations. Regularly review supplier performance based on quality metrics to ensure consistent standards are maintained.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

The strategic sourcing of abrasives is not just a procurement activity; it is a critical component of operational efficiency and cost management for businesses in diverse industries. By understanding the unique market dynamics in regions such as Africa, South America, the Middle East, and Europe, B2B buyers can leverage local insights to optimize their sourcing strategies. Key takeaways include the importance of establishing robust supplier relationships, prioritizing quality over cost, and being adaptable to changes in global supply chains.

As the demand for abrasives continues to grow, driven by sectors like manufacturing and construction, international buyers must remain proactive. This involves continuously evaluating supplier performance, exploring innovative materials, and embracing sustainable practices that align with global environmental standards.

Looking ahead, the landscape for abrasive sourcing will increasingly be shaped by technological advancements and shifting economic conditions. B2B buyers are encouraged to stay informed about market trends and consumer preferences, ensuring they are well-positioned to make strategic sourcing decisions that enhance their competitive edge. By taking these steps, businesses can not only secure their supply chains but also drive long-term growth and sustainability in their operations.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina