In the intricate landscape of international trade, understanding the abrasivos significado—the meaning and application of abrasives—presents a significant challenge for B2B buyers. Sourcing the right abrasive materials can be pivotal for industries ranging from manufacturing to construction, where efficiency and quality are paramount. This guide aims to demystify the diverse types of abrasives, their applications across various sectors, and the critical factors to consider when selecting a supplier.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, face unique hurdles in sourcing abrasives that meet their specific needs. This comprehensive guide will provide insights into the various forms of abrasives, including bonded, coated, and super abrasives, along with their respective uses in grinding, cutting, and polishing. Additionally, it will cover essential topics such as supplier vetting processes, cost considerations, and regional market trends that can influence purchasing decisions.

By leveraging the information in this guide, buyers will be empowered to make informed choices that align with their operational requirements and budget constraints. Understanding the nuances of abrasives will not only enhance product quality but also drive cost efficiency, ultimately fostering stronger supplier relationships and competitive advantages in the global market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Abrasives | Sourced from minerals; eco-friendly | Stone polishing, metalworking | Pros: Eco-friendly, cost-effective. Cons: Limited uniformity, slower processing. |

| Synthetic Abrasives | Manufactured from chemical compounds; high precision | Automotive, aerospace, and manufacturing | Pros: High performance, uniformity. Cons: Higher cost, potential environmental concerns. |

| Coated Abrasives | Abrasive grains adhered to a backing material | Sanding, grinding, and finishing operations | Pros: Versatile, various grit options. Cons: Can wear out quickly, may require frequent replacement. |

| Bonded Abrasives | Abrasives mixed with a bonding agent for rigidity | Heavy-duty grinding and cutting applications | Pros: Durable, suitable for tough materials. Cons: Less flexible, requires specific tools. |

| Diamond Abrasives | Utilizes diamond particles for extreme hardness | Precision machining, glass, and ceramics | Pros: Exceptional durability, precision. Cons: High initial investment, specialized applications. |

Natural abrasives are derived from naturally occurring minerals, making them an eco-friendly option for various applications. Common examples include garnet, emery, and pumice. They are particularly suitable for stone polishing and metalworking due to their ability to provide a smooth finish. When considering a purchase, B2B buyers should evaluate the sourcing practices to ensure sustainability and cost-effectiveness, as natural abrasives can sometimes offer lower uniformity compared to synthetic alternatives.

Synthetic abrasives are engineered from chemical compounds, which allows for greater consistency and precision in their application. Widely used in industries such as automotive and aerospace, these abrasives can be tailored to meet specific manufacturing needs. Buyers should consider the performance characteristics, such as grit size and bonding methods, to align with their production requirements. While they may come at a higher price, the long-term performance and efficiency can justify the investment.

Coated abrasives consist of abrasive grains that are adhered to a backing material, such as paper or cloth. This type is highly versatile and comes in various grit options, making it suitable for sanding, grinding, and finishing operations. When purchasing, buyers should assess the durability of the backing material and the type of adhesive used, as these factors influence the lifespan of the abrasive. Although coated abrasives may wear out more quickly than other types, their flexibility and range of applications often make them a preferred choice.

Bonded abrasives are made by mixing abrasive particles with a bonding agent, resulting in a rigid structure ideal for heavy-duty grinding and cutting applications. They excel in tasks that require durability and strength, such as metal fabrication. B2B buyers should consider the specific tools required for bonded abrasives and the types of materials they will be working with. While they are less flexible than other types, their longevity in demanding environments often makes them worth the investment.

Diamond abrasives are known for their exceptional hardness and precision, making them ideal for specialized applications like precision machining and working with glass and ceramics. Their unique properties allow for faster cutting and longer life compared to other abrasives. Buyers should weigh the high initial cost against the potential for increased productivity and reduced downtime. While they are not suitable for all applications, their performance in niche markets can provide a significant competitive advantage.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of abrasivos significado | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Surface finishing and polishing | Enhances product aesthetics and durability | Quality of abrasives, compatibility with materials |

| Construction | Concrete surface preparation | Improves adhesion for coatings and finishes | Abrasive grit size, environmental impact |

| Automotive | Paint removal and surface preparation | Reduces rework costs and improves finish quality | Chemical compatibility, safety standards |

| Metalworking | Deburring and edge finishing | Increases efficiency and reduces product defects | Abrasive type, equipment compatibility |

| Electronics | Wafer fabrication and polishing | Ensures precision and quality in semiconductor production | Supplier reliability, precision specifications |

In the manufacturing sector, abrasives are crucial for surface finishing and polishing processes. They are used to refine the surface of products, enhancing both aesthetics and durability. For B2B buyers, especially those in Africa and South America, sourcing high-quality abrasives that are compatible with the materials being processed is vital. This ensures that the final product meets both visual and functional standards, reducing the likelihood of defects and rework.

In construction, abrasives are primarily employed for concrete surface preparation. This application is essential for improving the adhesion of coatings and finishes, which directly impacts the longevity and performance of structures. International buyers should consider factors such as the grit size of abrasives and their environmental impact, particularly in regions like the Middle East, where sustainability is becoming increasingly important in construction practices.

The automotive industry extensively uses abrasives for paint removal and surface preparation. This application not only helps in achieving a superior finish but also significantly reduces rework costs associated with poor surface quality. Buyers from Europe and Africa should focus on the chemical compatibility of abrasives with automotive materials and ensure adherence to safety standards during sourcing to maintain compliance and safety in their operations.

In metalworking, abrasives are essential for deburring and edge finishing. These processes enhance product efficiency and minimize defects, which is crucial for maintaining competitive advantage in the market. For international B2B buyers, selecting the right type of abrasive and ensuring compatibility with existing equipment is key to optimizing production processes and achieving cost savings.

In the electronics sector, abrasives play a critical role in wafer fabrication and polishing. This application is vital for ensuring precision and quality in semiconductor production. For buyers, particularly in Europe and South America, supplier reliability and adherence to precision specifications are critical considerations. Ensuring that abrasives meet stringent quality standards can significantly affect the performance and reliability of electronic components.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

The Problem: For international B2B buyers, particularly in regions like Africa and South America, sourcing abrasives often comes with the challenge of understanding complex material specifications. Many suppliers present detailed technical data that can be overwhelming, especially for buyers without a deep background in materials science. Misinterpretations can lead to selecting inappropriate abrasives, which in turn can cause production delays, increased costs, and compromised product quality.

The Solution: To mitigate this issue, buyers should invest time in familiarizing themselves with the essential properties of abrasives, such as grit size, hardness, and bonding agents. Utilizing resources like industry webinars, supplier training sessions, and material datasheets can significantly enhance understanding. Furthermore, establishing a relationship with a trusted supplier who can provide clear explanations and recommendations based on specific applications will ensure that buyers choose the right abrasives. It's also advisable to request samples before making large purchases, allowing for real-world testing to verify compatibility with existing processes.

The Problem: A common concern for B2B buyers is the inconsistency in the quality of abrasives sourced from different suppliers. This inconsistency can stem from variations in manufacturing processes or raw materials, leading to unpredictable performance in applications such as machining or surface finishing. For buyers in the Middle East or Europe, where precision is critical, such variability can result in significant operational disruptions and increased waste.

The Solution: To ensure consistent quality, buyers should prioritize suppliers that adhere to international quality standards, such as ISO 9001. Conducting a thorough supplier audit or utilizing third-party inspection services can also help verify the supplier's quality control processes. Buyers should develop a detailed specification document outlining their quality requirements and communicate these clearly with potential suppliers. Additionally, maintaining a regular feedback loop with suppliers regarding product performance can facilitate improvements and ensure that quality standards are met consistently.

The Problem: Many B2B buyers, especially those new to the abrasives market, struggle with understanding the diverse applications of different abrasive materials. This lack of knowledge can lead to incorrect product selection for specific tasks, resulting in inefficient operations and increased costs. Buyers from regions like Africa and South America may not have easy access to expert advice, making it even more challenging to navigate this complexity.

The Solution: To overcome this knowledge gap, buyers should leverage the wealth of resources available online, including application guides and technical articles from reputable manufacturers. Engaging with industry forums and trade associations can also provide valuable insights into best practices and emerging trends. Furthermore, buyers should not hesitate to seek technical support from suppliers, as many companies offer consultation services to help customers identify the right abrasives for their specific applications. Building a network of industry contacts can also facilitate knowledge sharing and provide ongoing support in making informed purchasing decisions.

When selecting materials for abrasives, it is crucial for international B2B buyers to understand the properties and applications of common materials. Here, we analyze four prevalent materials used in abrasives, focusing on their key properties, advantages and disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

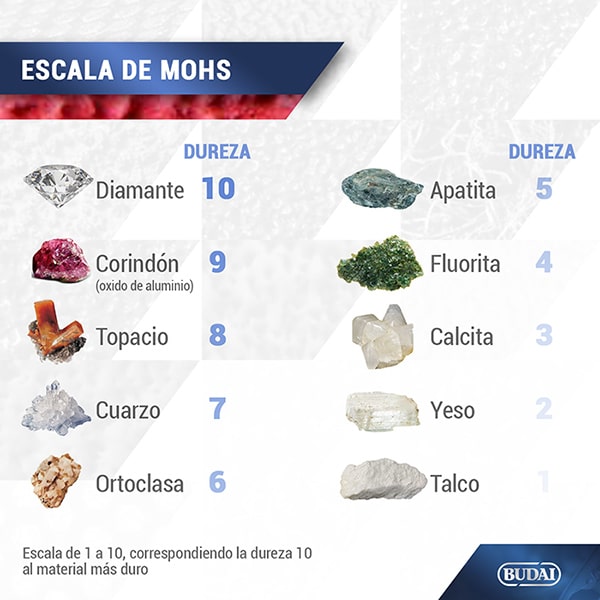

Key Properties: Aluminum oxide is known for its hardness and durability, with a Mohs hardness of 9. It can withstand high temperatures (up to 2000°C) and has excellent corrosion resistance.

Pros & Cons: This material is highly durable and effective for a variety of applications, including grinding and polishing. However, it can be more expensive than other abrasives, and its manufacturing complexity may lead to higher production costs.

Impact on Application: Aluminum oxide is compatible with ferrous and non-ferrous metals, making it suitable for a wide range of industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM and DIN. In regions like Africa and South America, where cost sensitivity is higher, the initial investment may be a concern, despite the long-term benefits.

Key Properties: Silicon carbide features a hardness of 9.5 on the Mohs scale and can operate effectively at temperatures up to 1600°C. It is also known for its thermal conductivity and low expansion coefficient.

Pros & Cons: This abrasive is highly effective for hard materials and provides a superior finish. However, it is more brittle than aluminum oxide, which can lead to premature wear in some applications.

Impact on Application: Silicon carbide is particularly effective for grinding glass, ceramics, and non-ferrous metals.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific grades required for their applications, as different grades may meet varying compliance standards.

Key Properties: Garnet is a naturally occurring mineral that offers a Mohs hardness of 7.5 to 8. It is non-toxic and has a good resistance to corrosion and wear.

Pros & Cons: Being eco-friendly and biodegradable, garnet is favored in industries that prioritize environmental impact. However, it is less durable than synthetic abrasives, which may limit its use in heavy-duty applications.

Impact on Application: Garnet is widely used in waterjet cutting and sandblasting, making it suitable for applications where environmental safety is a concern.

Considerations for International Buyers: Buyers from regions like South America may find garnet to be a cost-effective option, but they should verify the source and quality to ensure compliance with local regulations.

Key Properties: As the hardest known natural material, diamond has a Mohs hardness of 10 and can withstand extreme temperatures. It offers excellent thermal conductivity and chemical resistance.

Pros & Cons: Diamonds provide unparalleled cutting performance and longevity. However, they are significantly more expensive than other abrasives and require specialized manufacturing techniques.

Impact on Application: Diamonds are ideal for precision cutting and grinding applications, particularly in the aerospace and automotive industries.

Considerations for International Buyers: Buyers must consider the high cost and ensure that the application justifies the investment. Compliance with international standards is also crucial, especially in regulated markets in Europe and the Middle East.

| Material | Typical Use Case for abrasivos significado | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Grinding and polishing metals | Highly durable and versatile | Higher manufacturing costs | Medium |

| Silicon Carbide | Grinding glass and ceramics | Superior finish on hard materials | Brittle, prone to wear | High |

| Garnet | Waterjet cutting and sandblasting | Eco-friendly and biodegradable | Less durable than synthetic abrasives | Low |

| Diamond | Precision cutting in aerospace and automotive | Unmatched cutting performance | Very high cost | High |

This guide provides a comprehensive overview of the strategic material selection for abrasives, empowering international B2B buyers to make informed decisions based on their specific needs and regional considerations.

Abrasives play a crucial role in various industries, including metalworking, woodworking, and construction. Understanding the manufacturing processes involved in producing abrasives is essential for international B2B buyers to ensure quality and suitability for their specific applications. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

The first step in the manufacturing process is the preparation of raw materials. Common materials used in the production of abrasives include aluminum oxide, silicon carbide, and diamond. Each material is selected based on the specific application and desired properties of the abrasive product.

Raw Material Sourcing: Suppliers should be vetted for the quality of their raw materials. Buyers should consider sourcing from reputable manufacturers with a proven track record.

Material Processing: Raw materials undergo various processes such as crushing, grinding, and sieving to achieve the desired particle size and distribution. This stage is critical as it directly impacts the performance of the final product.

Additives Incorporation: In some cases, additives such as bonding agents and fillers are incorporated into the mixture to enhance performance characteristics. The formulation must be tailored to meet specific applications and industry standards.

Once the materials are prepared, the next step is forming. This stage involves shaping the abrasive materials into usable forms, which can include wheels, discs, belts, and powders.

A stock image related to abrasivos significado.

Pressing: For bonded abrasives, the mixture is typically pressed into molds using hydraulic or mechanical presses. The pressure applied is crucial for achieving the desired density and strength.

Casting: Some abrasives, especially those requiring intricate shapes, may be produced through casting techniques. This involves pouring a liquid abrasive mixture into a mold and allowing it to harden.

Extrusion: For certain applications, abrasive materials may be extruded into specific shapes, allowing for greater flexibility in design and application.

Finishing is the final stage in the manufacturing process, where the abrasives are refined and prepared for distribution.

Trimming and Shaping: After forming, the abrasives may require trimming to achieve precise dimensions. This is often done using saws or grinding tools.

Surface Treatment: To enhance performance, abrasives may undergo surface treatments such as coating with additional materials or undergoing heat treatment to improve durability.

Packaging: Finally, abrasives are packaged according to international shipping standards, ensuring that they are protected during transit and suitable for the end-user.

Quality assurance (QA) is a vital aspect of abrasive manufacturing, ensuring that products meet both international and industry-specific standards. For B2B buyers, understanding the QA measures in place can significantly influence their purchasing decisions.

ISO 9001: This international standard for quality management systems ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Buyers should prioritize suppliers with ISO 9001 certification as it indicates a commitment to quality.

CE Marking: For abrasives sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. B2B buyers in Europe should verify that their suppliers have CE certification for their products.

API Certification: In industries such as oil and gas, abrasives may require API certification, which ensures that products meet specific standards for performance and safety.

To maintain high-quality standards, manufacturers typically implement several quality control checkpoints throughout the production process.

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the production process. Ensuring that materials meet specified criteria is crucial for maintaining product quality.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect any deviations from quality standards. This may involve real-time monitoring of equipment and product characteristics.

Final Quality Control (FQC): Before products are shipped, final inspections are performed to ensure that abrasives meet the required specifications and standards. This includes dimensional checks, performance testing, and packaging verification.

For international B2B buyers, verifying a supplier's quality control measures is essential to mitigate risks associated with product quality and compliance.

Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should request access to audit reports and certifications.

Quality Reports: Suppliers should provide comprehensive quality reports detailing their testing processes, results, and any corrective actions taken in response to quality issues.

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of a supplier's quality control practices and product quality. This is particularly important for buyers in regions with varying quality standards.

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

Regional Standards Variability: Quality standards may vary significantly between regions. Buyers should familiarize themselves with local regulations and industry requirements to ensure compliance.

Language and Documentation: Ensure that all quality-related documentation is available in a language that is easily understood. This can prevent misinterpretations and compliance issues.

Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and collaboration with suppliers, enhancing the overall quality assurance process.

By being informed about manufacturing processes and quality assurance measures, international B2B buyers can make more informed purchasing decisions, ensuring that they receive high-quality abrasives that meet their specific needs.

In the international B2B marketplace, sourcing abrasives meaningfully impacts operational efficiency and product quality. This checklist is designed to guide buyers—especially those from Africa, South America, the Middle East, and Europe—through the essential steps for procuring abrasives effectively. By following this structured approach, you can ensure that your sourcing decisions align with your business needs and industry standards.

A stock image related to abrasivos significado.

Establishing clear technical specifications is critical for successful procurement. Determine the type of abrasives needed based on your applications—whether for metalworking, woodworking, or automotive industries. Consider factors such as grit size, material composition, and bonding type.

Conduct thorough research to identify potential suppliers that specialize in abrasives. Utilize industry directories, trade shows, and online platforms to compile a list of companies that meet your criteria. This initial research helps you understand the market landscape and available options.

Before engaging with suppliers, verify their certifications and quality standards. Certifications such as ISO 9001 ensure that the supplier adheres to international quality management principles. This step minimizes risks associated with product quality and compliance.

Once you have shortlisted suppliers, request samples to evaluate their products. Testing samples is vital for assessing the abrasives' performance and compatibility with your equipment. This hands-on approach helps you make informed decisions based on actual product performance.

After evaluating samples, compare pricing and payment terms across suppliers. Look beyond the initial cost and consider total cost of ownership, including shipping, duties, and potential discounts for bulk purchases. This comprehensive analysis ensures you get the best value for your investment.

Engage in negotiations with selected suppliers to finalize contracts. Clear communication about expectations, delivery timelines, and quality assurance measures is essential. A well-negotiated contract protects your interests and fosters a good relationship with the supplier.

Once the procurement process begins, establish a communication plan with your suppliers. Regular updates on production status, shipping schedules, and any potential issues are crucial for maintaining a smooth operation. Effective communication can help preempt challenges and strengthen supplier relationships.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring abrasives, ensuring that their sourcing decisions contribute positively to their operational goals.

When sourcing abrasives, understanding the cost structure is crucial for international B2B buyers. The primary cost components typically include:

Materials: The type of abrasive material (e.g., aluminum oxide, silicon carbide) significantly impacts the overall cost. Premium materials may offer better performance but come at a higher price.

Labor: Labor costs vary by region and can be influenced by local wage standards and skill levels. In countries with lower labor costs, such as some in Africa and South America, buyers may find more competitive pricing.

Manufacturing Overhead: This encompasses fixed costs related to production, such as utilities, rent, and equipment maintenance. Efficient production processes can minimize these overheads.

Tooling: The cost of tooling is critical, especially for customized abrasives. High-quality, specialized tooling may require a significant investment but can lead to better product consistency.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability. While it adds to the cost, it ultimately protects against costly defects and returns.

Logistics: Transportation costs play a pivotal role, especially for international shipments. Factors like distance, mode of transport, and import/export duties can significantly affect the final price.

Margin: Supplier profit margins can vary widely. Understanding the typical margin for abrasives can help buyers assess whether a quote is reasonable.

Several factors influence pricing in the abrasives market, particularly for international buyers:

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Buyers should evaluate their needs to maximize cost-efficiency.

Specifications and Customization: Customized abrasives tailored to specific applications may incur additional costs. Buyers should weigh the benefits against the price increase.

Materials and Quality Certifications: The quality of raw materials and certifications (e.g., ISO) can affect both price and performance. Buyers should prioritize suppliers who meet necessary industry standards.

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for clarifying who bears the shipping costs and risks. This knowledge can prevent unexpected expenses and facilitate smoother transactions.

Negotiating prices effectively can lead to significant savings for B2B buyers. Here are key strategies:

Research Market Prices: Familiarize yourself with average market prices for abrasives to provide a solid basis for negotiation.

Leverage Relationships: Establishing a long-term relationship with suppliers can result in better pricing and terms.

Focus on Total Cost of Ownership (TCO): Consider all costs associated with the product, including maintenance and replacement, rather than just the initial purchase price.

Be Transparent About Needs: Clearly communicate your requirements and purchasing volume, which can help suppliers provide more accurate quotes and potentially lower prices.

Negotiate Payment Terms: Flexible payment terms can also be a valuable point of negotiation, allowing for better cash flow management.

International buyers from regions like Africa, South America, the Middle East, and Europe should consider several pricing nuances:

Currency Fluctuations: Exchange rate volatility can impact pricing, so it’s wise to lock in rates where possible.

Import Duties and Taxes: Understanding local import regulations and taxes can help in calculating the total landed cost.

Cultural Differences: Different regions have varying negotiation styles and expectations. Being culturally aware can enhance communication and facilitate smoother negotiations.

Prices for abrasives can vary widely based on the aforementioned factors. This analysis provides a framework for understanding potential costs but should not be taken as definitive pricing guidance. Always consult multiple suppliers to obtain accurate quotes tailored to your specific needs.

When evaluating "abrasivos significado," it's crucial to consider various alternative solutions that may meet similar needs in the market. This analysis will compare abrasives with two prominent alternatives: Mechanical Abrasion and Chemical Abrasion. These alternatives serve similar purposes in industrial applications, and understanding their differences can help buyers make informed decisions.

| Comparison Aspect | Abrasivos Significado | Mechanical Abrasion | Chemical Abrasion |

|---|---|---|---|

| Performance | High durability and effectiveness in surface finishing | Effective for heavy material removal but may cause surface damage | High precision with minimal surface impact |

| Cost | Moderate initial investment, but long-term savings on material usage | Generally lower upfront costs but higher wear costs | Higher initial investment due to chemicals used |

| Ease of Implementation | Requires specialized knowledge for optimal use | Easy to implement with standard machinery | Requires safety protocols and specialized training |

| Maintenance | Low maintenance; lasts longer than alternatives | Moderate maintenance; regular checks needed | High maintenance due to chemical storage and disposal |

| Best Use Case | Ideal for precision finishing in metal and woodworking | Best for heavy-duty applications like metal fabrication | Suitable for delicate processes needing precision without abrasion |

Mechanical abrasion involves the use of physical means, such as grinding or sanding, to remove material from a surface. This method is widely used in industries where heavy material removal is necessary, such as metal fabrication and woodworking.

Pros: It is cost-effective for initial setup and can handle large surface areas efficiently. Additionally, it can be adapted to various materials and applications.

Cons: However, mechanical abrasion can sometimes lead to surface damage or inconsistencies, especially if not properly managed. It may also require additional finishing processes to achieve desired surface quality.

Chemical abrasion employs chemical reactions to remove material from surfaces, often using acids or other reactive substances. This method is particularly advantageous in industries that require high precision and minimal damage to the substrate.

Pros: The precision offered by chemical abrasion allows for intricate work without altering the base material significantly. It is excellent for delicate materials that cannot withstand mechanical abrasion.

Cons: On the downside, chemical abrasion involves higher initial costs due to chemical procurement and disposal. Furthermore, it requires stringent safety measures and specialized training to handle hazardous materials safely.

When selecting between "abrasivos significado" and its alternatives, B2B buyers must consider their specific operational needs, budget constraints, and safety requirements. For applications requiring durable and effective surface finishing, abrasivos significado may be the best choice. However, for heavy material removal, mechanical abrasion could be more cost-effective, while chemical abrasion offers unparalleled precision for delicate tasks. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make a choice that aligns with their operational goals and resource availability.

Understanding the essential technical properties of abrasives is crucial for B2B buyers, particularly in industries such as manufacturing, construction, and metalworking. Here are some of the most important specifications to consider:

Material Grade

- Abrasives come in various material grades, including aluminum oxide, silicon carbide, and diamond. The grade affects the hardness, durability, and application suitability of the abrasive. For instance, diamond abrasives are ideal for cutting hard materials, while aluminum oxide is commonly used for general-purpose grinding.

Grain Size

- The grain size of abrasives, often measured in mesh, determines the coarseness or fineness of the material. A lower mesh number indicates larger grains suitable for aggressive material removal, while a higher mesh number is appropriate for finer finishing tasks. Selecting the correct grain size is essential for achieving desired surface finishes and operational efficiency.

Bond Type

- Abrasives can be bonded using different materials, such as resin, rubber, or metal. The bond type influences the abrasive's performance, including its ability to withstand heat and pressure. For example, resin-bonded abrasives are preferred for flexibility and durability in various applications, while metal bonds are used for high-stress environments.

Tolerance

- Tolerance refers to the allowable variation in the dimensions of the abrasive tool or product. In precision applications, tighter tolerances are necessary to ensure consistent performance and quality. Understanding tolerance specifications helps buyers select products that meet their operational needs without compromising quality.

Density

- The density of an abrasive material impacts its weight, strength, and performance. Higher density abrasives tend to be more durable and effective in heavy-duty applications. This property is particularly significant for B2B buyers needing products that can withstand rigorous use in challenging environments.

Familiarity with industry terminology is essential for navigating the abrasives market effectively. Here are some common trade terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

- An OEM produces products that are used as components in another company's end product. For buyers, working with OEMs can ensure that the abrasives meet specific quality and performance standards required for their machinery or tools.

MOQ (Minimum Order Quantity)

- MOQ refers to the minimum quantity of product a supplier is willing to sell. Understanding MOQ is critical for buyers to plan their procurement strategy effectively, especially when dealing with manufacturers that may have high minimums.

RFQ (Request for Quotation)

- An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This process helps buyers compare offers from multiple suppliers, ensuring they secure the best deal for their abrasive needs.

Incoterms (International Commercial Terms)

- Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping and delivery. Familiarity with these terms helps buyers understand their obligations and risks involved in the shipping process.

Lead Time

- Lead time is the period between placing an order and receiving the product. Understanding lead times is crucial for B2B buyers to manage their production schedules and avoid delays in their operations.

Surface Finish

- This term refers to the texture of the surface after processing with abrasives. The required surface finish can affect material performance and aesthetic quality, making it vital for buyers to specify their needs to suppliers accurately.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategies and operational efficiency in the abrasives market.

The abrasivos significado sector is undergoing significant transformations driven by technological advancements and evolving market demands. Key drivers include the increasing need for precision in manufacturing processes, the rise of automation, and the ongoing expansion of industries such as automotive, aerospace, and construction. B2B buyers from regions like Africa, South America, the Middle East, and Europe must navigate these dynamics to leverage opportunities effectively.

Emerging technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) are reshaping sourcing strategies. For instance, predictive analytics can help companies forecast demand more accurately, optimizing inventory levels and reducing costs. Additionally, digital platforms are increasingly used for sourcing, facilitating direct interactions between suppliers and buyers, which is particularly beneficial for international transactions. Buyers should consider integrating these technologies into their procurement processes to enhance efficiency and competitiveness.

Moreover, sustainability is becoming a pivotal concern in the abrasivos significado sector. Buyers are increasingly seeking suppliers who demonstrate environmentally friendly practices, not only to comply with regulations but also to meet consumer expectations. This shift is prompting suppliers to innovate and offer products that reduce waste and energy consumption, which can ultimately lead to cost savings for B2B buyers.

Sustainability and ethical sourcing are critical considerations for B2B buyers in the abrasivos significado sector. The environmental impact of abrasive materials, including energy consumption and waste generation, necessitates a proactive approach to sourcing. Buyers should prioritize suppliers that are committed to reducing their carbon footprint and have clear sustainability practices in place.

Ethical supply chains are also gaining prominence. This involves ensuring that the materials used are sourced responsibly, without compromising on human rights or labor standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainable practices. By selecting suppliers with these certifications, B2B buyers can enhance their brand reputation and meet the growing demand for responsible sourcing.

Furthermore, the use of 'green' materials—such as recycled abrasives or those produced through eco-friendly processes—can significantly reduce the environmental impact of operations. Buyers should actively seek information on the sourcing practices of potential suppliers and consider the long-term benefits of investing in sustainable products.

The abrasivos significado sector has evolved significantly over the decades, transitioning from traditional, labor-intensive production methods to advanced, technology-driven processes. Initially, abrasives were primarily made from natural materials, but the demand for higher efficiency and precision led to the development of synthetic alternatives.

The industrial revolution marked a pivotal point, as advancements in manufacturing techniques allowed for the mass production of abrasive materials. This evolution was further accelerated by the rise of the automotive and aerospace industries, which required high-performance abrasives for precision machining and surface finishing.

Today, the sector is characterized by continuous innovation, with a focus on developing smarter, more sustainable products that meet the rigorous demands of modern manufacturing. B2B buyers must understand this historical context to appreciate the current landscape and make informed sourcing decisions that align with industry trends.

How do I solve issues with sourcing abrasivos significado from international suppliers?

To effectively source abrasivos significado, begin by identifying potential suppliers through industry directories, trade shows, and online platforms. Conduct thorough research to verify their credibility by checking reviews, certifications, and their history in international trade. Engage in direct communication to discuss your specific needs, request samples, and assess their response time and customer service. Establishing clear terms regarding quality assurance and delivery timelines can help mitigate potential issues.

What is the best type of abrasivos significado for industrial applications?

The best type of abrasivos significado for industrial applications largely depends on the specific tasks at hand. For heavy-duty grinding, diamond abrasives are preferred due to their durability and effectiveness. Conversely, for polishing and finishing, silicon carbide or aluminum oxide may be more suitable. It’s essential to evaluate the material you will be working with and the desired finish to select the most appropriate abrasive type.

What should I consider when vetting suppliers for abrasivos significado?

When vetting suppliers for abrasivos significado, consider their manufacturing capabilities, quality control processes, and compliance with international standards. Request certifications such as ISO or equivalent to ensure product quality. Additionally, review their experience in exporting to your region, as familiarity with local regulations can streamline the import process. Establishing a good rapport and clear communication channels is also crucial for long-term partnerships.

What are the common minimum order quantities (MOQ) for abrasivos significado?

Minimum order quantities (MOQ) for abrasivos significado can vary significantly based on the supplier and the type of abrasive. Typically, MOQs can range from 50 to 500 units for standard products. However, custom abrasives may require higher MOQs due to production constraints. It's advisable to discuss your specific needs with the supplier and negotiate terms that align with your purchasing capacity.

How can I negotiate favorable payment terms when sourcing abrasivos significado?

To negotiate favorable payment terms, be transparent about your budget and payment capabilities. Propose options such as a letter of credit or partial upfront payments, which may reduce risk for both parties. Building a solid relationship with the supplier can also lead to more flexible terms, such as extended payment periods or bulk purchase discounts. Always ensure that the agreed-upon terms are documented in your contract to prevent misunderstandings.

What quality assurance practices should I expect from suppliers of abrasivos significado?

Suppliers of abrasivos significado should have robust quality assurance practices in place, including regular testing of their products against industry standards. Look for suppliers who implement ISO 9001 or similar quality management systems. Additionally, request documentation of testing results and product specifications. Regular audits and third-party inspections can further ensure that the products meet your quality requirements before shipment.

How do logistics impact the sourcing of abrasivos significado internationally?

Logistics play a critical role in the timely and cost-effective sourcing of abrasivos significado. Factors such as shipping methods, customs regulations, and local distribution channels can significantly influence delivery times and costs. It’s essential to collaborate with suppliers who have experience in international shipping and can provide insights into the best practices for your region. Understanding the potential challenges in customs clearance can also help avoid delays.

What are the key trends in the abrasivos significado market that B2B buyers should be aware of?

Key trends in the abrasivos significado market include the increasing demand for eco-friendly and sustainable abrasive materials, driven by environmental regulations and consumer preferences. Additionally, advancements in technology are leading to the development of more efficient abrasives that enhance performance while reducing waste. B2B buyers should also monitor shifts in global supply chains, as geopolitical factors can affect availability and pricing. Staying informed about these trends can aid in making strategic sourcing decisions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the rapidly evolving landscape of B2B procurement, understanding the nuances of "abrasivos significado" is crucial for international buyers, especially those in Africa, South America, the Middle East, and Europe. Strategic sourcing allows businesses to optimize costs, enhance product quality, and ensure a reliable supply chain. By leveraging local insights and global trends, buyers can make informed decisions that resonate with their specific market dynamics.

What are the key benefits of adopting a strategic sourcing approach?

As we look to the future, it is essential for international B2B buyers to remain agile and adaptable. Embracing innovative sourcing strategies and building strong partnerships will be vital in navigating the complexities of global trade. Take the next step in your sourcing journey—explore new suppliers, invest in relationship-building, and leverage data-driven insights to stay ahead in the competitive marketplace.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina