In today's competitive global market, sourcing high-quality fused alumina brand names can pose significant challenges for international B2B buyers. With varying specifications, applications, and suppliers scattered across continents, navigating this complex landscape is crucial for businesses aiming to enhance their product offerings. This guide provides a comprehensive overview of the fused alumina sector, covering essential topics such as types of fused alumina, their industrial applications, effective supplier vetting strategies, and cost considerations.

By detailing the characteristics and uses of different fused alumina products, this guide empowers buyers from regions like Africa, South America, the Middle East, and Europe—particularly those in emerging markets such as Argentina and Indonesia—to make informed purchasing decisions. With actionable insights and practical tips, you will be equipped to identify reputable suppliers, evaluate product quality, and negotiate favorable terms, ensuring that your investments yield optimal results.

Whether you're looking to enhance your manufacturing processes, improve the performance of your materials, or simply expand your supplier network, this guide is designed to streamline your sourcing efforts. Dive in to discover how to leverage the global market for fused alumina effectively, enabling your business to thrive in an ever-evolving industrial landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Brown Alumina | High toughness, excellent wear resistance | Abrasives, refractory materials | Pros: Cost-effective, versatile; Cons: Limited thermal stability compared to other types. |

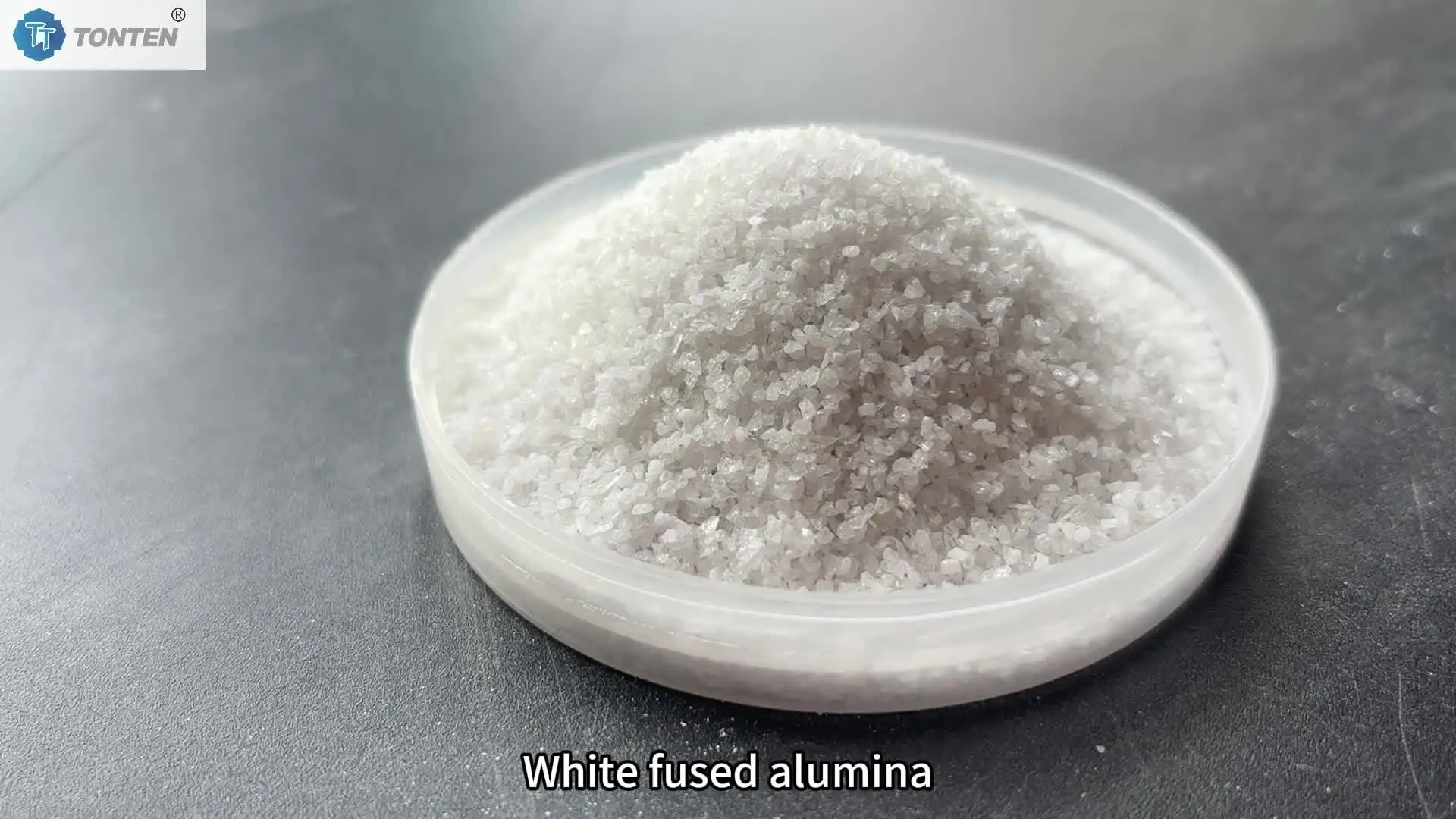

| Fused White Alumina | High purity, low iron content | Precision abrasives, ceramics | Pros: Superior finish, consistent quality; Cons: Higher price point. |

| Fused Pink Alumina | Good balance of hardness and toughness | Grinding wheels, polishing applications | Pros: Enhanced performance in grinding; Cons: Availability can be limited. |

| Fused Sapphire Alumina | Exceptional hardness and thermal stability | High-performance applications | Pros: Ideal for specialized uses; Cons: Expensive and overkill for standard applications. |

| Fused Black Alumina | Unique microstructure, high toughness | Coating and blasting applications | Pros: Effective for surface preparation; Cons: Less widely available. |

Fused Brown Alumina is characterized by its high toughness and excellent wear resistance, making it a popular choice for a variety of industrial applications. Its cost-effectiveness and versatility allow it to be used in abrasives and refractory materials, making it suitable for manufacturers looking for reliable, durable solutions without breaking the bank. Buyers should consider the balance between cost and performance, especially when thermal stability is not a primary concern.

Fused White Alumina is known for its high purity and low iron content, which makes it ideal for precision abrasives and ceramics. This type is particularly valued in industries requiring a superior finish and consistent quality. However, its higher price point may deter some buyers, especially those focused on budget constraints. It is essential for B2B buyers to evaluate the quality requirements of their end products against the investment in Fused White Alumina.

Fused Pink Alumina strikes a good balance between hardness and toughness, making it suitable for grinding wheels and polishing applications. Its enhanced performance in grinding tasks makes it a preferred choice for companies seeking efficiency in their operations. Buyers should be aware that while it offers significant advantages, availability can sometimes be an issue, which may affect supply chain considerations.

Fused Sapphire Alumina is recognized for its exceptional hardness and thermal stability, making it suitable for high-performance applications in demanding environments. While it provides ideal solutions for specialized uses, the cost can be prohibitive for standard applications. Buyers need to assess whether the benefits outweigh the expenses, especially in industries where performance is critical.

Fused Black Alumina features a unique microstructure that provides high toughness, making it effective for surface preparation in coating and blasting applications. Its ability to deliver consistent results is a significant advantage for manufacturers. However, its availability can be less widespread than other types, prompting buyers to consider sourcing options when planning their procurement strategies.

Related Video: White fused alumina

| Industry/Sector | Specific Application of fused alumina brand name | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Abrasives Manufacturing | Production of grinding wheels and abrasive tools | Enhanced durability and efficiency in machining processes | Quality certifications, particle size distribution, and purity levels |

| Refractory Materials | High-temperature insulation and linings | Improved thermal stability and energy efficiency | Compliance with international standards, sourcing reliability, and thermal properties |

| Ceramics and Glass | Raw material for ceramic and glass applications | Superior strength and thermal resistance | Consistency in quality, availability of various grades, and cost-effectiveness |

| Metal Casting | Sand casting applications | Increased mold strength and reduced defects in cast products | Grain size, shape uniformity, and compatibility with casting processes |

| Construction and Building | Component in concrete and asphalt production | Enhanced strength and longevity of construction materials | Sourcing from certified suppliers, environmental impact, and performance metrics |

Fused alumina is extensively utilized in the production of grinding wheels and various abrasive tools. Its hardness and durability make it ideal for machining applications, where precision and efficiency are paramount. For international B2B buyers, especially those in Africa and South America, sourcing high-quality fused alumina with precise particle size distribution is critical to ensure optimal performance in abrasive products. Ensuring quality certifications and understanding the specific needs of the machining process can significantly enhance productivity and reduce costs.

A stock image related to fused alumina brand name.

In the refractory materials sector, fused alumina is used for high-temperature insulation and linings in furnaces and kilns. Its ability to withstand extreme temperatures without degrading makes it essential for industries such as metallurgy and ceramics. Buyers from the Middle East and Europe should focus on sourcing fused alumina that complies with international standards to ensure reliability and performance. Additionally, understanding the thermal properties and sourcing from reputable suppliers can lead to significant energy savings and operational efficiency.

Fused alumina serves as a critical raw material in the ceramics and glass industries, contributing to the strength and thermal resistance of finished products. Its unique properties allow for the production of high-performance ceramics that can withstand high temperatures and mechanical stress. For B2B buyers, particularly in Europe and Africa, consistency in quality and the availability of various grades of fused alumina are essential considerations. Evaluating suppliers based on their ability to provide reliable and cost-effective solutions can enhance product quality and market competitiveness.

In metal casting, fused alumina is utilized in sand casting applications, where it increases the strength and durability of molds. This leads to a reduction in defects and improves the overall quality of cast products. International buyers, particularly from South America and Africa, should consider the grain size and shape uniformity of the fused alumina they source, as these factors directly impact casting performance. Collaborating with suppliers who provide detailed specifications and testing results can help ensure the best outcomes in metal casting operations.

Fused alumina is increasingly being incorporated into concrete and asphalt production, enhancing the strength and longevity of construction materials. For B2B buyers in the construction sector, particularly in the Middle East, sourcing high-quality fused alumina can lead to improved structural integrity and resilience of building materials. Key considerations include sourcing from certified suppliers who can demonstrate the environmental impact of their products and provide performance metrics to support the expected benefits in construction applications.

Related Video: Alumina Ceramics: The Complete Guide

The Problem: Many B2B buyers, particularly in regions like Africa and South America, face challenges in ensuring the consistent quality of fused alumina products. Variability in batch quality can lead to issues in production processes, affecting the final product’s performance and reliability. This inconsistency can stem from variations in raw materials, production methods, or even supplier practices, leading to a lack of trust in sourcing decisions.

The Solution: To mitigate quality assurance issues, buyers should establish strong relationships with reputable suppliers who adhere to strict quality control protocols. When sourcing fused alumina, request detailed documentation of the supplier's quality assurance processes, including certificates of analysis and compliance with industry standards. Regularly conduct audits and site visits to ensure that the supplier maintains the necessary quality standards. Implement a robust internal quality control system that includes regular testing of incoming materials. This proactive approach not only helps in maintaining product integrity but also fosters a reliable partnership with suppliers.

The Problem: International buyers, especially in the Middle East and Europe, often encounter high shipping costs and delays in receiving fused alumina shipments. These logistical challenges can disrupt production schedules and lead to increased operational costs, negatively impacting profitability and customer satisfaction.

The Solution: To overcome shipping challenges, B2B buyers should consider consolidating orders to optimize shipping costs. Engage with suppliers who offer flexible shipping options, including bulk shipping or freight forwarding services that can provide more competitive rates. Additionally, utilizing local warehousing solutions can help mitigate delays; by keeping a buffer stock of fused alumina closer to production facilities, companies can respond quickly to demand fluctuations. Establishing partnerships with reliable logistics providers can also streamline the shipping process, ensuring timely deliveries and reducing overall costs.

The Problem: B2B buyers often struggle with the technical aspects of using fused alumina, especially when it comes to specifying the right grades for their applications. This knowledge gap can lead to improper usage, resulting in suboptimal performance and potential product failures. Buyers in regions like South America may find it particularly challenging to access knowledgeable support from suppliers.

The Solution: To bridge the technical expertise gap, buyers should seek suppliers who provide comprehensive technical support and consultation services. When engaging with a supplier of fused alumina, inquire about their technical resources, such as product data sheets, application guides, and access to technical experts. Additionally, consider participating in training sessions or workshops offered by suppliers to deepen your understanding of how to select and utilize fused alumina effectively. Collaborating with industry experts or consultants can also provide tailored solutions that align with specific production requirements, ultimately enhancing product performance and reliability.

When selecting materials for fused alumina products, international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in the production of fused alumina, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Fused alumina is a synthetic material derived from bauxite, known for its exceptional hardness and thermal stability. It can withstand high temperatures (up to 2000°C) and has excellent chemical resistance, making it suitable for a wide range of applications, including abrasives and refractory products.

Pros:

- High durability and wear resistance.

- Excellent thermal and chemical stability.

- Versatile for various applications.

Cons:

- Higher production costs compared to natural alumina.

- Limited flexibility in shaping and forming.

Impact on Application:

Fused alumina is particularly effective in abrasive applications due to its hardness. It is compatible with a variety of media, including metals and ceramics, making it a preferred choice for grinding and cutting tools.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN, particularly in industries like automotive and aerospace, where material performance is critical.

Silicon carbide is another common material used in conjunction with fused alumina. It offers high thermal conductivity and is exceptionally hard, making it ideal for abrasive applications.

Pros:

- Superior hardness and thermal conductivity.

- Excellent resistance to oxidation and thermal shock.

- Suitable for high-temperature applications.

Cons:

- More brittle than fused alumina, which can lead to chipping.

- Higher cost due to complex manufacturing processes.

Impact on Application:

Silicon carbide is often used in high-performance grinding wheels and cutting tools, particularly in industries requiring high precision and durability.

Considerations for International Buyers:

Buyers in regions with stringent environmental regulations should verify the sourcing and production processes to ensure compliance with local laws.

Zirconia is known for its toughness and resistance to wear and corrosion. It is often used in applications where high mechanical strength is required.

Pros:

- Excellent toughness and resistance to wear.

- Good thermal stability and low thermal conductivity.

- Suitable for applications in aggressive environments.

Cons:

- Higher cost compared to fused alumina and silicon carbide.

- More complex manufacturing process.

Impact on Application:

Zirconia is particularly effective in applications involving harsh chemicals or extreme temperatures, such as in the manufacturing of cutting tools and wear-resistant components.

Considerations for International Buyers:

Buyers should consider the availability of zirconia in their local markets and whether it meets the required international standards for their specific applications.

This composite combines alumina with titania to enhance certain properties, such as toughness and thermal stability. It is increasingly used in advanced applications.

Pros:

- Improved toughness compared to pure alumina.

- Good thermal shock resistance.

- Versatile for various industrial applications.

Cons:

- More expensive due to the additional processing.

- Limited availability in some regions.

Impact on Application:

The alumina-titania composite is suitable for high-performance applications in the aerospace and automotive sectors, where material integrity is crucial.

Considerations for International Buyers:

Buyers should assess the supply chain for this composite material, particularly in regions where access to advanced materials is limited.

| Material | Typical Use Case for fused alumina brand name | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Alumina | Abrasives, grinding tools | High durability and wear resistance | Higher production costs | High |

| Silicon Carbide | High-performance grinding wheels | Superior hardness and thermal conductivity | Brittle, prone to chipping | High |

| Zirconia | Cutting tools, wear-resistant components | Excellent toughness and corrosion resistance | Higher cost, complex manufacturing | High |

| Alumina-Titania Composite | Aerospace, automotive applications | Improved toughness over pure alumina | More expensive, limited availability | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with industry standards.

Fused alumina, a critical material in various industrial applications, undergoes a meticulous manufacturing process. Understanding these stages is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, who seek quality and reliability.

The manufacturing process begins with the preparation of raw materials. Bauxite, the primary source of aluminum oxide, is sourced and purified. The process may also involve the blending of other materials to achieve specific properties. This stage is crucial as the quality of raw materials directly impacts the final product's performance. Buyers should inquire about the sourcing practices of their suppliers, as high-quality raw materials are essential for producing top-grade fused alumina.

Once the materials are prepared, they are subjected to a melting process in an electric arc furnace. This furnace reaches high temperatures, typically around 2000°C, allowing the raw materials to fuse together. The molten alumina is then poured into molds to form various shapes, such as grains or blocks. The forming techniques used can significantly affect the physical properties of the final product. B2B buyers should consider suppliers that utilize advanced forming technologies to ensure consistency and quality.

After forming, the fused alumina undergoes a cooling process, followed by breaking and grinding to achieve the desired particle size and distribution. This finishing stage is crucial as it determines the material's suitability for various applications, including abrasives, refractories, and ceramics. Buyers should pay attention to the finishing techniques employed by suppliers, as these can influence the performance characteristics of the fused alumina.

Quality assurance (QA) is integral to the manufacturing of fused alumina. The process adheres to international standards such as ISO 9001, which ensures a consistent quality management system. Additionally, industry-specific certifications like CE and API may be relevant, depending on the end-use applications.

Quality control (QC) checkpoints are established throughout the manufacturing process. These typically include:

Each of these checkpoints plays a vital role in maintaining the integrity of the manufacturing process. B2B buyers should ask suppliers about their specific QC protocols and the frequency of inspections.

Several testing methods are employed to assess the quality of fused alumina, including:

Understanding these testing methods helps buyers gauge the reliability of the products they are considering.

For international B2B buyers, especially those in regions like Africa and South America, verifying the quality control practices of suppliers is crucial. Here are some actionable strategies:

By implementing these strategies, buyers can mitigate risks associated with product quality and ensure they are sourcing from reputable suppliers.

International B2B buyers must also be aware of specific nuances in quality control that may vary by region. For instance, compliance with local regulations and standards is critical, as these can differ significantly between Africa, South America, the Middle East, and Europe.

Additionally, understanding the logistics of transporting fused alumina can impact quality, especially if the material is sensitive to temperature or moisture. Buyers should discuss with suppliers how they manage these factors during shipping and handling.

In summary, the manufacturing processes and quality assurance measures for fused alumina are critical for ensuring product reliability and performance. By understanding these aspects and actively verifying supplier practices, B2B buyers can make informed decisions that align with their operational needs and standards. Emphasizing quality assurance in supplier relationships will ultimately lead to better outcomes for businesses across various regions.

This practical sourcing guide is designed to assist international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, in procuring fused alumina brand name effectively. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their technical requirements and business goals.

Clearly articulating your technical specifications is the first step in the sourcing process. Fused alumina comes in various grades and forms, such as alumina powder, grit, and tiles, each serving different applications from abrasive manufacturing to refractory materials. Understanding the specific qualities you need—like particle size, purity levels, and intended usage—will help you communicate effectively with suppliers and avoid costly mistakes.

Before reaching out to suppliers, conduct thorough market research to understand pricing trends and availability. Investigate competitors who use fused alumina and identify their suppliers. This will give you a benchmark for evaluating potential suppliers and help you negotiate better terms, ensuring that you get a fair price for the quality you require.

Compile a list of potential suppliers that specialize in fused alumina. Utilize online B2B marketplaces, industry directories, and trade shows to find reputable manufacturers. Pay attention to their market presence and customer reviews, as this can provide insights into their reliability and product quality.

Before entering into any agreements, verify the certifications of your shortlisted suppliers. Look for ISO certifications or industry-specific quality standards that demonstrate their commitment to quality control. This step is crucial for ensuring that the fused alumina meets international quality and safety standards, especially if you are exporting or using it in regulated industries.

Once you have narrowed down your options, request samples of the fused alumina products you are interested in. Testing these samples in your specific application will provide valuable insights into their performance and compatibility. This step helps mitigate risks associated with bulk purchases and ensures that the product meets your operational needs.

After selecting a supplier based on your testing results, engage in negotiations regarding pricing, delivery schedules, and payment terms. Clear communication during this phase is essential to establish a mutually beneficial relationship. Ensure that you discuss warranties and return policies to safeguard your investment.

Finally, set up a communication plan with your chosen supplier. Regular updates regarding production, shipping, and quality checks will help maintain transparency and address any issues promptly. A solid communication strategy fosters a collaborative relationship, ensuring that both parties are aligned on expectations throughout the procurement process.

By following these steps, B2B buyers can navigate the sourcing of fused alumina effectively, ensuring they make informed decisions that support their business objectives.

When sourcing fused alumina, understanding the cost structure is essential for making informed purchasing decisions. The cost components can be categorized as follows:

Materials: The primary raw material used in the production of fused alumina is bauxite, which can vary in price based on global market conditions. Other additives may also be required for specific applications, influencing overall material costs.

Labor: Labor costs include wages for skilled workers involved in the production process, quality control, and logistics. Regions with lower labor costs can provide competitive pricing, but it is important to assess the skill level and training of the workforce.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing practices can help reduce these overhead costs, which can be passed on to the buyer.

Tooling: Custom tooling for specific product requirements can add to initial costs. However, investing in quality tooling can improve production efficiency and product consistency in the long run.

Quality Control (QC): Implementing stringent QC measures ensures that the fused alumina meets the required specifications and certifications. While this may increase upfront costs, it can prevent costly returns and rework.

Logistics: Transportation costs, including shipping and handling, can vary significantly based on the distance between supplier and buyer, as well as the chosen Incoterms. Understanding these costs is crucial for accurate pricing.

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand and competition.

Several factors can influence the pricing of fused alumina:

Volume and Minimum Order Quantity (MOQ): Larger orders often come with discounts, making it advantageous for buyers to consolidate their purchases. Understanding the MOQ is essential for effective negotiation.

Specifications and Customization: Customized products tailored to specific applications can lead to higher costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

Material Quality and Certifications: Higher quality materials and recognized certifications can command premium prices. Buyers should assess their quality needs against their budget to determine the best options.

Supplier Factors: Supplier reputation, reliability, and geographical location can all influence pricing. Establishing a relationship with a reputable supplier can lead to better pricing and service.

Incoterms: The terms of delivery (e.g., FOB, CIF) impact overall costs. Understanding these terms can help buyers calculate the total landed cost of the product.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should consider the following strategies to negotiate effectively:

Conduct Market Research: Understanding current market prices and trends for fused alumina can provide leverage during negotiations. Buyers should gather data from multiple suppliers to compare offers.

Focus on Total Cost of Ownership (TCO): Rather than solely considering the purchase price, evaluate the total cost of ownership, including logistics, maintenance, and disposal costs. This holistic view can justify a higher upfront investment if it results in lower long-term expenses.

Build Long-term Relationships: Establishing a long-term partnership with suppliers can lead to better pricing and terms. Regular communication and transparency about needs can foster trust and collaboration.

Leverage Volume for Discounts: If possible, consolidate orders to meet MOQs or negotiate volume discounts. This approach can significantly reduce per-unit costs.

Be Aware of Pricing Nuances: Different regions may have varying pricing strategies. Understanding the local market dynamics can provide insights into potential negotiation points.

Please note that the prices for fused alumina can fluctuate based on market conditions, supplier capabilities, and regional economic factors. It is advisable to obtain quotes from multiple suppliers and consider all associated costs to ensure the best purchasing decision.

When considering the procurement of industrial materials, particularly abrasive products like fused alumina, it's essential to evaluate various alternatives that can meet specific operational requirements. This section provides a comparative analysis of 'Fused Alumina Brand Name' against viable alternative solutions, helping B2B buyers make informed decisions.

| Comparison Aspect | Fused Alumina Brand Name | Alternative 1: Silicon Carbide | Alternative 2: Zirconia Alumina |

|---|---|---|---|

| Performance | High hardness, excellent wear resistance, suitable for various applications | Extremely hard, better for high-temperature applications | Good toughness, suitable for heavy-duty applications |

| Cost | Moderate price per ton | Generally lower cost | Higher initial investment |

| Ease of Implementation | Easy to integrate into existing processes | Requires slight adjustments in machinery | May need specialized equipment |

| Maintenance | Low maintenance required | Low maintenance, but wear can be rapid in some conditions | Moderate maintenance due to wear |

| Best Use Case | General-purpose abrasive, ideal for metal and wood finishing | Ideal for grinding hard materials and in extreme conditions | Best for applications requiring high durability |

Silicon carbide (SiC) is recognized for its exceptional hardness and thermal conductivity, making it an excellent choice for high-temperature applications. It is typically less expensive than fused alumina, which can be a significant factor for budget-conscious buyers. However, while it performs well in grinding applications, its wear rate can be higher in certain environments, leading to more frequent replacements. Additionally, integrating silicon carbide into existing processes may require minor adjustments to machinery, which could lead to increased downtime.

Zirconia alumina is favored for its toughness and resistance to fracturing, making it suitable for heavy-duty applications, such as grinding metals and other hard materials. This material provides excellent performance under heavy loads, but it does come with a higher initial investment compared to fused alumina. The maintenance requirements can also be moderate, as it may wear down faster in specific applications. Buyers considering zirconia alumina should evaluate whether the added durability justifies the cost in their specific operational context.

When selecting between fused alumina and its alternatives, B2B buyers should assess their specific operational needs, including the materials they will be working with, the required durability, and budget constraints. Understanding the performance characteristics, costs, and maintenance requirements of each option is crucial. Additionally, considering the ease of implementation and any necessary adjustments to existing processes can help in making a well-informed decision. Ultimately, the choice should align with the long-term goals of operational efficiency, cost-effectiveness, and quality assurance in production. By thoroughly analyzing these aspects, buyers from regions like Africa, South America, the Middle East, and Europe can select the most suitable abrasive solution for their needs.

Fused alumina is a critical material used in various industrial applications, particularly in abrasives, refractories, and ceramics. Understanding its essential technical properties is crucial for B2B buyers to ensure they select the right product for their needs.

Material Grade

- Material grades of fused alumina denote its purity and performance characteristics. Common grades include white, brown, and pink fused alumina, each offering different hardness and durability levels. For instance, white fused alumina is often used for high-precision applications due to its high purity, while brown fused alumina is more suitable for general applications due to its cost-effectiveness. Selecting the appropriate grade can significantly affect the performance and longevity of the final product.

Particle Size Distribution

- The particle size distribution (PSD) of fused alumina is vital for its application in abrasives. This specification determines how the material will perform in grinding, cutting, or polishing applications. A consistent PSD ensures uniformity in the final product, reducing the risk of defects. Buyers should inquire about the PSD to ensure compatibility with their specific processing requirements.

Bulk Density

- Bulk density refers to the mass of fused alumina per unit volume and is an essential property for applications requiring specific weight parameters. A higher bulk density often translates to better abrasion resistance, making it crucial for manufacturers in industries like automotive and aerospace. Buyers should consider bulk density to ensure the material meets their operational criteria.

Hardness

- Hardness is a critical property that indicates the material's ability to resist deformation and wear. Fused alumina typically has a hardness rating of around 9 on the Mohs scale, making it suitable for heavy-duty applications. Understanding the hardness of fused alumina is essential for B2B buyers who require materials that can withstand high-stress environments.

Thermal Stability

- Thermal stability is crucial for applications involving high temperatures, such as in refractory products. Fused alumina maintains its structural integrity at elevated temperatures, making it ideal for industries such as steel manufacturing. Buyers should assess thermal stability to ensure the material will perform effectively under their specific operating conditions.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some key trade terms related to fused alumina:

OEM (Original Equipment Manufacturer)

- An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fused alumina, knowing the OEM can help buyers understand the quality and specifications of the materials they are sourcing.

MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and ensure they are not overcommitting to a product that may not meet their needs.

RFQ (Request for Quotation)

- An RFQ is a document sent to suppliers requesting a quote for specific products or services. For B2B buyers of fused alumina, issuing an RFQ allows them to compare prices and terms from various suppliers, facilitating informed purchasing decisions.

Incoterms (International Commercial Terms)

- Incoterms are a set of international rules that define the responsibilities of sellers and buyers for the delivery of goods. Knowing the appropriate Incoterms for fused alumina shipments helps buyers understand shipping costs, insurance, and risk management, which are critical for international trade.

Lead Time

- Lead time is the period between the initiation of an order and its completion. Understanding lead times for fused alumina can help buyers plan their production schedules and manage supply chain expectations effectively.

By mastering these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing fused alumina, ensuring their investments yield the best possible results.

The fused alumina sector is experiencing significant growth driven by various global factors, including the increasing demand for advanced materials in industries such as automotive, electronics, and construction. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in sourcing opportunities due to technological advancements and evolving market dynamics. For instance, the introduction of automation and AI in manufacturing processes has led to enhanced efficiency and cost-effectiveness, making fused alumina products more accessible.

Emerging trends in sourcing include a greater emphasis on digital procurement platforms, which streamline the purchasing process and facilitate better supplier relationships. Buyers are increasingly utilizing data analytics to make informed decisions, enabling them to identify the best suppliers and negotiate favorable terms. Moreover, the shift towards a circular economy is influencing sourcing strategies, as companies seek sustainable alternatives and environmentally friendly materials. This is particularly relevant for buyers in regions like Europe, where regulatory pressures for sustainable sourcing are more stringent.

Sustainability has become a cornerstone of modern B2B operations, with a growing focus on the environmental impact of sourcing decisions. The production of fused alumina can have significant ecological consequences if not managed responsibly. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability practices. This includes implementing efficient resource management, reducing waste, and minimizing carbon footprints.

Moreover, the demand for 'green' certifications is on the rise. Buyers are looking for materials that are certified by recognized bodies, ensuring that their sourcing practices align with global sustainability standards. For instance, certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are gaining traction among B2B buyers in sectors that utilize fused alumina products. These certifications not only enhance brand reputation but also meet the expectations of environmentally conscious consumers and stakeholders.

The fused alumina sector has evolved significantly over the past few decades, transitioning from traditional manufacturing methods to more advanced production techniques. Initially, fused alumina was primarily used in abrasive applications; however, its versatility has led to expanded uses in various industries, including ceramics, refractories, and coatings.

In recent years, the focus has shifted towards enhancing product performance and sustainability. Innovations in production processes, such as the use of electric arc furnaces, have improved the quality and consistency of fused alumina products. Additionally, the integration of digital technologies in supply chain management has transformed how buyers source and procure materials, paving the way for a more efficient and transparent marketplace.

In conclusion, international B2B buyers must stay informed about the dynamic market trends and sustainability practices in the fused alumina sector to make informed sourcing decisions. By embracing these changes, buyers can enhance their competitive edge and contribute positively to environmental stewardship.

How do I choose the right fused alumina supplier for my business needs?

Choosing the right fused alumina supplier involves several key considerations. Start by assessing the supplier's industry experience and reputation in the market. Look for certifications and compliance with international standards, which can indicate quality assurance. Additionally, request samples to evaluate product quality firsthand. It’s also essential to check their production capacity and lead times to ensure they can meet your demands, especially if you are sourcing from regions like Africa or South America where logistics can be challenging.

What are the benefits of sourcing fused alumina from international suppliers?

Sourcing fused alumina from international suppliers can offer competitive pricing, access to advanced manufacturing techniques, and a wider variety of grades and specifications. Particularly in regions like the Middle East and Europe, suppliers may have established supply chains that ensure timely delivery. Furthermore, working with international suppliers can help diversify your supply base, reducing dependency on local markets and mitigating risks associated with local economic fluctuations.

What are the typical minimum order quantities (MOQ) for fused alumina?

Minimum order quantities for fused alumina can vary significantly depending on the supplier and the specific product grade. Generally, MOQs can range from 500 kg to several tons. It’s advisable to discuss your needs directly with potential suppliers to negotiate MOQs that align with your purchasing capabilities. Some suppliers may offer flexibility, particularly for new customers or bulk orders, which can be beneficial for businesses in regions like Africa and South America looking to optimize their procurement strategies.

What payment terms should I expect when sourcing fused alumina internationally?

Payment terms for international transactions can vary by supplier, but common practices include advance payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that are favorable for your cash flow while ensuring the supplier feels secure in the transaction. Be aware of additional costs such as tariffs and shipping fees that may influence your total expenditure. Establishing a clear agreement on payment terms can help prevent misunderstandings and foster a positive supplier relationship.

How can I ensure quality assurance when sourcing fused alumina?

To ensure quality assurance when sourcing fused alumina, request detailed documentation such as material safety data sheets (MSDS) and certificates of analysis (COA) from your supplier. Conduct periodic quality audits and consider third-party testing to verify that the products meet your specifications. Additionally, building a strong relationship with your supplier can facilitate open communication regarding quality issues and improvements, which is particularly important in international trade contexts.

What logistics considerations should I keep in mind when importing fused alumina?

When importing fused alumina, consider logistics factors such as shipping methods, customs regulations, and potential delays. Choose a reliable freight forwarder familiar with international trade in your region. Ensure all necessary documentation is prepared in advance, including import permits and customs declarations. Additionally, factor in the cost of shipping and insurance, as these can significantly impact your total landed cost, especially when sourcing from suppliers in Europe or the Middle East.

Can I customize my fused alumina order?

Yes, many suppliers offer customization options for fused alumina orders, including variations in grain size, purity levels, and packaging. Discuss your specific requirements with potential suppliers, as they may have the capability to tailor their products to better suit your applications. Customization can be particularly advantageous for businesses in niche markets or those requiring specialized materials for unique industrial applications.

What are the common applications of fused alumina in various industries?

Fused alumina is widely used across several industries, including abrasives, ceramics, and refractories. Its hardness and durability make it ideal for abrasive products like sandpaper and grinding wheels. In the ceramics industry, it serves as a crucial component in producing tiles and porcelain. Understanding the specific applications relevant to your business can help you communicate effectively with suppliers and ensure you procure the right type of fused alumina for your needs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In summary, strategic sourcing for fused alumina presents a unique opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging a thorough understanding of supplier capabilities and market dynamics, buyers can optimize their procurement processes, ensuring they obtain high-quality materials at competitive prices. The importance of building strong supplier relationships cannot be overstated, as these partnerships can lead to improved supply chain resilience and innovation.

As you navigate the complexities of sourcing fused alumina, consider implementing data-driven decision-making strategies. Utilize market analysis and supplier performance metrics to enhance your procurement strategies. This proactive approach not only mitigates risks but also positions your organization for sustainable growth in an increasingly competitive landscape.

Looking ahead, the demand for high-quality fused alumina is projected to rise, driven by advancements in various industries, including ceramics and abrasives. By embracing strategic sourcing practices now, you will be well-prepared to capitalize on future market opportunities. Engage with suppliers who align with your values and quality standards, and take decisive steps toward securing your supply chain's future. The time to act is now—position yourself as a leader in your sector through effective sourcing strategies.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina