In today's global market, understanding the cost of aluminium oxide is crucial for international B2B buyers looking to make informed purchasing decisions. Sourcing high-quality aluminium oxide at competitive prices can be a daunting challenge, particularly in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the complexities associated with aluminium oxide costs, offering insights into various types, applications, and key factors influencing pricing.

This guide will explore the diverse forms of aluminium oxide, from calcined to activated varieties, along with their specific applications in industries such as ceramics, electronics, and metallurgy. Moreover, we will delve into the crucial aspects of supplier vetting, ensuring that buyers can identify reputable sources that meet their quality and compliance requirements. By analyzing market trends and providing actionable insights, this guide empowers international B2B buyers to navigate the procurement landscape with confidence.

In an increasingly interconnected world, the ability to accurately assess aluminium oxide costs is not just a financial necessity but a strategic advantage. Buyers in regions like France and Italy, as well as emerging markets, will find valuable information tailored to their unique challenges and opportunities. With this knowledge, businesses can enhance their operational efficiency and optimize their supply chain, ultimately leading to better profitability and growth.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Calcined Aluminium Oxide | High purity, produced by heating alumina | Abrasives, ceramics, refractory materials | Pros: High thermal stability; Cons: Higher cost due to processing. |

| Activated Aluminium Oxide | Greater surface area, enhanced adsorption properties | Catalysts, adsorbents | Pros: Effective in chemical reactions; Cons: Limited availability. |

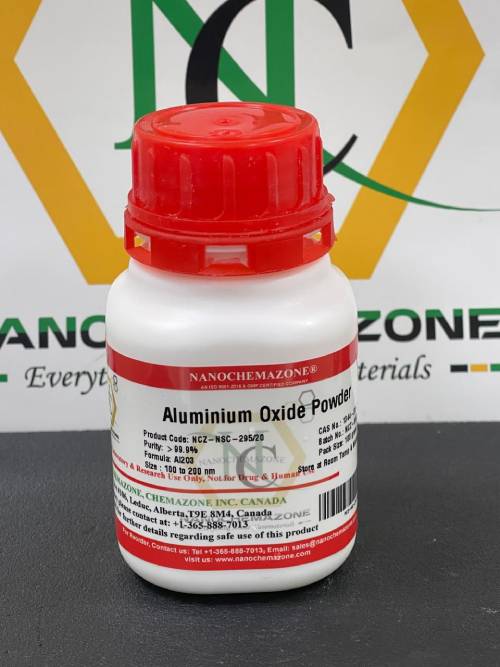

| Aluminium Oxide Powder | Fine particles, versatile in applications | Coatings, paints, plastics | Pros: Easy to incorporate; Cons: May require specific handling. |

| Aluminium Oxide Grit | Coarse form, ideal for abrasive applications | Sandblasting, surface preparation | Pros: Cost-effective for bulk use; Cons: Less suitable for fine applications. |

| Sapphire Substrate | Single crystal form, exceptional optical properties | Electronics, optics, LED substrates | Pros: High performance; Cons: Expensive and requires specialized sourcing. |

Calcined aluminium oxide is produced through the thermal treatment of alumina, resulting in a high-purity material. This type is primarily utilized in industries requiring high thermal stability and resistance to chemical attack, such as ceramics and refractories. B2B buyers should consider its high cost due to the extensive processing involved, but its superior performance in demanding applications often justifies the investment.

Activated aluminium oxide features a significantly increased surface area, making it suitable for applications such as catalysts and adsorbents. Its enhanced adsorption properties are crucial in chemical processes where surface interaction is vital. Buyers should evaluate its availability, as it may not be as widely stocked as other types, potentially leading to longer lead times.

Aluminium oxide powder is characterized by its fine particle size, which allows for easy incorporation into various formulations, including coatings and plastics. Its versatility makes it a popular choice among manufacturers looking for a multipurpose filler. Buyers should be aware of the specific handling requirements, as the powder can pose inhalation risks and necessitate safety measures during transportation and application.

Aluminium oxide grit is a coarse form of aluminium oxide, primarily used in abrasive applications such as sandblasting and surface preparation. Its cost-effectiveness makes it an attractive option for bulk purchases. However, buyers should note that its coarse nature limits its use in more delicate applications, where finer materials might be required.

Sapphire substrates are a specialized form of aluminium oxide, known for their exceptional optical properties and used extensively in electronics and LED manufacturing. While they offer high performance and durability, the cost is significantly higher compared to other types of aluminium oxide. B2B buyers should carefully assess their project requirements and budget constraints before opting for this premium material.

Related Video: GCSE Chemistry Revision "Electrolysis of Aluminium Oxide"

| Industry/Sector | Specific Application of aluminium oxide cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of aerospace components | Lightweight and high-strength materials improve fuel efficiency | Certification requirements, supplier reliability, and quality assurance |

| Automotive | Manufacturing of engine components and brake pads | Enhanced performance and durability reduce maintenance costs | Material grades, compliance with industry standards, and pricing stability |

| Electronics | Insulation in electronic devices | Improved thermal stability and electrical insulation | Sourcing from certified suppliers, environmental compliance, and pricing |

| Construction | Use in concrete and ceramics for construction | Increases durability and resistance to environmental wear | Regional availability, transportation costs, and bulk pricing options |

| Metallurgical Processes | As a refining agent in metal production | Increases yield and purity of metals, reducing operational costs | Supplier’s technical support, consistency in supply, and price fluctuations |

In the aerospace sector, aluminium oxide is utilized in the production of components such as turbine blades and structural parts. The lightweight and high-strength properties of aluminium oxide contribute to improved fuel efficiency, which is critical in aviation. International buyers should consider the certification of materials, supplier reliability, and stringent quality assurance processes when sourcing. This ensures compliance with aerospace standards and minimizes risks associated with material failure.

In automotive manufacturing, aluminium oxide is often incorporated into engine components and brake pads. Its ability to enhance performance and durability translates to reduced maintenance costs and increased vehicle safety. For buyers, understanding material grades and ensuring compliance with industry standards is vital. Additionally, maintaining stable pricing is important to protect against market fluctuations, especially for international buyers from regions with varying currency stability.

Aluminium oxide serves as an essential insulating material in electronic devices, providing improved thermal stability and electrical insulation. This is particularly important in high-performance applications where overheating can lead to device failure. B2B buyers should prioritize sourcing from certified suppliers to ensure product quality and environmental compliance, as these factors can significantly impact the longevity and efficiency of electronic components.

In the construction industry, aluminium oxide is added to concrete and ceramics to enhance durability and resistance to environmental wear. This application is particularly beneficial in regions with harsh climates or high moisture levels. When sourcing aluminium oxide for construction, buyers should consider regional availability and transportation costs, as well as bulk pricing options to optimize their procurement strategy.

Aluminium oxide is employed as a refining agent in metallurgical processes, aiding in the production of high-purity metals. This application increases yield and reduces operational costs, making it attractive for manufacturers. Buyers should evaluate a supplier's technical support and the consistency of supply, as fluctuations in aluminium oxide pricing can affect overall production costs. Understanding market dynamics is crucial for international buyers to make informed purchasing decisions.

Related Video: What is Aluminium Anodizing and How Does It Work | Anodizing Process Overview

The Problem: B2B buyers often face the challenge of fluctuating aluminium oxide prices, which can disrupt budgets and financial forecasts. This volatility can be particularly problematic for buyers in regions like Africa and South America, where import costs may further escalate due to additional tariffs or shipping fees. When prices spike unexpectedly, companies may struggle to meet contract obligations or may need to renegotiate terms with suppliers, leading to strained relationships.

The Solution: To mitigate the impact of price fluctuations, buyers should consider establishing long-term agreements with suppliers that include fixed pricing for a defined period. This approach not only provides cost predictability but can also foster stronger partnerships. Additionally, buyers should conduct thorough market research to understand price trends and leverage this data to negotiate better terms. Employing tools such as price tracking software can help monitor market conditions and enable buyers to make informed purchasing decisions, potentially securing better rates before price increases occur.

The Problem: Quality variability in aluminium oxide can pose a significant challenge for B2B buyers, particularly in industries such as ceramics, metallurgy, and electronics. Buyers may receive products that do not meet their specifications, leading to production delays, increased waste, and quality control issues. This is especially critical for manufacturers in Europe, where adherence to stringent quality standards is essential.

The Solution: To ensure consistent quality, buyers should implement a rigorous supplier evaluation process. This includes assessing suppliers based on their production processes, certifications, and past performance. Buyers can also establish clear specifications and quality benchmarks in their contracts, ensuring that suppliers are held accountable for meeting these standards. Regular audits and sampling of products before shipment can further help in maintaining quality assurance. Engaging in collaborative relationships with suppliers, where feedback is shared and improvements are discussed, can lead to better quality control over time.

The Problem: As sustainability becomes a priority for many businesses, B2B buyers are increasingly challenged to source aluminium oxide that aligns with eco-friendly practices. Buyers from the Middle East and Europe, where regulations around sustainability are tightening, may find it difficult to identify suppliers that provide environmentally responsible products without compromising on cost.

The Solution: To address sustainability concerns, buyers should prioritize suppliers who provide transparency regarding their sourcing and production practices. This includes looking for certifications such as ISO 14001, which indicates a commitment to environmental management. Buyers can also explore partnerships with suppliers who utilize recycled aluminium oxide, which not only reduces environmental impact but can also lower costs. Engaging in sustainability audits and requiring suppliers to report on their environmental practices can further ensure compliance with the buyer’s sustainability goals. Additionally, integrating sustainability criteria into the procurement process can help reinforce the commitment to responsible sourcing and foster a competitive advantage in the marketplace.

By addressing these pain points with actionable solutions, B2B buyers can navigate the complexities of aluminium oxide procurement more effectively, ensuring they meet their operational and financial objectives while maintaining quality and sustainability standards.

When selecting materials related to aluminium oxide, it's crucial to understand their properties, advantages, disadvantages, and their impact on applications. Below, we analyze four common materials that play a significant role in determining the cost of aluminium oxide from a B2B perspective.

Alumina is the most common form of aluminium oxide and is widely used in various applications due to its excellent properties. It boasts high thermal stability, making it suitable for high-temperature applications, and has a strong resistance to corrosion and wear.

Pros & Cons:

- Advantages: Alumina is durable, chemically inert, and has a high melting point, which makes it ideal for refractory applications.

- Disadvantages: The manufacturing process can be complex and costly, especially for high-purity grades, which can affect overall pricing.

Impact on Application: Alumina is compatible with various media, including acidic and alkaline substances, making it versatile for industries like ceramics and electronics.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential, particularly for European buyers. Understanding local regulations regarding material sourcing can also impact costs.

Aluminium nitride is known for its exceptional thermal conductivity and electrical insulation properties. It is often used in electronic applications where heat dissipation is critical.

Pros & Cons:

- Advantages: AlN provides excellent thermal management, which is vital in high-performance electronics.

- Disadvantages: The cost of AlN is generally higher than that of alumina, and it can be more challenging to process.

Impact on Application: AlN is particularly effective in applications involving high temperatures and electrical insulation, making it suitable for semiconductor devices.

Considerations for International Buyers: Buyers in Africa and South America should consider the availability of AlN and its sourcing challenges, as it may not be as readily available as alumina.

Silicon carbide is another material that is gaining traction in the aluminium oxide market due to its hardness and thermal stability. It is often used in abrasive applications and high-temperature environments.

Pros & Cons:

- Advantages: SiC has superior hardness and thermal conductivity, making it ideal for wear-resistant applications.

- Disadvantages: The manufacturing process for SiC can be expensive and energy-intensive, leading to higher costs.

Impact on Application: SiC is compatible with high-pressure applications and can withstand extreme conditions, making it suitable for aerospace and automotive industries.

Considerations for International Buyers: Compliance with international standards is crucial, and buyers should ensure that their suppliers meet these requirements to avoid potential legal issues.

Zirconia is known for its toughness and is often used in applications requiring high strength and wear resistance. It is also used in dental and biomedical applications due to its biocompatibility.

Pros & Cons:

- Advantages: Zirconia has excellent mechanical properties and can operate under high stress.

- Disadvantages: The cost of zirconia is typically higher than that of alumina and SiC, which may limit its use in cost-sensitive applications.

Impact on Application: Zirconia is particularly effective in environments where mechanical strength is paramount, such as in cutting tools and dental implants.

Considerations for International Buyers: Buyers from Europe, particularly France and Italy, should be aware of the stringent regulations regarding the use of zirconia in medical applications, which can affect sourcing and costs.

| Material | Typical Use Case for aluminium oxide cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | Ceramics, electronics | High thermal stability | Complex manufacturing process | Medium |

| Aluminium Nitride | Semiconductor devices | Excellent thermal conductivity | Higher cost and processing challenges | High |

| Silicon Carbide | Aerospace, automotive | Superior hardness and thermal stability | Expensive and energy-intensive production | High |

| Zirconia | Dental, biomedical applications | Excellent mechanical properties | Higher cost limits usage in sensitive applications | High |

This strategic material selection guide aims to equip international B2B buyers with actionable insights to make informed decisions regarding aluminium oxide costs, tailored to their specific regional and industrial contexts.

The manufacturing process of aluminium oxide, commonly referred to as alumina, involves several critical stages that ensure the production of high-quality material. Understanding these stages is essential for international B2B buyers to evaluate suppliers effectively.

Material Preparation

The process begins with the extraction of bauxite, the primary ore of aluminium. The bauxite is crushed and mixed with a caustic soda solution. This mixture is then heated under pressure to extract alumina through the Bayer process. Buyers should inquire about the sourcing of bauxite and the environmental impact of extraction, as this can affect both cost and sustainability.

Forming

Once the alumina is extracted, it is typically formed into various shapes depending on the intended application. This can involve processes such as pressing, casting, or extrusion. For buyers, understanding the forming methods can reveal insights into the supplier's capabilities and flexibility in meeting specific requirements.

Assembly

In the case of complex products, assembly may be necessary. This could involve combining alumina with other materials or components. Buyers should assess the supplier's assembly techniques, which can influence the final product's quality and performance.

Finishing

The final stage involves surface treatment processes such as grinding, polishing, or coating to achieve desired specifications. Each of these finishing techniques can impact the cost and quality of the final product. Buyers should consider how these processes align with their own quality expectations.

Quality assurance is crucial in ensuring that aluminium oxide products meet international and industry-specific standards. Familiarity with these standards can help B2B buyers from Africa, South America, the Middle East, and Europe make informed decisions.

International Standards (ISO 9001)

ISO 9001 is a widely recognized quality management standard that outlines the criteria for an effective quality management system. Buyers should verify whether their suppliers are ISO 9001 certified, as this indicates a commitment to quality and continuous improvement.

Industry-Specific Certifications

Depending on the application, other certifications may be relevant. For example, CE marking is crucial for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards. API certification may be relevant for products used in the oil and gas sector. Buyers should inquire about the specific certifications applicable to their industry.

Quality control (QC) checkpoints throughout the manufacturing process ensure that products meet required standards before they reach the market. Understanding these checkpoints is essential for B2B buyers to assess supplier reliability.

Incoming Quality Control (IQC)

This initial step involves inspecting raw materials, such as bauxite and other chemicals, to ensure they meet specified standards. Effective IQC processes can prevent defects in the final product.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves monitoring various stages to identify and rectify issues in real-time. This includes assessing parameters such as temperature, pressure, and chemical composition.

Final Quality Control (FQC)

Before shipment, FQC ensures that the finished alumina products meet all quality standards. This may involve physical testing, chemical analysis, and dimensional checks. B2B buyers should request FQC reports to ensure compliance with their specifications.

Testing methods play a vital role in quality assurance, ensuring that aluminium oxide products meet specified standards. B2B buyers should be familiar with these methods to evaluate supplier quality effectively.

Chemical Composition Analysis

Techniques such as X-ray fluorescence (XRF) or inductively coupled plasma (ICP) spectrometry are commonly used to analyze the chemical composition of alumina. Buyers should request certification of chemical analysis to confirm product specifications.

Mechanical Testing

Tests for mechanical properties, such as hardness, tensile strength, and fracture toughness, are critical in assessing the material's performance. Common methods include Vickers hardness tests and tensile testing.

Thermal Analysis

Techniques such as differential thermal analysis (DTA) and thermogravimetric analysis (TGA) help evaluate the thermal stability and behavior of alumina under varying temperatures. Buyers should inquire about these analyses, especially for high-temperature applications.

To ensure the integrity of the supply chain, B2B buyers should implement strategies to verify supplier quality control practices. This is especially important for international transactions where standards may vary.

Supplier Audits

Conducting on-site audits allows buyers to assess the supplier's manufacturing processes and QC practices firsthand. This helps identify potential issues before they affect product quality.

Quality Reports

Buyers should request detailed quality reports, including IQC, IPQC, and FQC data. These reports provide insights into the supplier's QC performance and reliability.

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier's quality practices. This is particularly beneficial for international buyers who may not have the resources for on-site audits.

Navigating quality control and certification can be complex for international B2B buyers. Understanding these nuances is essential for successful transactions.

Regional Standards Variability

Quality standards can vary significantly across regions. Buyers in Europe, for example, may prioritize CE marking, while those in Africa may focus on local regulatory compliance. Familiarizing oneself with regional standards is crucial for ensuring product acceptance.

Documentation Requirements

International transactions often require extensive documentation, including certificates of compliance and quality assurance reports. Buyers should ensure that their suppliers can provide all necessary documentation to facilitate smooth customs clearance and compliance.

Cultural Considerations

Cultural differences can impact communication regarding quality expectations. Buyers should approach discussions with suppliers with an understanding of these differences to foster effective collaboration.

By understanding the manufacturing processes, quality assurance standards, testing methods, and verification practices, international B2B buyers can make informed decisions when sourcing aluminium oxide. This knowledge not only aids in identifying reliable suppliers but also ensures that the products meet the necessary quality standards for their intended applications.

To assist international B2B buyers in navigating the procurement process for aluminium oxide, this practical sourcing guide offers a step-by-step checklist. By following these steps, buyers can ensure they make informed decisions, secure competitive pricing, and establish reliable supplier relationships.

Establishing clear technical specifications is essential when sourcing aluminium oxide. This includes understanding the required purity levels, particle size distribution, and any specific applications such as abrasives or ceramics. Precise specifications help narrow down potential suppliers and ensure you receive products that meet your operational needs.

Understanding the current market landscape is crucial for effective sourcing. Research trends in aluminium oxide pricing, supply chain dynamics, and regional availability. This information will empower you to negotiate better prices and terms.

Before committing to a supplier, it's critical to conduct a thorough evaluation. This includes reviewing company profiles, seeking case studies, and obtaining references from other buyers in similar industries.

Gather quotations from multiple suppliers to compare pricing effectively. Ensure that the quotes include all relevant costs, such as shipping, taxes, and duties, to avoid unexpected expenses.

Evaluating the financial stability of potential suppliers is vital for long-term partnerships. A financially stable supplier is more likely to fulfill orders consistently and adapt to market changes.

Once you have selected a supplier, ensure that all agreements are documented in a formal contract. This should outline pricing, delivery schedules, payment terms, and any warranties or guarantees.

After procurement, maintain regular communication with your supplier to ensure ongoing satisfaction. Schedule periodic reviews to assess performance and address any issues that may arise.

By following this checklist, B2B buyers can streamline the sourcing process for aluminium oxide, enhance supplier relationships, and achieve favorable pricing and quality.

Understanding the cost structure of aluminium oxide is essential for international B2B buyers. The primary cost components include:

Raw Materials: The cost of bauxite, the primary ore for aluminium oxide, fluctuates based on global demand and mining regulations. Prices can vary significantly between regions, affecting sourcing strategies for buyers in Africa, South America, the Middle East, and Europe.

Labor Costs: Labor expenses in the manufacturing process can differ based on the geographical location of the supplier. Countries with lower labor costs may offer more competitive pricing, but quality and reliability should not be compromised.

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Buyers should inquire about how these overheads are factored into the pricing.

Tooling and Equipment: Initial investments in machinery and tools can impact the overall price of aluminium oxide. Understanding the supplier’s capacity for production can provide insights into potential cost efficiencies.

Quality Control (QC): Effective QC processes ensure product quality and compliance with industry standards. Suppliers with stringent QC measures may have higher costs, but this can lead to reduced risks for buyers.

Logistics: Transportation costs are influenced by distance, shipping methods, and local infrastructure. Buyers should evaluate logistics options and their associated costs, especially when sourcing from international suppliers.

Profit Margins: Suppliers will typically include a margin to cover their costs and generate profit. Understanding industry benchmarks for margins can help buyers negotiate better pricing.

Several factors influence the pricing of aluminium oxide, and understanding these can aid in better negotiation:

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should assess their needs and consider bulk purchasing to maximize cost efficiency.

Specifications and Customization: Custom formulations or specific grades of aluminium oxide can lead to increased costs. Buyers must clarify their requirements upfront to avoid unexpected charges.

Material Quality and Certifications: Premium quality materials and specific certifications (such as ISO or ASTM) can significantly influence pricing. Buyers should ensure that the supplier meets their quality expectations without paying for unnecessary certifications.

Supplier Factors: The supplier's reputation, production capacity, and reliability can impact pricing. Established suppliers with a track record may command higher prices but often provide better service and quality assurance.

Incoterms: Understanding the terms of trade is crucial. Different Incoterms (like FOB, CIF) can affect the total cost of ownership, as they dictate who is responsible for shipping costs, insurance, and risk.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-effectiveness:

Negotiate Terms: Always negotiate not only on price but also on payment terms, delivery schedules, and other conditions. Flexibility can lead to cost savings.

Total Cost of Ownership (TCO): Consider all costs associated with the procurement process, including logistics, tariffs, and potential wastage. A lower purchase price may not always equate to lower overall costs.

Stay Informed on Market Trends: Keeping abreast of global aluminium markets, including price trends and supply chain disruptions, can empower buyers to make informed purchasing decisions.

Supplier Diversification: Relying on multiple suppliers can mitigate risks and enhance bargaining power. This approach is particularly useful in regions with fluctuating supply conditions.

Understand Pricing Nuances: Prices can vary widely based on regional factors. Buyers in Europe may face different pricing structures than those in Africa or South America, influenced by local demand and supply chains.

It is important to note that the prices discussed in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Buyers should conduct thorough market research and engage directly with suppliers to obtain accurate pricing tailored to their needs.

When evaluating the cost of aluminium oxide, it's essential to consider viable alternatives that may offer similar functionalities at different price points or performance levels. The selection of an alternative depends on specific applications, regional market conditions, and procurement strategies. This analysis will help international B2B buyers make informed decisions by comparing aluminium oxide with other potential solutions.

| Comparison Aspect | Aluminium Oxide Cost | Alternative 1: Silicon Carbide | Alternative 2: Zinc Oxide |

|---|---|---|---|

| Performance | High durability; excellent thermal and electrical insulation | High hardness; excellent thermal conductivity | Good electrical insulation; lower hardness |

| Cost | Moderate, varies by purity and application | Generally higher than aluminium oxide | Lower than aluminium oxide |

| Ease of Implementation | Standard processes widely available | Requires specialized equipment for processing | Easily available and processed |

| Maintenance | Low maintenance; resistant to wear | Moderate; can wear down in certain conditions | Low; stable under various conditions |

| Best Use Case | Electronics, ceramics, abrasives | High-performance applications like cutting tools | Coatings, rubber, and plastics |

Silicon carbide (SiC) is known for its exceptional hardness and thermal conductivity, making it an ideal choice for high-performance applications such as cutting tools and abrasives. However, it typically comes at a higher price point compared to aluminium oxide. The processing of SiC may require specialized equipment, which can increase initial setup costs for manufacturers. While maintenance is moderate, it can wear down faster in certain abrasive applications. Thus, it is best suited for industries where performance outweighs cost considerations.

Zinc oxide is often a more cost-effective alternative to aluminium oxide. It provides good electrical insulation and is stable under various environmental conditions. However, its hardness is lower, which may limit its use in high-stress applications. The ease of availability and processing of zinc oxide makes it an attractive option for applications like coatings and plastics. It requires minimal maintenance and can be a viable solution for businesses looking for a budget-friendly alternative.

When selecting between aluminium oxide and its alternatives, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and availability of materials. For high-performance applications where durability and thermal resistance are critical, aluminium oxide or silicon carbide may be more suitable despite their higher costs. Conversely, for applications where cost is a primary concern, zinc oxide could provide a sufficient solution without compromising too much on performance.

Ultimately, conducting a thorough cost-benefit analysis tailored to the specific context of use will empower international buyers from regions like Africa, South America, the Middle East, and Europe to make decisions that align with their operational goals and financial parameters.

When evaluating aluminium oxide for B2B applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

Material Grade

Aluminium oxide comes in various grades, each with specific purity levels and chemical compositions. Common grades include 99.5% (high purity) and 95% (standard purity). Selecting the appropriate grade is vital as it directly impacts the performance of the end product, especially in applications like electronics and ceramics.

Particle Size Distribution

The particle size of aluminium oxide can significantly influence its application, especially in grinding and polishing. Finer particles are typically used for polishing applications, while coarser sizes may be used in abrasives. B2B buyers should specify the desired particle size to ensure compatibility with their production processes.

Tolerance Levels

Tolerance refers to the acceptable variation in dimensions or physical properties. For aluminium oxide, tight tolerances are essential in precision applications, such as in the manufacturing of cutting tools or medical devices. Understanding and specifying tolerances can prevent costly production errors and ensure product quality.

Thermal Stability

Aluminium oxide exhibits excellent thermal stability, making it suitable for high-temperature applications, such as refractory materials and thermal insulation. Buyers should assess the thermal properties to ensure that the material meets the thermal requirements of their specific applications.

Chemical Resistance

The chemical resistance of aluminium oxide is another vital property, particularly in environments where exposure to acids or bases is expected. High chemical resistance ensures longevity and reliability in harsh conditions, which is a critical factor for industries such as chemical manufacturing.

Density and Hardness

The density and hardness of aluminium oxide contribute to its strength and durability. Hardness is particularly important in abrasive applications, where the material must withstand wear and tear. Understanding these properties helps B2B buyers select the right grade for their specific needs.

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some critical trade terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminium oxide, an OEM might require specific formulations or grades tailored for their products.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage their inventory effectively and reduce overhead costs. This term is especially relevant for international buyers who may need to align their purchase quantities with shipping constraints.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. This is a critical step in the procurement process, allowing buyers to compare costs and conditions from multiple suppliers.

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to understand their liabilities and obligations, particularly when importing aluminium oxide from different regions.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for effective supply chain management, especially in industries where timely delivery is critical.

Certification Standards

Various certification standards (such as ISO or ASTM) ensure that the aluminium oxide meets specific quality and safety criteria. Buyers should inquire about certifications to ensure compliance with regulatory requirements and industry standards.

By understanding these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing aluminium oxide more effectively, ensuring they make informed decisions that align with their business needs.

The global aluminium oxide market is witnessing significant transformation, driven by increased demand across various industries, including automotive, aerospace, and electronics. The rise in production capacities in countries like China and Brazil is reshaping supply dynamics, leading to competitive pricing. Additionally, the push towards lightweight materials in manufacturing is elevating the demand for aluminium oxide, particularly in high-performance applications.

Emerging technologies such as artificial intelligence and blockchain are redefining sourcing strategies. AI-driven analytics are helping B2B buyers optimize procurement processes by predicting price fluctuations and identifying cost-saving opportunities. Meanwhile, blockchain enhances transparency in the supply chain, allowing buyers to trace the origin of materials and verify supplier claims, which is crucial for maintaining compliance with international standards.

For international buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential. Buyers should leverage market intelligence tools to stay updated on trends and shifts in demand, enabling them to negotiate better pricing and secure reliable suppliers.

The environmental impact of aluminium oxide production cannot be overlooked. The extraction and refining processes are energy-intensive and can lead to significant carbon emissions. As a result, there is a growing emphasis on sustainability and ethical sourcing within the B2B sector. Buyers are increasingly prioritizing suppliers that adhere to environmentally friendly practices and hold certifications like ISO 14001 for environmental management.

Ethical supply chains are becoming a competitive advantage. B2B buyers are encouraged to assess suppliers based on their sustainability initiatives, including waste reduction and energy efficiency measures. Furthermore, opting for 'green' materials, such as those sourced from recycled aluminium, not only lowers the carbon footprint but can also result in cost savings.

For buyers in emerging markets, establishing partnerships with certified suppliers can enhance their market reputation and appeal to environmentally conscious consumers. Engaging in sustainable sourcing practices not only mitigates environmental risks but also aligns with global trends towards responsible consumption.

A stock image related to aluminium oxide cost.

Aluminium oxide, known for its durability and versatility, has a rich history that dates back to its first commercial production in the 19th century. Initially, it was primarily used as an abrasive material. Over the decades, advancements in extraction and refining technologies have expanded its applications significantly, particularly in the fields of ceramics, electronics, and metallurgy.

A stock image related to aluminium oxide cost.

Today, aluminium oxide plays a crucial role in the manufacturing of high-performance components, thanks to its excellent thermal and electrical insulating properties. The evolution of this material underscores its importance in supporting modern technological advancements, making it a vital component for B2B buyers looking to leverage innovative materials in their products.

Understanding the historical context of aluminium oxide not only provides insight into its current applications but also helps buyers appreciate the ongoing innovations that could influence future pricing and availability.

How can I calculate the cost of aluminium oxide for my business needs?

To calculate the cost of aluminium oxide, start by determining your required quantity and grade, as prices can vary significantly based on these factors. Contact multiple suppliers to obtain quotes and compare their pricing structures, including shipping costs. Additionally, consider any potential tariffs or import duties that may apply in your region. Using a cost-per-ton approach can help you understand the overall expense and make informed purchasing decisions.

What factors influence the price of aluminium oxide in international markets?

Several factors impact the price of aluminium oxide, including raw material costs, production methods, and global demand. Currency fluctuations can also affect pricing for international buyers. Supply chain disruptions, geopolitical tensions, and changes in regulations may lead to price volatility. Understanding these factors will help you anticipate market trends and negotiate better deals with suppliers.

What are the minimum order quantities (MOQ) for aluminium oxide?

Minimum order quantities for aluminium oxide can vary widely among suppliers, often ranging from a few tons to several hundred tons. It's essential to communicate your specific needs to potential suppliers, as some may offer flexibility in MOQs for larger contracts. Additionally, consider the implications of MOQ on your inventory management and cash flow, especially if you're a smaller business.

How can I vet suppliers for aluminium oxide to ensure quality and reliability?

When vetting suppliers, request product samples and certifications that demonstrate compliance with industry standards. Investigate their production processes and quality assurance protocols. Check for customer reviews and testimonials, and consider conducting site visits if feasible. Building a relationship with suppliers who have a proven track record can enhance trust and reliability in your procurement process.

What payment terms should I negotiate with aluminium oxide suppliers?

Payment terms can vary, but common practices include net 30, net 60, or advance payments. Consider negotiating terms that align with your cash flow needs and risk tolerance. It's also advisable to explore options like letters of credit or escrow services for larger transactions to protect your investment. Clear communication about payment expectations can foster a positive supplier relationship.

How do I ensure the quality of aluminium oxide during international shipping?

To ensure quality during shipping, work with suppliers who use reputable logistics partners and offer proper packaging to protect the product. Request quality assurance documentation, including inspection reports, before shipment. Additionally, consider insuring your shipment against damage or loss. Establishing clear communication channels with suppliers and logistics providers will help you monitor the shipping process and address any issues promptly.

What customization options are available for aluminium oxide products?

Many suppliers offer customization options for aluminium oxide, including variations in particle size, purity levels, and packaging types. Discuss your specific requirements with potential suppliers to explore available options. Custom formulations may incur additional costs, so it's important to clarify these before placing an order. Collaborating closely with suppliers can result in tailored solutions that meet your business's unique needs.

What logistics challenges should I anticipate when sourcing aluminium oxide internationally?

When sourcing aluminium oxide, be prepared for logistics challenges such as customs clearance, potential delays, and varying regulations in different countries. It's essential to understand the import requirements for your region, including any documentation needed. Working with experienced logistics providers can streamline the shipping process and mitigate risks. Establishing a contingency plan for potential disruptions will help ensure a smoother procurement experience.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In conclusion, the cost of aluminium oxide remains influenced by a myriad of factors including global demand, supply chain dynamics, and geopolitical considerations. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these elements is essential for effective strategic sourcing. By leveraging market intelligence and establishing strong supplier relationships, businesses can mitigate risks associated with price volatility and secure competitive pricing.

Investing in strategic sourcing not only optimizes procurement costs but also enables buyers to access high-quality materials, which is crucial in industries like manufacturing and construction. Additionally, diversifying suppliers can provide leverage against price fluctuations and ensure continuity of supply, particularly important in regions facing logistical challenges.

Looking ahead, it is crucial for B2B buyers to stay informed about market trends and technological advancements that could impact aluminium oxide production and pricing. Engage with industry experts, participate in trade forums, and utilize analytics tools to forecast future costs accurately.

In this ever-evolving market landscape, proactive strategies will empower businesses to navigate challenges and seize opportunities. Let’s connect and explore how we can enhance your sourcing strategy for aluminium oxide today!

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina