In the dynamic landscape of international trade, sourcing black rainbow carborundum presents unique challenges for B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This multifaceted material, known for its exceptional hardness and versatility, is increasingly sought after for various industrial applications, ranging from abrasives to advanced ceramics. However, navigating the complexities of global supply chains, price fluctuations, and quality assurance can be daunting.

This comprehensive guide aims to empower B2B buyers by providing in-depth insights into the types of black rainbow carborundum available, its myriad applications, and effective supplier vetting strategies. We will explore cost factors, enabling buyers to make informed purchasing decisions that align with their operational needs and budget constraints. Furthermore, understanding regional market trends and supplier profiles will be instrumental in identifying reliable partners.

By leveraging the information in this guide, international buyers will be better equipped to tackle the challenges of sourcing black rainbow carborundum, ensuring that they not only meet their material requirements but also foster sustainable and profitable business relationships across the globe. The knowledge gained here will serve as a strategic asset in enhancing your procurement strategies, ultimately driving success in your respective markets.

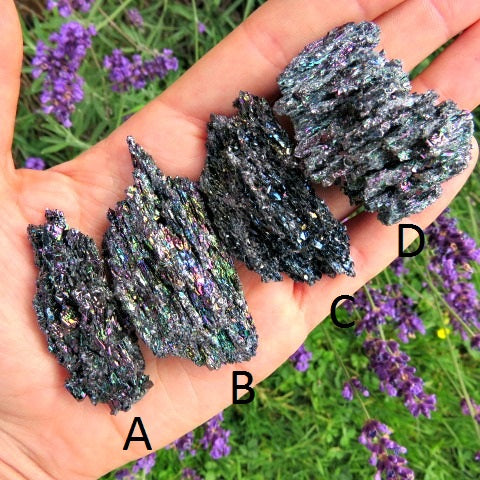

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Rainbow Carborundum A | High purity, excellent thermal stability | Semiconductor manufacturing | Pros: Superior performance; Cons: Higher cost. |

| Black Rainbow Carborundum B | Enhanced electrical conductivity | Electronics and power systems | Pros: Efficient energy transfer; Cons: Limited availability. |

| Black Rainbow Carborundum C | Unique optical properties, varied grain size | Optical devices and sensors | Pros: Versatile applications; Cons: Requires specialized handling. |

| Black Rainbow Carborundum D | Composite material with added durability | Aerospace and automotive sectors | Pros: Increased strength; Cons: Heavier than alternatives. |

| Black Rainbow Carborundum E | Cost-effective option with decent quality | General industrial applications | Pros: Affordable; Cons: Lower performance compared to premium types. |

Black Rainbow Carborundum A is characterized by its high purity and exceptional thermal stability, making it suitable for applications in semiconductor manufacturing. Buyers should consider its superior performance in high-temperature environments, which can lead to increased efficiency in production processes. However, the higher cost may be a drawback for companies operating on tighter budgets.

This variation is known for its enhanced electrical conductivity, making it ideal for electronics and power systems. It facilitates efficient energy transfer, which is crucial for modern electronic devices. However, its limited availability can pose a challenge for buyers, necessitating long-term supply agreements to ensure consistency.

Black Rainbow Carborundum C features unique optical properties and a varied grain size, which makes it particularly suitable for optical devices and sensors. Its versatility allows for a wide range of applications, but buyers must be prepared for specialized handling requirements to maintain its integrity during processing and usage.

This type serves as a composite material that provides added durability, making it a preferred choice in aerospace and automotive sectors. Its increased strength can significantly enhance the performance of components subjected to extreme conditions. However, its heavier weight compared to alternatives may limit its application in lightweight designs.

Black Rainbow Carborundum E is a cost-effective alternative that offers decent quality for general industrial applications. Its affordability makes it an attractive option for businesses seeking to minimize costs without sacrificing too much on performance. However, buyers should be aware that it may not perform as well as premium variants in specialized applications.

Related Video: The Genius Behind Bach's Goldberg Variations: CANONS

| Industry/Sector | Specific Application of black rainbow carborundum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of high-performance abrasives | Enhances precision in component finishing, reducing waste | Ensure compliance with aerospace industry standards and certifications. |

| Automotive | Production of grinding wheels for engine parts | Improves efficiency and lifespan of grinding tools | Assess the grit size and bonding agents suitable for specific applications. |

| Electronics | Semiconductor wafer polishing | Achieves ultra-smooth surfaces for better electrical conductivity | Verify material purity and consistency to meet semiconductor specifications. |

| Construction | Surface preparation for concrete and masonry | Increases adhesion and durability of coatings and adhesives | Evaluate particle size distribution for optimal surface treatment. |

| Metalworking | Tool manufacturing and sharpening | Extends the life of cutting tools and reduces downtime | Investigate the hardness and thermal stability of the carborundum. |

In the aerospace industry, black rainbow carborundum is utilized in the manufacturing of high-performance abrasives. These abrasives are essential for precision finishing of components, ensuring that parts meet stringent quality standards. By using this material, businesses can significantly reduce waste during the machining process, which translates to cost savings and improved efficiency. Buyers in this sector must ensure that the sourced materials comply with aerospace industry standards and possess the necessary certifications.

In automotive manufacturing, black rainbow carborundum finds application in the production of grinding wheels specifically designed for engine parts. The unique properties of this material enhance the efficiency and lifespan of grinding tools, which is crucial for maintaining productivity in manufacturing processes. For international buyers, assessing the appropriate grit size and bonding agents is vital to align with specific grinding requirements for various engine components.

The electronics sector employs black rainbow carborundum for semiconductor wafer polishing, where achieving ultra-smooth surfaces is critical. This smoothness is directly linked to better electrical conductivity, making it essential for high-performance electronic devices. Buyers in this field should verify the material's purity and consistency to ensure compliance with semiconductor specifications, which can vary significantly across different manufacturers.

In construction, black rainbow carborundum is used for surface preparation of concrete and masonry surfaces. The material enhances the adhesion and durability of coatings and adhesives applied to these surfaces, ensuring long-lasting results. For construction firms, evaluating the particle size distribution is crucial to achieving optimal surface treatment and ensuring compatibility with various types of coatings.

Within the metalworking industry, black rainbow carborundum is essential for tool manufacturing and sharpening. The material extends the life of cutting tools and significantly reduces downtime associated with tool replacement. Buyers need to investigate the hardness and thermal stability of the carborundum to ensure that it meets the specific demands of various metalworking applications, ultimately leading to improved productivity and reduced operational costs.

Related Video: Akua Carborundum Gel with Wax Mediums

The Problem: Many B2B buyers from regions like Africa and South America often face difficulties in sourcing high-quality black rainbow carborundum due to a lack of transparency in the supply chain. This leads to uncertainty about the material's composition and properties, which are crucial for applications such as abrasives, ceramics, and electronics. Buyers may receive inconsistent quality or materials that do not meet their specifications, resulting in operational inefficiencies and increased costs.

The Solution: To overcome this challenge, buyers should prioritize sourcing from reputable suppliers who provide detailed specifications and certifications for their products. Conducting thorough due diligence, such as visiting production facilities and requesting samples, can help ensure the material meets quality standards. Additionally, leveraging digital platforms that specialize in B2B transactions can facilitate better communication and verification of supplier claims. Establishing long-term relationships with trusted suppliers can also lead to improved quality assurance processes and cost-effectiveness.

The Problem: B2B buyers often struggle to understand the various applications of black rainbow carborundum across different industries, which can hinder their ability to fully utilize the material's properties. For instance, while some buyers may be aware of its use in abrasives, they might overlook its potential in the production of advanced ceramics or as a semiconductor material. This lack of awareness can result in missed opportunities for cost savings and innovation.

The Solution: Buyers should invest time in researching and collaborating with industry experts who can provide insights into the diverse applications of black rainbow carborundum. Attending industry conferences and participating in webinars can also enhance understanding of how this material can be utilized effectively across various sectors. Furthermore, suppliers often provide case studies and application notes that demonstrate successful uses of the material; leveraging these resources can inspire creative solutions and applications tailored to specific business needs.

The Problem: Buyers in the Middle East and Europe often encounter regulatory hurdles when importing black rainbow carborundum due to varying safety standards and environmental regulations. Non-compliance can lead to legal issues, fines, and disruptions in the supply chain. Additionally, navigating these regulations can be time-consuming and requires a deep understanding of local laws, which may differ significantly from those in the country of origin.

The Solution: To address this pain point, B2B buyers should proactively familiarize themselves with the regulatory landscape of their target markets. This includes understanding the specific safety standards applicable to black rainbow carborundum and ensuring that their suppliers comply with these regulations. Engaging a compliance consultant who specializes in materials can provide valuable insights and streamline the import process. Additionally, maintaining clear and open communication with suppliers about compliance documentation and certifications can help mitigate risks associated with regulatory challenges.

When selecting materials for black rainbow carborundum, it is essential to consider various options that can enhance product performance and suitability for specific applications. Below, we analyze four common materials used in the production of black rainbow carborundum, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Key Properties: Silicon carbide (SiC) exhibits exceptional hardness and thermal conductivity, withstanding temperatures up to 1600°C. Its corrosion resistance makes it suitable for harsh environments.

Pros & Cons: The durability of SiC is a significant advantage, making it ideal for applications requiring long-lasting performance. However, the manufacturing complexity can lead to higher production costs, which may not be suitable for all end products.

Impact on Application: SiC is compatible with various media, including corrosive chemicals, making it a preferred choice for industries such as electronics and automotive.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should ensure that suppliers can meet local regulations regarding material quality and safety.

Key Properties: Alumina (Al2O3) is known for its high melting point (over 2000°C) and excellent wear resistance, making it suitable for high-temperature applications.

Pros & Cons: Its cost-effectiveness is a significant advantage, particularly for large-scale production. However, its brittleness can limit its application in environments subject to impact or shock.

Impact on Application: Alumina is often used in ceramics and refractory materials, providing good compatibility with various media, including molten metals.

Considerations for International Buyers: Buyers in Europe and the Middle East should pay attention to the sourcing of alumina to ensure it meets EU and GCC standards for environmental safety.

Key Properties: Zirconia (ZrO2) is characterized by its exceptional toughness and thermal stability, withstanding temperatures up to 2700°C. It also offers excellent resistance to corrosion and wear.

Pros & Cons: The primary advantage of zirconia is its ability to perform under extreme conditions. However, it is more expensive than other materials, which could affect overall project budgets.

Impact on Application: Zirconia is ideal for applications in the aerospace and medical industries, where reliability and performance are paramount.

Considerations for International Buyers: Buyers from Turkey and Brazil must consider the availability of zirconia and its compliance with local and international standards, particularly in high-stakes industries.

Key Properties: Graphene is renowned for its remarkable strength-to-weight ratio and electrical conductivity. It can operate effectively at high temperatures and is resistant to corrosion.

Pros & Cons: The main advantage of graphene is its potential to enhance the performance of composite materials significantly. However, its high production cost and complexity can be limiting factors for widespread adoption.

Impact on Application: Graphene is suitable for advanced applications in electronics and energy storage, providing compatibility with various media.

Considerations for International Buyers: Buyers in Africa and South America should be aware of the emerging standards for graphene materials and their applications, as regulations are still developing in these regions.

| Material | Typical Use Case for black rainbow carborundum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | Electronics, automotive applications | Exceptional hardness and durability | Higher manufacturing complexity | High |

| Alumina | Ceramics, refractory materials | Cost-effective for large-scale use | Brittle, limiting impact resistance | Medium |

| Zirconia | Aerospace, medical applications | High performance under extreme conditions | Expensive compared to alternatives | High |

| Graphene | Advanced electronics, energy storage | Outstanding strength-to-weight ratio | High production cost and complexity | High |

This analysis provides a comprehensive overview of the materials commonly used in black rainbow carborundum, equipping international B2B buyers with the insights necessary for informed decision-making.

A stock image related to black rainbow carborundum.

The manufacturing process of black rainbow carborundum, a specialized form of silicon carbide, involves several critical stages that ensure the quality and performance of the final product. Understanding these stages can help B2B buyers assess suppliers effectively.

The first step involves sourcing high-quality raw materials, primarily silica sand and carbon. The purity of these materials is crucial, as impurities can affect the properties of the final product. Suppliers often perform initial screenings and chemical analyses to ensure material quality.

Once the materials are prepared, they undergo forming processes. This typically includes mixing the silica and carbon in specific ratios, followed by pressing them into molds. Common forming techniques include:

Both methods require precise control to achieve the desired density and strength of the carborundum.

In some applications, black rainbow carborundum may need to be combined with other materials or components. Assembly can involve:

This step is critical for ensuring the structural integrity of the final product.

Finishing processes enhance the aesthetic and functional properties of black rainbow carborundum. Common techniques include:

These finishing techniques can significantly influence the product's marketability and performance.

Quality assurance (QA) is paramount in ensuring that black rainbow carborundum meets international standards and customer expectations. B2B buyers should be familiar with the relevant quality standards and checkpoints throughout the manufacturing process.

B2B buyers should look for manufacturers that comply with recognized international quality standards, such as:

Compliance with these standards not only assures product quality but also facilitates smoother international trade.

Quality control (QC) checkpoints are integrated into the manufacturing process to monitor and verify product quality at different stages. Key checkpoints include:

These checkpoints help identify issues early in the process, minimizing waste and ensuring high-quality output.

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are some actionable steps to ensure quality:

Performing audits allows buyers to evaluate the supplier's manufacturing processes, quality control systems, and adherence to international standards. This can be done through:

Buyers should ask suppliers for quality assurance reports that detail the results of testing and inspections. These reports should include:

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier's quality control processes. These services can conduct independent audits and testing, providing an additional layer of assurance.

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

A stock image related to black rainbow carborundum.

By being proactive and thorough in their approach to verifying quality control, B2B buyers can mitigate risks and ensure that they receive high-quality black rainbow carborundum products that meet their needs.

In this practical sourcing guide, we aim to provide international B2B buyers with a comprehensive checklist for procuring black rainbow carborundum. This material, known for its unique aesthetic and functional properties, is increasingly sought after in various industries, including construction, manufacturing, and art. Below is a step-by-step checklist designed to streamline your sourcing process and ensure successful procurement.

Before reaching out to suppliers, clearly outline your technical requirements. This includes understanding the specific grades, sizes, and purity levels of black rainbow carborundum that align with your applications.

- Consider the end-use: Different applications might require variations in grain size or hardness.

- Document your needs: Create a detailed specification sheet to ensure consistency when communicating with potential suppliers.

Conduct thorough research to identify reputable suppliers of black rainbow carborundum. Utilize industry directories, trade shows, and online marketplaces to compile a list.

- Check for industry experience: Suppliers with a proven track record in your specific sector are more likely to meet your quality expectations.

- Read reviews and testimonials: Insights from previous clients can provide valuable information on a supplier’s reliability and product quality.

Ensure that the suppliers you are considering have the necessary certifications and compliance with international standards.

- Look for ISO certifications: This indicates adherence to quality management systems.

- Check compliance with local regulations: Especially important if you are importing materials into specific regions like Africa or South America.

Once you have shortlisted potential suppliers, request samples of black rainbow carborundum to evaluate quality and suitability for your application.

- Assess the samples: Analyze physical properties and visual appeal to ensure they meet your specifications.

- Conduct tests if necessary: Depending on your application, you may want to perform specific tests for durability and performance.

Engage with suppliers to understand their pricing models. Request detailed quotes that include the costs of shipping, taxes, and any additional fees.

- Compare total costs: Don’t just focus on the unit price; consider overall expenses including logistics.

- Negotiate terms: Suppliers may offer discounts for bulk orders or long-term contracts, so be prepared to discuss pricing.

Effective communication is key to a successful sourcing relationship. Ensure that you have clear lines of communication with your chosen supplier.

- Set expectations: Discuss timelines for delivery, response times for inquiries, and methods of communication.

- Use project management tools: This can help track progress and maintain transparency throughout the procurement process.

After selecting a supplier, finalize the procurement agreement. Ensure all terms are clearly documented, including payment terms, delivery schedules, and quality assurance measures.

- Include clauses for quality control: This protects your interests in case the delivered product does not meet your specifications.

- Review legal implications: It may be prudent to have a legal expert review the contract, especially for international transactions.

By following this checklist, B2B buyers can streamline the sourcing process for black rainbow carborundum, ensuring that they partner with reliable suppliers who can meet their specific needs effectively.

When sourcing black rainbow carborundum, understanding the cost structure is crucial for international B2B buyers. The main components of the cost include:

Materials: The primary raw material, silicon carbide, significantly influences the total cost. Prices may vary based on purity, grain size, and source location. Buyers should consider sourcing from regions with lower raw material costs to enhance profitability.

Labor: Labor costs are influenced by the region of production. In emerging markets in Africa and South America, labor costs may be lower compared to Europe. However, the skill level of labor can impact the quality and production efficiency.

Manufacturing Overhead: This encompasses costs related to utilities, depreciation of machinery, and facility maintenance. Understanding the overhead costs can help buyers negotiate better terms by evaluating the efficiency of potential suppliers.

Tooling: The initial investment in tooling can be significant, particularly for custom specifications. Buyers should assess whether suppliers have the capability to produce specialized tooling or if they will need to invest in it themselves.

Quality Control (QC): Ensuring the quality of black rainbow carborundum is essential. Implementing stringent QC measures can increase costs but is vital for maintaining product standards. Buyers should inquire about the QC processes of suppliers to ensure compliance with industry standards.

Logistics: Shipping costs, including freight and insurance, can add a substantial amount to the total cost. Factors such as distance, shipping method, and the Incoterms agreed upon can greatly affect logistics expenses.

Margin: The supplier's profit margin will also influence the final price. Understanding market benchmarks can help buyers assess whether the quoted prices are competitive.

Several factors can influence the pricing of black rainbow carborundum:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capacity to optimize costs.

Specifications and Customization: Custom requirements can lead to increased costs. Buyers should clearly communicate their specifications to avoid unexpected charges and ensure they receive the desired product.

Material Quality and Certifications: Higher quality materials and relevant certifications (e.g., ISO, ASTM) can raise prices. Buyers should balance the need for quality with budget constraints.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their products, while less-known entities might offer lower prices but come with higher risks.

Incoterms: The chosen Incoterms can significantly affect the total landed cost. Buyers should evaluate the implications of different Incoterms on shipping responsibilities and costs.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential:

Conduct Thorough Market Research: Understanding market prices and supplier capabilities can empower buyers during negotiations. This knowledge helps in setting realistic expectations and identifying competitive offers.

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes shipping, handling, and potential waste costs. A supplier with a lower initial price may not always provide the best overall value.

Negotiate Payment Terms: Flexible payment terms can improve cash flow and reduce financial risk. Discuss options such as partial payments or extended payment schedules to find mutually beneficial arrangements.

Build Long-term Relationships: Establishing strong relationships with suppliers can lead to better pricing and priority service. Long-term partnerships often result in improved communication and reliability.

Stay Informed on Market Trends: Keep abreast of industry trends and price fluctuations. This knowledge can aid in timing purchases effectively and avoiding price hikes.

Prices for black rainbow carborundum can fluctuate based on market conditions, supplier negotiations, and regional factors. It is advisable for buyers to obtain multiple quotes and conduct due diligence to ensure they are making informed purchasing decisions.

In the competitive landscape of industrial materials, B2B buyers often seek alternatives that can meet their specific requirements while optimizing performance and cost. Black rainbow carborundum is a notable option in various applications, but understanding how it compares to alternative solutions is essential for informed decision-making.

| Comparison Aspect | Black Rainbow Carborundum | Alternative 1: Silicon Carbide | Alternative 2: Aluminum Oxide |

|---|---|---|---|

| Performance | High thermal resistance; excellent hardness | Very high hardness; good thermal conductivity | Good hardness; less thermal resistance |

| Cost | Moderate price point | Generally lower cost | Lower cost than both options |

| Ease of Implementation | Requires specialized handling | Easier to integrate into existing processes | Widely used, easy to source |

| Maintenance | Low maintenance required | Moderate maintenance; can wear down | Low maintenance; durable |

| Best Use Case | Ideal for high-temperature applications | Suitable for high-stress environments | Best for general abrasive needs |

Silicon carbide (SiC) is a widely recognized alternative to black rainbow carborundum, particularly in high-performance applications. Its high hardness and excellent thermal conductivity make it suitable for demanding environments, such as automotive and aerospace industries. However, it typically comes at a lower price point, making it appealing for cost-sensitive projects. On the downside, while SiC can perform exceptionally well, its implementation may require modifications to existing processes, which can lead to additional upfront costs.

Aluminum oxide (Al2O3) is another common substitute that excels in general abrasive applications. It is known for its durability and low maintenance requirements, making it a reliable choice for various industries. The cost-effectiveness of aluminum oxide is a significant advantage, as it tends to be cheaper than both black rainbow carborundum and silicon carbide. However, it lacks the high thermal resistance of black rainbow carborundum, which can limit its applicability in extreme conditions.

When selecting between black rainbow carborundum and its alternatives, B2B buyers should consider several critical factors. First, assess the specific application requirements, such as temperature resistance and mechanical stress. Next, evaluate the budget constraints, as cost can significantly impact the overall project viability. Additionally, consider the ease of implementation and maintenance requirements, as these factors can influence operational efficiency. By aligning these considerations with the unique demands of their projects, buyers can make informed decisions that drive long-term success.

Understanding the essential technical properties of black rainbow carborundum is critical for international B2B buyers, especially those in industries such as manufacturing, construction, and abrasives. Here are some of the most significant specifications to consider:

The material grade of black rainbow carborundum typically ranges from 99% to 99.5% silicon carbide (SiC). Higher grades indicate purer material, which translates to better performance in abrasive applications. For B2B buyers, selecting the appropriate grade ensures that the product meets the specific requirements of their applications, such as cutting, grinding, or polishing.

The particle size of black rainbow carborundum affects its abrasiveness and suitability for various applications. Common distributions range from coarse (20-40 mesh) to fine (100-200 mesh). B2B buyers should understand the implications of particle size on the performance and finish quality of their products, as finer particles typically provide smoother finishes.

Tolerance levels refer to the permissible variations in dimensions and characteristics of the carborundum grains. Typical tolerances can be ±5% for size and shape. Maintaining these tolerances is essential for ensuring consistent performance in industrial applications. Buyers must ensure that their suppliers can meet these specifications to avoid disruptions in production.

Black rainbow carborundum has a hardness rating of 9.5 on the Mohs scale, making it one of the hardest materials available. This property is crucial for applications requiring durability and resistance to wear, such as in abrasive tools and cutting materials. B2B buyers should prioritize hardness ratings when sourcing materials for high-performance applications.

The thermal conductivity of black rainbow carborundum is relatively high, which allows it to dissipate heat effectively during machining processes. This property is vital for minimizing thermal damage to both the workpiece and the tool. Buyers should consider thermal conductivity when evaluating materials for applications involving high temperatures.

Familiarity with industry-specific terminology can significantly enhance communication and negotiation processes for B2B buyers. Here are some common terms you should know:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure that they receive high-quality materials that meet specific industry standards.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget effectively. Suppliers may set MOQs based on production costs and economies of scale.

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should prepare detailed RFQs to receive accurate pricing and terms from potential suppliers, ensuring that their needs are clearly communicated.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms can help buyers mitigate risks related to shipping and logistics costs, ensuring that they know who is responsible for various aspects of the delivery process.

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is crucial for inventory management and ensuring timely project completion. Buyers should inquire about lead times when negotiating contracts with suppliers.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing black rainbow carborundum, ultimately enhancing their operational efficiency and product quality.

The black rainbow carborundum sector is witnessing a dynamic shift driven by various global factors. As industries increasingly prioritize efficiency and performance, the demand for high-quality abrasives has surged. The automotive, aerospace, and manufacturing sectors are at the forefront, pushing for advanced materials that enhance durability and reduce processing times. Notably, the rise of automation and Industry 4.0 is leading to a greater focus on precision in sourcing. Technologies such as AI and IoT are becoming integral in supply chain management, enabling buyers to track sourcing trends in real-time and optimize inventory levels.

Emerging markets in Africa and South America are also becoming significant players in the black rainbow carborundum market. Countries like Brazil and South Africa are investing in infrastructure and manufacturing capabilities, creating a growing demand for abrasives in construction and mining. Additionally, the ongoing transition to greener technologies is influencing sourcing decisions, with buyers increasingly seeking suppliers who can demonstrate environmental responsibility.

Sustainability has become a focal point for businesses in the black rainbow carborundum sector. The environmental impact of production processes is under scrutiny, leading to a demand for greener alternatives. B2B buyers are now prioritizing suppliers who adhere to sustainable practices, including responsible sourcing of raw materials and energy-efficient manufacturing methods.

Ethical supply chains are equally important, as businesses recognize the necessity of transparency in sourcing. Certifications such as ISO 14001 and adherence to environmental standards are becoming prerequisites for suppliers aiming to compete in the global marketplace. Furthermore, buyers are looking for materials with lower carbon footprints, prompting manufacturers to innovate in developing eco-friendly black rainbow carborundum products. Emphasizing sustainability not only enhances brand reputation but also aligns with the increasing regulatory pressures regarding environmental responsibility.

The black rainbow carborundum sector has evolved significantly over the past few decades. Initially used primarily in abrasive applications, its unique properties have led to its adoption in various high-performance industrial uses. The introduction of advanced manufacturing techniques has improved the quality and consistency of black rainbow carborundum, making it a preferred choice among manufacturers seeking reliable materials.

As global demand for abrasives has increased, so has the emphasis on research and development. This evolution has led to the introduction of specialized formulations tailored to specific industry needs, enhancing the versatility of black rainbow carborundum. The focus on technological advancements and sustainability is expected to drive further innovations, ensuring that this material continues to meet the changing demands of B2B buyers across various regions.

By understanding these market dynamics and sourcing trends, international buyers from regions like Africa, South America, the Middle East, and Europe can make informed decisions and leverage opportunities within the black rainbow carborundum sector.

How can I ensure the quality of black rainbow carborundum before purchasing?

To ensure the quality of black rainbow carborundum, request certification and quality assurance documents from suppliers. Look for compliance with international standards, such as ISO certifications. Additionally, consider ordering a sample batch for testing purposes. Engaging a third-party inspection agency to conduct a quality check before shipment can further guarantee that the product meets your specifications.

What factors should I consider when selecting a supplier for black rainbow carborundum?

When selecting a supplier, evaluate their reputation in the industry, years of experience, and customer reviews. Assess their production capabilities and whether they can meet your volume requirements. Verify their financial stability and willingness to provide references from other international clients. Additionally, consider their logistical capabilities and the ability to customize products according to your needs.

What are the typical minimum order quantities (MOQs) for black rainbow carborundum?

Minimum order quantities for black rainbow carborundum can vary significantly depending on the supplier and your specific requirements. Generally, MOQs can range from 100 kg to several tons. It’s advisable to discuss your needs with potential suppliers to negotiate terms that suit your business, especially if you are a smaller buyer or require customized products.

What payment terms are commonly accepted for international orders of black rainbow carborundum?

Payment terms can vary by supplier but typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers prefer a 30% deposit with the balance due before shipment. It’s crucial to clarify payment terms upfront and ensure they are documented in the contract to avoid any misunderstandings.

How do I handle logistics and shipping for black rainbow carborundum?

Handling logistics involves coordinating with your supplier to determine the best shipping method based on cost and delivery time. You may choose between air freight for speed or sea freight for cost-effectiveness. Ensure that the supplier provides the necessary documentation for customs clearance. Additionally, consider working with a freight forwarder who can assist with the logistics process and handle any potential complications.

What customization options are available for black rainbow carborundum products?

Customization options for black rainbow carborundum may include size, shape, and specific properties tailored to your application. Discuss your requirements with the supplier to see if they can accommodate modifications. Some suppliers may offer custom formulations that enhance specific characteristics, such as grit size or bonding agents, making it essential to communicate your needs clearly.

How can I assess the reliability of a supplier for black rainbow carborundum?

To assess supplier reliability, start by checking their business licenses and certifications. Look for reviews or testimonials from previous clients, particularly those in your industry. Conducting a site visit, if feasible, can provide insights into their operations and quality control processes. Additionally, consider their response time and customer service quality during your initial interactions, as these are indicative of their overall reliability.

What are the key applications of black rainbow carborundum in various industries?

Black rainbow carborundum is primarily used in abrasive applications such as grinding, polishing, and cutting tools. It is also utilized in the manufacturing of ceramics and as a refractory material in high-temperature environments. Industries such as automotive, aerospace, and construction benefit from its durability and performance. Understanding these applications can help you identify potential markets and uses for your purchased materials.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

In the rapidly evolving landscape of industrial materials, black rainbow carborundum stands out as a versatile and high-performance option for various applications. What are the key benefits of black rainbow carborundum for B2B buyers? Its unique properties, including exceptional hardness and thermal conductivity, make it an ideal choice for sectors ranging from manufacturing to electronics.

Strategic sourcing of black rainbow carborundum not only ensures access to superior materials but also enhances supply chain resilience. By establishing strong partnerships with reliable suppliers, businesses can mitigate risks associated with fluctuating material costs and availability. How can international buyers optimize their sourcing strategies? Engaging with suppliers from diverse regions, particularly in Africa, South America, the Middle East, and Europe, can lead to more competitive pricing and innovative solutions tailored to specific needs.

Looking ahead, the demand for black rainbow carborundum is poised to grow as industries prioritize sustainability and efficiency. What steps should B2B buyers take now? By proactively exploring sourcing options and establishing long-term relationships with manufacturers, international buyers can position themselves favorably in a competitive market. Embrace the potential of black rainbow carborundum and unlock new opportunities for innovation and growth.

Tags: Black Silicon Carbide, White Fused Alumina, Brown Fused Alumina, Pink Fused Alumina, Black Fused Alumina